Processing method for integrally riveting separated type retainer

A processing method and cage technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of no positioning reference, low riveting efficiency, inconvenient finishing, etc., and achieve uniform riveting force, The effect of improving riveting efficiency and increasing riveting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

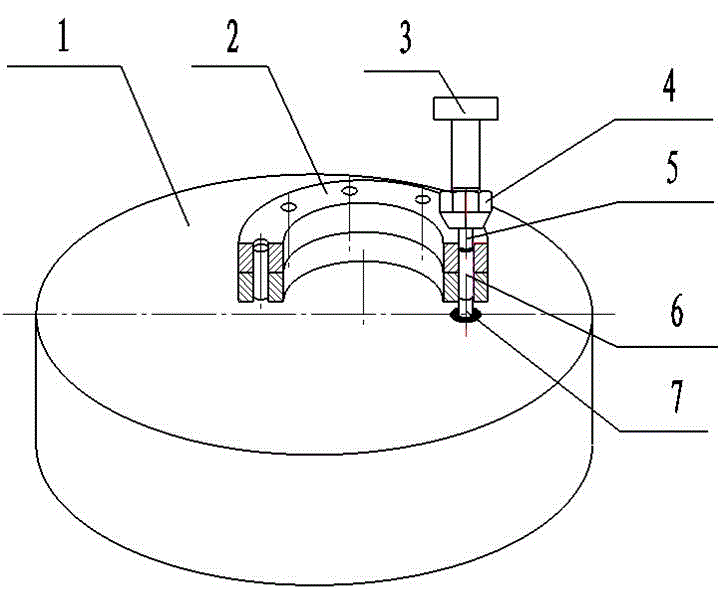

[0018] The invention relates to a processing method for integral riveting of a detachable cage.

[0019] The processing method of the present invention relates to the support table 1, the claws 3, the lock nut 4, the punch 5 and the support head 7, and also relates to the pressure frame, the stroke of which is adjustable. Although the pressure is on figure 1 Does not appear in, but because the pressure frame is a common device in this field, so the pressure frame is not described too much, but the pressure frame has been used in the processing method of the present invention, the pressure frame is either mechanical or hydraulic, or It is electric.

[0020] Secondly, the diameter of the rivet hole of the to-be-riveted separable cage 2 is set to D, the height of the rivet hole of the to-be riveted separable cage 2 is set to H, the diameter of the rivet 6 matches the above-mentioned D, and the height of the rivet 6 set to H 1 , H 1 <H.

[0021] Processing method of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com