Traffic sign aluminum alloy bottom plate automatic riveting machine

A signboard and aluminum alloy technology, which is applied in the field of automatic riveting machines for aluminum alloy bottom plates of traffic signboards, can solve the problems of signboard plate separation and damage, increase the production and molding time of signboards, and relative stress conflicts between plates, and overcome the difficulty of maintaining unity , The riveting process is orderly, efficient, and highly automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. To explain the present invention, but not as a limitation of the present invention.

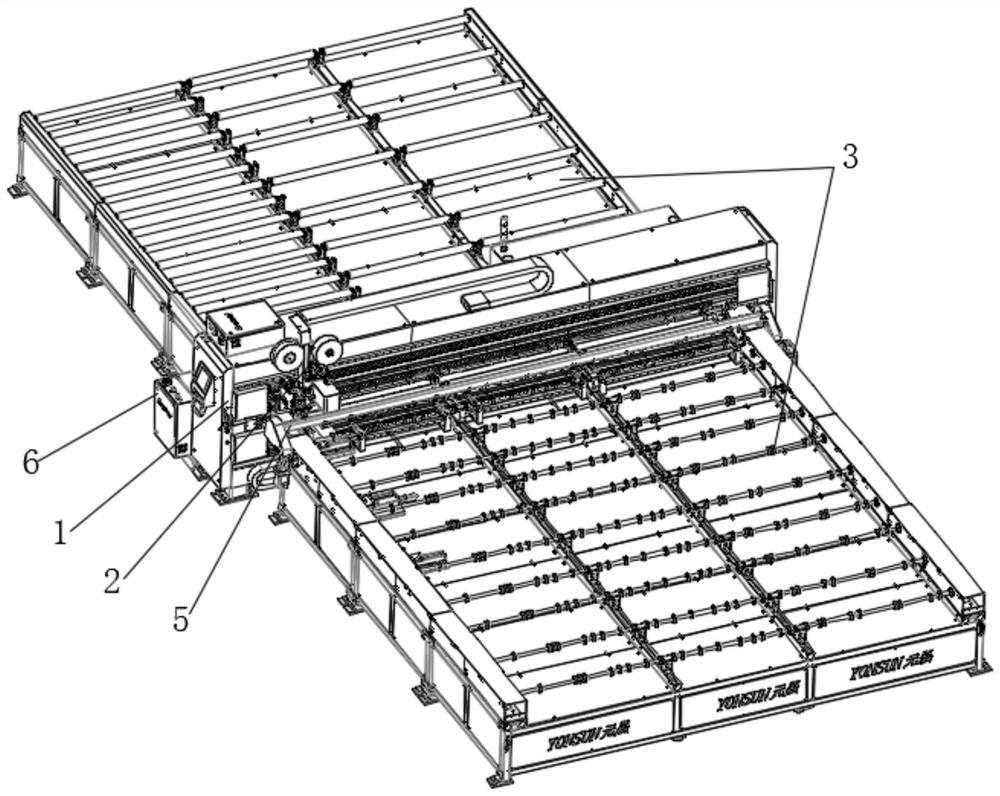

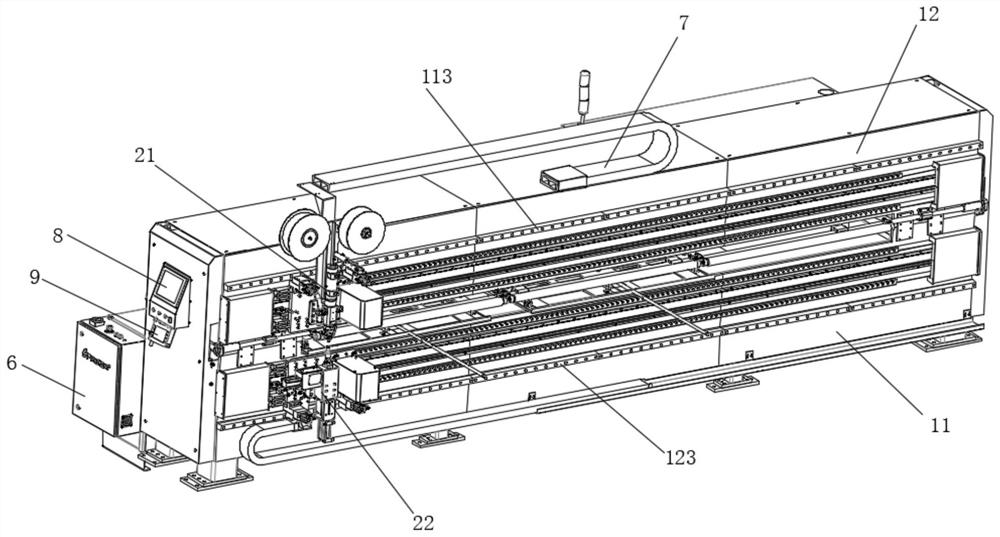

