Multi-station rotary riveting machine

A riveting machine and multi-station technology, which is applied in the field of filter manufacturing, can solve the problems of low production efficiency, slow production rhythm, and high labor intensity of operators, and achieve the effects of beautiful appearance, reduced labor intensity, and improved riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

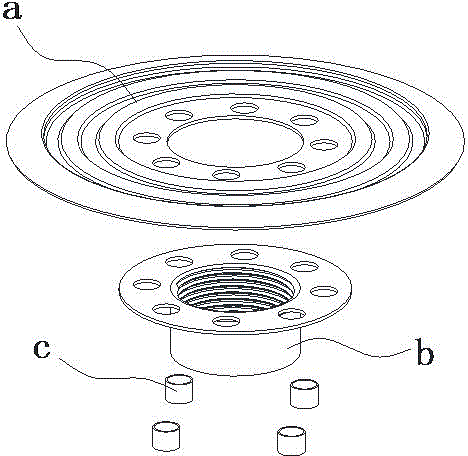

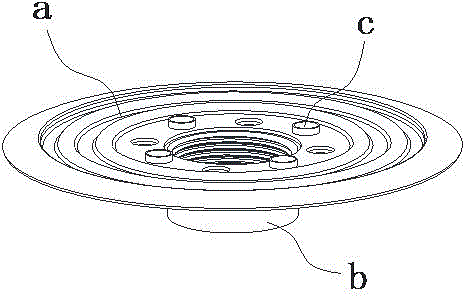

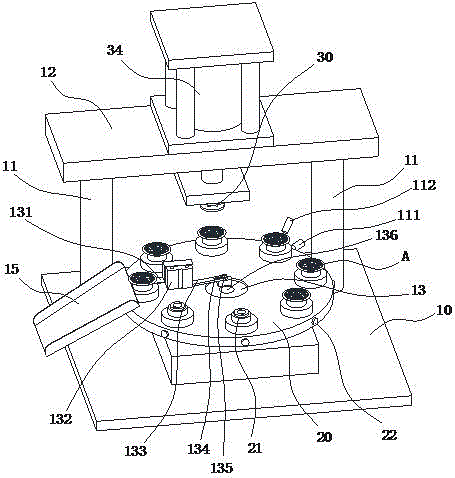

[0020] like image 3 As shown, a multi-station rotary riveting machine includes a positioning seat 21 for fixing the end cover A to be riveted, and a punch 30 arranged to reciprocate vertically above the positioning seat 21, and the positioning seat 21 is fixed On the turntable 20, the turntable 20 is rotatably arranged on the base 10, and there are at least two positioning seats 21, and each positioning seat 21 is arranged in a circular array on the turntable 20 with the rotation center of the turntable 20 as the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com