Self-adaptive positioning nut riveting tool and method

A riveting tooling and self-adaptive technology, applied in the field of machining, can solve the problems of low riveting qualification rate of riveting shaft nut, and achieve the effect of solving the low riveting qualification rate, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

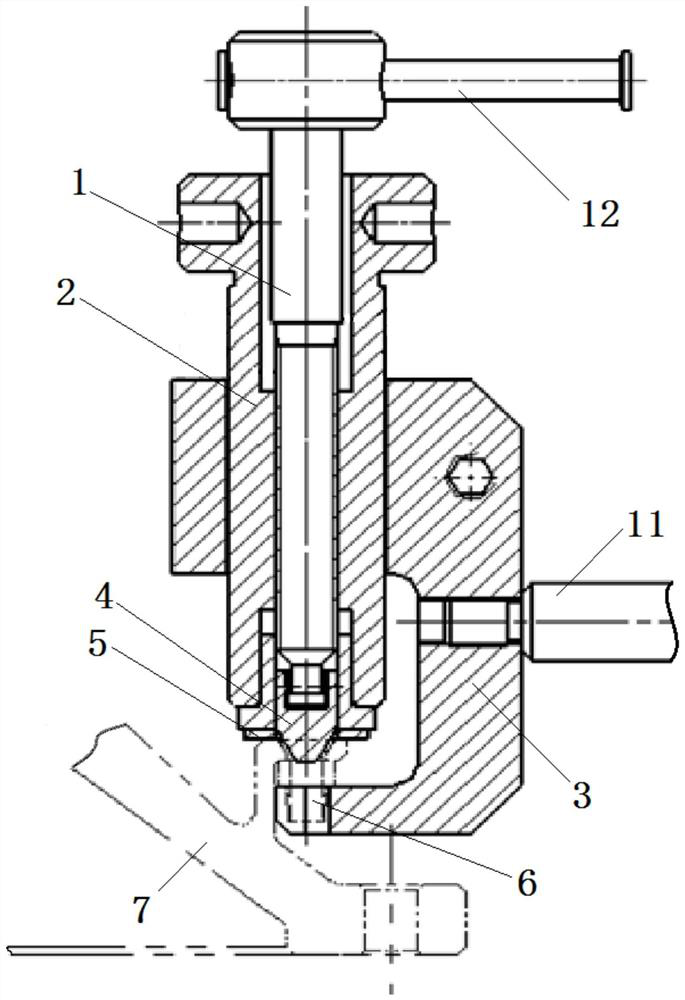

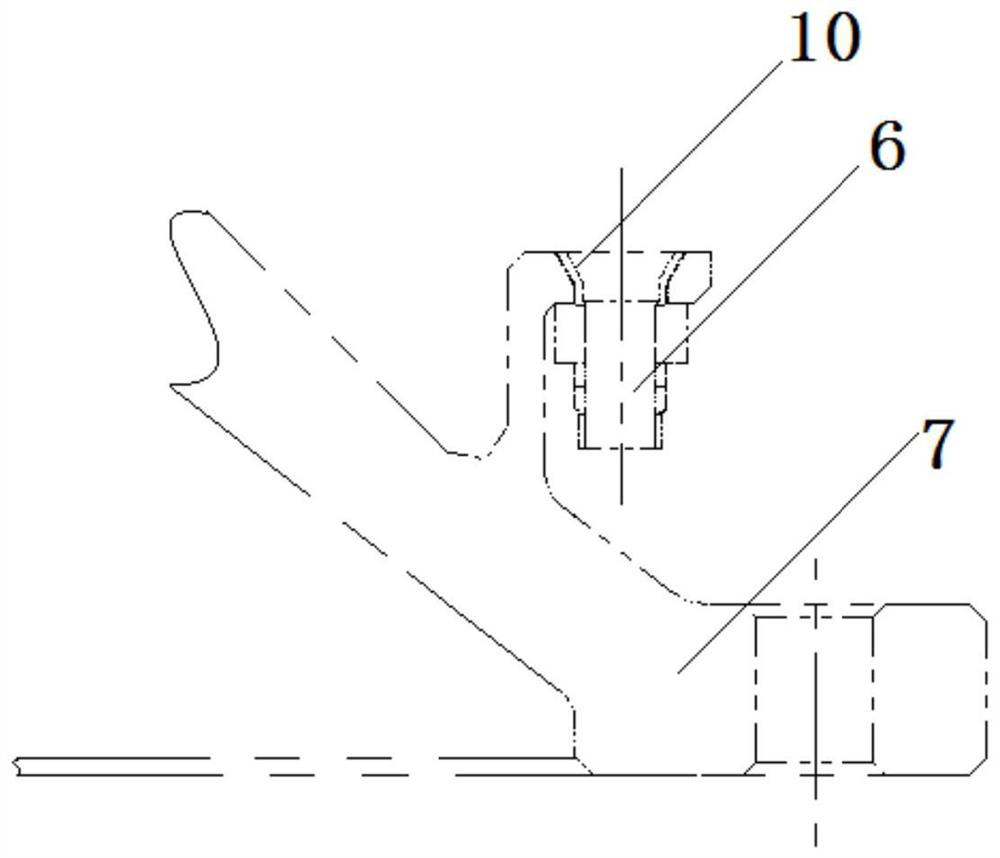

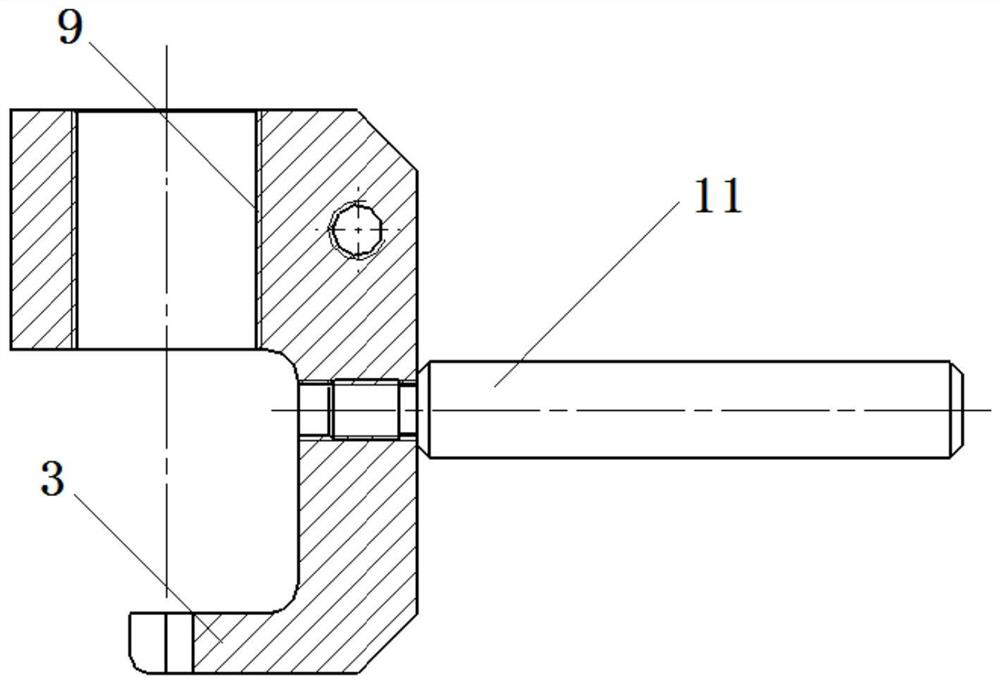

[0044]Nut riveting in low-pressure turbine shaft workpieces as an example, such as Figure 1 to Figure 5 As shown, an adaptive positioning nut riveting tool is characterized in that it includes a push rod 1, a positioning compression sleeve 2, a bow body, a conical head 4 and an end face positioning sleeve 5; the ejector rod 1 and the positioning compression sleeve 2 The ejector rod thread 8 is set between them; the positioning sleeve thread 8 is set between the positioning compression sleeve 2 and the arched body. The riveting mandrel 1 is driven by the mandrel thread 8, and the axial load is transmitted to the conical head 4 at the front end of the mandrel to realize the expansion of the riveting shaft nut 6; the positioning sleeve thread 9 is used to drive the positioning compression sleeve 2, and transmit the shaft The load is given to the end face positioning sleeve 5 to realize the compression and abutment of the end face positioning sleeve 5 and the mounting edge end fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com