[0048] like Figure 1 to Figure 21 As shown, an automatic riveting machine for the aluminum alloy bottom plate of a traffic sign, comprising:

[0049] A gantry support 1, the gantry support 1 comprising a first gantry 11 and a second gantry 12; the second gantry 12 is fixedly mounted on the top surface of the first gantry 11;

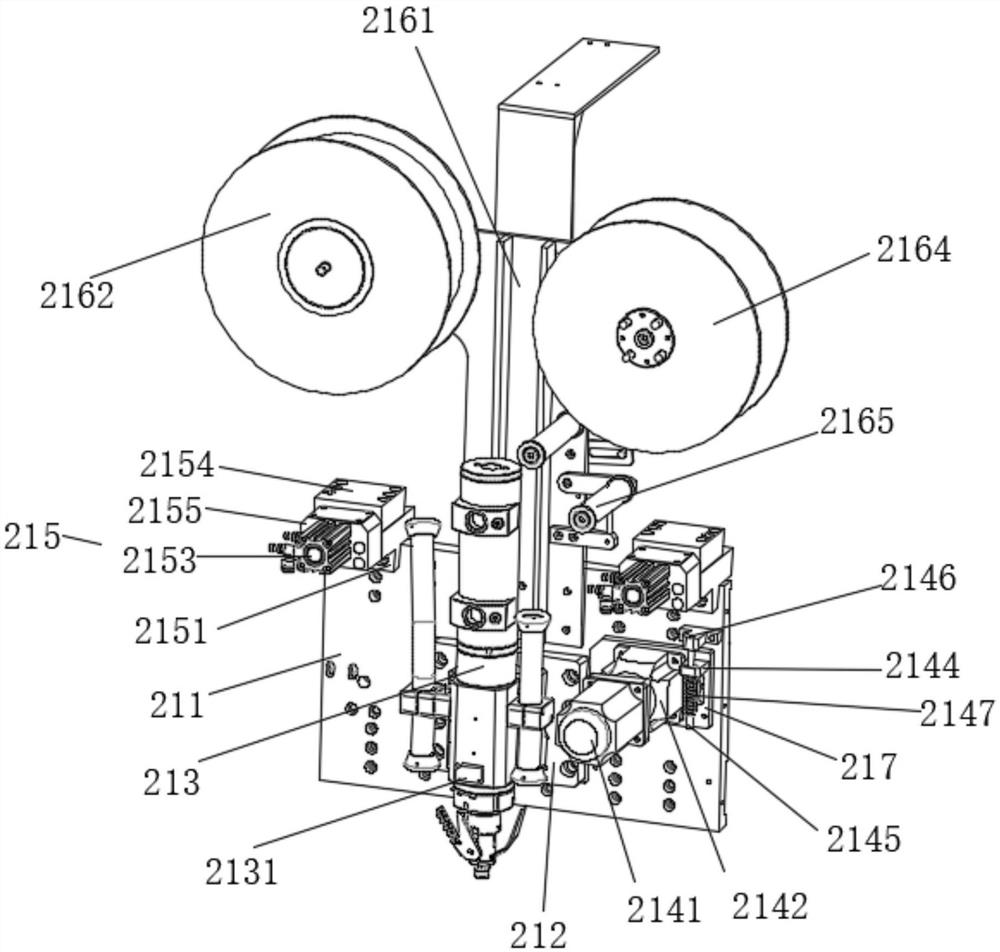

[0050] A riveting mechanism 2, the riveting mechanism 2 includes a self-propelled upper riveting module 21 and a self-propelled lower riveting module 22; the self-propelled upper riveting module 21 is movably mounted on the second gantry 12; The self-propelled lower riveting module 22 is movably installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com