Vertical hydraulic riveting machine

A technology of riveting machine and hydraulic mechanism, which is applied in the field of vertical hydraulic riveting machines, can solve the problems of uneven riveting quality, difficult to guarantee riveting quality, and unsightly appearance of products, and achieve stable product quality, good riveting quality and good appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

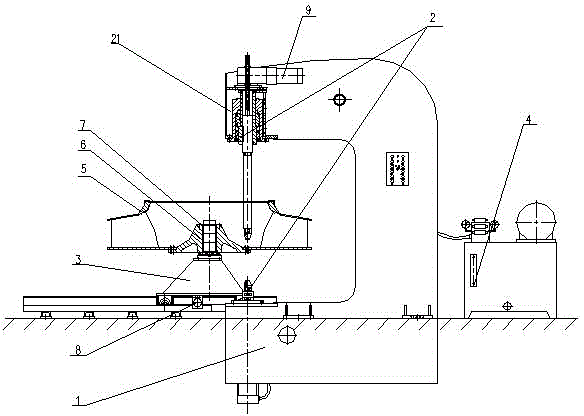

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

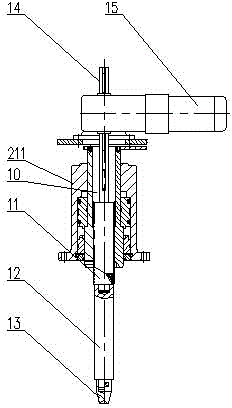

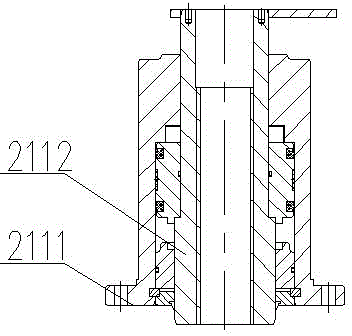

[0018] like figure 1 As shown, the vertical hydraulic riveting machine of the present invention includes a fuselage 1, a riveting hydraulic mechanism 2, a carrying trolley 3 and a hydraulic pump station 4. The riveting hydraulic mechanism 2 includes an upper riveting hydraulic mechanism 21 and a lower riveting hydraulic mechanism 22, and the hydraulic pump station 4 is respectively connected to the upper riveting hydraulic mechanism 21 and the lower riveting hydraulic mechanism 22 through hydraulic pipelines, and is an upper riveting hydraulic mechanism. Mechanism 21 and lower riveting hydraulic mechanism 22 provide hydraulic power.

[0019] The fuselage 1 is configured as a bow-shaped fuselage as required, and the upper riveting hydraulic mechanism 21 and the lower riveting hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com