Automatic conveying and riveting device and riveting method thereof

A technology of riveting device and automatic feeding, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low riveting efficiency, low degree of automation, and difficulty in blanking, and achieves improved riveting efficiency, compact device layout, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

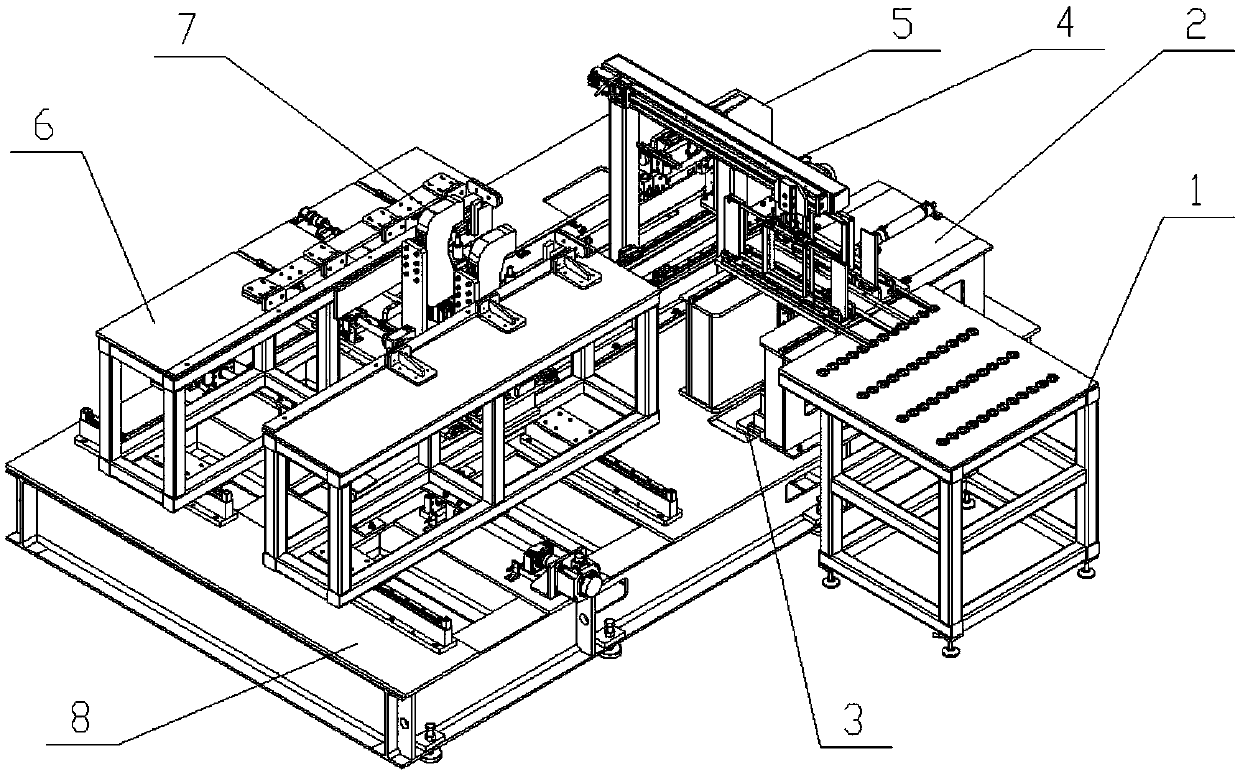

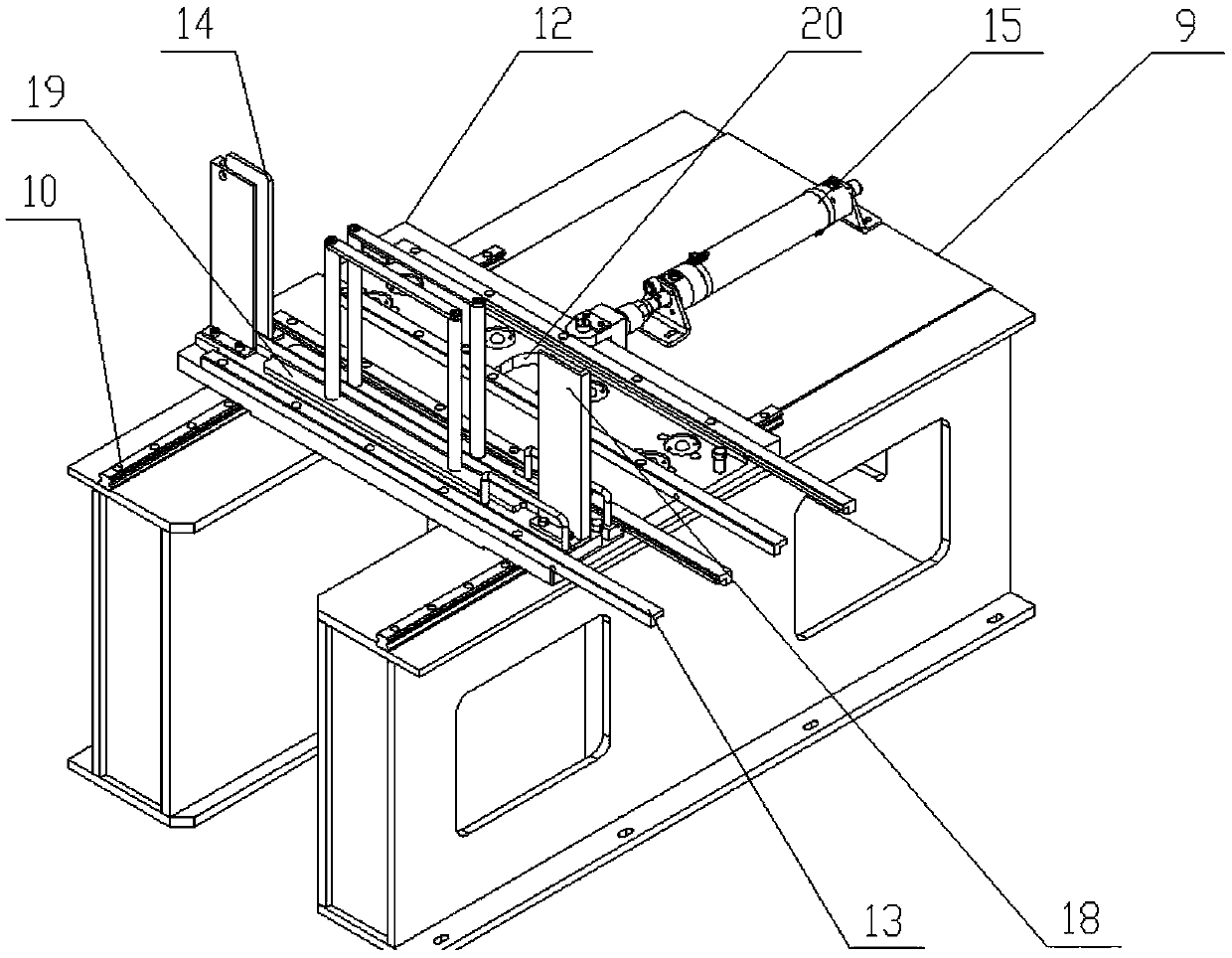

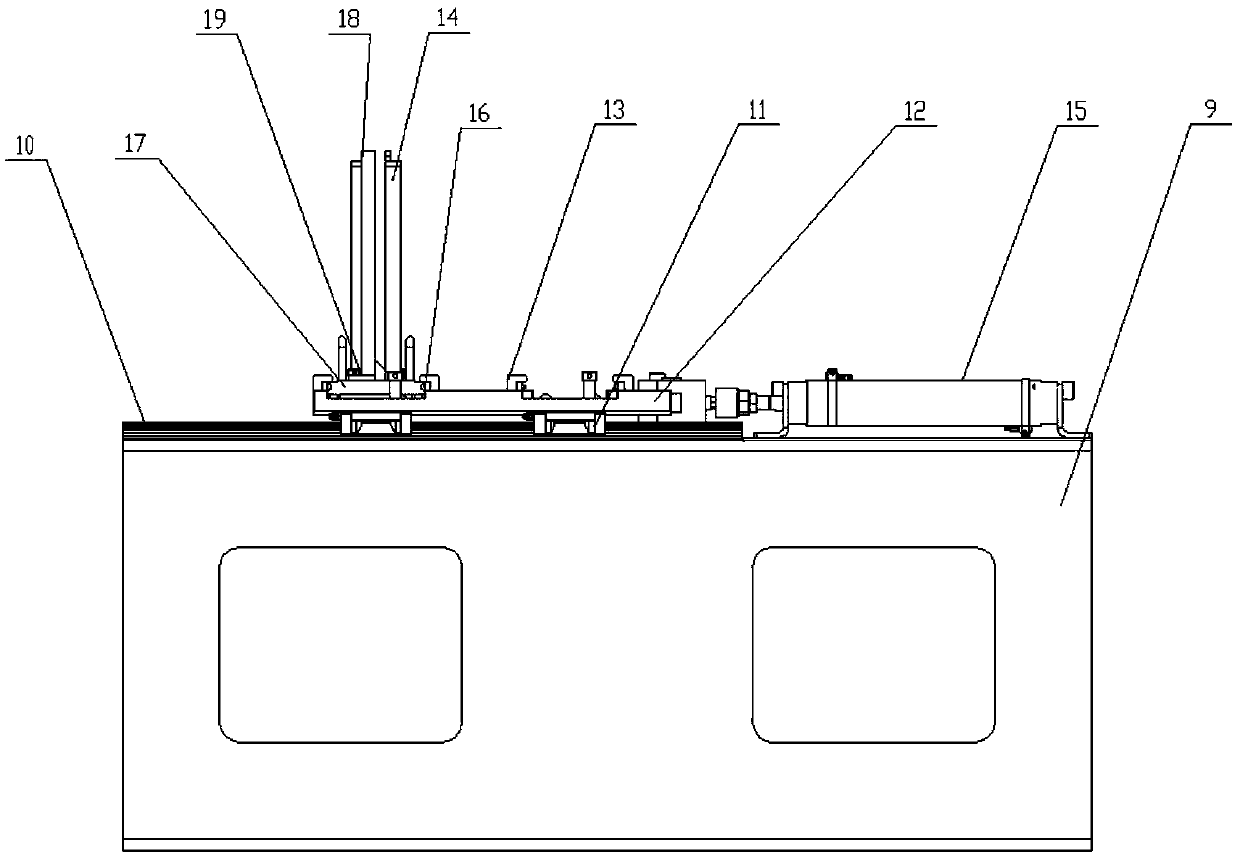

[0048] refer to figure 1 , figure 2 and image 3 , the material 67 is put into the material box 14 in turn, and the two ends of the material 67 are against the material positioning riser 18 respectively. After filling the material box 14, the material box 14 is moved along the guide bar 13 from The feeding table 1 is pushed into the magazine 2, and then the ball plunger 16 on the guide bar 13 blocks the magazine 14, and the positioning of the magazine 14 is completed;

[0049] refer to figure 1 , Figure 4 and Figure 5 , the suction cylinder 30 in the feeding assembly 4 drives the electromagnet connection block 31 to move down until it sucks the material 67 in the material box 14 and lifts the material 67, and then un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com