A kind of assembly equipment of ignition tube assembly

A technology for assembling equipment and ignition tubes, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as poor riveting accuracy, no detection device, fixed support, etc., to improve riveting accuracy and effect, reasonable and ingenious design , Improve the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

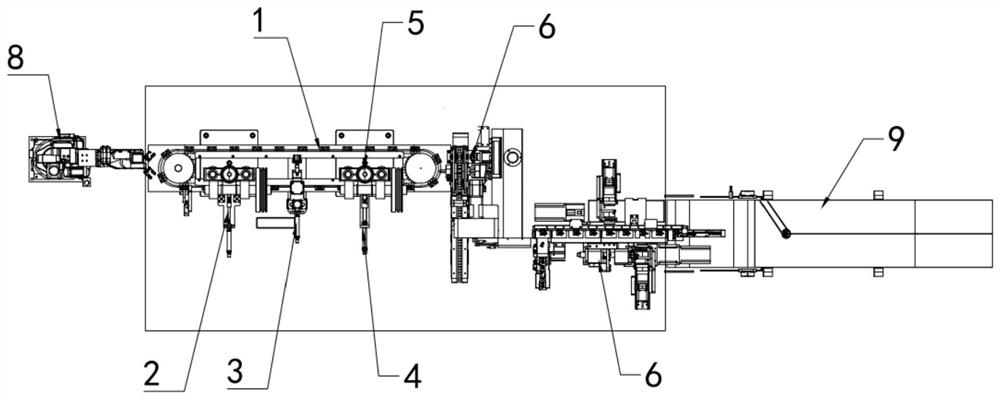

[0030] Example: see Figure 1 to Figure 7 , an assembly device for an ignition tube assembly provided in this embodiment, which includes a riveting device and a detection device arranged in sequence;

