Rivet rolling substrate machine of potentiometer

A potentiometer and rolling riveting technology, which is applied in the manufacture of resistors, circuits, and resistors, can solve problems such as easy loosening, low work efficiency, and ineffective riveting and fixing, so as to improve production efficiency and strengthen structural firmness , the effect of eliminating the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

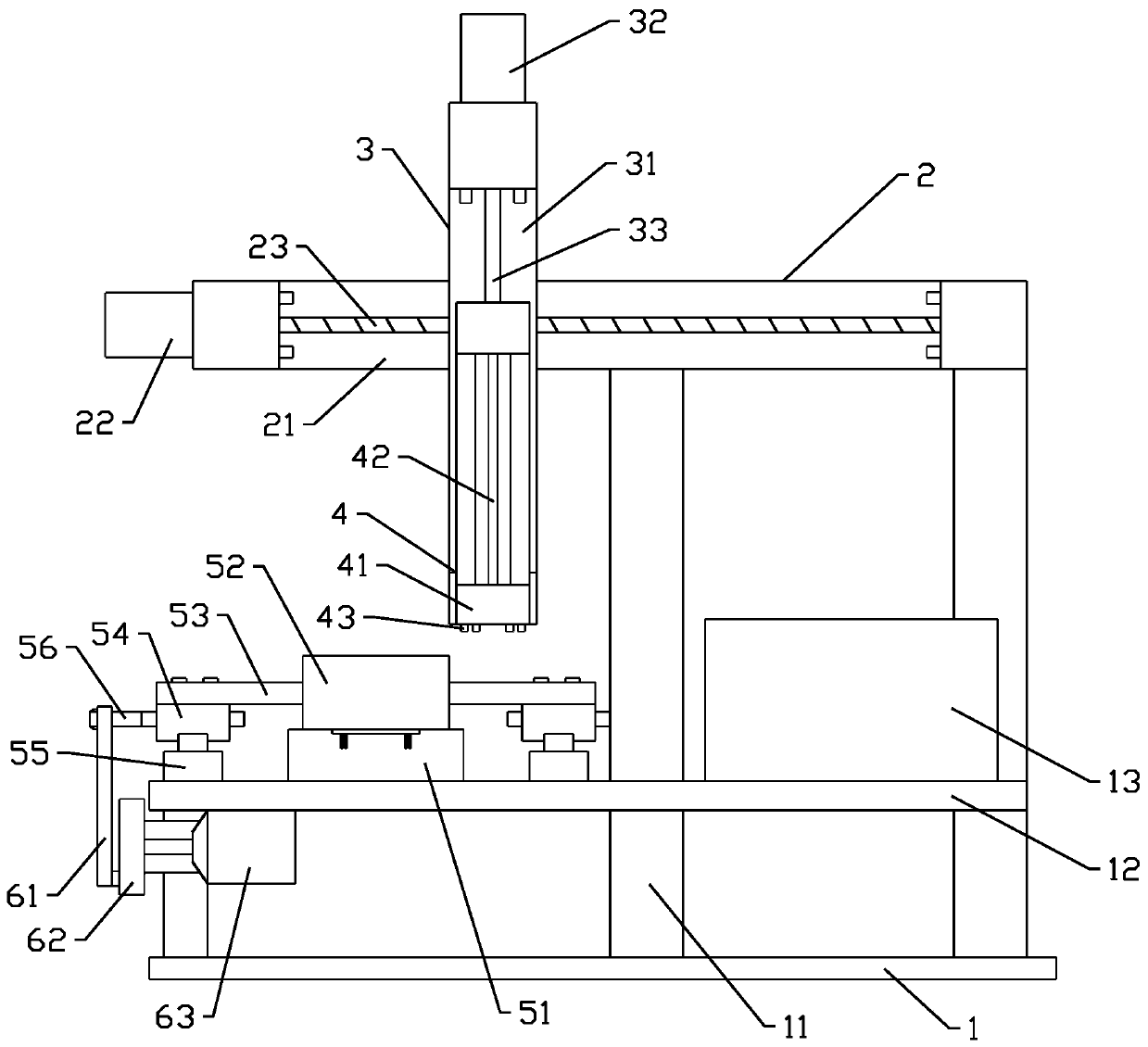

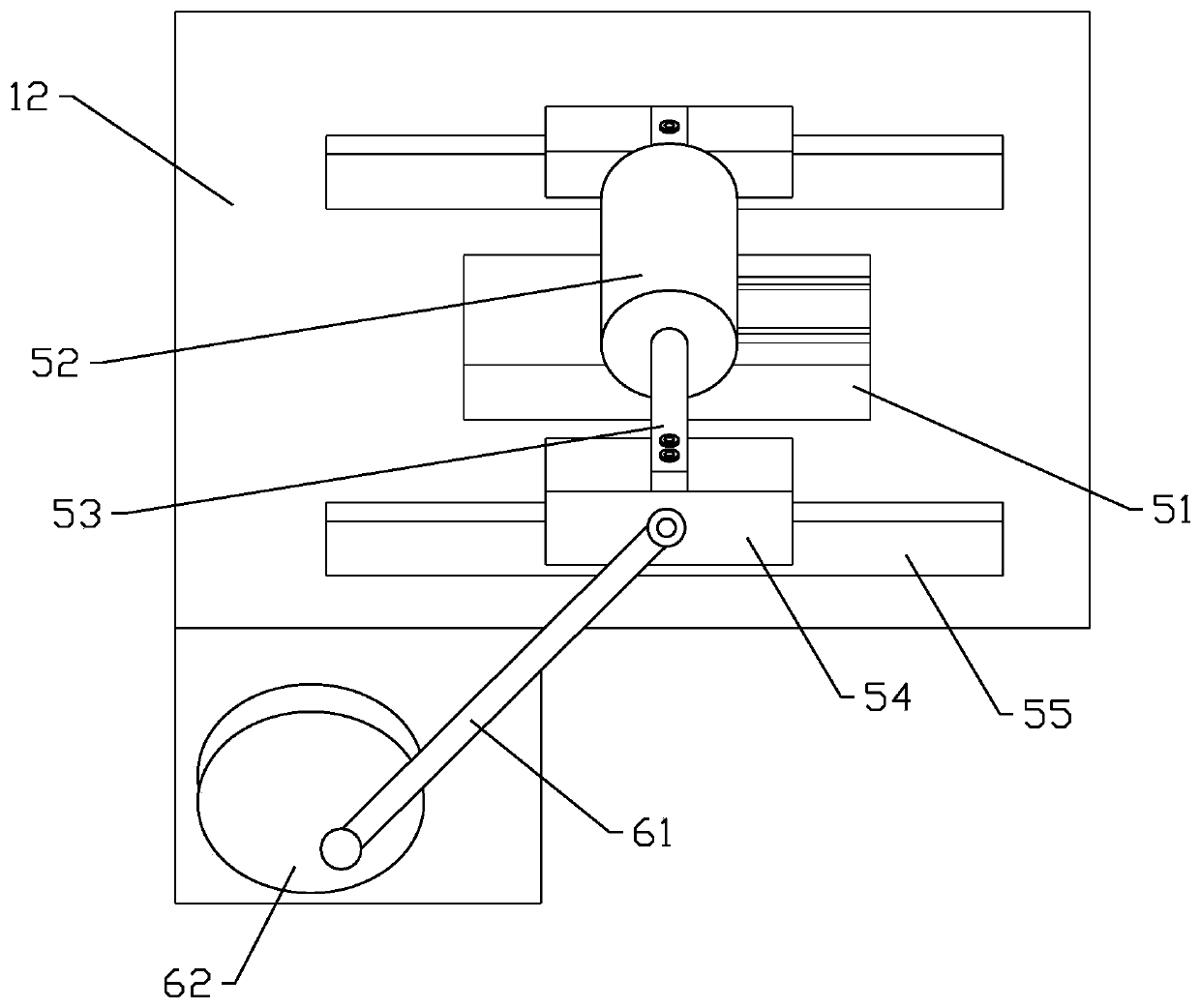

[0025] Please refer to figure 1 , this embodiment provides a potentiometer rolling riveting substrate machine, which includes: a body 1, a lateral displacement device 2, a vertical displacement device 3, an absorber 4, a rolling riveting assembly and a driving assembly, and the lateral displacement device 2 is installed on the body 1. The vertical displacement device 3 is installed on the horizontal displacement device 2, the absorber 4 is installed on the vertical displacement device 3, the rolling riveting assembly is installed on the body 1, the driving assembly is respectively connected to the rolling riveting assembly and the body 1, and the body 1 includes a frame 11 , platen 12 and collection box 13, the lateral displacement device 2 includes a horizontal seat 21, a lateral servo motor 22 and a horizontal threaded shaft 23, and the vertical displacement device 3 includes a vertical seat 31, a vertical servo motor 32 and a vertical threaded shaft 33 , the adsorber 4 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com