Riveting and positioning device applied to T-shaped electric brake component

A technology of positioning device and electric switch, applied in the field of pressure riveting positioning device, can solve the problems such as the influence of product processing accuracy, punch wear, punch positioning and guiding function influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

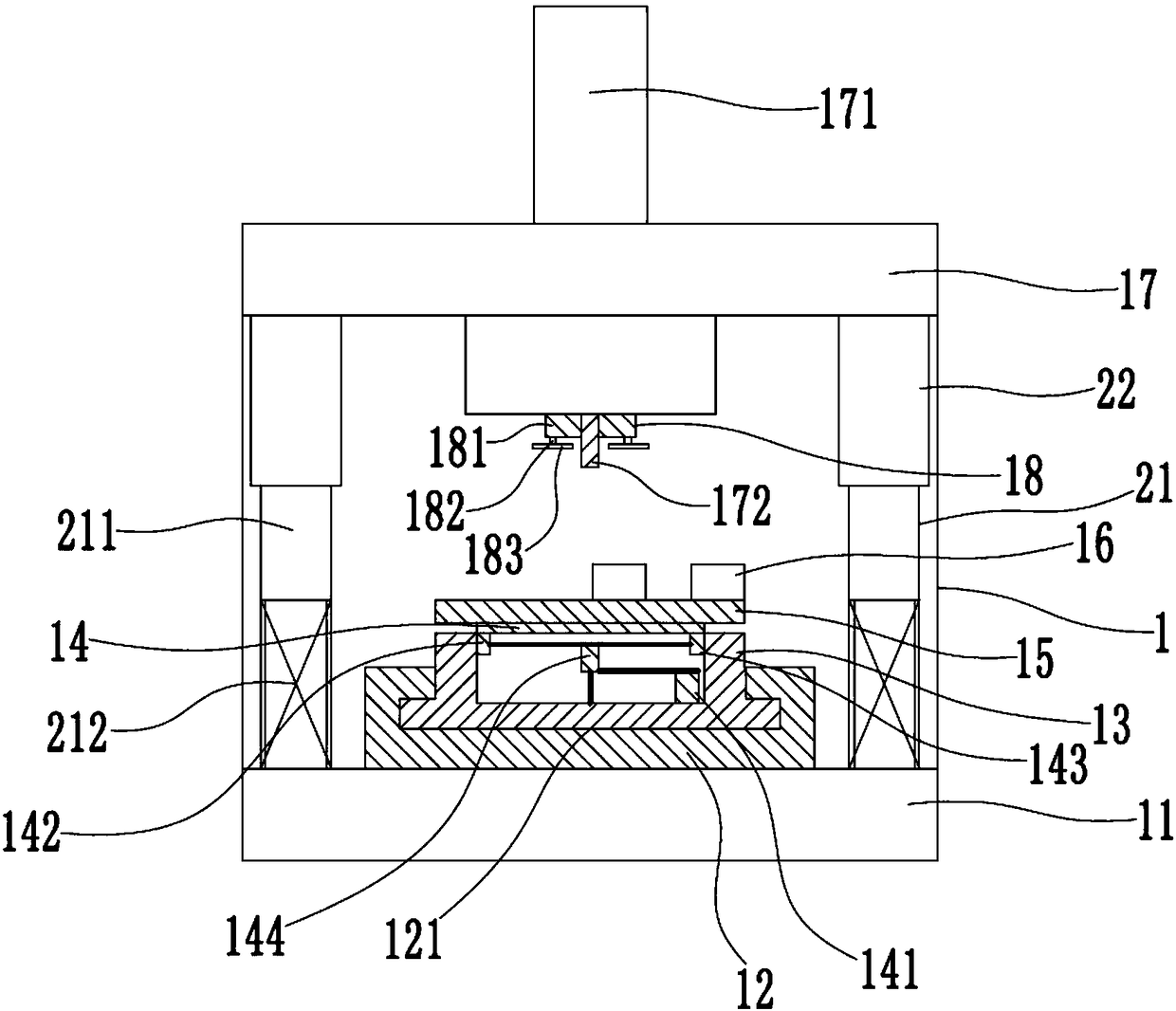

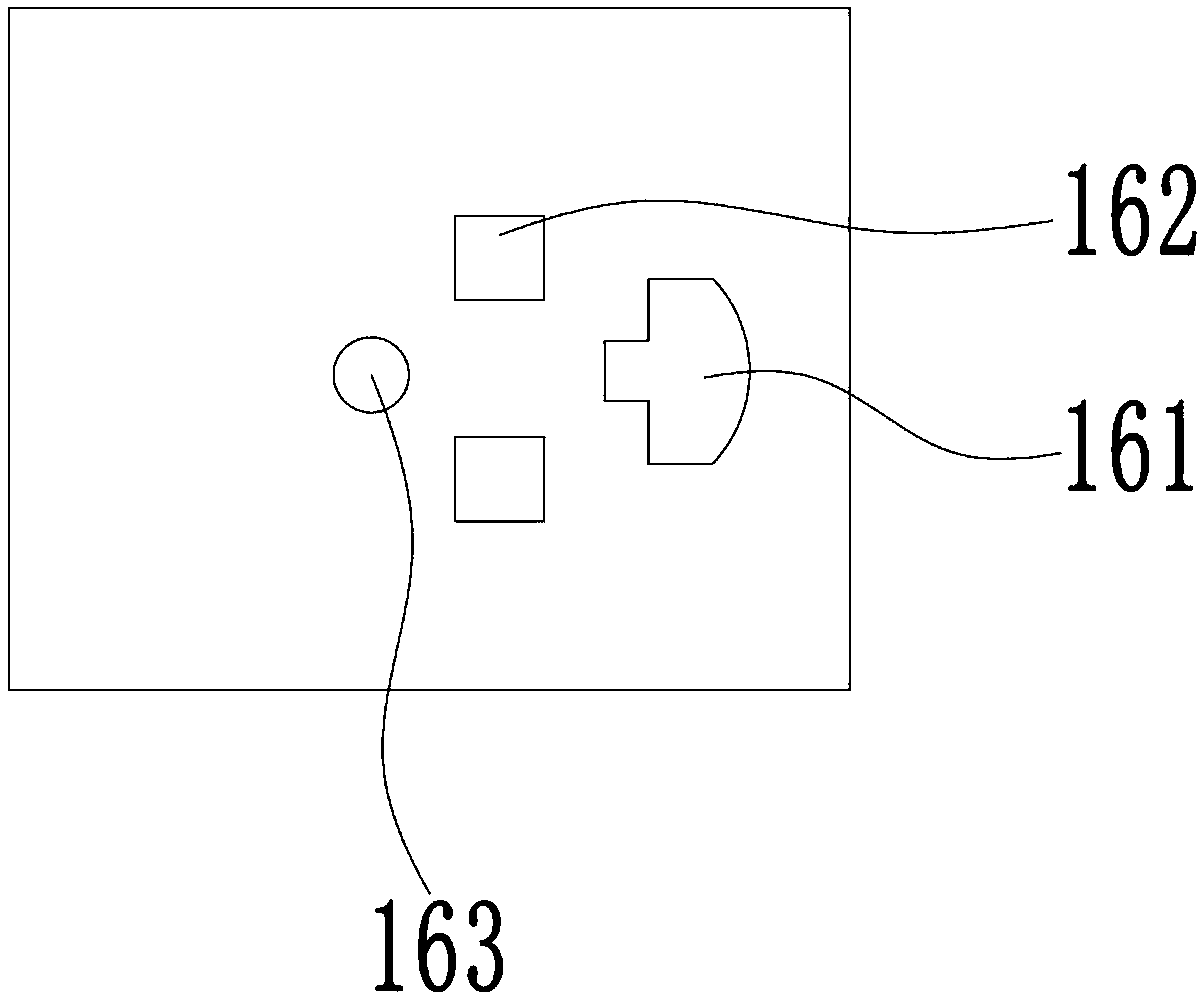

[0021] see Figure 1 to Figure 2 , the figure shows a pressure riveting positioning device applied to T-shaped electric brake parts provided by Embodiment 1 of the present invention, which includes a frame 1, a base 11 is provided on the bottom of the frame 1, and a mounting bracket is fixedly installed on the base 11. Plate 12, a chute 121 is opened on the mounting plate 12, a first positioning plate 13 is slidably connected in the chute 121, and a rotating shaft 14 is installed on the first positioning plate 13, and the rotating shaft 14 is connected to the eccentric shaft 141 in transmission, and the rotating shaft 14 is connected to There is a second positioning plate 15, the surface of the second positioning plate 15 is provided with a positioning portion 16, the movable plate 17 movable in the vertical direction is installed on the frame 1, the movable plate 17 is connected with the driving cylinder 171, and the bottom of the movable plate 17 is equipped with The rivet p...

Embodiment 2

