Electromagnetic riveting press suitable for large-diameter rivets and press riveting method thereof

A riveting machine and large-diameter technology, applied in the field of riveting, can solve the problems of high operating level requirements for operators, difficulty in strictly controlling the amount of interference, and damage to composite material installation, so as to improve the stability of riveting quality, improve riveting ability and process Flexibility, the effect of avoiding installation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

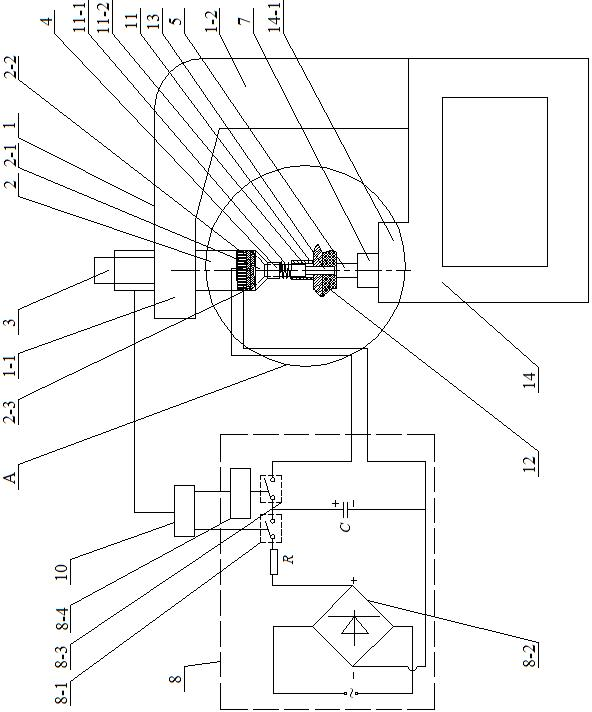

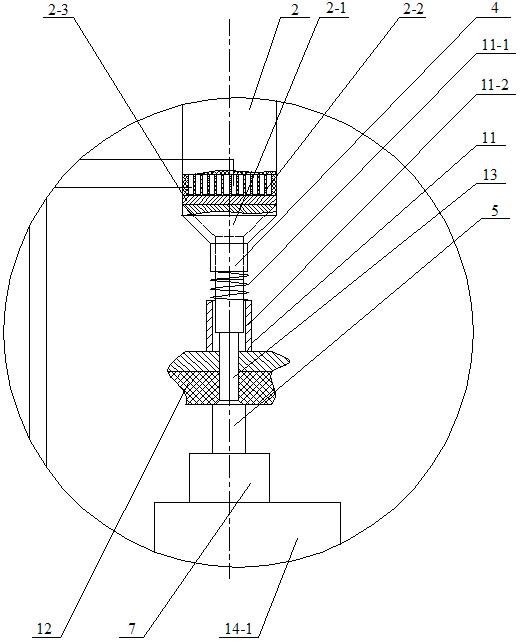

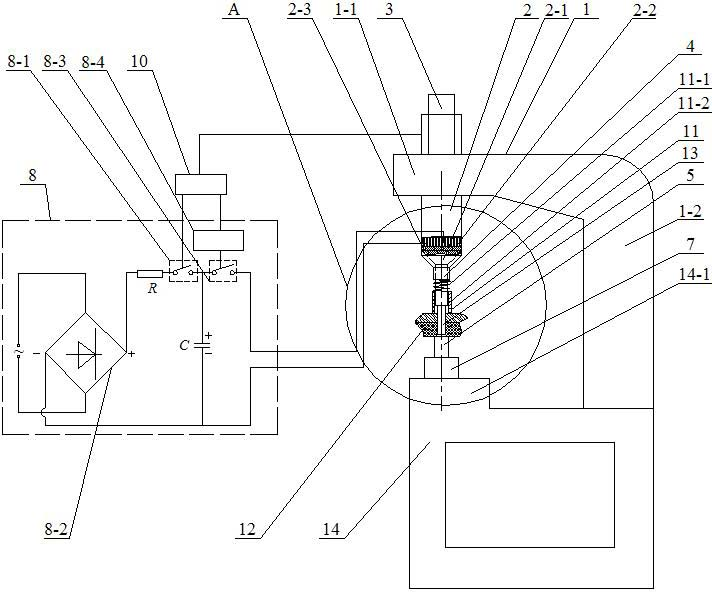

[0013] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, an electromagnetic riveting machine suitable for large-diameter rivets in this embodiment consists of a bent upper arm 1, an electromagnetic riveting gun 2, a power source 3 for riveting gun stroke control, an upper riveting die 4, and a lower riveting die 5 , workbench 7, low-voltage electromagnetic riveting device 8, control box 10, spring compactor 11 and base 14; An integrated horizontal arm 1-1 and a vertical arm 1-2 are formed. The lower end of the vertical arm 1-2 is fixedly connected to the upper end surface of the base 14, and the upper end surface of the base 14 is provided with a raised platform 14-1. 7 is fixed on the protruding platform 14-1, the upper riveting die 4 and the lower riveting die 5 are set coaxially from top to bottom, and the lower riveting die 5 is set on the workbench 7, and the die sleeve 11-2 is set on the upper riveting die On the mold 4 and the ...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1Describe this embodiment, the low-voltage electromagnetic riveting device 8 of this embodiment consists of an electromagnetic riveting charging switch 8-1, a capacitor bank C, a current limiting resistor R, a rectifier 8-2, a high-frequency thyristor discharge switch 8-3 and a high-voltage pulse generator 8-4; the two ends of the power supply are respectively connected to the two AC voltage input terminals of the rectifier 8-2, the positive output terminal of the DC voltage of the rectifier 8-2 is connected to one end of the current limiting resistor R, and the other end of the current limiting resistor R It is connected with one end of the electromagnetic riveting charging switch 8-1, and the other end of the electromagnetic riveting charging switch 8-1 is respectively connected with one end of the high-frequency thyristor discharge switch 8-3 and the positive end of the capacitor bank C, and the high-frequency thyri...

specific Embodiment approach 3

[0016] Specific embodiment three, combine figure 1 Describe this embodiment mode, a kind of pressure riveting method suitable for large-diameter rivets in this embodiment mode is realized by the following steps: 1. Select the upper riveting die 4 and the lower riveting die 5 according to the structural form of the structural assembly 12 to be riveted, and select the rivet 13 Large-diameter titanium alloy rivets or large-diameter aluminum alloy rivets, the head of the rivet 13 is in the shape of a countersunk or semi-round head, the diameter of the large-diameter titanium alloy rivet is Ф2-Ф6mm, and the diameter of the large-diameter aluminum alloy rivet is Ф4-Ф10mm; 1. The upper end surface of the upper riveting die 4 is attached to or integrated with the lower end face of the stress wave modulator 2-1 of the electromagnetic riveting gun 2, and the lower riveting die 5 is placed on the workbench 7; Three, connect the electromagnetic pressure The riveting gun stroke of the rive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com