Digital display high and low pressure pump riveting machine hydraulic station and riveting process

A high-low pressure pump and riveting machine technology, applied in mechanical equipment, fluid pressure actuating device, fluid pressure actuating system components, etc., can solve the problems of difficult processing, complex structure, many failure points, etc., and achieve intuitive display. , the principle is simple, the effect of fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

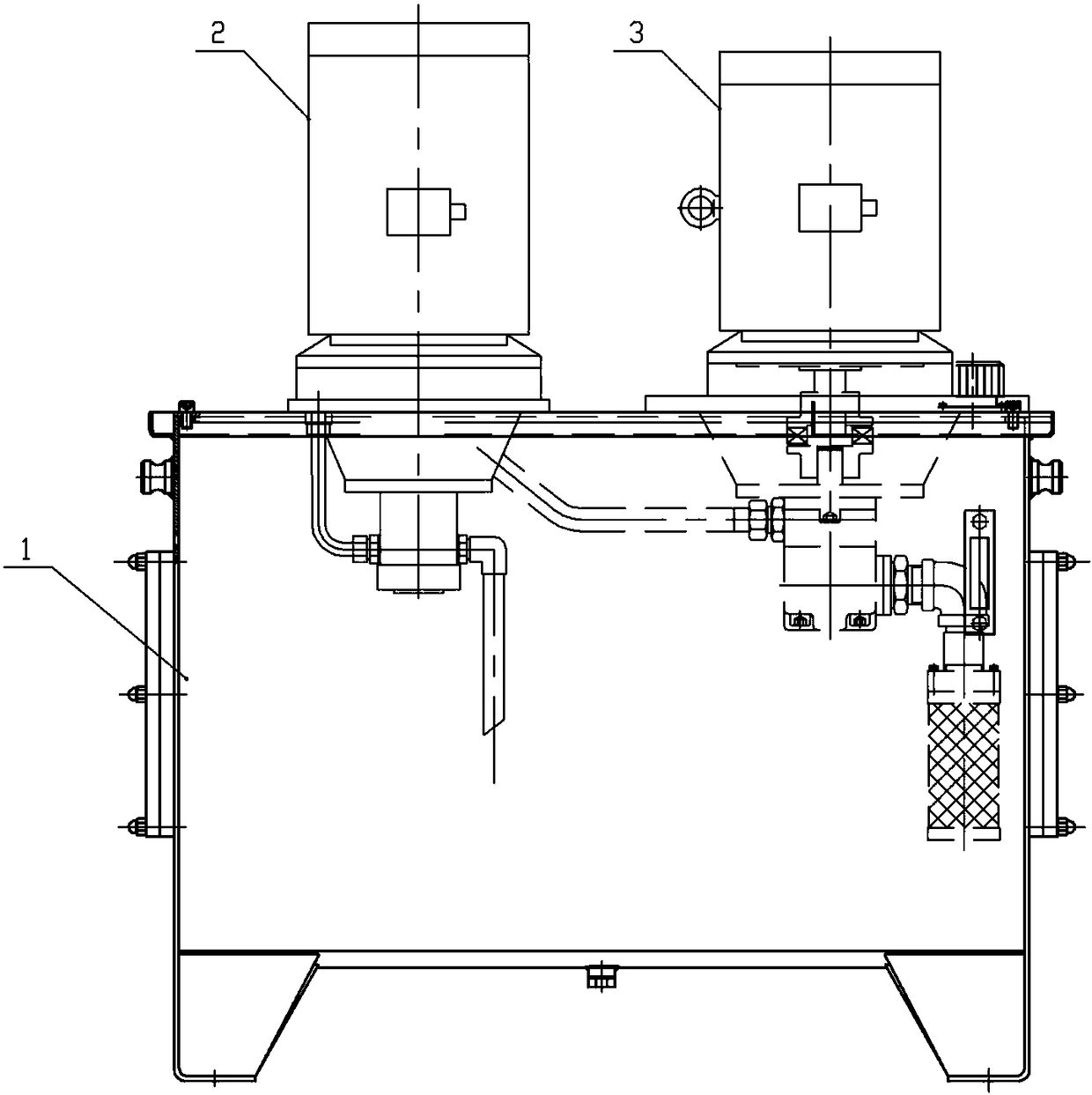

