Bridge-shaped contact riveting clamp of frame circuit breaker and assembly operation method of bridge-shaped contact riveting clamp

A frame circuit breaker and bridge contact technology, which is applied to circuits, feeding devices, positioning devices, etc., can solve the problems of slow riveting speed, inability to meet production progress, and scrapped workpieces, and achieve good force and fast riveting speed. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

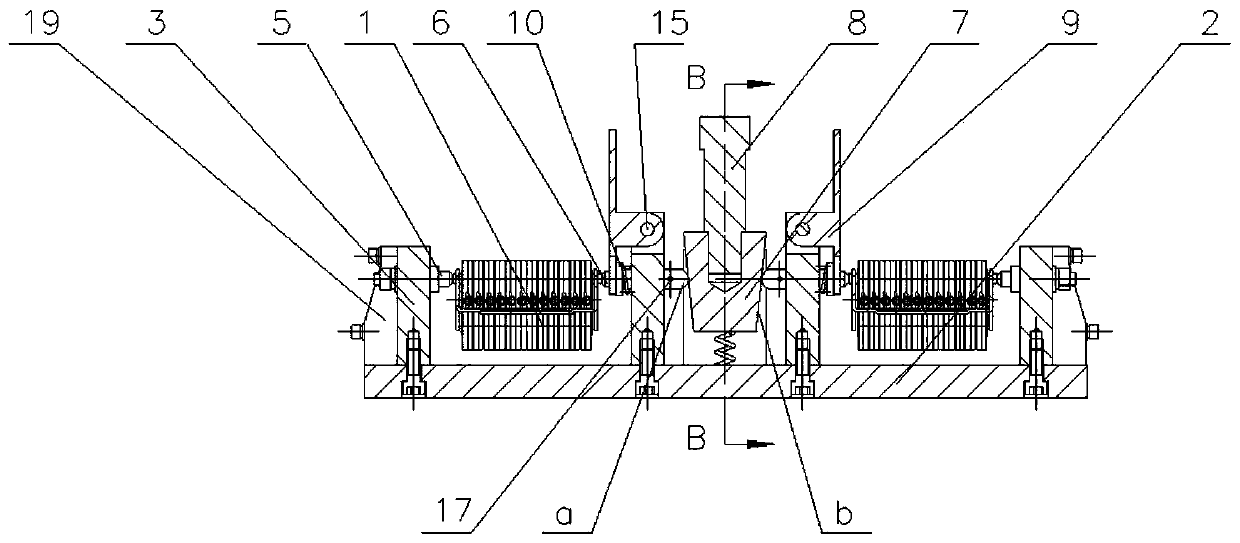

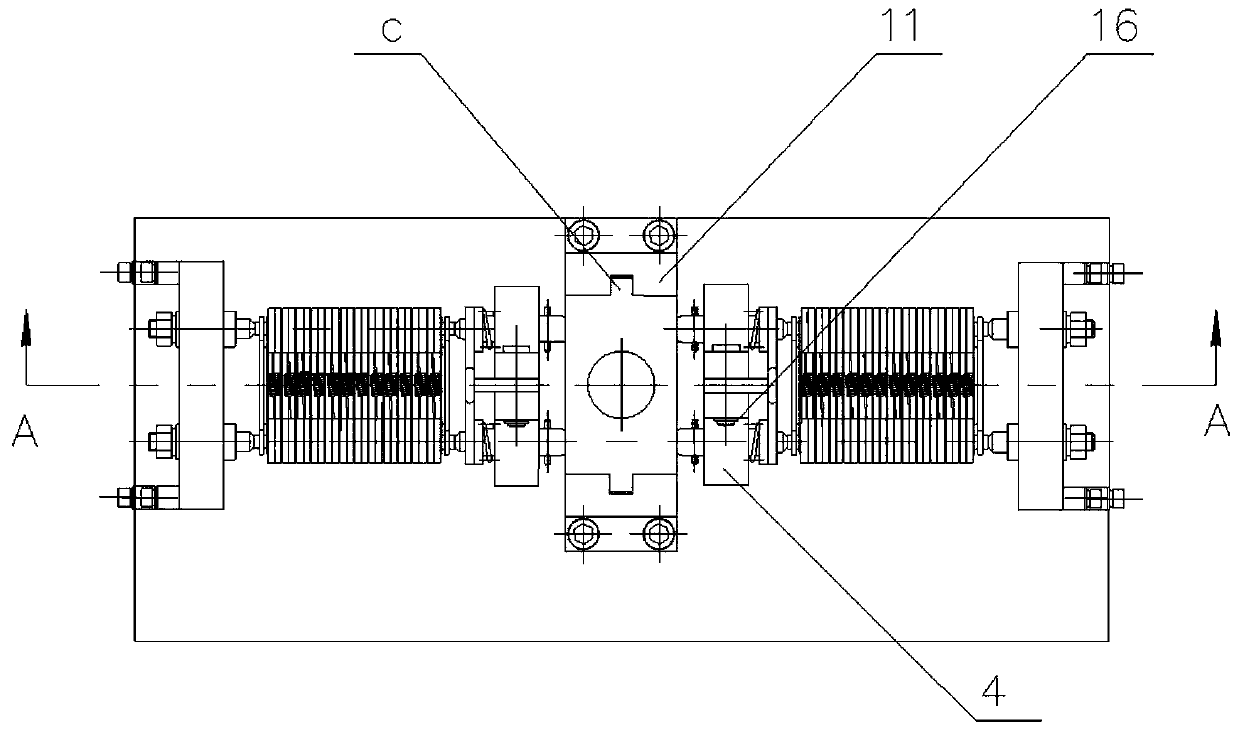

[0029] Embodiment 1: As shown in the figure, a bridge contact riveting fixture for a frame circuit breaker includes a bridge contact 1 and a bottom plate 2, and the upper part of the bottom plate 2 is provided with two spaced apart clamping fixtures. device, the