Pre-buried groove channel rivet rod riveting device

A technology of riveting device and pre-embedded channel, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of loosening, low processing efficiency, slow speed, etc., to reduce friction, prolong service life, and improve operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

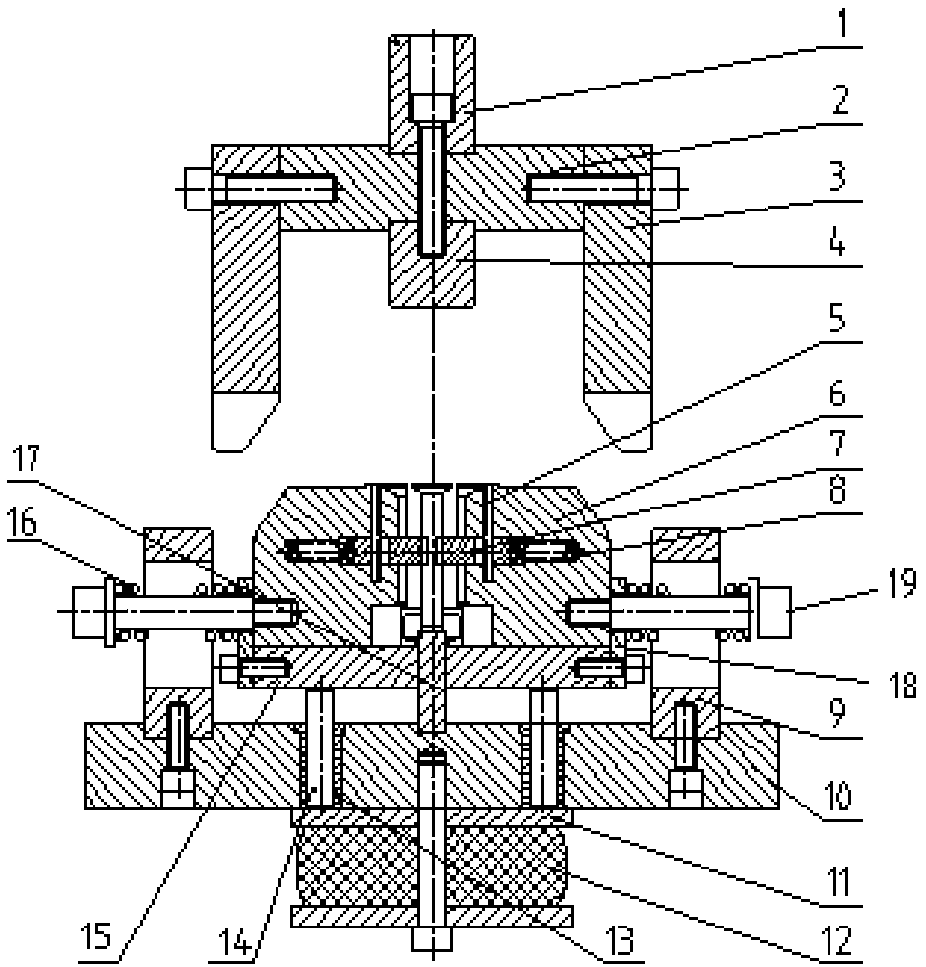

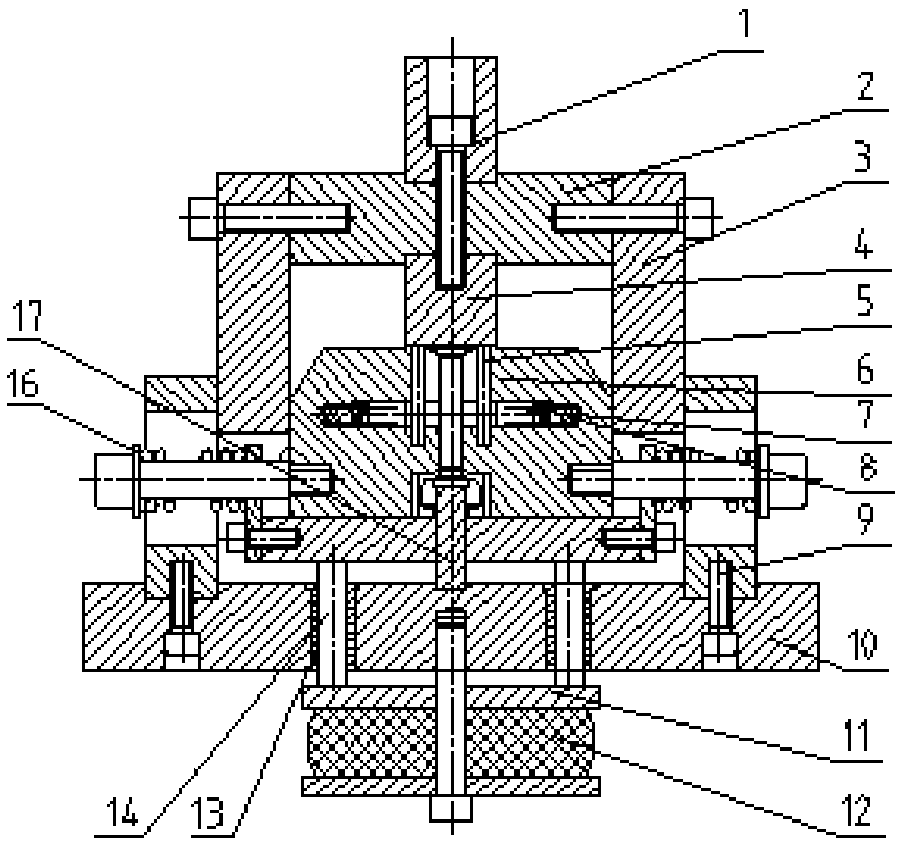

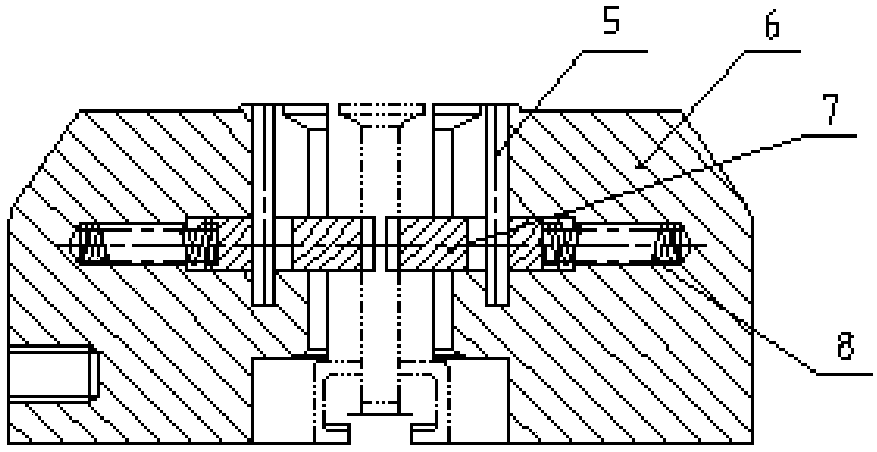

[0026] like Figure 1-Figure 4 As shown, the pre-buried channel riveting rod riveting device includes a crimping structure, and the crimping structure includes an upper mold 2, a lower mold 17 and a base 10; a clamping mechanism is provided between the upper mold 2 and the lower mold 17; The clamping mechanism includes a supporting plate 15, the middle of the supporting plate 15 is provided with a lower mold groove, and the two sides of the supporting plate are provided with a clamping mechanism; the lower end of the lower mold 17 is fixed on the base 10, and the upper end is placed on the base. In the lower mold groove described above, it can slide up and down relative to the lower mold groove. The base 10 is provided with a number of guide holes, and the lower end surface of the supporting plate 15 is provided with a number of guide posts 14 matched with the guide holes, and the guide posts 14 are loaded into the guide In the hole, a bushing 13 is provided in the guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com