Double-end pressure riveting method, riveting pin and pressure riveting device

A riveting pin and double-ended technology, applied in rivets and other directions, can solve problems such as journal upsetting, component product performance degradation, and functional failure, and achieve the effects of stable riveting process, reduced riveting cost, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

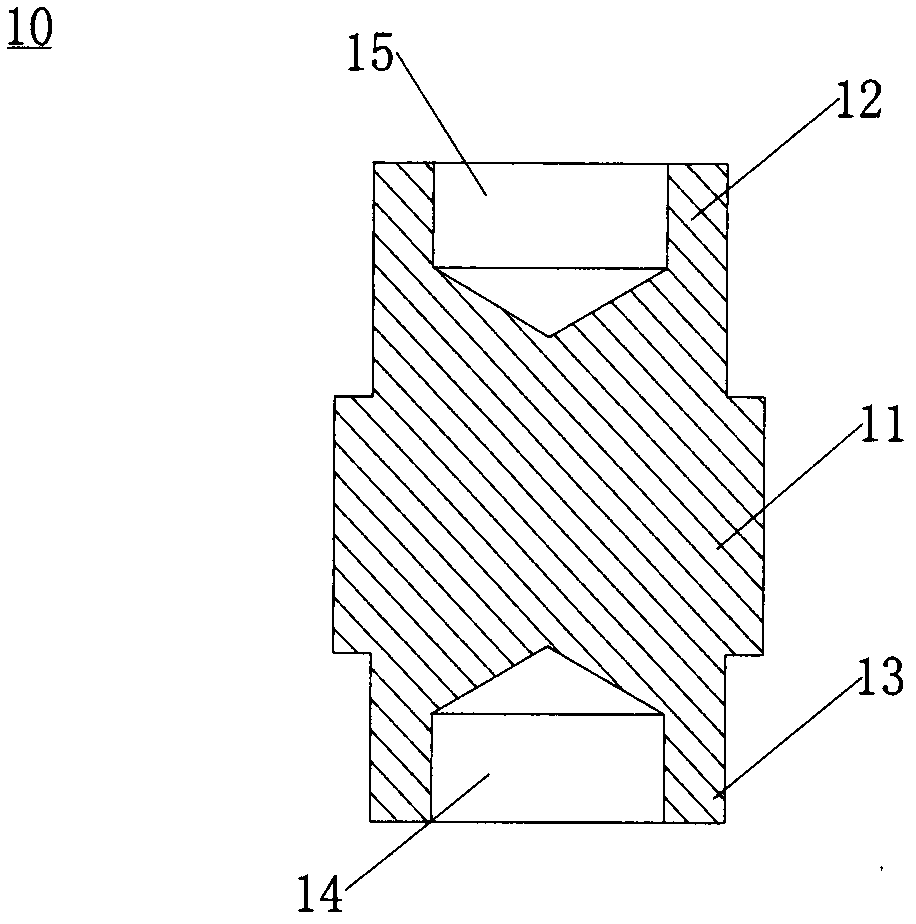

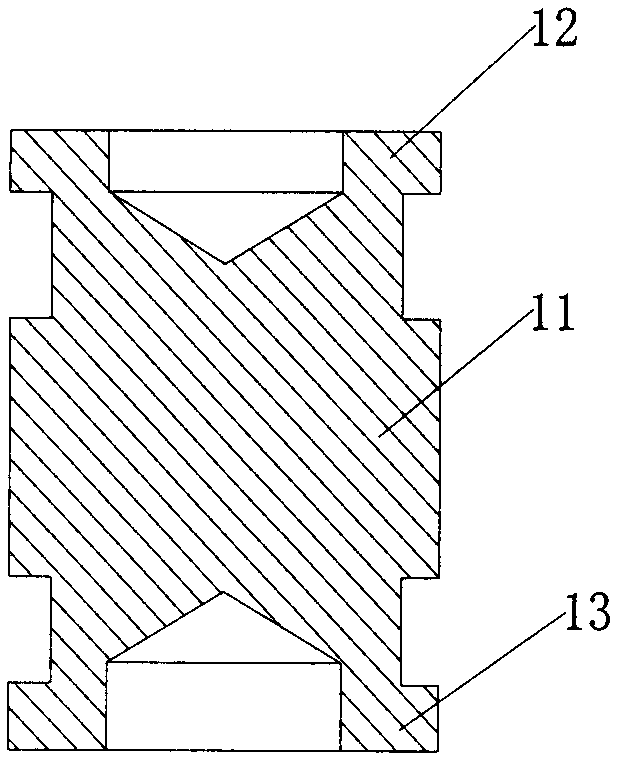

[0024] like figure 1 and figure 2 As shown, the riveting pin used in the double-end pressure riveting method is a three-segment journal riveting pin 10, the size of the middle journal 11 is larger than that of the two ends of the journals 12 and 13, and the two ends of the journal are partially hollow Structure; after pressure riveting, the journals at both ends of the riveting pin are locally upset. Since the journals at both ends are provided with recesses 15 and 14 along the axial direction of the riveting pin, the outer walls of the recesses are locally upset after riveting.

