Automatic press-riveting device for collecting element

An automatic and mounting seat technology, applied in the field of pressure riveting devices, can solve the problems of scratching the upper side of the pressure riveting point, etc., and achieve the effect of easy operation and high pressure riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

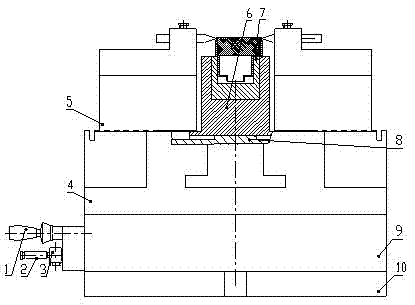

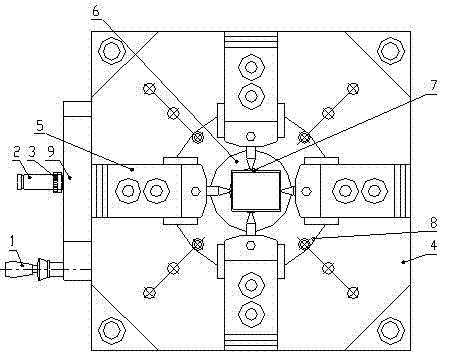

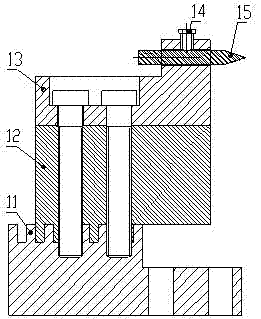

[0015] An automatic pressure riveting device for collecting elements, comprising: a pneumatic mechanism 9, a check valve 2, a switching handle 1, an air pressure gauge 3, a fixing plate 4, and also includes: a pressure riveting mechanism 5, a fixing seat 6, an adapter seat 7, an installation Seat 8, base 10; wherein, the riveting mechanism 5 includes: locking screw 14, carrier block 13, T-shaped slider 11, claw 12, thimble 15.

[0016] The base 10, the pneumatic mechanism 9 and the fixed plate 4 are all square in cross-section with the same cross-sectional size. The center of the base 10 has a threaded hole, the center of the pneumatic mechanism 9 has a through hole, and the center of the fixed plate 4 has a through hole. The base 10 is fixed on the horizontal platform, the pneumatic mechanism 9 is placed on the base 10 and fixed with screws, and the fixing plate 4 is placed on the pneumatic mechanism 9 and fixed with screws. There are four slide rails with a T-shaped section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com