Trench

A technology of trenches and trenches, which is applied to waterway systems, sewer systems, water supply devices, etc., can solve the problems of complex construction sites, long construction periods, and slow laying progress of trenches, and achieve fast riveting speed and reduced construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

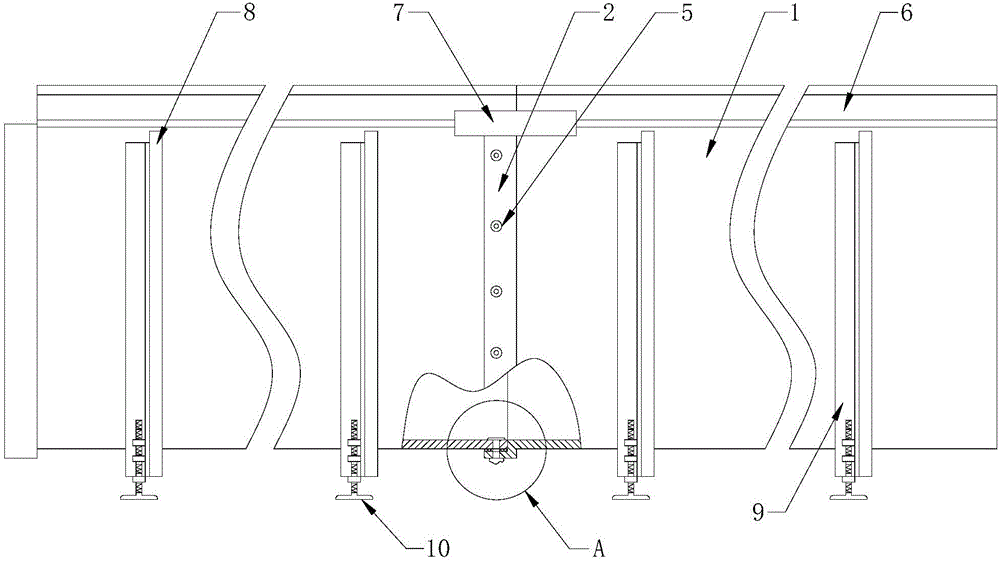

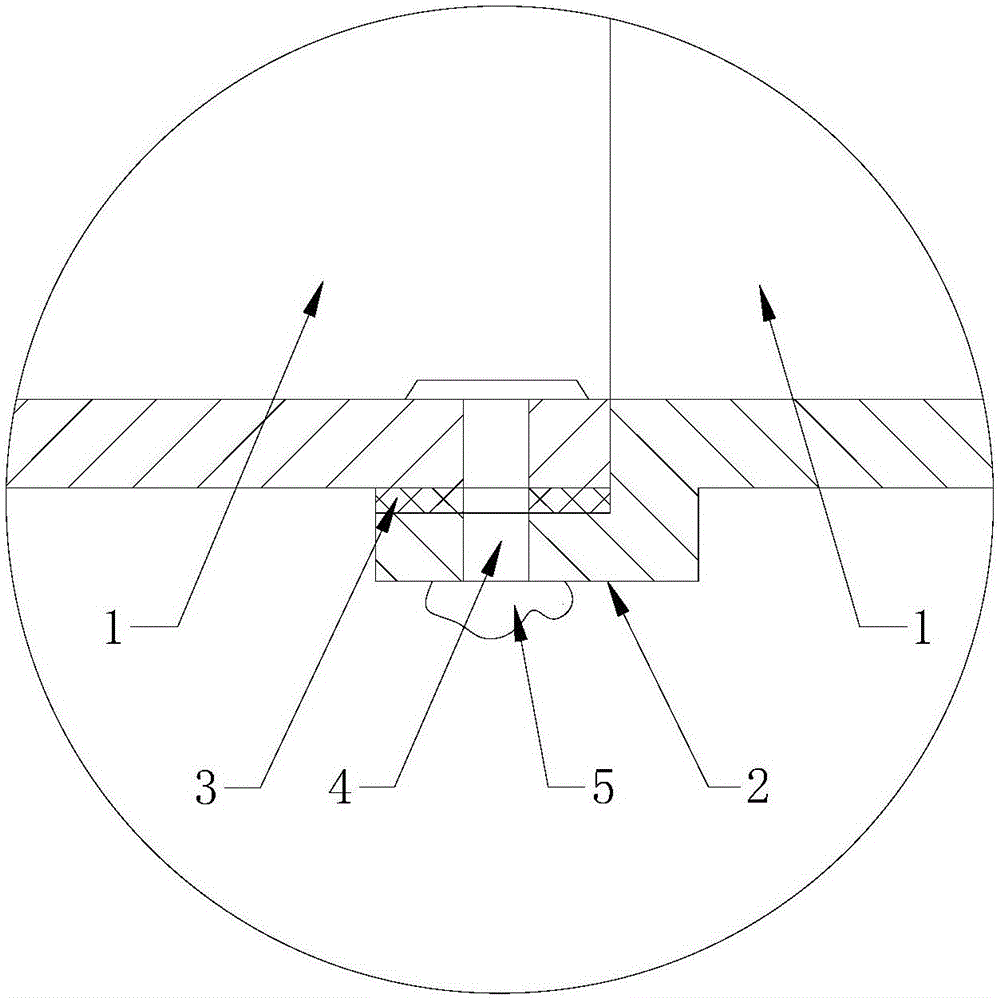

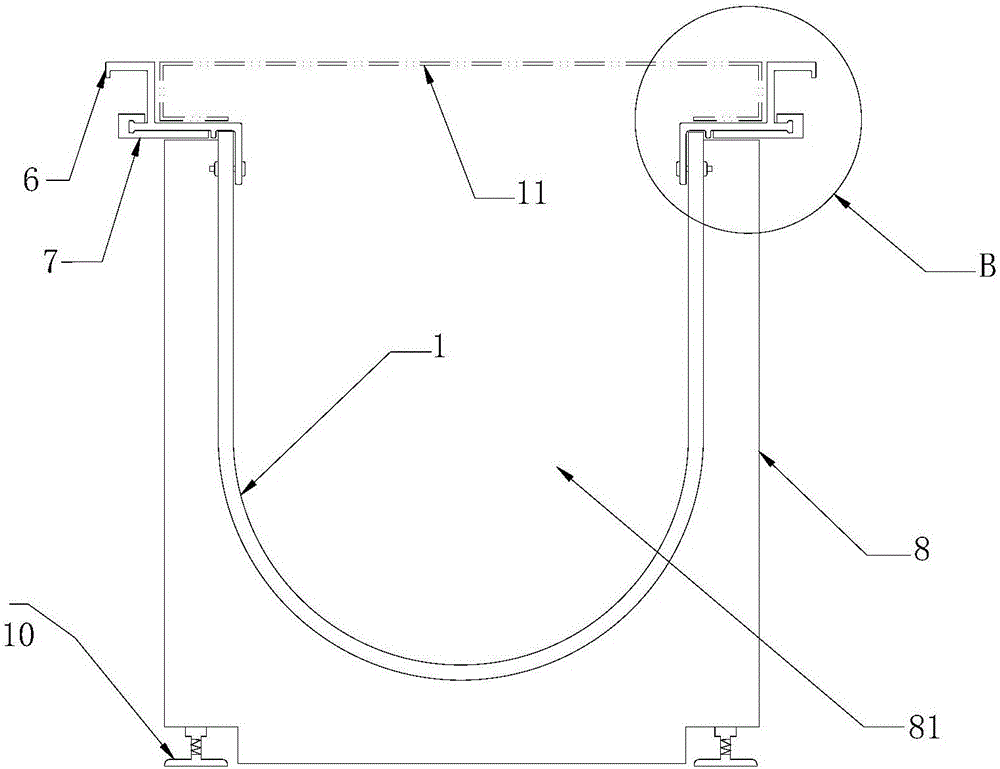

[0019] Such as figure 1 The shown trench is formed by connecting several tank bodies 1 sequentially, and the tank body 1 is molded by a stainless steel plate, combined with Figure 1 to Figure 5 The trough body 1 has a U-shaped cross-section perpendicular to its axial direction, one end of the trough body 1 is radially expanded to form an outer expansion part 2, and the other end is a smooth end, and the inner size of the outer expansion part 2 is not less than a smooth The outer dimensions of the end, the outer expansion part 2 of the tank body 1 is sleeved on the smooth end of the adjacent tank body 1, and a seal 3 is provided between the outer expansion part 2 and the smooth end to prevent joint water leakage, between the outer expansion part 2 and the smooth end. A corresponding riveting hole 4 is respectively provided on the smooth ends,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com