clamping device is provided with a detachable and fixed bridge contact 1, and a punch riveting device is provided between the two clamping devices, and the punch riveting device synchronously controls the two clamping devices.

[0030] As a preference, the clamping device includes a support 3 and a support seat 4 arranged on the bottom plate 1, the support 3 and the support seat 4 are distributed in intervals, and the support 4 is provided with a fixed top 5 , the support seat 4 is provided with a movable top 6, and the bridge-shaped contact 1 is arranged between the fixed top 5 and the movable top 6;

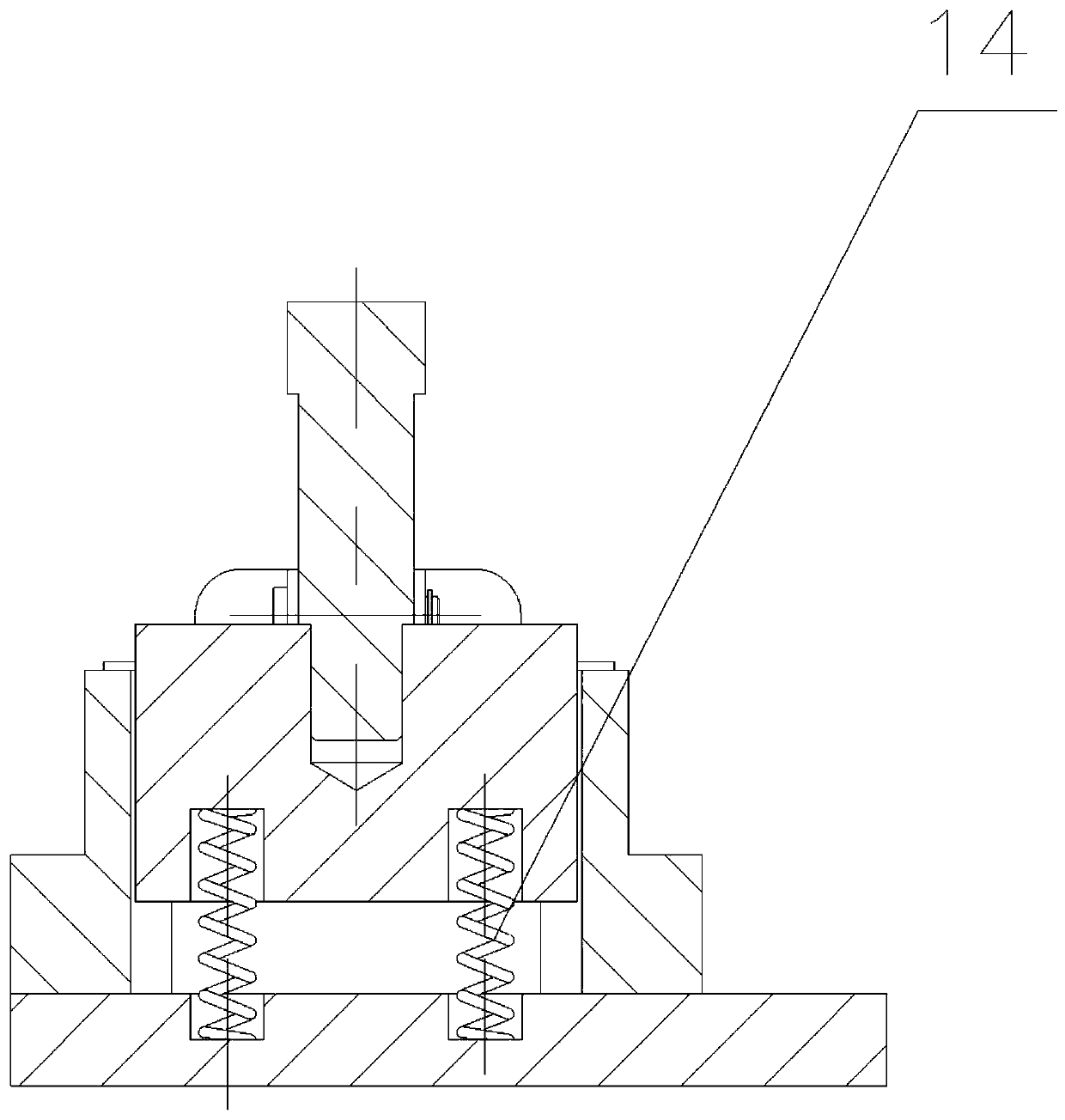

[0031] The punch riveting device includes a movable block 7, the movable block 7 is displaced downward by the punch 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com