Cylindrical shape automatic riveted-joint apparatus

A riveting device and cylindrical technology, applied in the field of pressure screens, can solve the problems of welding heating, affecting product accuracy, micro-deformation, etc., and achieve the effects of high work efficiency, product accuracy, and riveting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

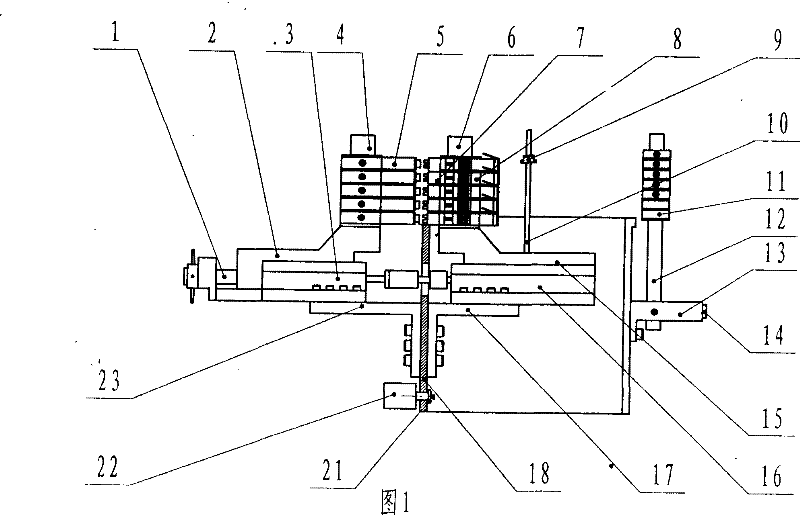

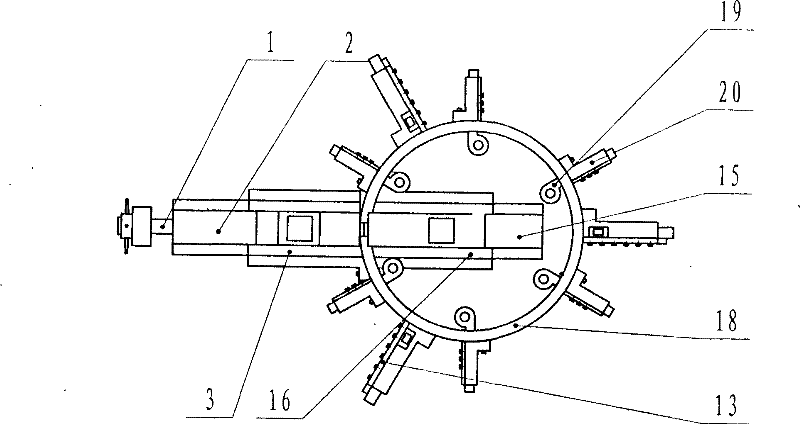

[0010] Refer to attached figure 1 , 2 , it includes a two-way screw 1, the two-way screw 1 and the positioning block nut 2 form a transmission pair, the positioning block nut 2 is installed on the guide rail 3, the guide rail 3 is fixed on the positioning block nut bracket 23, and the positioning block nut bracket 23 is fixed on the outer wall of the main body 18 of the cylindrical riveting device, the positioning block guide rail 4 is equipped with the positioning block nut 2, and several positioning blocks 5 are installed on the positioning block guide rail 4, and the steam riveting gun screw nut 15 is installed on the steam riveting gun guide rail 16, the steam riveting gun guide rail 16 is installed on the steam riveting gun nut bracket 17, and the steam riveting gun screw nut bracket 17 is fixed on the inner wall of the riveting device main body 18, and the steam riveting gun screw nut 15 and the two-way lead screw 1 form a transmission pair , steam riveting gun position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com