Intelligent flexible production line with double robot cooperative automatic assembling and operation method for same

A flexible production line and dual-robot technology, applied in the field of mechanical processing, can solve problems that affect work efficiency and cannot guarantee the high requirements of product processing quality in the aviation field, achieve high processing accuracy, ensure operational flexibility and riveting rate, and suppress burrs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

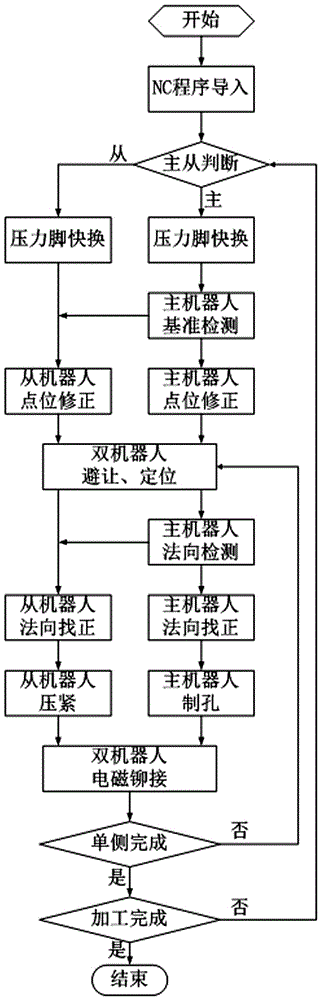

[0050] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0051] An intelligent flexible production line for dual-robot collaborative automatic assembly, which is equipped with industrial computer, laser tracker, flexible tooling, knife-testing station, dual industrial robots working in cooperation, and two parallel (parallel) tracks. The dual industrial robot includes a first robot and a second robot, the first robot is installed on one track through the first mobile platform, and the second robot is installed on the other track through the second mobile platform.

[0052] The dual industrial robots are equipped with end effectors respectively, and both end effectors are equipped with drilling stations. The pressure feet installed on the end effector drilling stations include the main pressure feet that press the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com