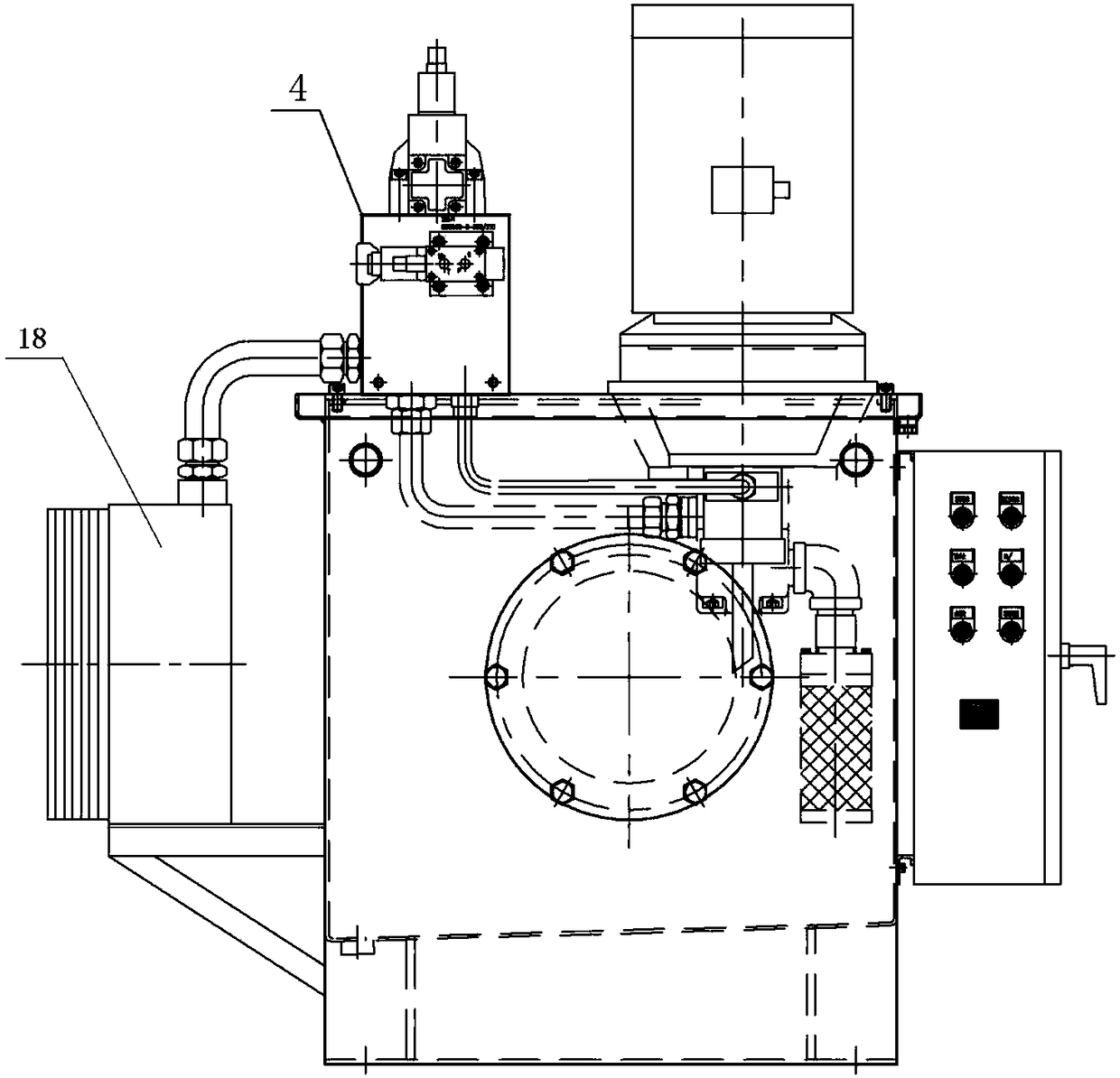

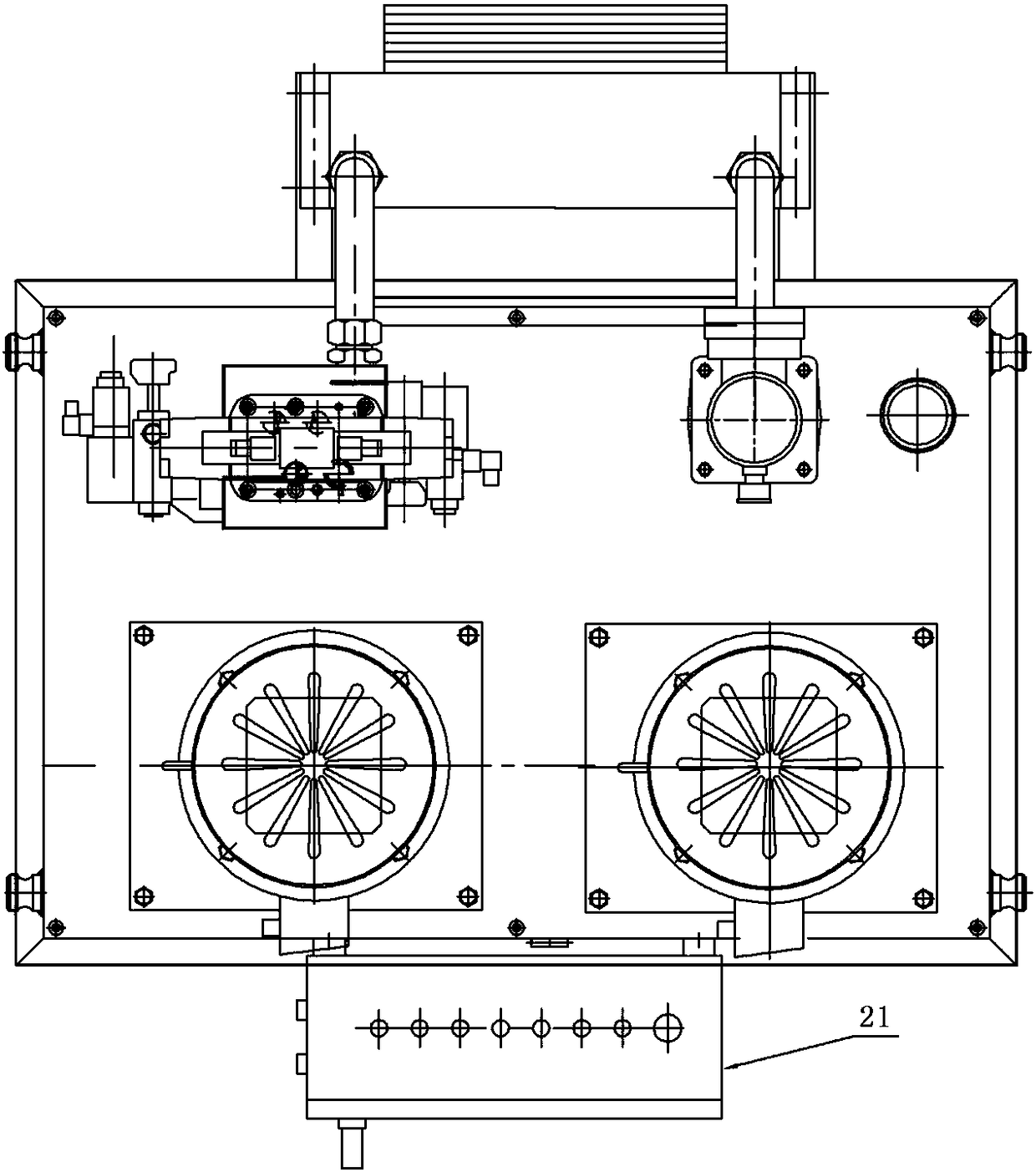

[0029] Embodiment 1: A digital display high and low pressure pump riveting machine hydraulic station, see figure 1 and figure 2 , including oil tank 1, low-pressure oil pump circuit, high-pressure oil pump circuit, cooling device 18 and electrical control device, the electrical control device is a digital display electrical control device, and also includes a touch LCD screen, which uses advanced touch screen technology to digitally display the pressure and adjustment, no longer use traditional pressure gauges and pressure relays to observe and control the pressure, use touch LCD screen and pressure sensor to collect, display and adjust the pressure, you can display the riveting pressure and riveting times from the touch LCD screen, you can also Set multiple riveting pressures through the touch screen.

[0030] The low-pressure oil pump circuit includes a low-pressure oil pump motor unit 2 (motor one 2-1, low-pressure oil pump 2-2) and a low-pressure relief valve assembly. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com