Riveting mechanism of automobile skylight

A riveting mechanism and a technology for automobile sunroofs are applied in the field of riveting of automobile sunroofs, which can solve the problems of improper use, poor riveting quality and low efficiency, and achieve the effect of improving efficiency and riveting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

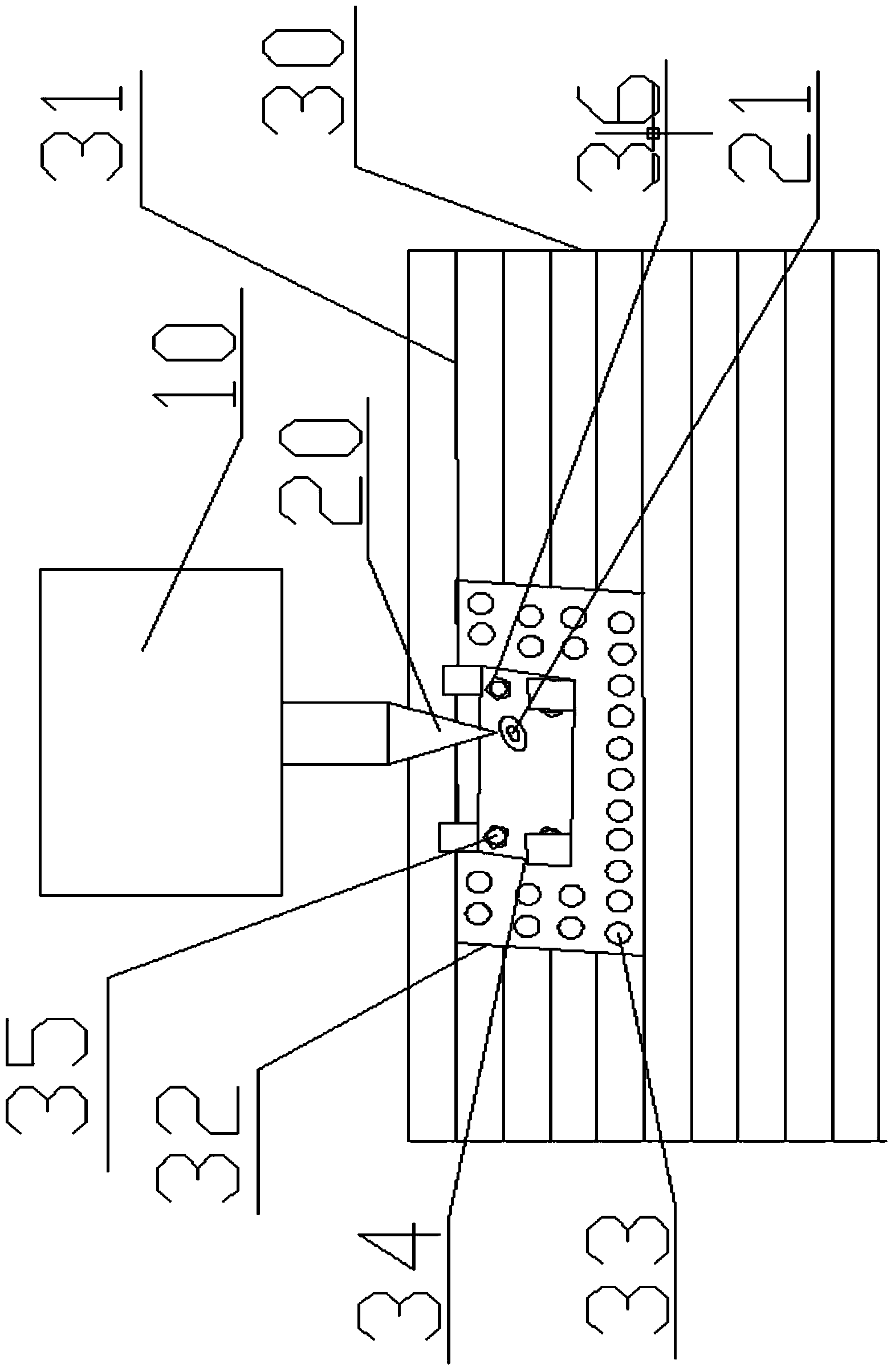

[0013] The invention provides a car sunroof riveting mechanism, such as figure 1 Shown, comprise riveting machine (10), riveting head (20) and riveting machine support (30), it is characterized in that: described riveting machine support (30) is provided with a plurality of slideways (31), slideway The more the number of (31) is, the characteristics of fast displacement and fast riveting can be achieved when adjusting the angle or riveting; the plurality of slideways (31) are provided with sliding seats (32) for cooperating use, and the The sliding seat (32) is provided with a plurality of thread holes (33), and the thread holes (33) can be replaced with different sliding seats (32) according to different production needs. The sliding seat (32) is provided with a U-shaped machine Seat (34), a plurality of screw holes (35) are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com