Patents

Literature

572results about How to "Wide range of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

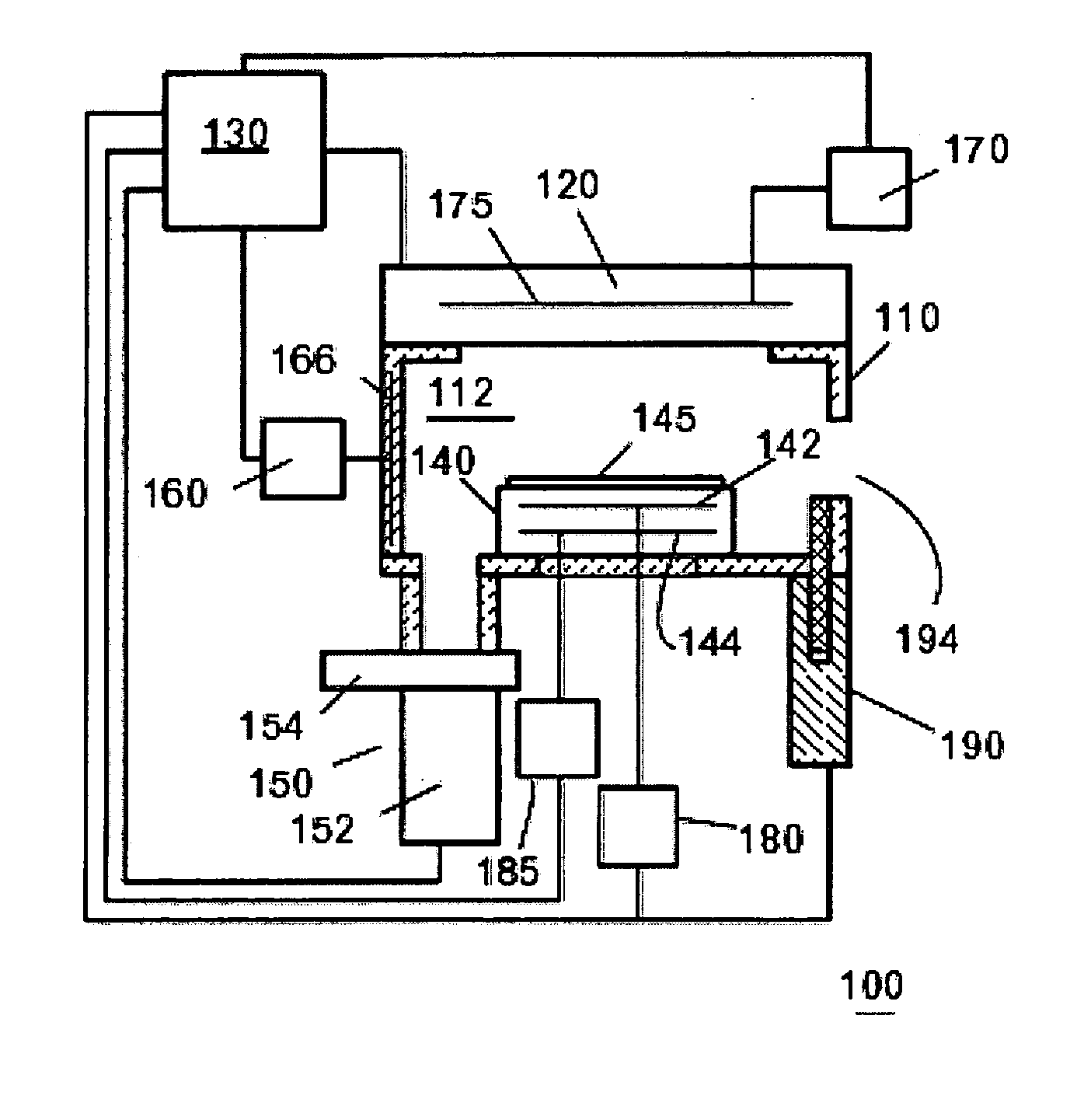

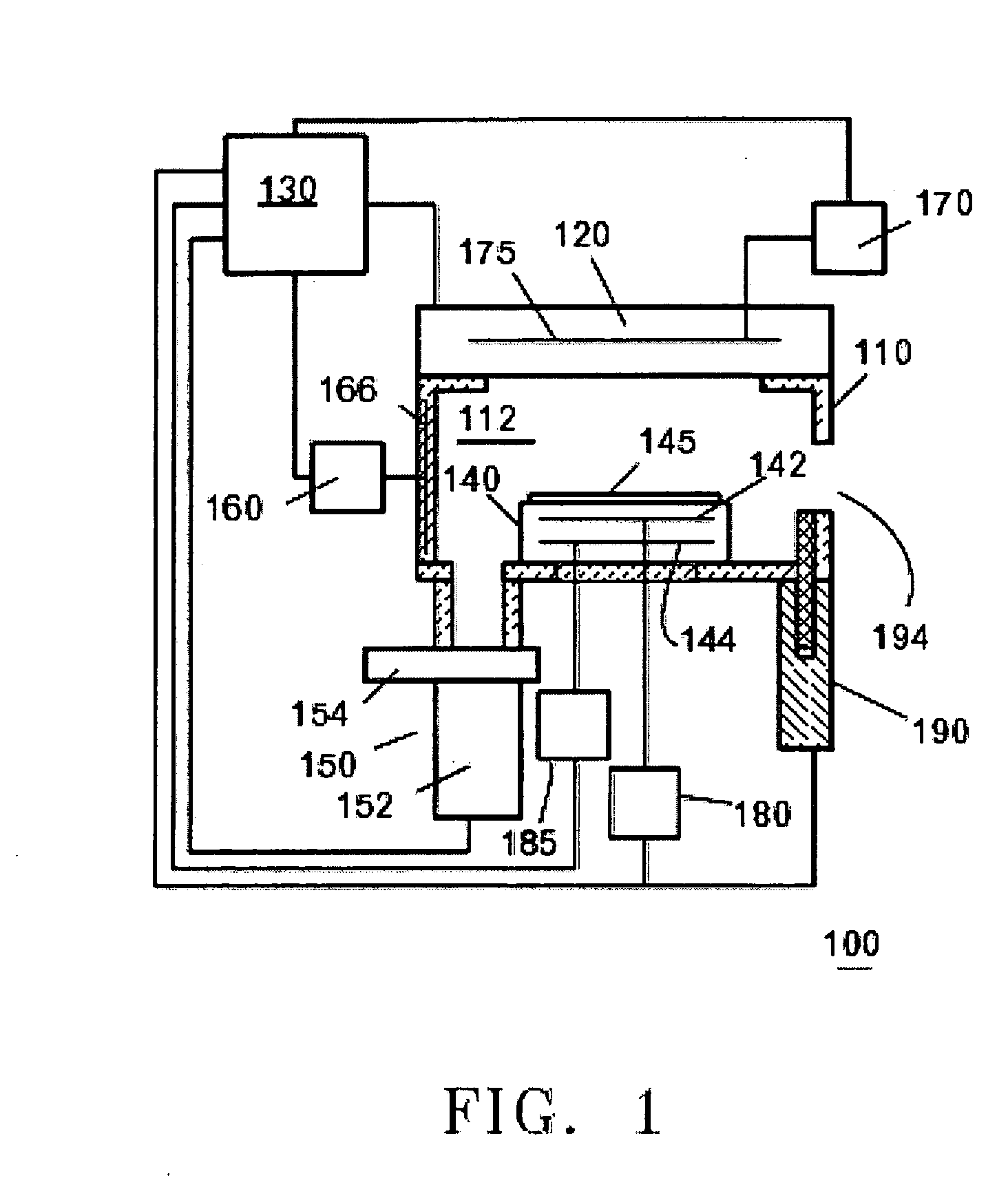

