A heating and feeding device for shaft riveting

The technology of a feeding device and a heating device is applied in the field of sheet metal parts processing, which can solve the problems of high rejection rate and the inability of the gear box to meet the requirements of use, and achieve the effects of good jointing, riveting accuracy and machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

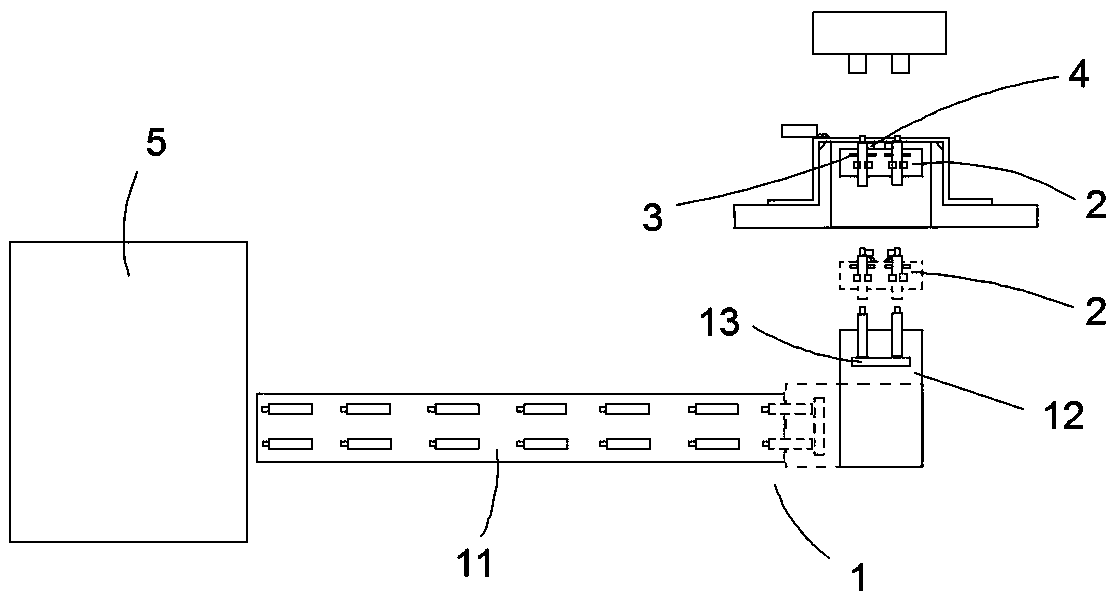

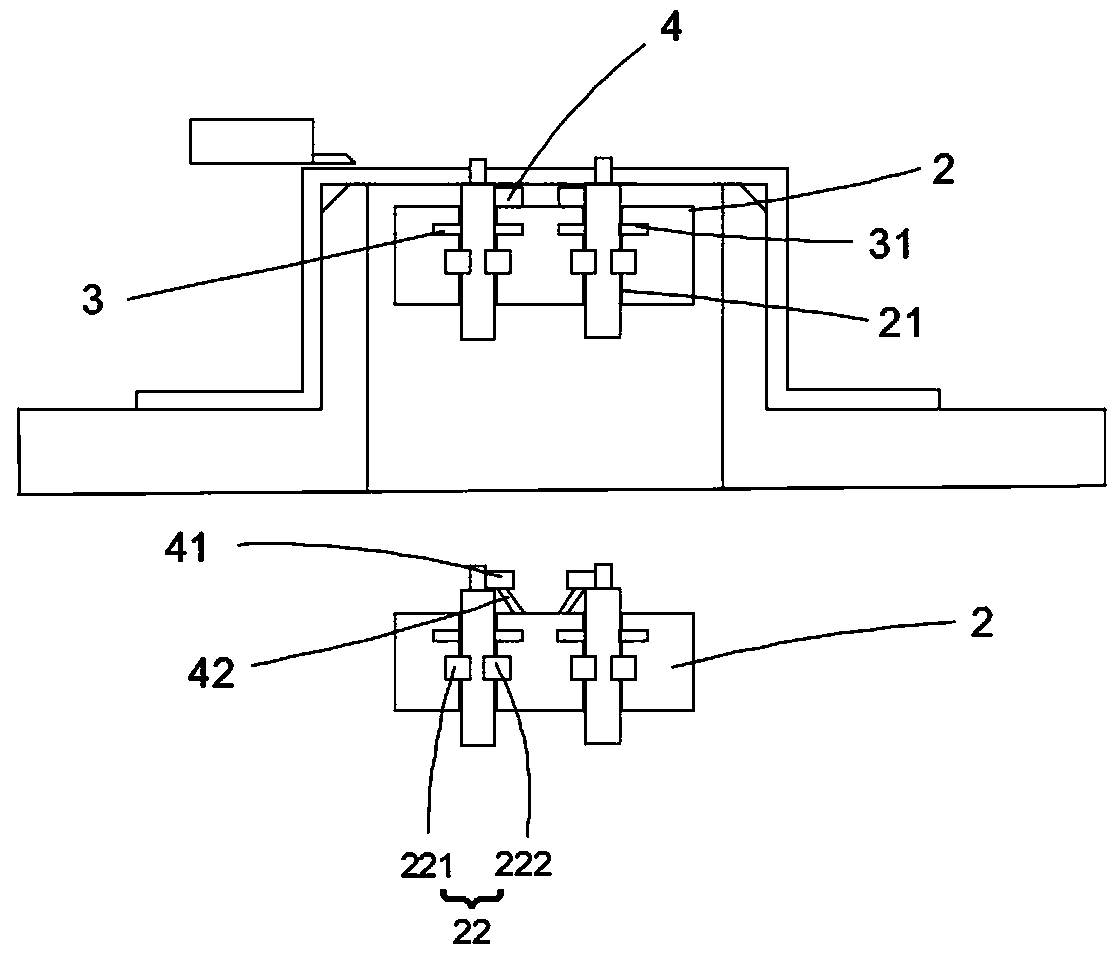

[0025] The invention discloses a heating and feeding device for shaft riveting, such as Figure 1 to Figure 3 As shown, it includes a feeding device 1, a material clamping and feeding device 2, a heating device 4 and a control module, and the described material clamping and feeding device 2 includes