Terminal post riveting device and breaking tool

A technology of riveters and poles, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easy loose connection of pole bolts, poor electrical contact, etc., to solve poor electrical contact, facilitate maintenance, and avoid stress Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

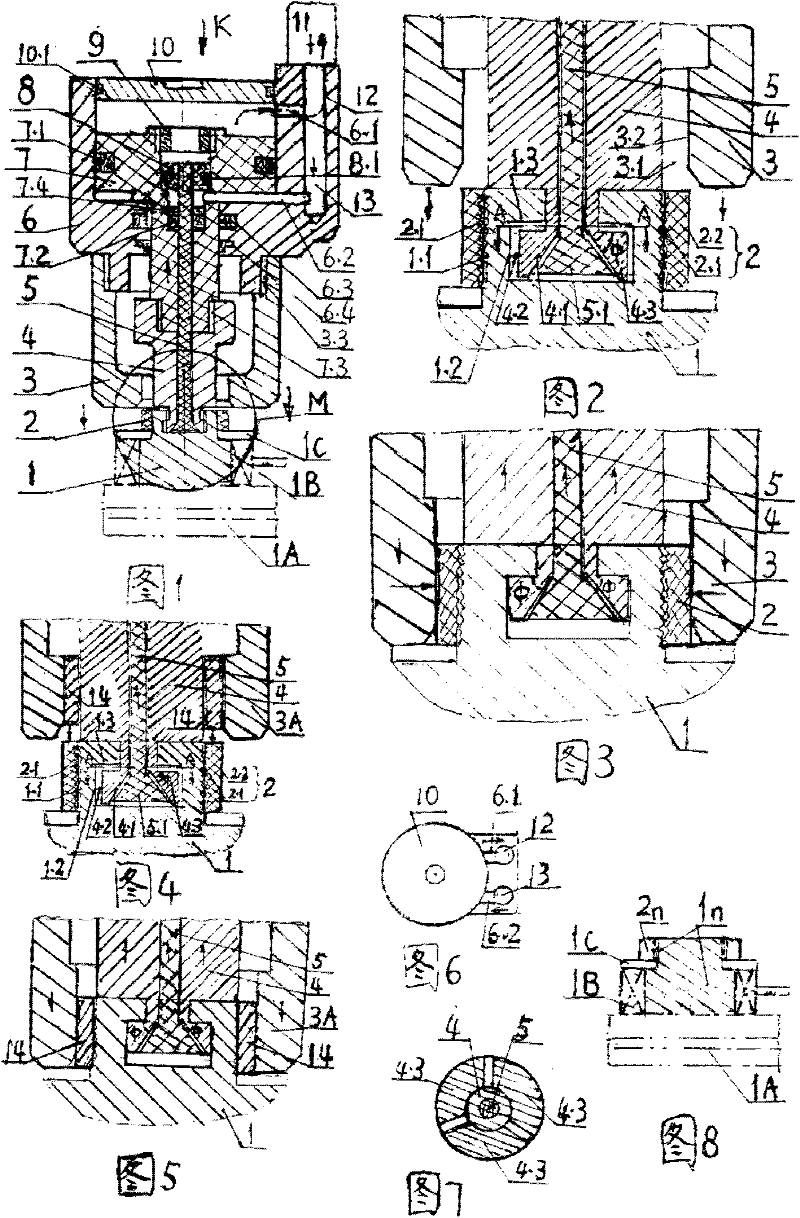

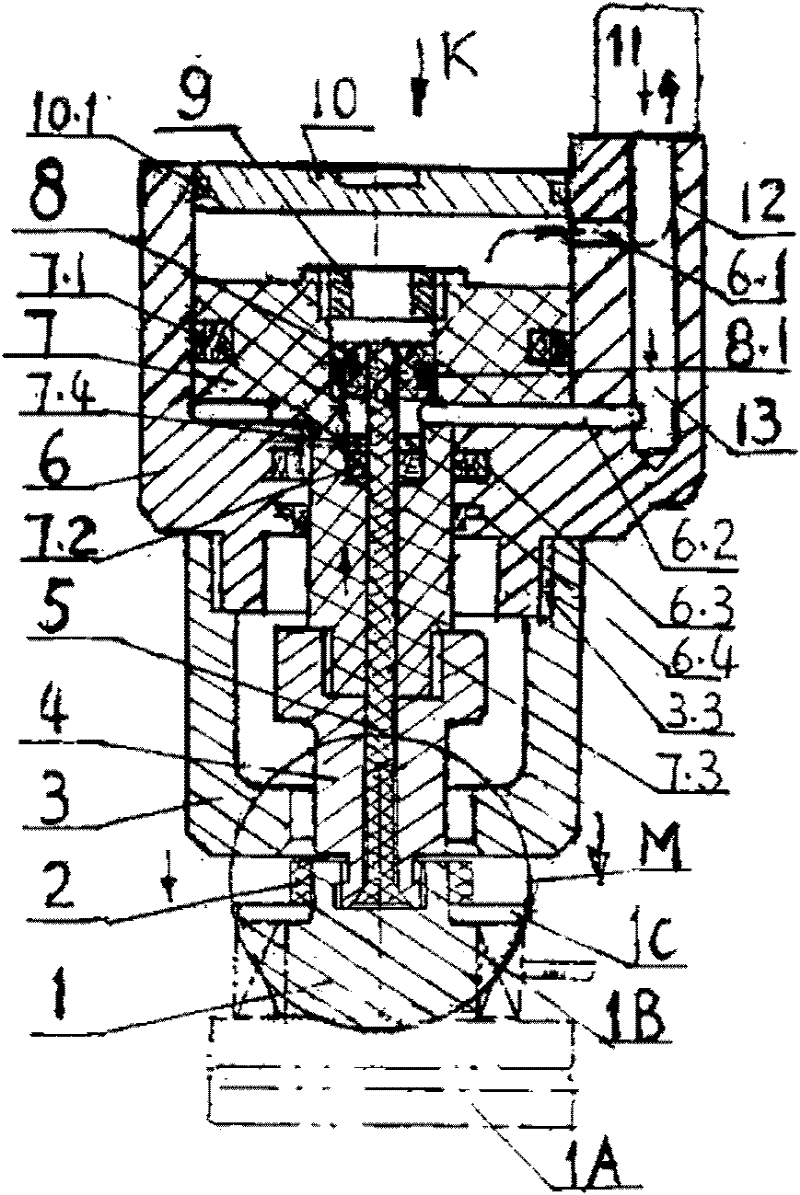

[0017] Example 1: Riveter for pole rivets figure 1 , figure 2 , image 3 , Image 6 and Figure 7 .

[0018] Pole rivet structure: see figure 1 , figure 2 , the outer circumference of the upper end of the pole 1 of the electric vehicle storage battery 1A is an outer ring groove 1.1, and the outer ring groove 1.1 is in interference fit with the inner ring groove 2.1 of the inner hole of the collar 2; a T-shaped groove 1.2 is opened in the center of the upper plane of the pole, And form step 1.3. Riveter structure: see figure 2 , a strut 5 is arranged at the center of the cylinder body 6, and the gripping rod 4 is tightly sleeved on the outside of the strut. The included angle Φ between the side and the radial direction is selected as 8°. The inner hole 4.1 at the bottom end of the grab bar is consistent with the trumpet-shaped body at the bottom end of the strut bar, and the outer circumference 4.2 at the bottom end of the grab bar is consistent with the T-shaped ...

Embodiment 2

[0022] Embodiment 2: breaking tool, see figure 1 , Figure 4 Figure 5 Image 6 Figure 7 . The pole rivet breaking tool is identical to Embodiment 1 except for the following features:

[0023] 1) see Figure 4 , Figure 5 In this embodiment, the outer casing 3A of the cutting tool is formed by installing two axial feed cutter heads 14 evenly distributed along the circumferential direction on the inner circle of the outer casing 3 of the pole rivet riveter. Cutting process: see figure 1 and Figure 4 , the cutting process is the same as that of the riveting process, the up and down movements of the oil cylinder, the support rod, the grip rod, and the jacket are the same, except that during riveting, the upward movement of the support rod and the downward movement of the jacket is to squeeze the collar 2, while the riveting is In the cutting collar. See Figure 4 , the initial position of the breaking tool, the collar exists. See Figure 5 , the position where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com