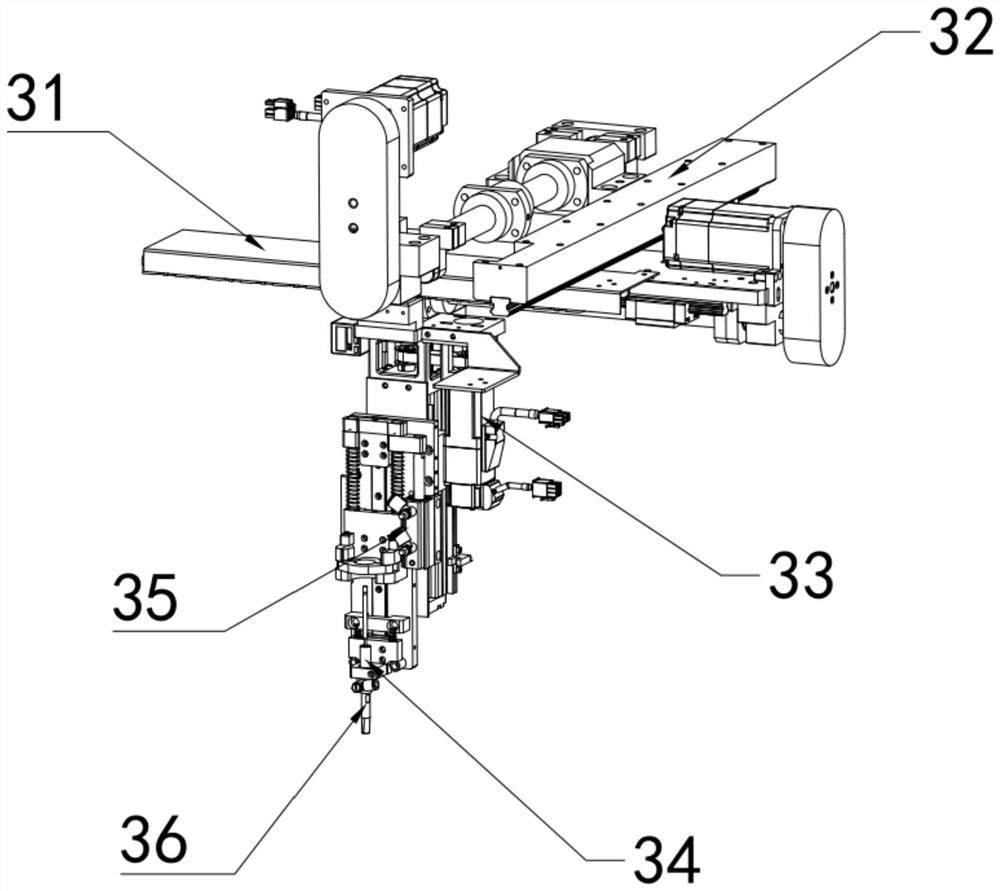

[0031] The riveting device includes a first conveying mechanism 1, and a first fastener mechanism 2, a second fastener mechanism 3 and a riveting mechanism 4 arranged in sequence along the conveying direction of the first conveying mechanism 1, and the riveting mechanism 4 A position adjustment mechanism 5 is arranged on the first conveying mechanism 1, and a plurality of workpiece placement seats for placing workpieces are arranged on the first conveying mechanism 1 according to the interval distance; a first magnetic adsorption part is arranged at the bottom of the workpiece placement seat to absorb and fix Workpiece, improve the positioning accuracy of the workpiece;

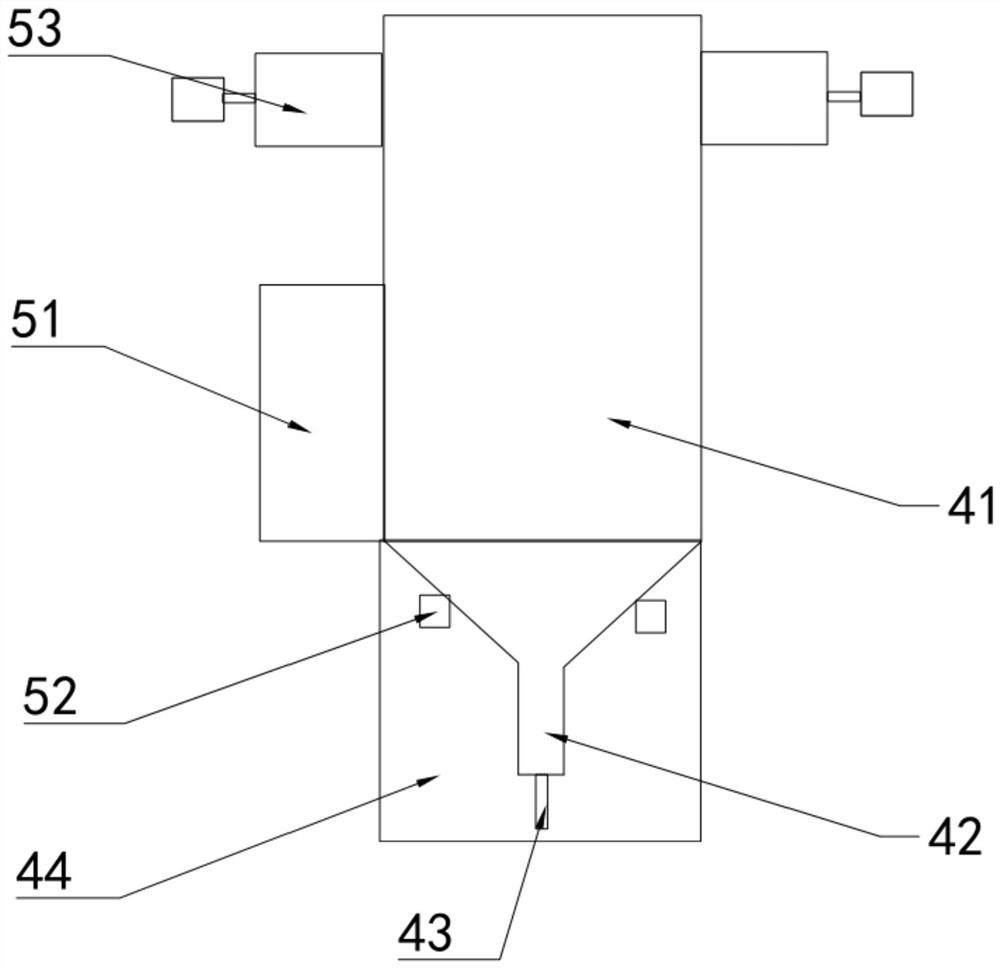

[0032] The riveting mechanism 4 includes a riveting support, a balancer arranged on the riveting support, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com