Multi-station full-automatic pneumatic rotating riveting machine

A fully automatic, rotary riveting machine technology, applied in the field of mechanical processing, can solve the problems of automatic adjustment of the angle and spacing of workpieces that cannot be processed, and achieve the effects of improving riveting accuracy and efficiency, convenient maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

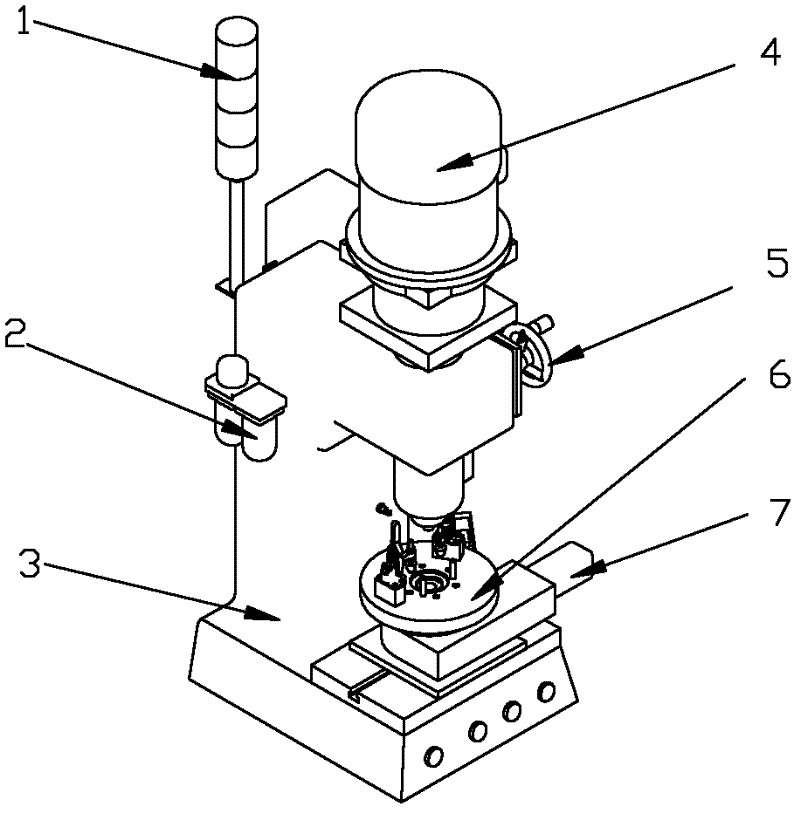

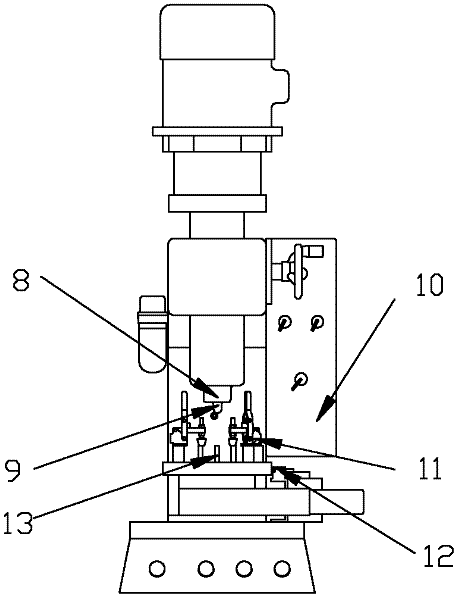

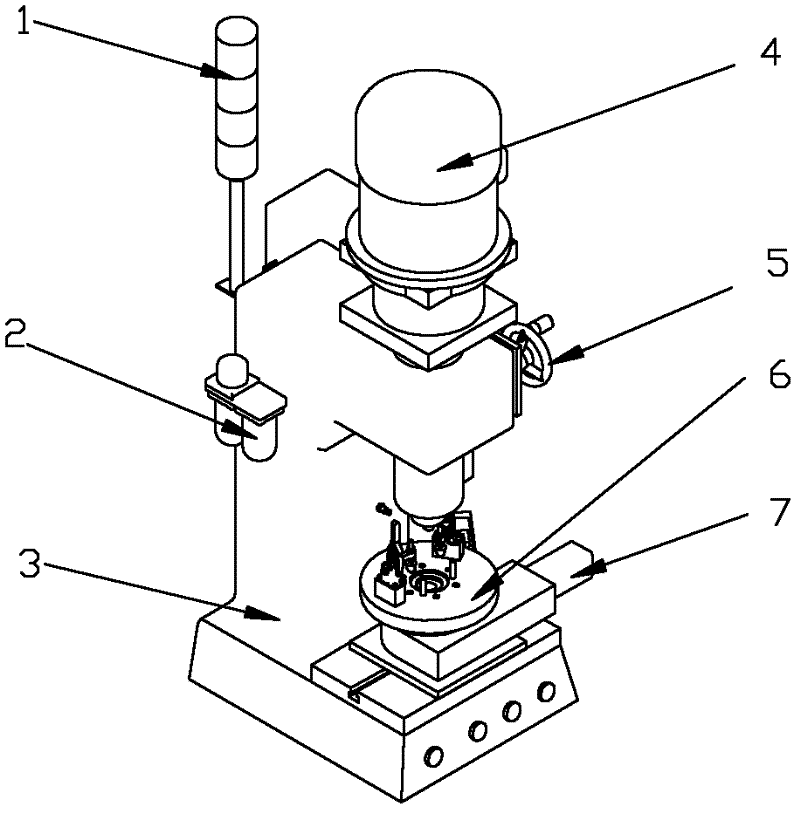

[0015] like figure 1 , 2 As shown, as shown, the present invention includes a machine base 3 and an indicator light 1 installed on the machine base, a pressure regulating valve 2, a motor 4, a manual lifting turntable 5, an indexing plate 6, a cylinder 7, an electrical box 10, and A spin riveting head 8 is installed, and a spin riveting rod 9 is installed on the spin riveting head. Wherein the indexing plate is installed under the rivet rod, and the indexing plate is driven by the cylinder, and positioned 12 by the limit stroke switch installed on the cylinder. The control line of the cylinder is connected with the main control board in the electrical box, and the main control board receives the operation instructions of various operation keys on the surface of the electrical box, and pre-sets the stroke of the pneumatic indexing plate.

[0016] In order to carry out riveting processing to the workpiece better, positioning rods 13 and tightening pliers 11 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com