Riveting machine

A technology of riveting machine and riveting die, which is applied in the direction of connection, electrical components, circuits, etc., can solve the problems of difficult quality management, poor riveting, and many processing personnel, so as to improve the efficiency of riveting operations, ensure high accuracy, and ensure the riveting position. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

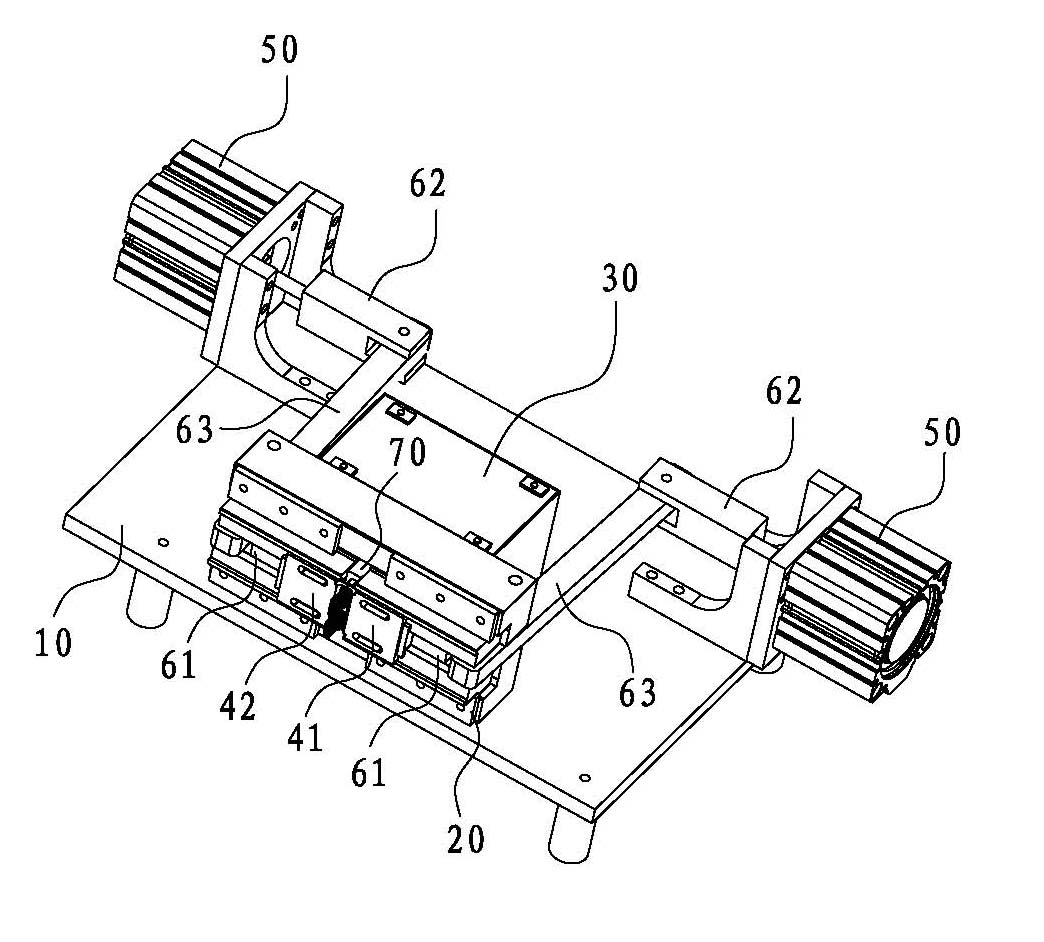

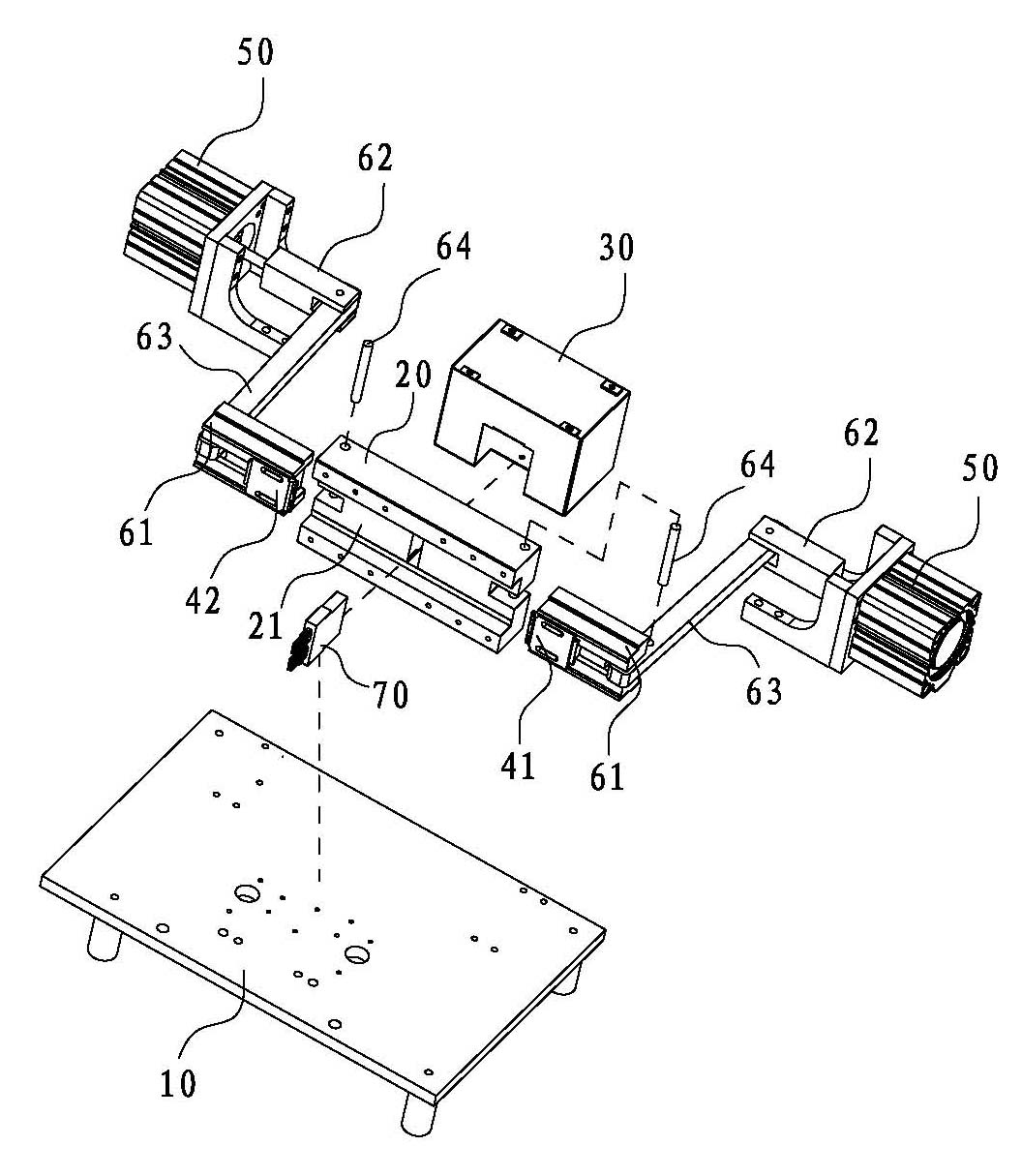

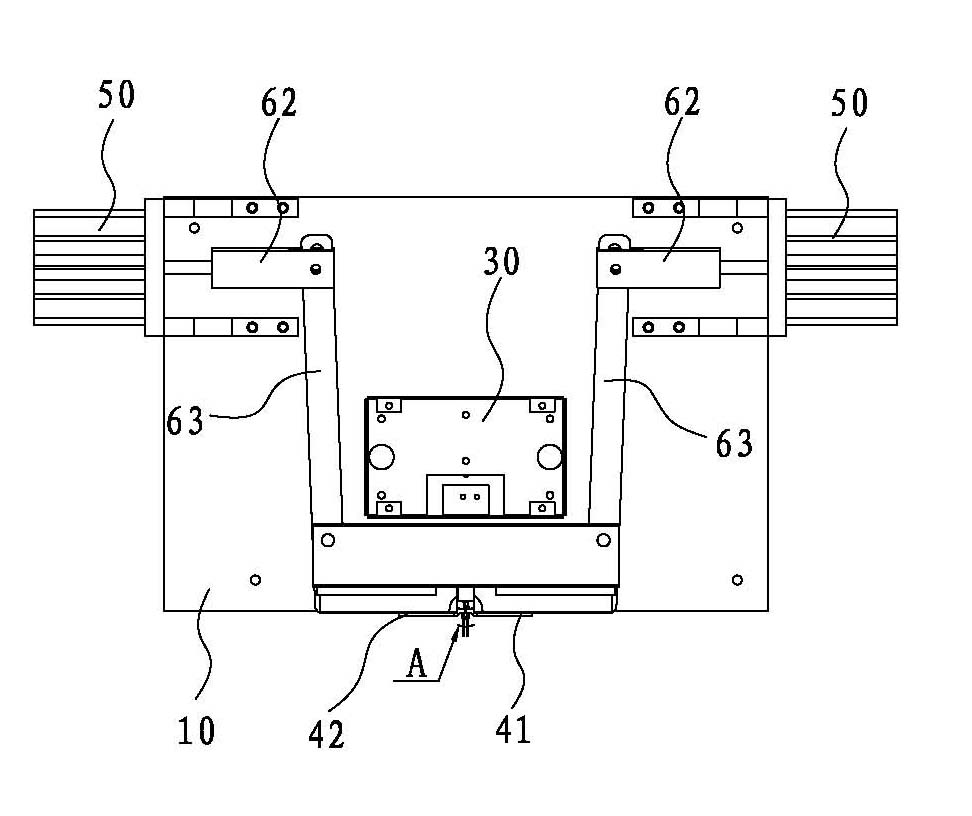

[0042] See Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including an organic base 10, a fixing frame 20 installed on the base 10, and an electric control device 30, wherein the electric control device 30 is connected to the lower The driving device 50 is used to control the operation of the driving device 50.

[0043] combine figure 2 , Figure 5 and Image 6 As shown, the fixed frame 20 is provided with a chute 21 extending in the left and right direction, and the fixed frame 20 is provided with a connector installation part 70, the connector installation part 70 is detachably installed in the fixed frame 20, the connection Two positioning grooves 71 extending along the front and rear directions for installing the connector are opened on the connector mounting part 70, and the two positioning grooves 71 are arranged in a row along the vertical direction, and the two upper positioning grooves 71 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com