Automatic frame riveting machine

The technology of riveting machine and frame is applied in the field of automatic frame riveting machine and riveting device for solenoid valve assembly and application. Good, suitable for large-scale mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

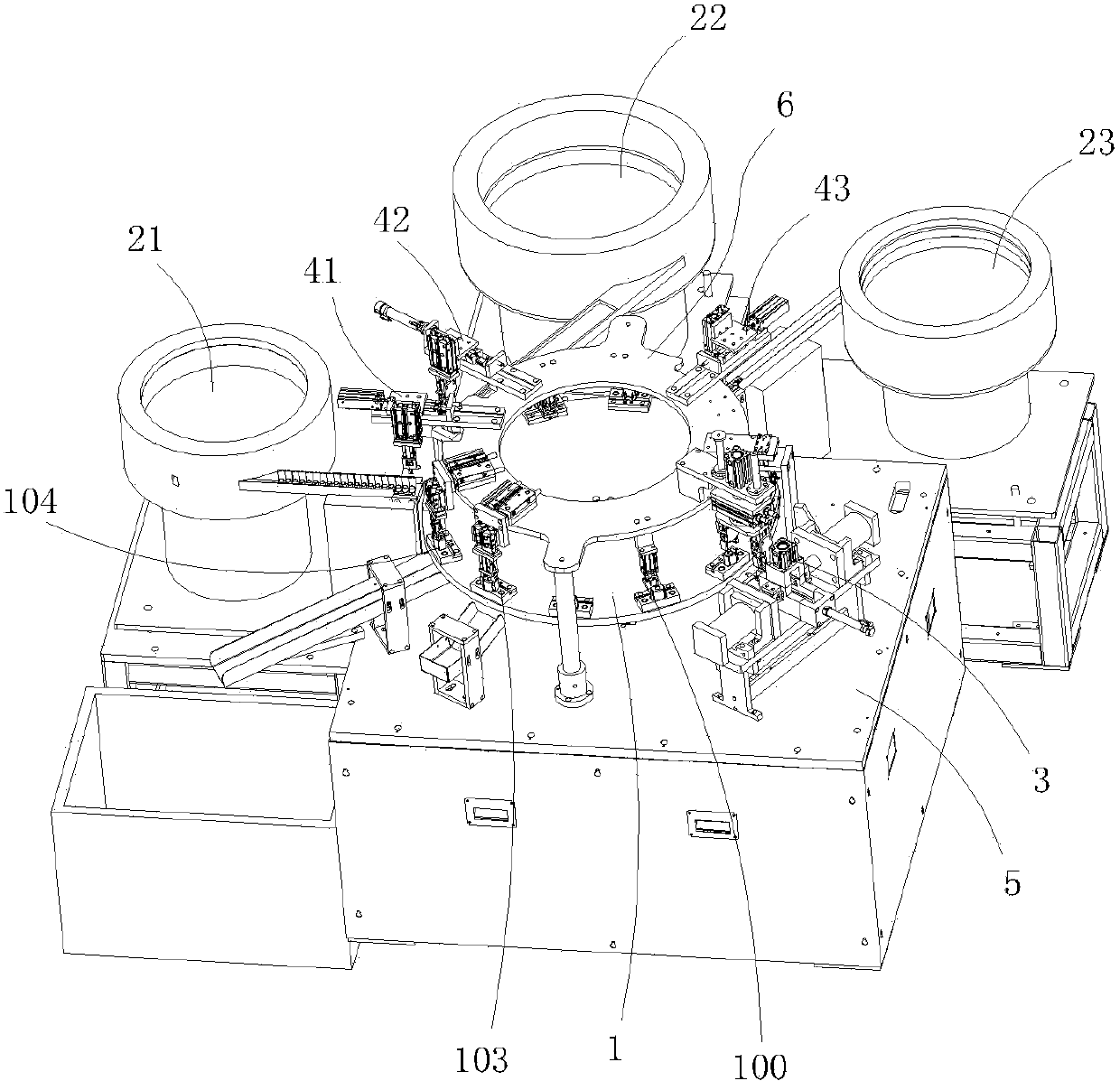

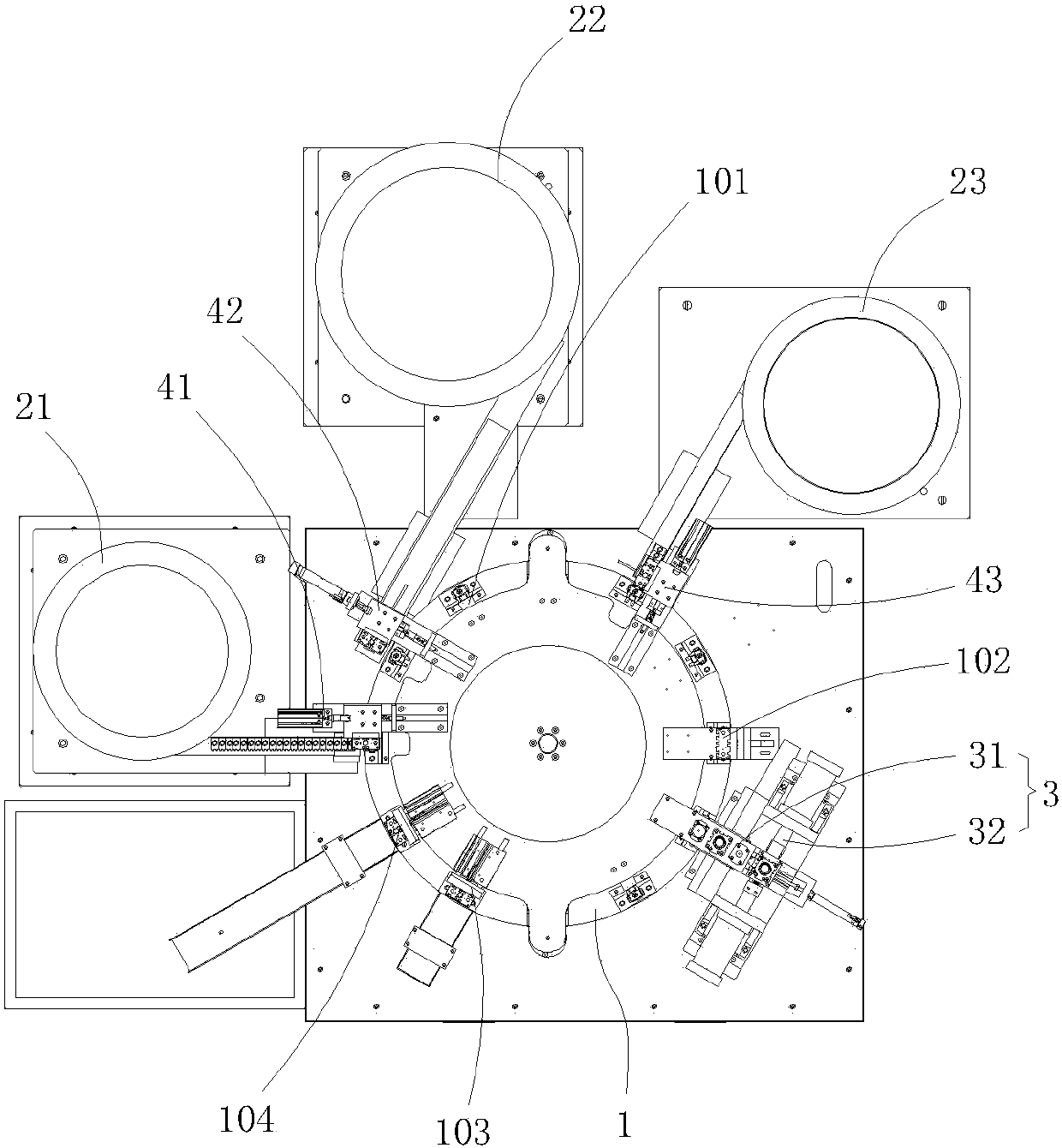

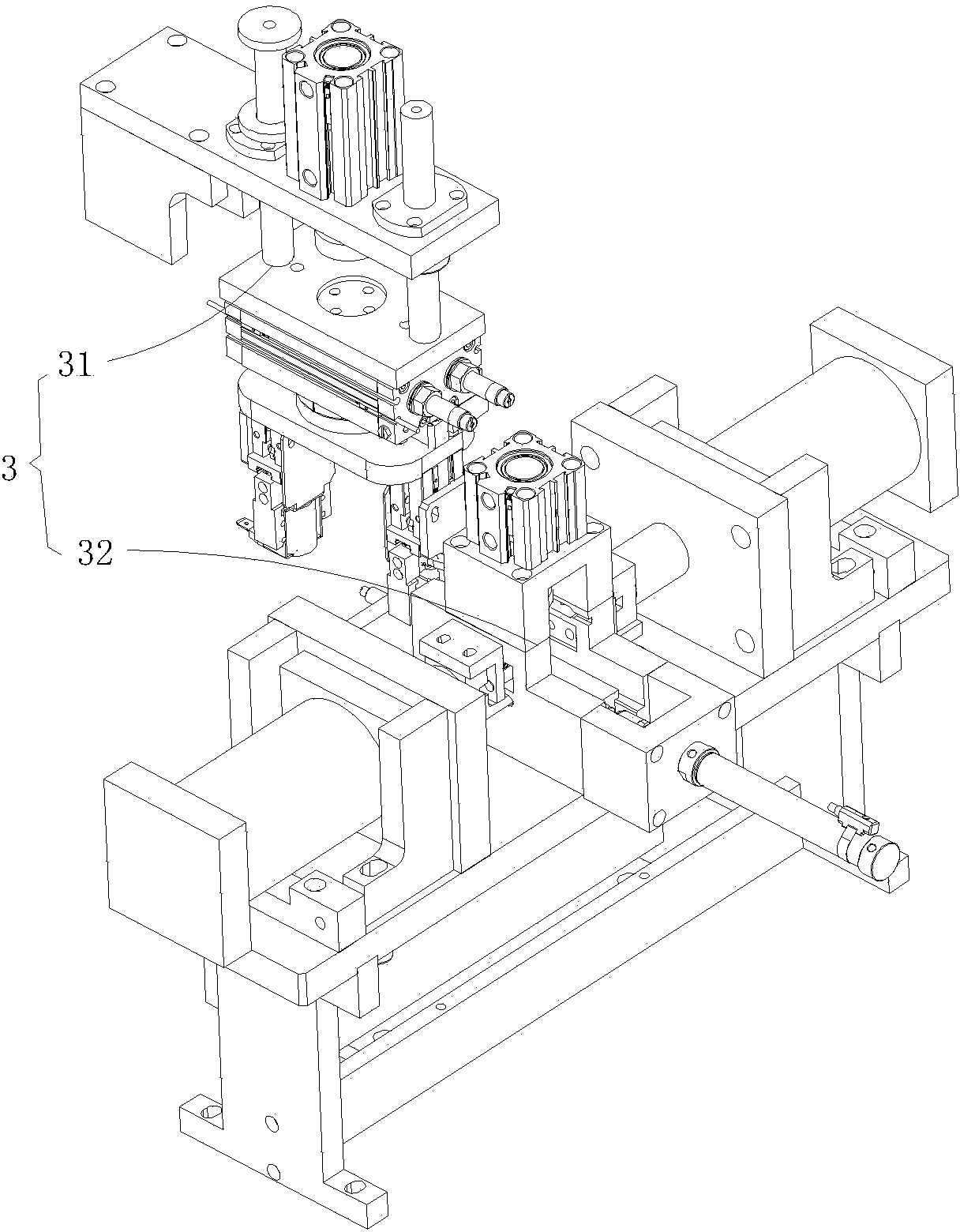

[0032] Example: see Figure 1 to Figure 13 , an automatic riveting machine for frames, comprising a rotary table 1, a lower frame feeder 21, a coil feeder 22, an upper frame feeder 23 and a transposition riveting device 3, the outer circumference of the rotary table 1 is at least provided with The lower frame station, coil station, upper frame station and riveting station, each station corresponds to the lower frame feeder, coil feeder, upper frame feeder and transposition riveting device installed around the rotary table, each A workpiece fixing device 100 is installed at a station, and each workpiece fixing device and the rotary table rotate simultaneously to perform the assembly and riveting operation of the solenoid valve A, above the lower frame station, the coil station and the upper frame station of the rotary table Clamping devices (respectively lower frame clamping device 41, coil clamping device 42, and upper frame clamping device 43) are provided to transfer the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com