Riveting machine

A riveting machine and riveting technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of easy forming inconsistency, high labor intensity of operators, and insufficient accuracy, so as to improve accuracy and quality and save labor. cost, the effect of avoiding manual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

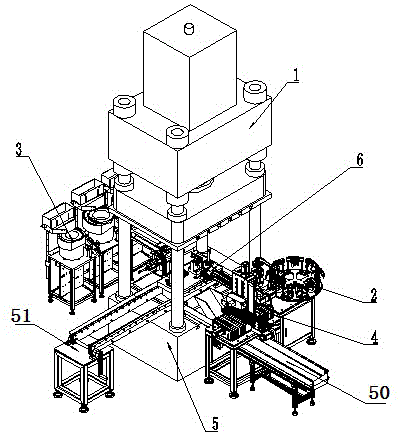

[0029] Example 1 :like Figures 1 to 10 As shown, a riveting machine includes a press 1 with a base 5 on which a riveting station 6 is arranged, and also includes a feeding device 2, a rivet placing device 3 and a retrieving device 4; wherein the feeding The device 2 , the press 1 and the rivet placing device 3 are horizontally arranged side by side, and the said retrieving device 4 is arranged vertically side by side with the said feeding device 2 .

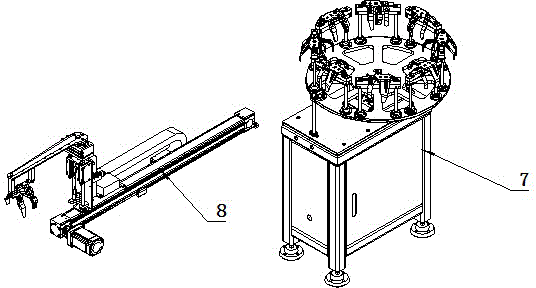

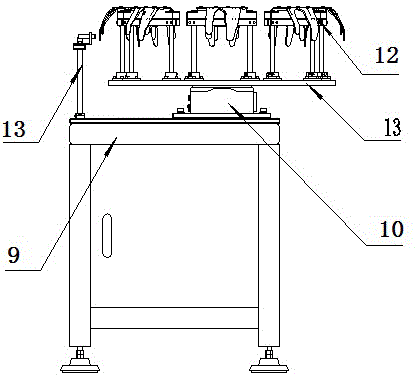

[0030] The feeding device 2 includes a turntable 7 and a feeding manipulator 8, and the feeding manipulator 8 is installed on the base 5 of the press 1; the turntable 7 includes a base 9, a turntable 10 and an indexing plate 11; wherein , the turntable 10 is fixedly arranged on the base 9, a rotating shaft is arranged in the turntable 10, and the indexing plate 11 is installed on the rotating shaft; uniformly on the outer ring of the indexing plate 11 A plurality of workpiece placement tables 12 are provided; a detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com