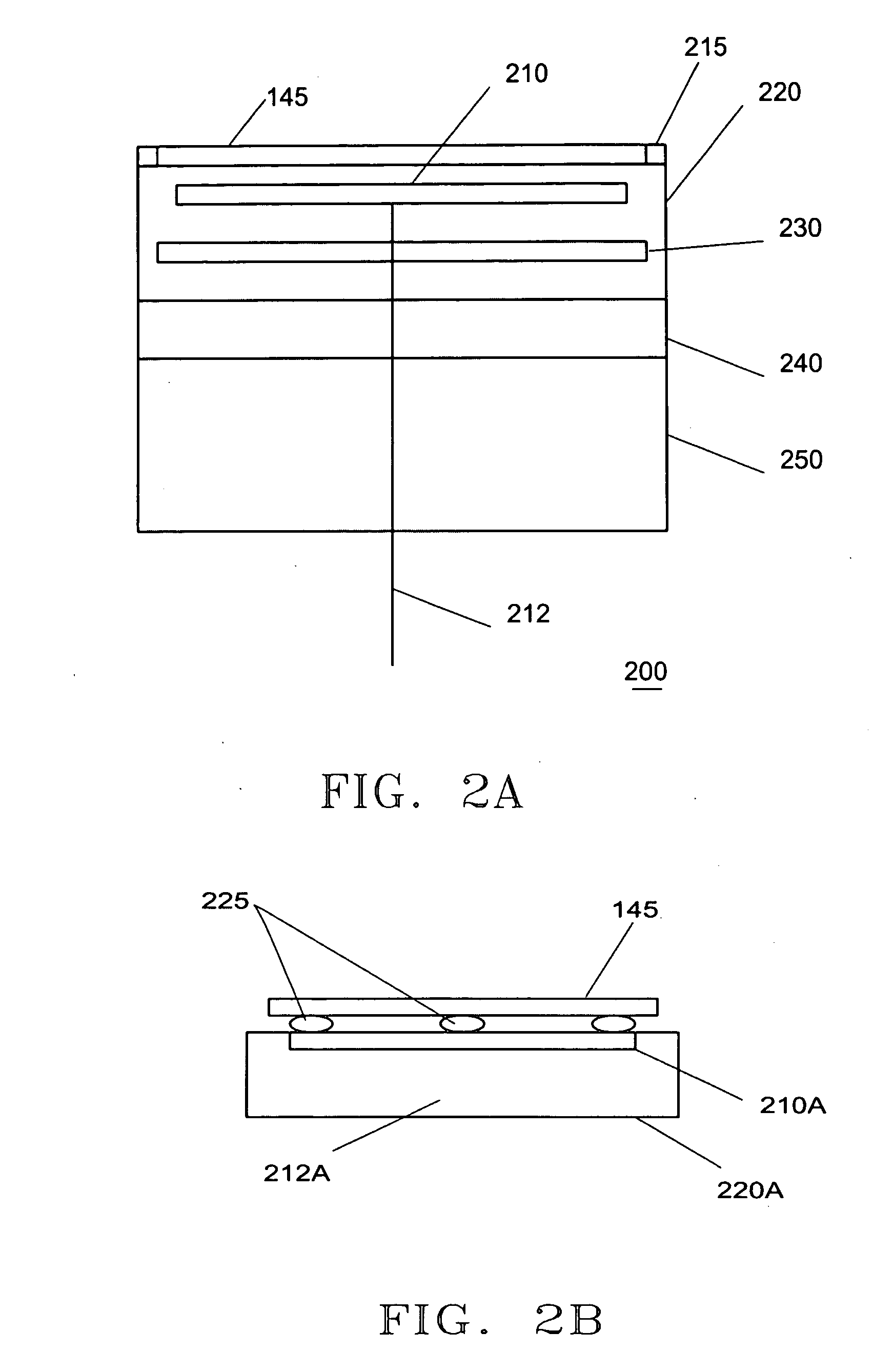

Wafer heater assembly

InactiveUS20050217799A1Uniform heating characteristicFast response timeElectric discharge tubesSemiconductor/solid-state device manufacturingSingle crystalQuartz