a group of shaft placement chambers 21, a clamping device 22 and a clamping drive device; the heating device 4 It includes a heating end 41, a telescopic arm 42 and a telescopic driving device; the heating end 41 is in contact with the riveted part of the shaft, and the telescopic arm 42 is connected to the telescopic driving device; the clamping device 22 is connected to the clamping driving device; The clamping and feeding device 2 is connected with a feeding driving device.

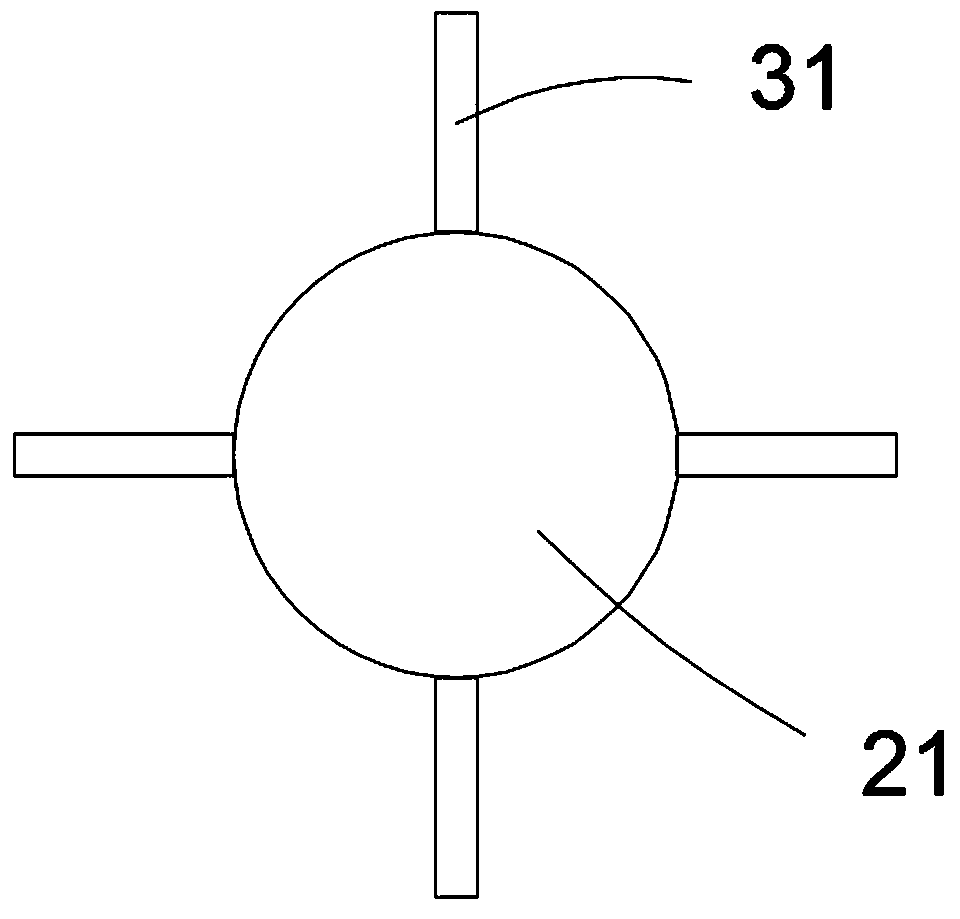

[0026] In this embodiment, a detection and adjustment device 3 is also included. The detection and adjustment device 3 includes a verticality detection device, a set of adjustment push rods 31 and an adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com