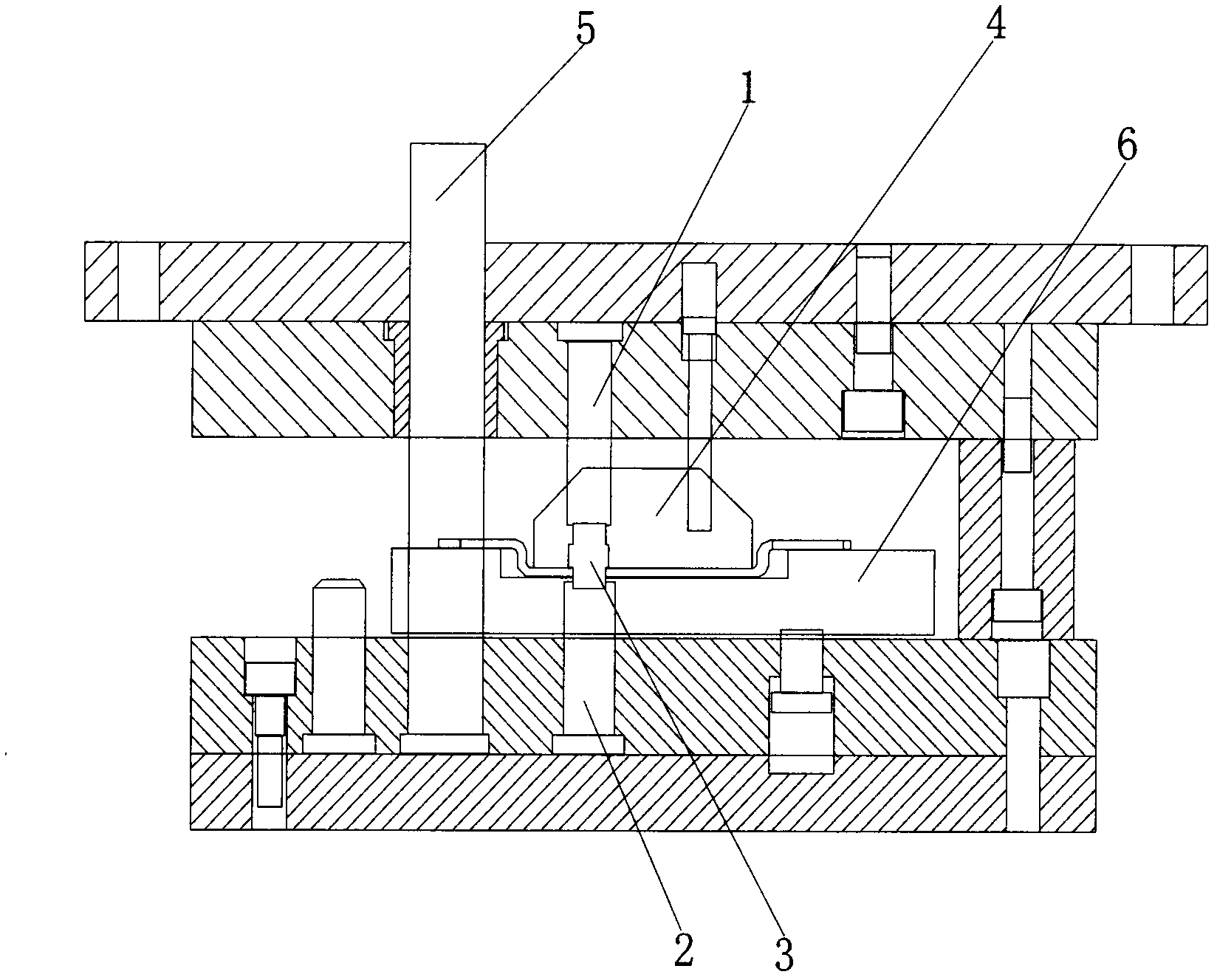

[0025] like image 3 As shown, the riveting device used in the double-ended riveting method includes an upper riveting die and a lower riveting die, the upper riveting head 1 and the lower riveting head 2 are respectively fixed on the upper riveting die and the lower riveting die, and the upper riveting die and the lower riveting die are fixed respectively. A riveting guide post 5 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com