Owner:TOKYO ELECTRON LTD

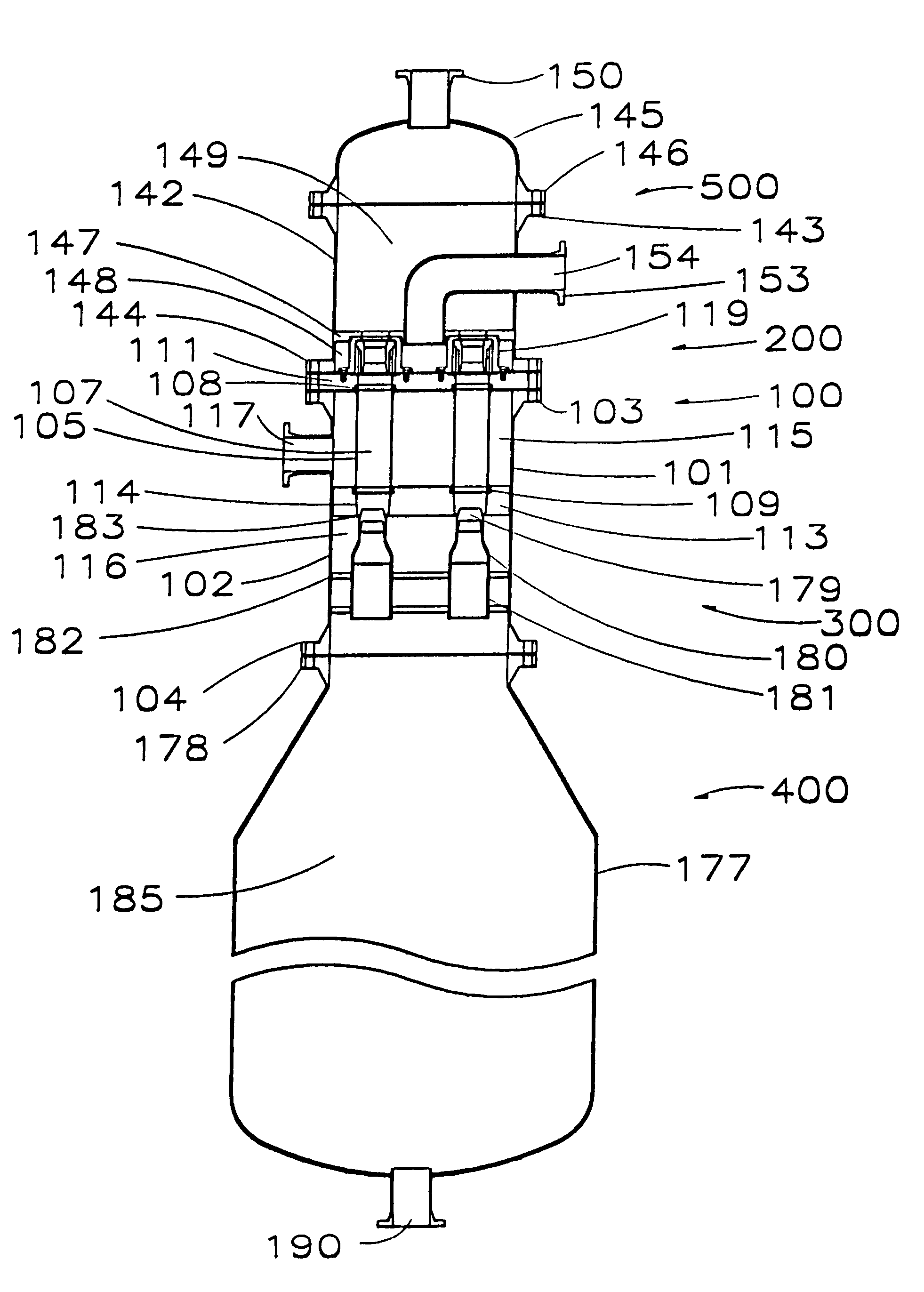

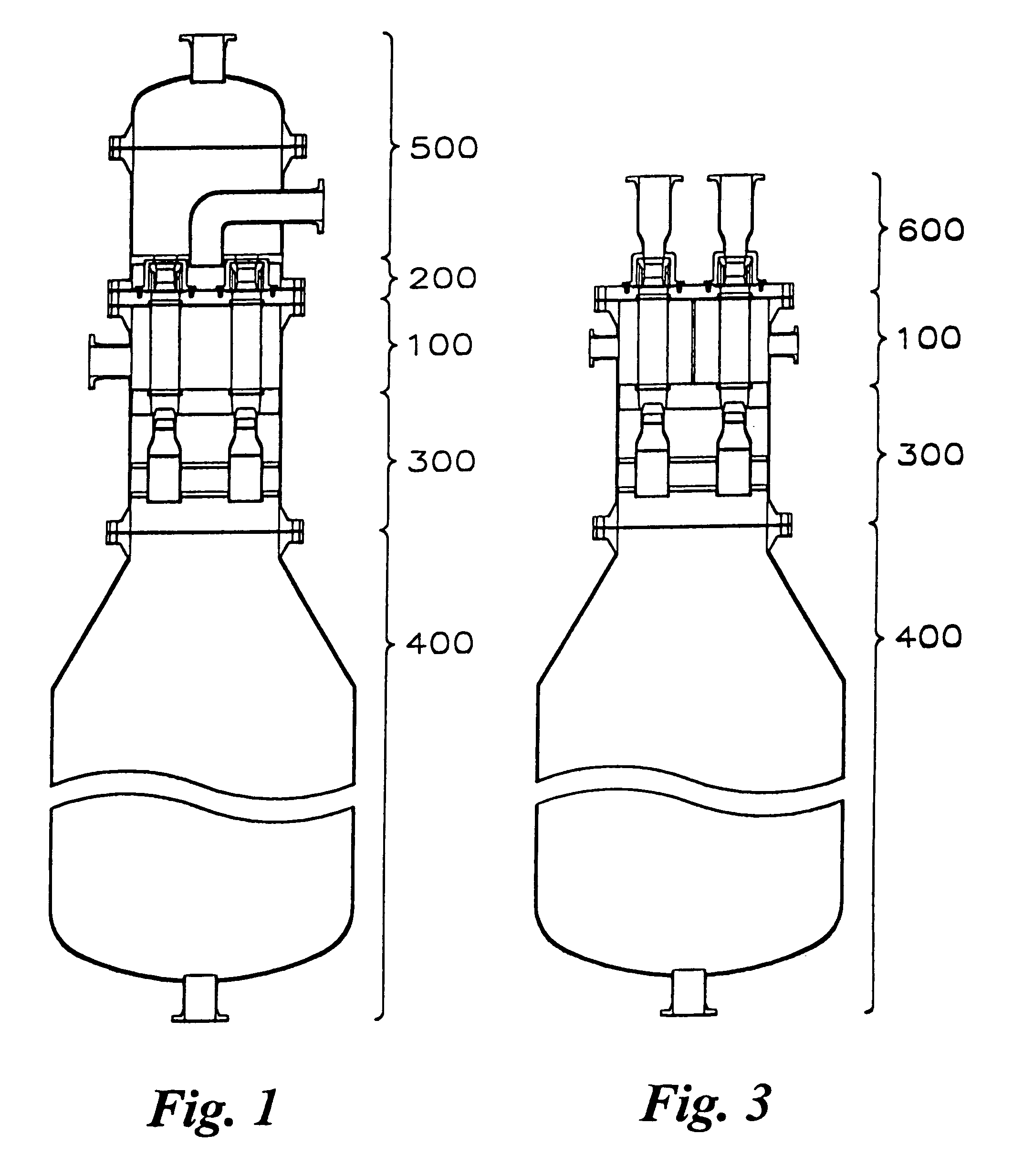

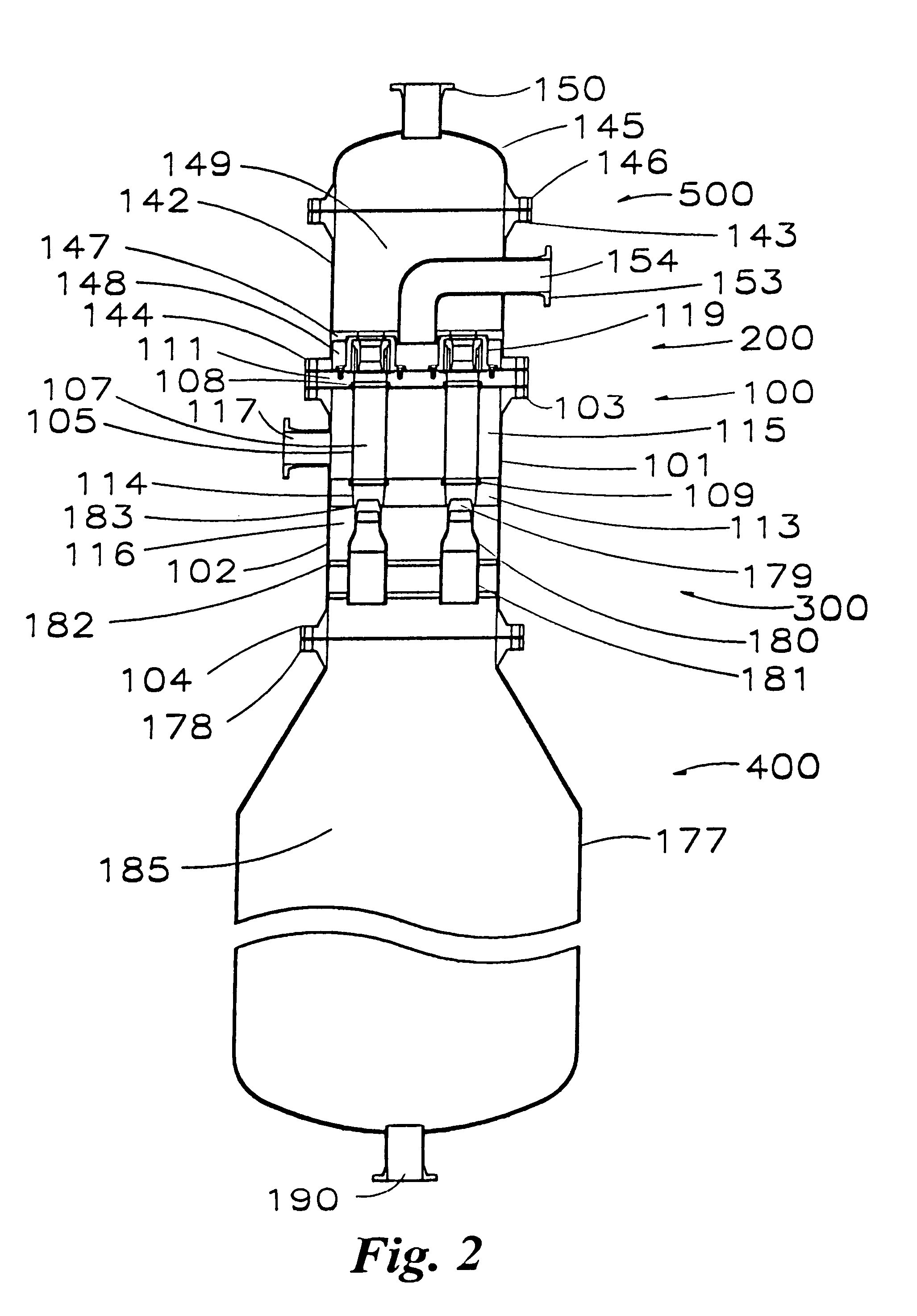

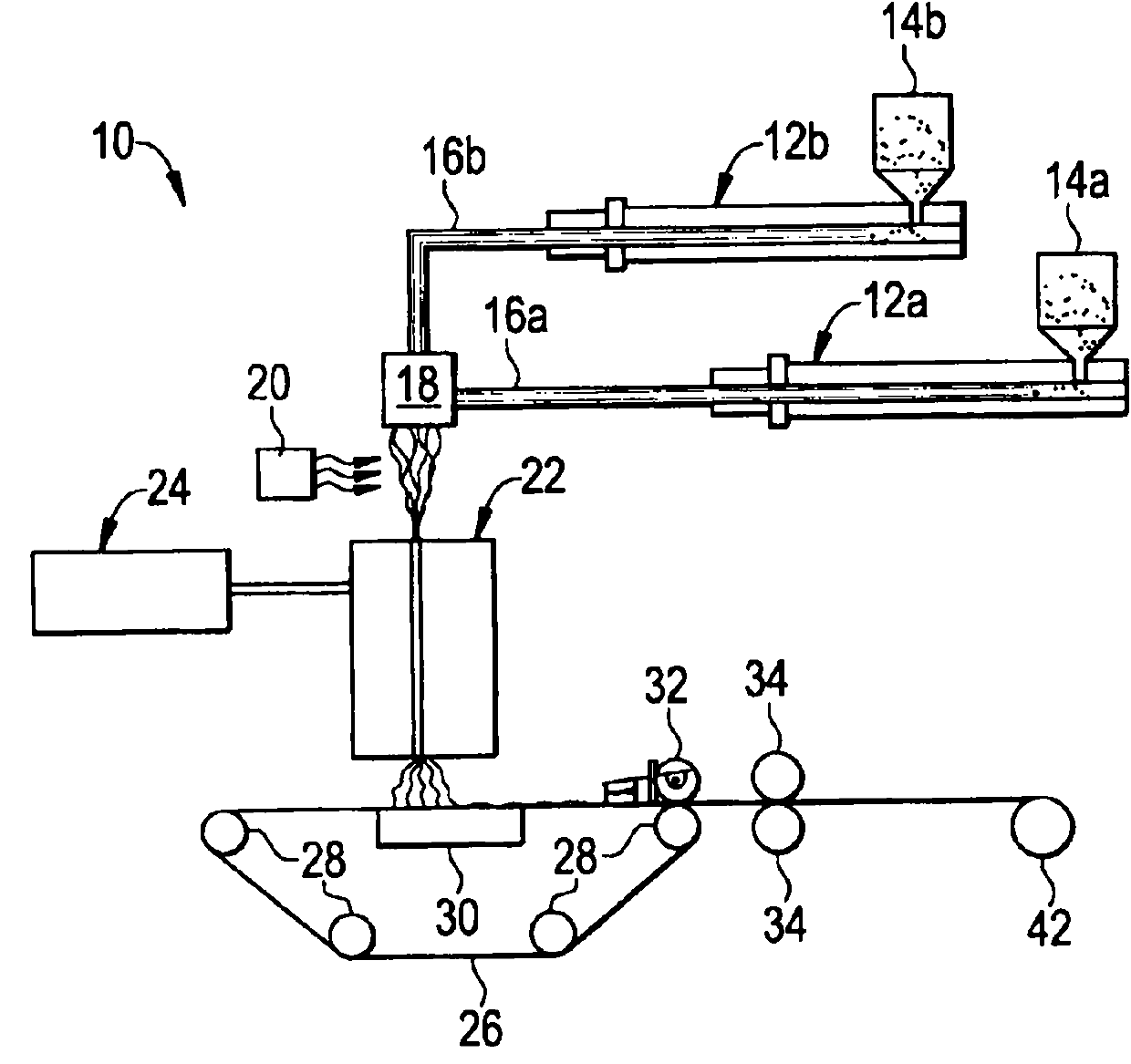

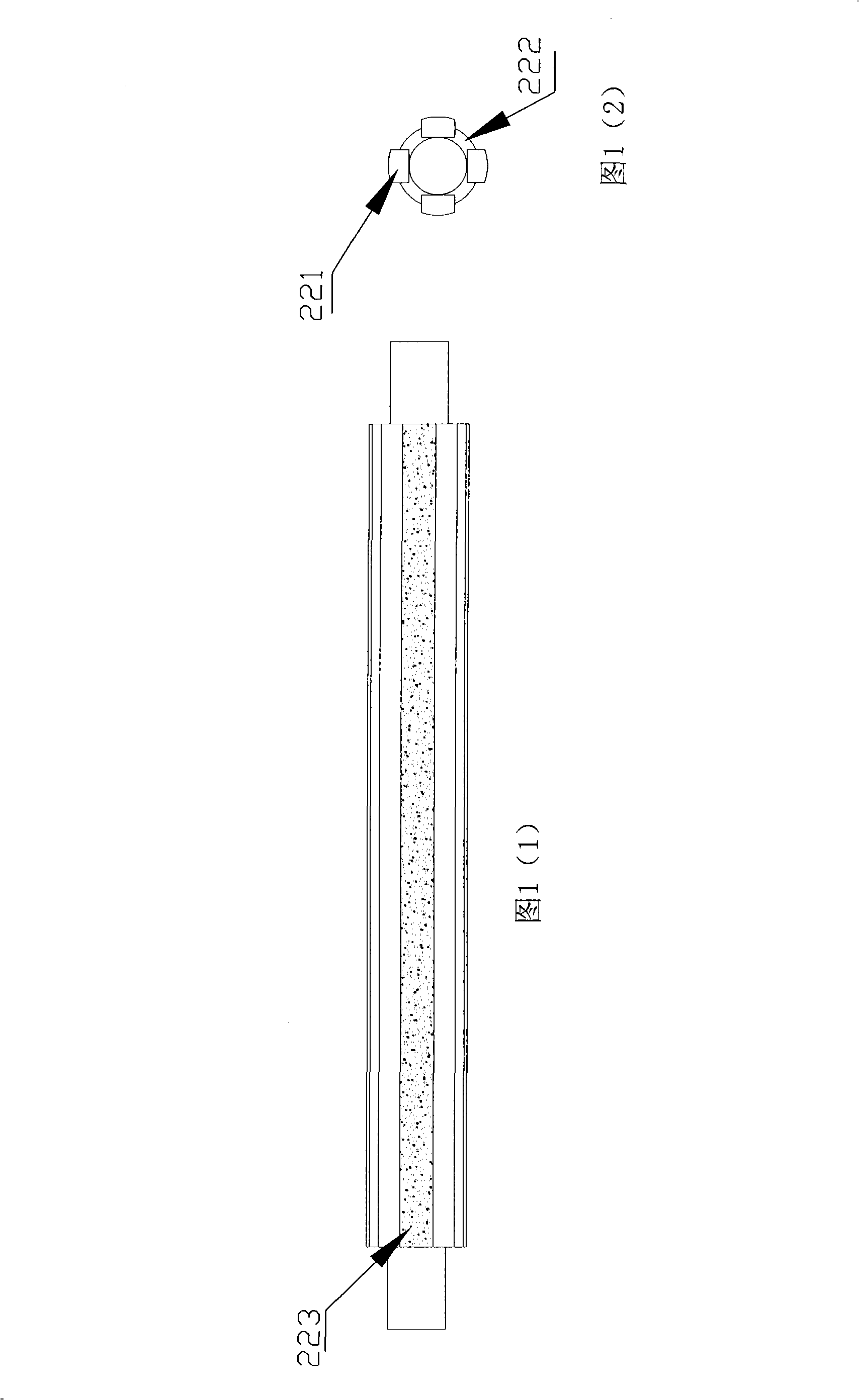

Method for contacting large volumes of gas and liquid across microscopic interfaces

InactiveUS6918949B1Improve efficiencyReduced spatial separationCarburetting airLiquid degasificationPorous mediumTransfer procedure

A method for contacting large volumes of gas and liquid together on a microscopic scale for mass transfer or transport processes wherein the contact between liquid and gas occurs at the interfaces of a multitude of gas bubbles. Multiple porous tubes assembled in a bundle inside a pressure vessel terminate at each end in a tube sheet. A thin film helical liquid flow is introduced into the inside of each porous tube around and along its inside wall. Gas is sparged into the porous media and the liquid film so that an annular two phase flow with a uniform distribution of tiny gas bubbles results. The gas flow is segregated from the liquid flow without first passing through the porous media and through the liquid film. Nozzles at the lower end of the tubes divert liquid flow to a vessel and redirect the gas flow in a countercurrent direction.

