A rapid riveting process for washer and basin frame

A technology of riveting and basin frame, which is applied in the field of rapid riveting technology of Huasi and basin frame, can solve the problems of low riveting efficiency, uneven riveting force, long time, etc., and achieve high product quality, uniform riveting force, The effect of high riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

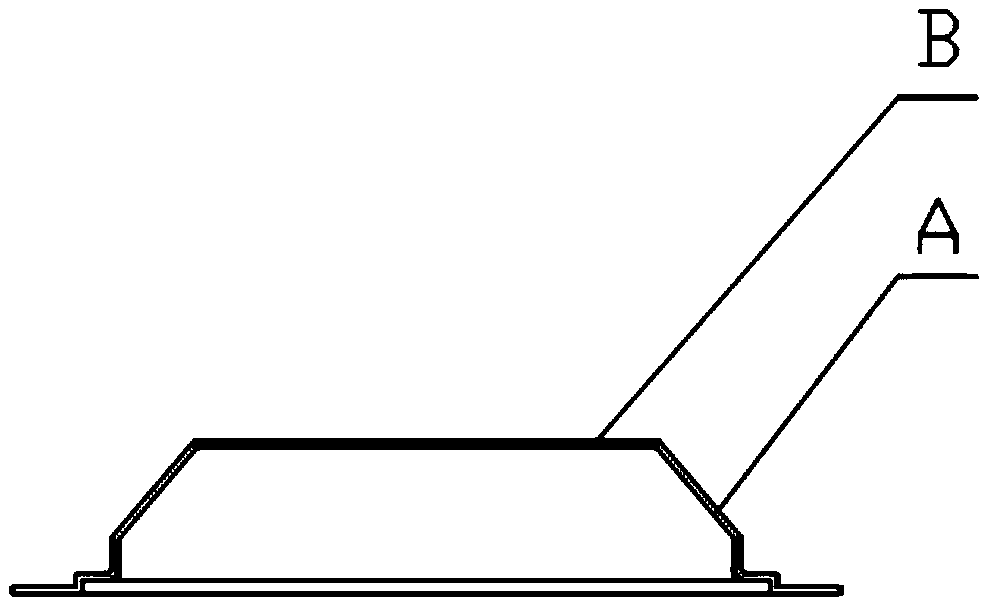

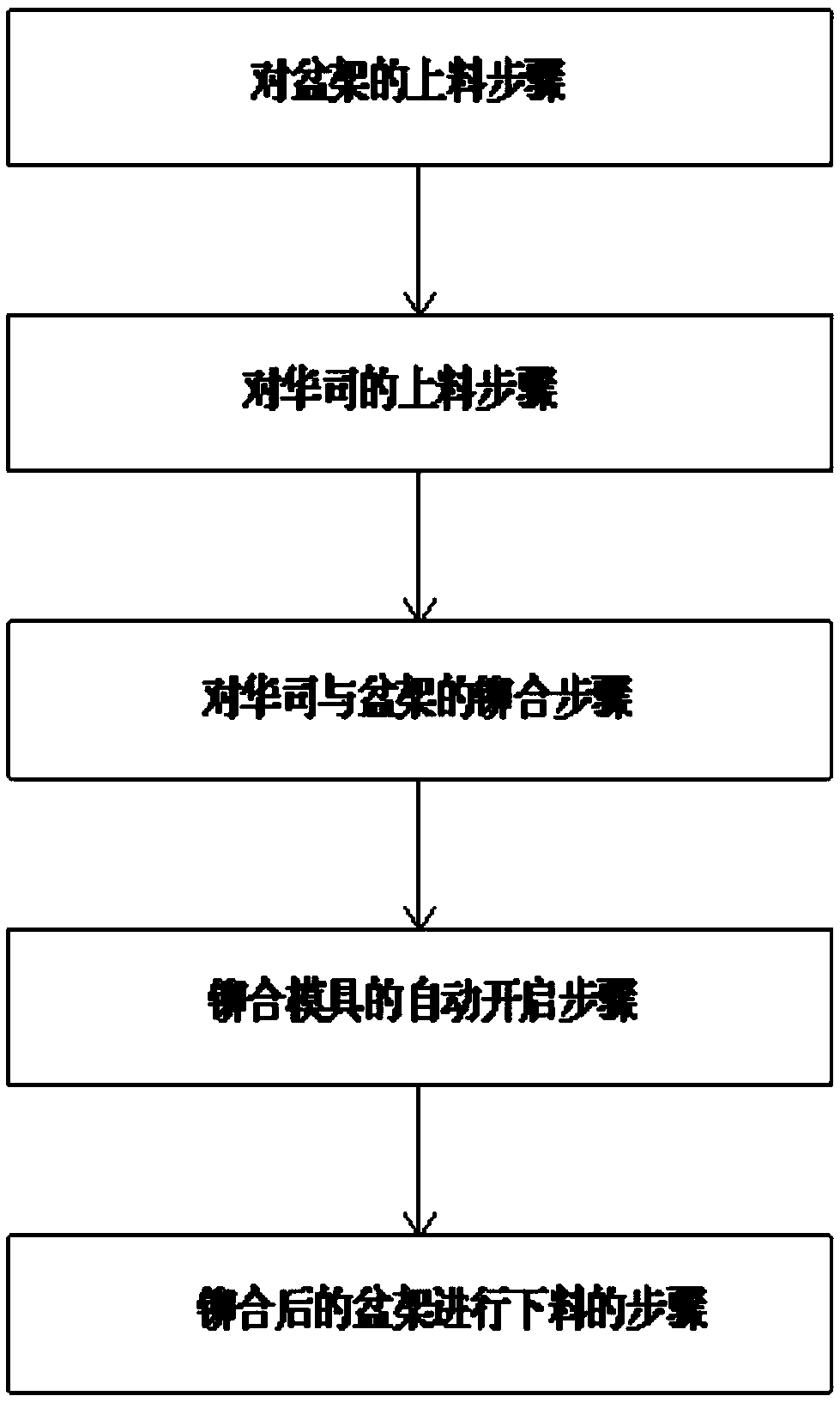

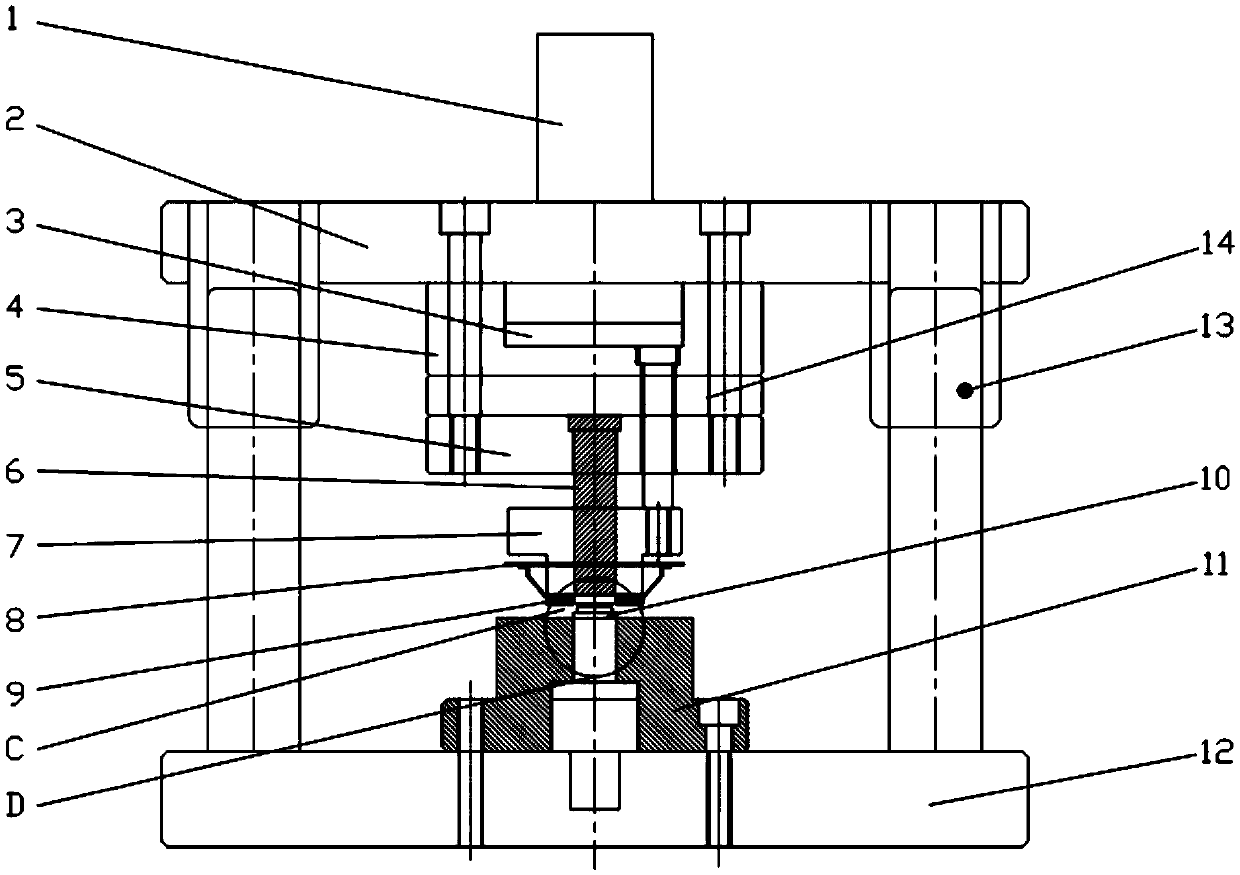

[0019] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] refer to figure 2 and image 3 As shown, the present invention provides a rapid riveting process for washer and pot frame, which is used for quickly riveting the washer 9 on the pot frame 8, and the rapid riveting process includes loading the pot frame 8 step, the step of loading the washer 9 and the riveting step of the washer 9 and the basin frame 8, and the riveting step is to use a riveting mold for riveting, and the riveting mold is set There is a positioning rod 10 for placing the pot frame 8, and a riveting station C for placing the washer 9. When the riveting mold is riveted, the washer 9 in the riveting station C Realize rapid riveting with the pot frame 8 on the positioning bar 10.

[0021] The present invention also includes the step of automatically opening the riveting mold after the riveting step, and the step of unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com