Full automatic three-dimensional multipoint hot riveting assembling process technique for die casting of magnesium alloy

A fully automatic, hot riveting technology, applied in the field of die-casting magnesium alloy automatic three-dimensional multi-point hot riveting assembly process, can solve the problems of low quality and efficiency of riveting, high labor intensity of workers, low production efficiency, etc., and achieve high production efficiency , high quality and connection firmness, and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

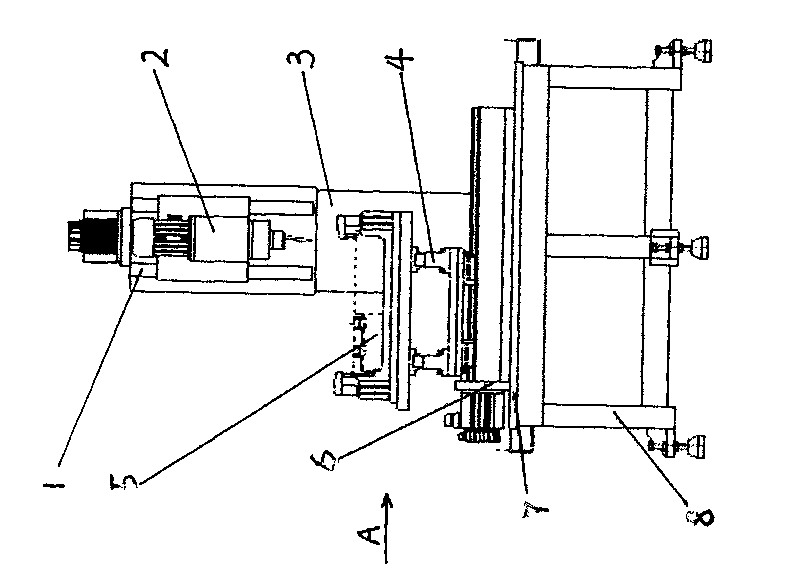

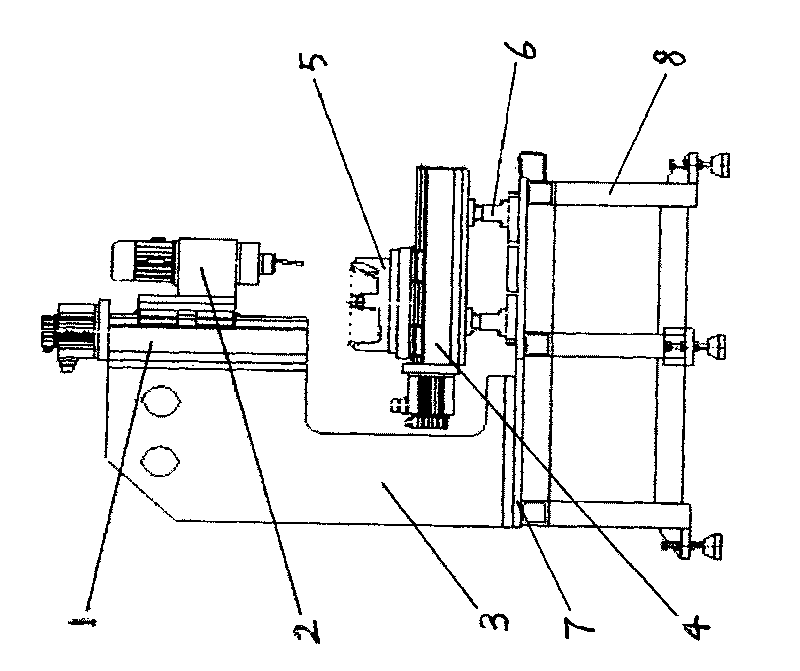

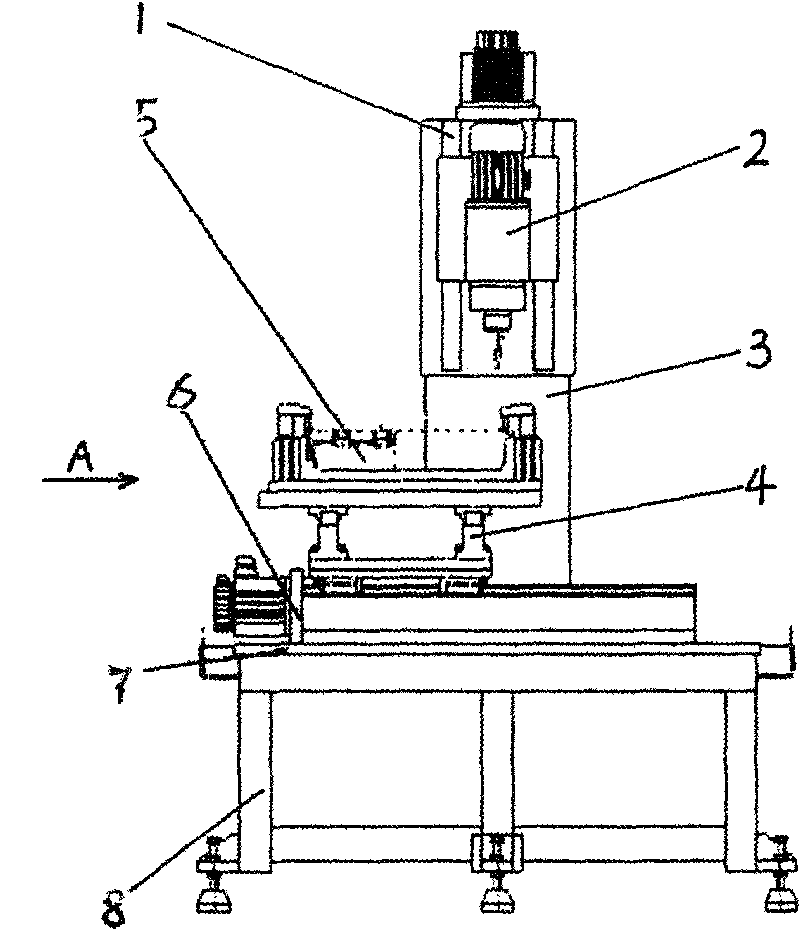

[0009] Such as figure 1 As shown, the present invention has a special equipment for full-automatic three-dimensional multi-point hot riveting of die-casting magnesium alloy. Y-direction servo linear slide table 4, workpiece riveting fixture 5, horizontal X-direction servo linear slide table 6, workbench panel 7, and frame 8, wherein the slide table power installation base 3 and workbench panel 7 are respectively installed on the machine On the frame 8, the rivet power head system 2 is installed on the vertical Z-direction servo linear slide 1, the vertical Z-direction servo linear slide 1 is installed on the slide table power installation base 3, and the workpiece rivet fixture 5 is installed on the horizontal Y-direction On the servo linear slide 4, the horizontal Y-direction servo linear slide 4 is installed on the horizontal X-direction servo linear slide 6, the horizontal X-direction servo linear slide 6 is installed on the workbench panel 7, and the riveting power head sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com