[0024] see Figure 1 to Figure 2 , the figure shows a riveting positioning device applied to T-shaped electric brake components provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The bottom of the rotating shaft 14 is connected with a first shaft body 142 and a second shaft body 143, and the first shaft body 142 and the second shaft body 143 are connected to the eccentric shaft 141; the first shaft body 142 and the second shaft body 143 are connected to the third Shaft body 144, the third shaft body 144 is arranged facing the center of the rotating shaft 14, the third shaft body 144 is connected to the eccentric shaft 141; the first shaft body 142 is connected to the third shaft body 144 through a rod body, and the second shaft body 143 is connected to the second shaft body through a rod body Triaxial body 144 . Through the arrangement of the above structure,...

Embodiment 3

[0026] see Figure 1 to Figure 2 , the figure shows a riveting positioning device applied to T-shaped electric brake components provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The limit part 18 is set on the riveting head 172; the limit part 18 includes a mounting block 181, and the mounting block 181 is set on the riveting head 172, and a plurality of limit rods are installed on the bottom of the mounting block 181 182; the end of the limit rod 182 is connected with a rotatable gear 183. Through the setting of the above structure, after the limit rod touches the surface of the product, the gear rotates with the driving action of the rotating shaft, so that the upper surface of the product can also maintain levelness, thereby further improving the machining accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com