A gas-hydraulic pressurized self-piercing riveting machine

A gas-liquid pressurized, self-piercing riveting technology, applied in the field of machinery manufacturing equipment, can solve the problems of complex riveting process, fatigue strength reduction, high-strength material temperature sensitivity, etc., to achieve small structural space occupation area, low production cost, The effect of fast riveting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

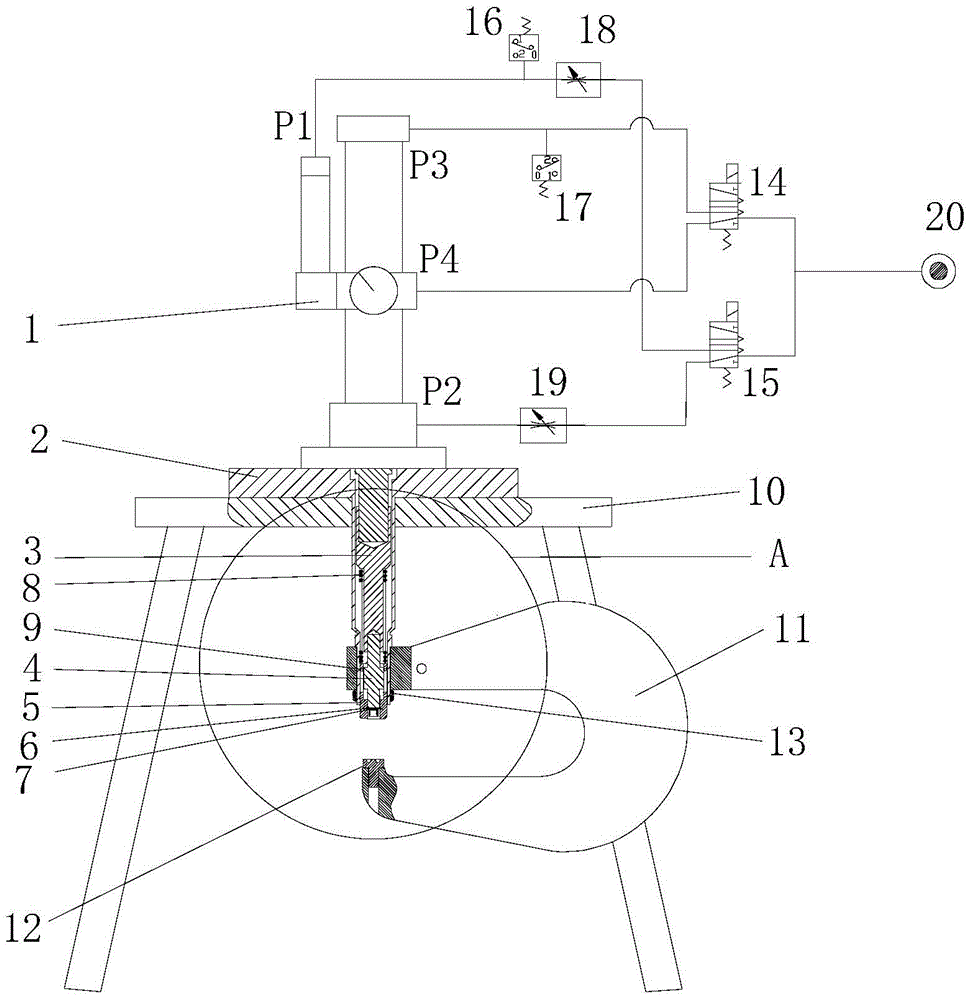

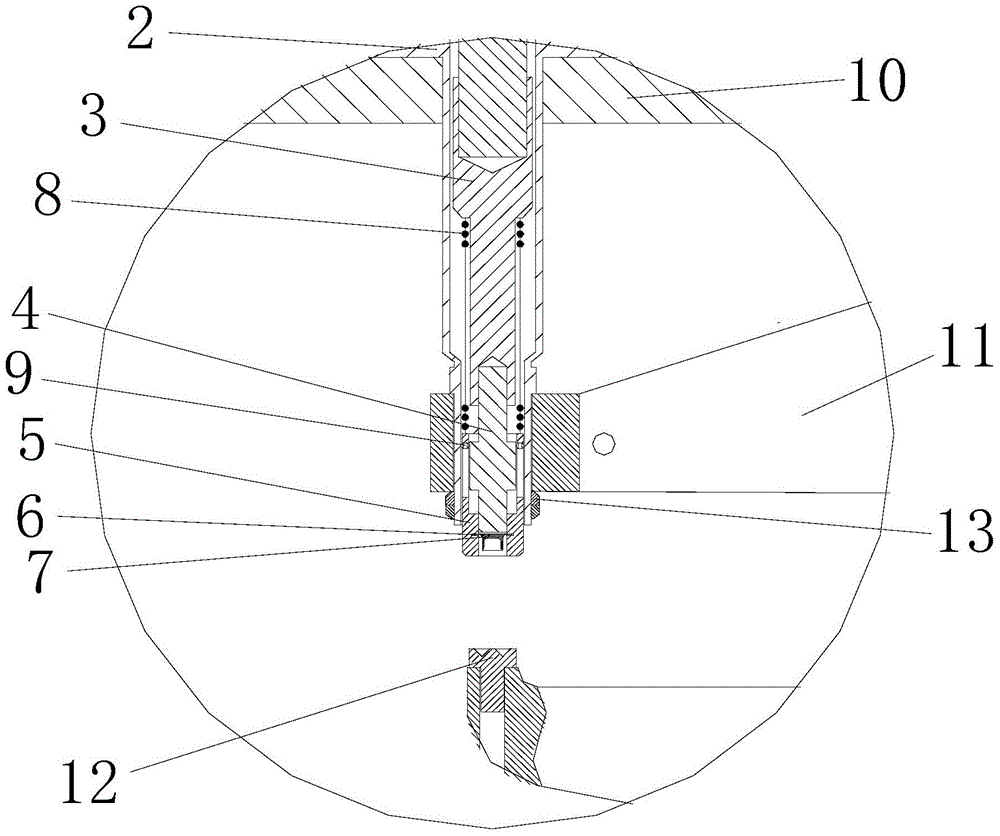

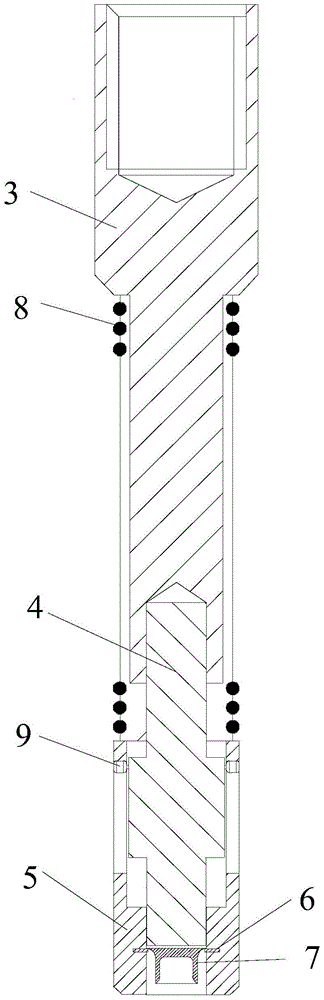

[0042] figure 1 It is a structural schematic diagram of the present invention, a gas-liquid pressurized self-piercing riveting machine, including a gas-liquid pressurized control system, a self-piercing riveting mechanism, a circuit control system and a support seat, the gas-liquid pressurized control system includes a gas-liquid pressurized Pressure cylinder 1, compressed air pump 20, 2-position 5-way reversing valve A14, 2-position 5-way reversing valve B15, speed regulating throttle valve 18, 19, normally open air pressure control switch 16, normally closed air pressure Control the switch 17 and the air pipe, the gas-liquid booster cylinder 1 is connected to the self-piercing riveting mechanism; the compressed air pump 20 is connected to the two-position five-way reversing valve A14 and the two-position five-way reversing valve B15 through the air pipe, and the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com