Owner:JAECO TECH

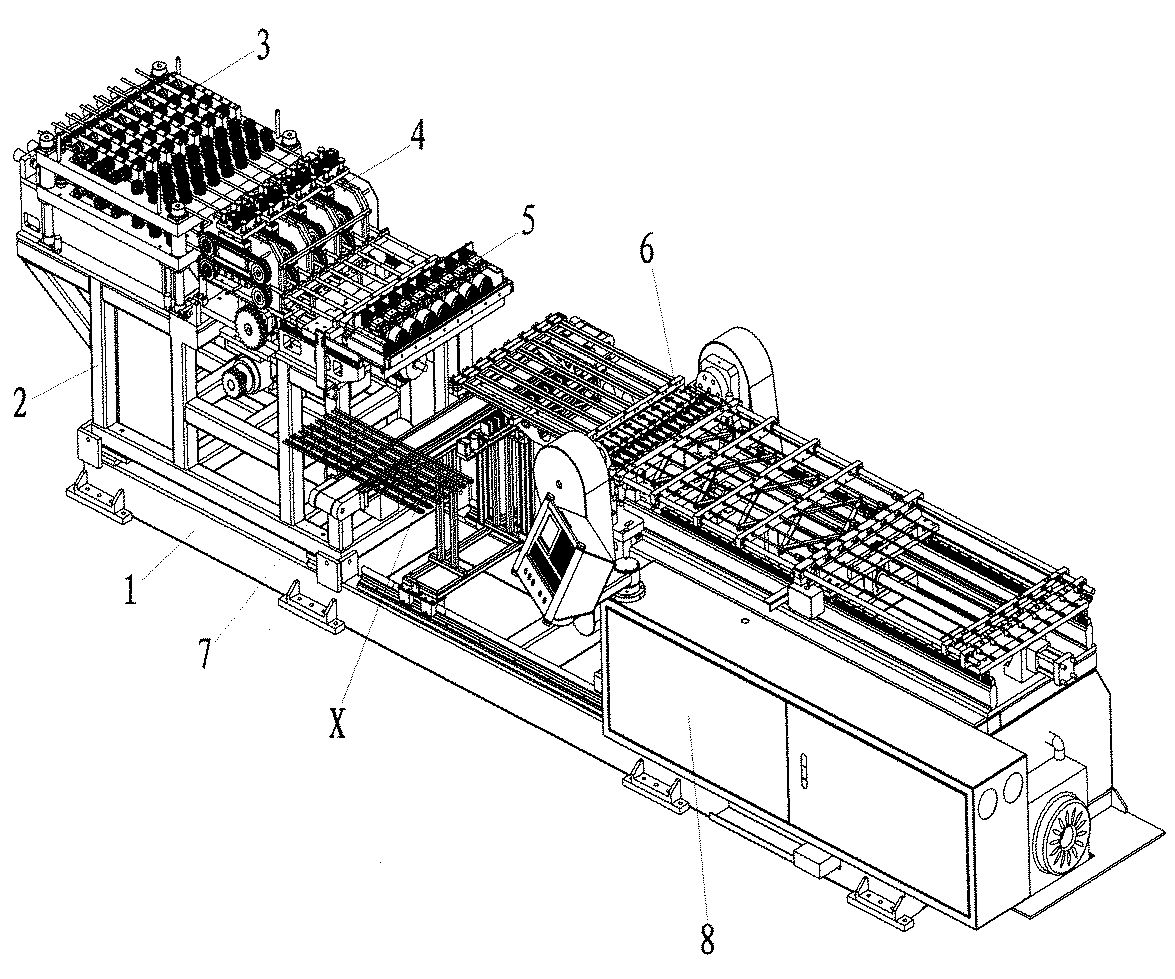

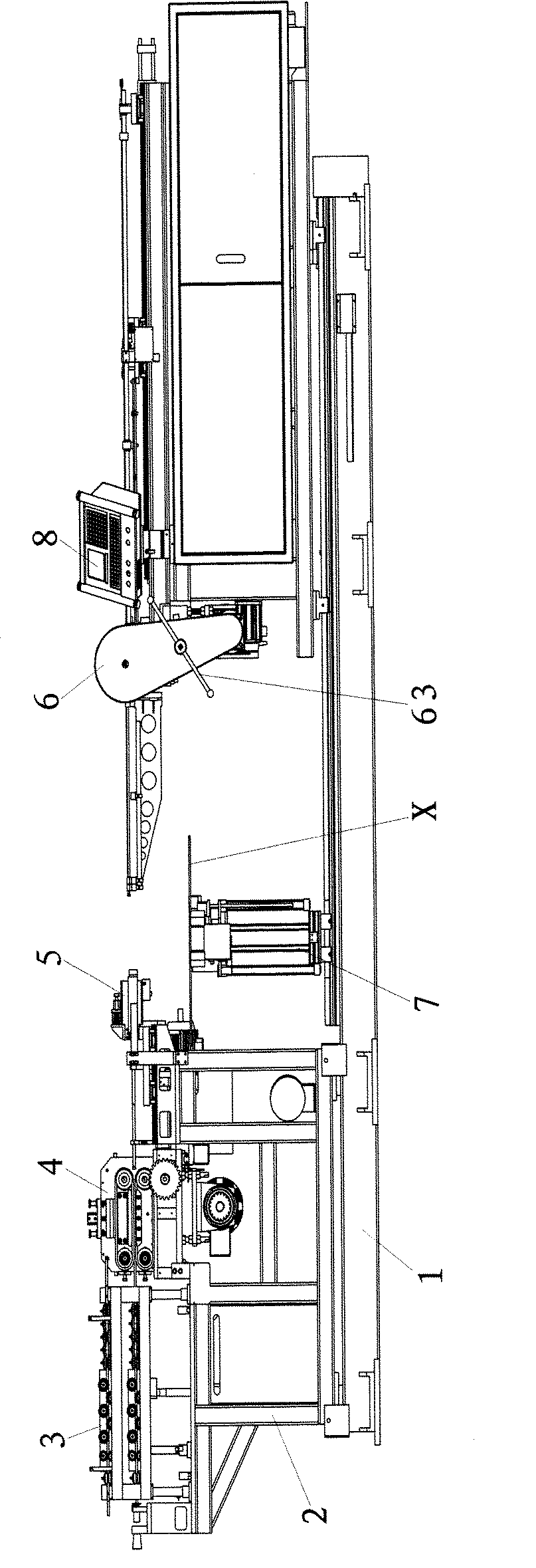

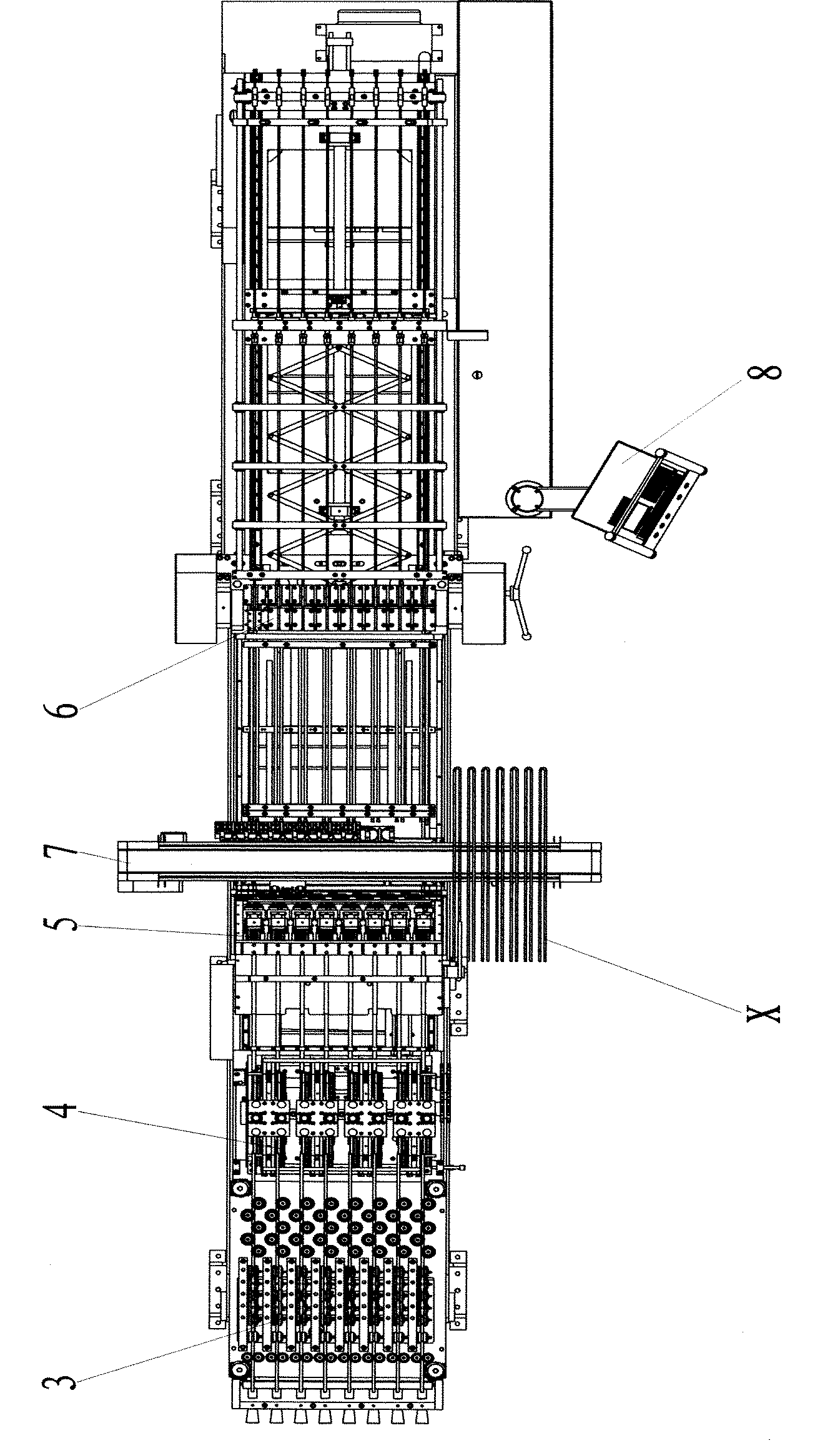

