Full-automatic punching riveting system and working process thereof

A stamping riveting, fully automatic technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting efficiency, low production efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

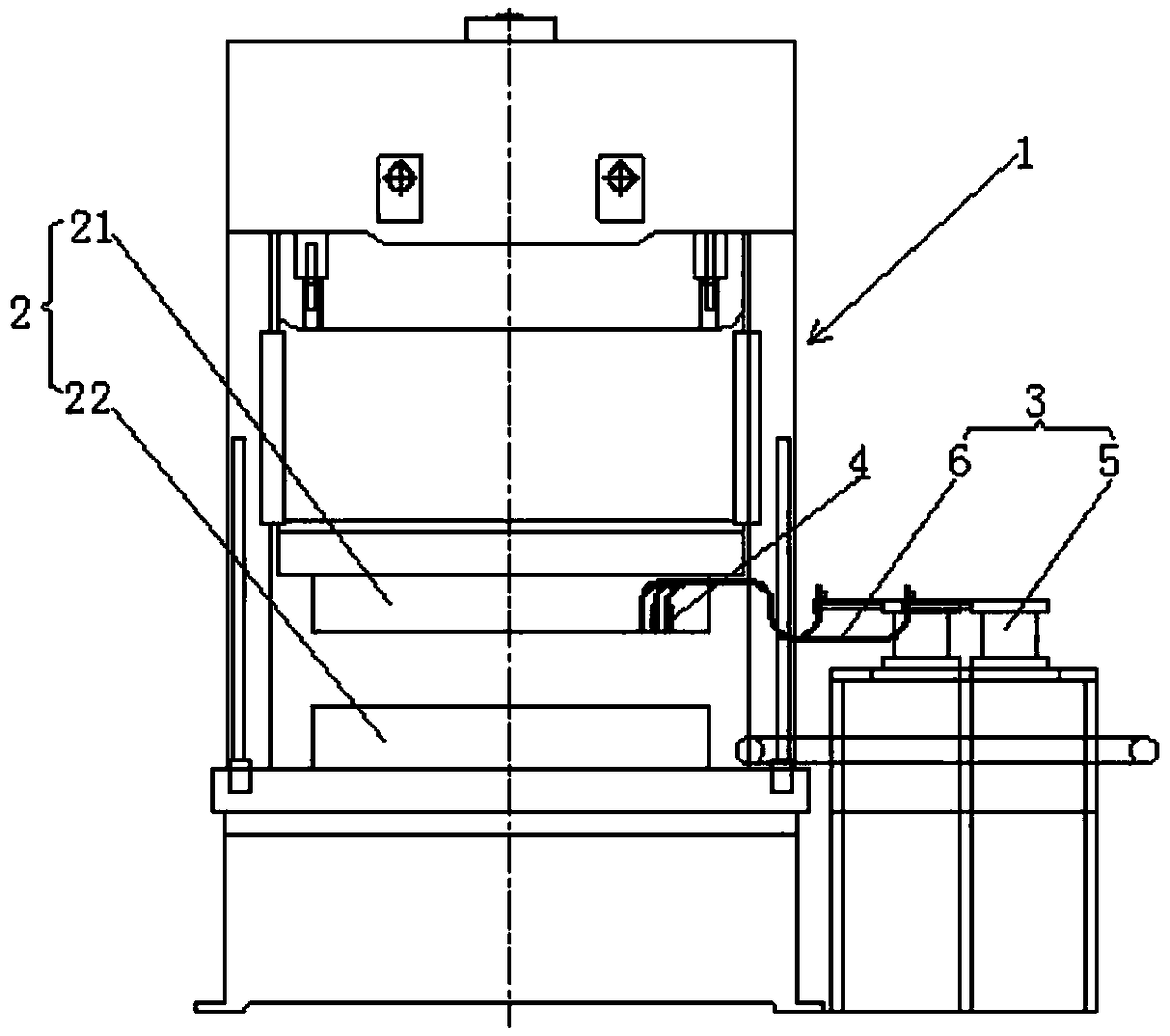

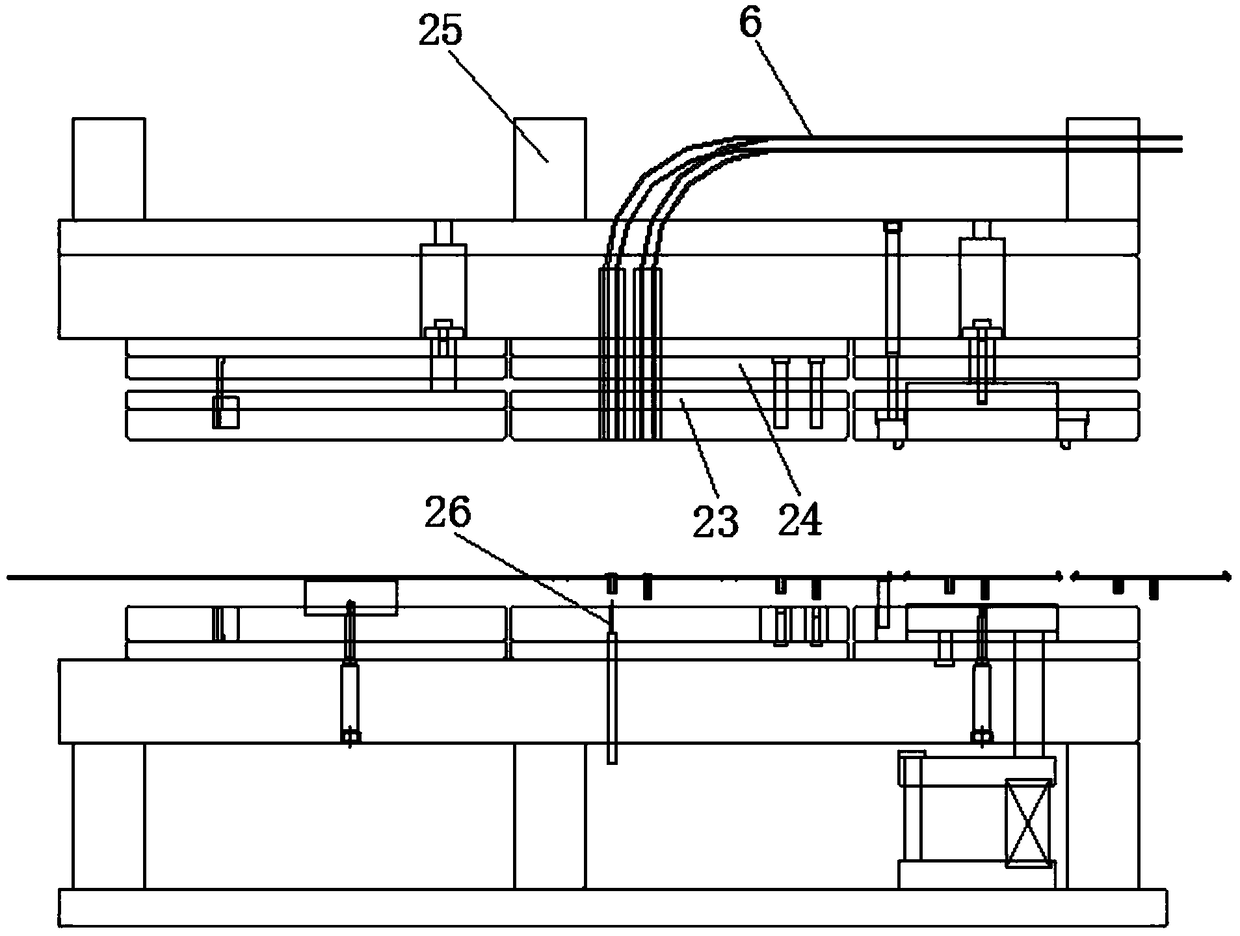

[0056] as attached figure 1 , 2 As shown, a kind of full-automatic stamping riveting system of the present invention comprises punching machine 1, mold 2, feeder and finished product discharge conveyor belt, also includes rivet conveying device 3, positioning ejection device 4 and control center; The feeder is used for Stamping continuous die provides flat material, and according to stroke accuracy requirements, completes feeding smoothly at an appropriate speed, and cooperates with the action of punch press and mold; the control center is used to control the movement of punch press, mold, rivet conveying positioning detection device and feeder Coordination Consistent, so that the entire automatic stamping die riveting system can run safely and efficiently; the punch press 1 is an automatic punch press, and is equipped with an electronic cam; figure 2Among them, the leftmost part of the mold 2 is the stamping module, which completes the punching of the gap part of the materi...

Embodiment 2

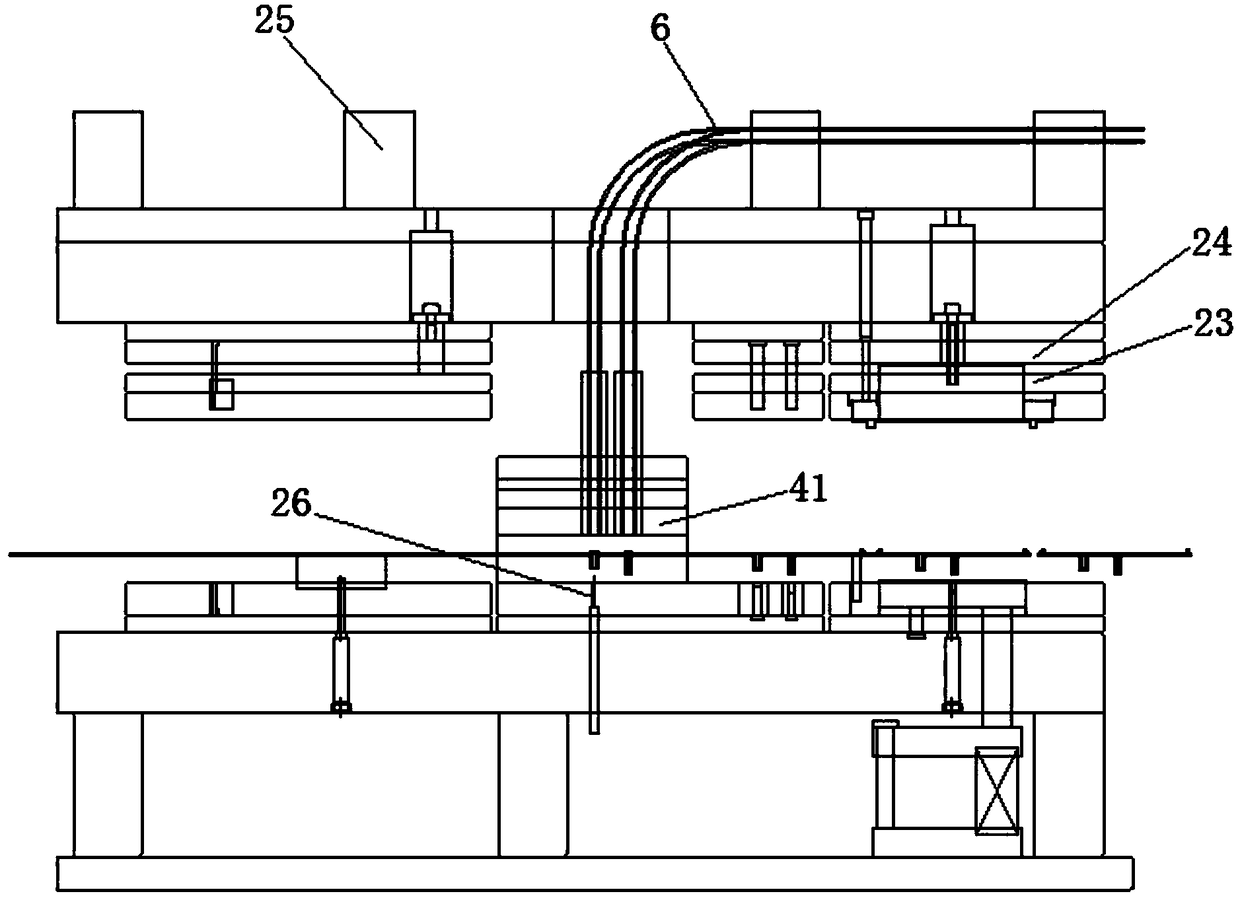

[0063] as attached figure 1 , 3 As shown, the positioning ejection device 4 is fixedly connected to the lower mold 22 through the ejection gun installation mechanism 41; the height dimension of each layer of the ejection gun installation mechanism 41 is the same as that of the upper mold. The downward movement of the stopper plate 23 and the downward movement of the laminate corresponding to the splint 24 in the ejection gun installation mechanism 41 also trigger the clamping mechanism to loosen the rivet. All the other structures are the same as in Embodiment 1.

[0064] In this embodiment, the positioning and ejecting device 4 is arranged in the overhead layer above the lower die, and an observation hole can be opened on the ejection gun installation mechanism to facilitate observation of the movement of the rivet. When a fault occurs, the operator can directly observe the positioning and ejecting device 4, It is easy to check and maintain, but in the position where the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com