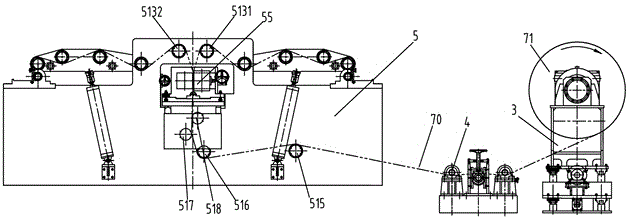

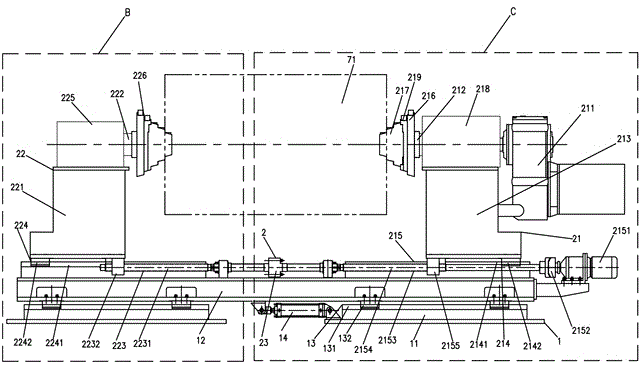

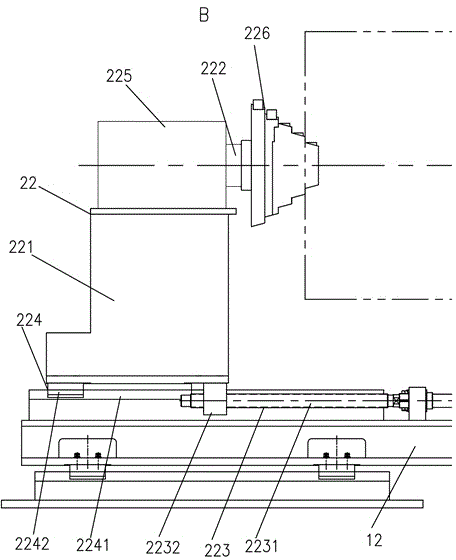

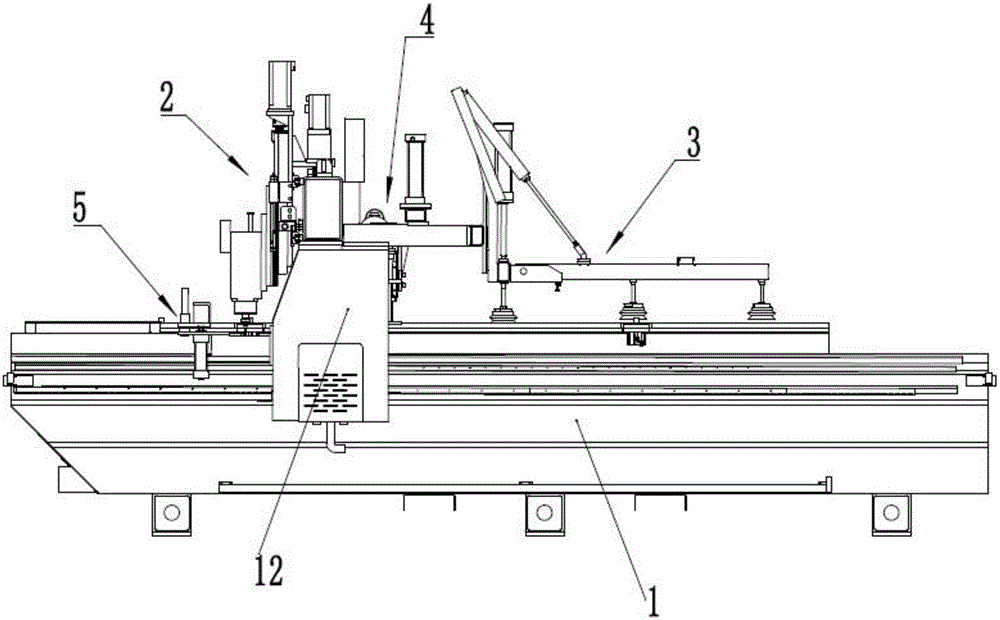

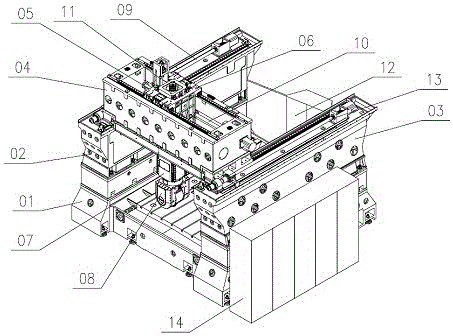

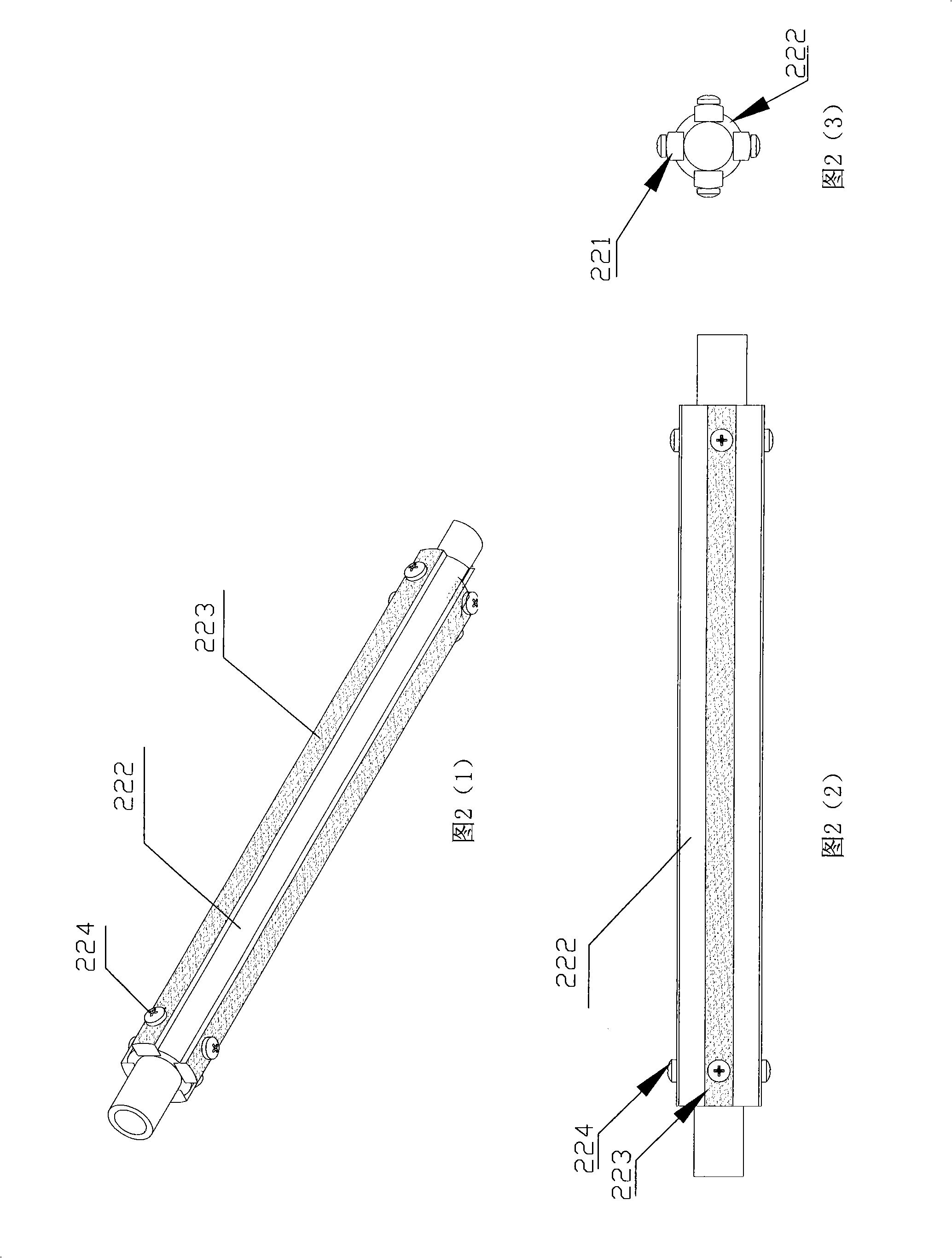

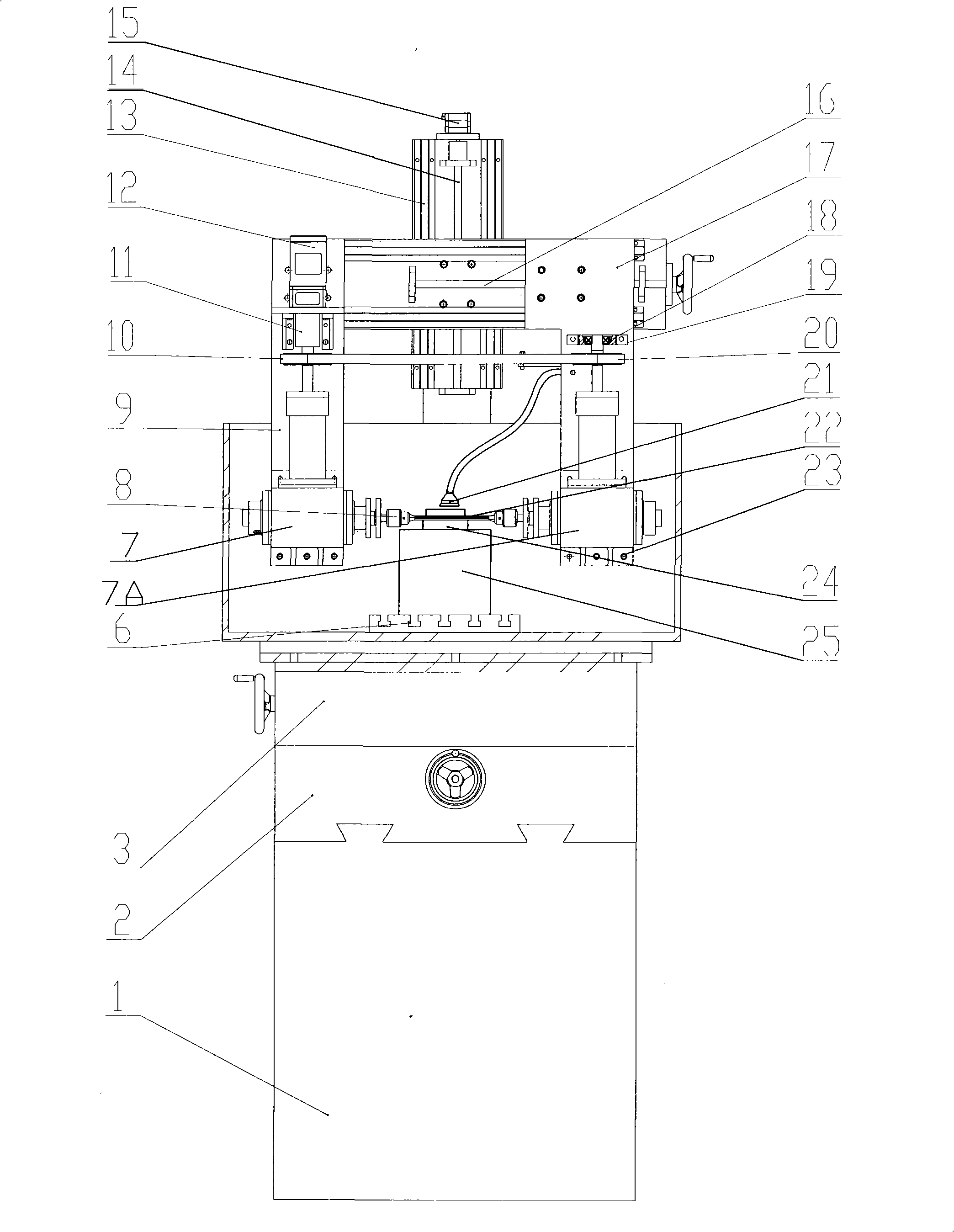

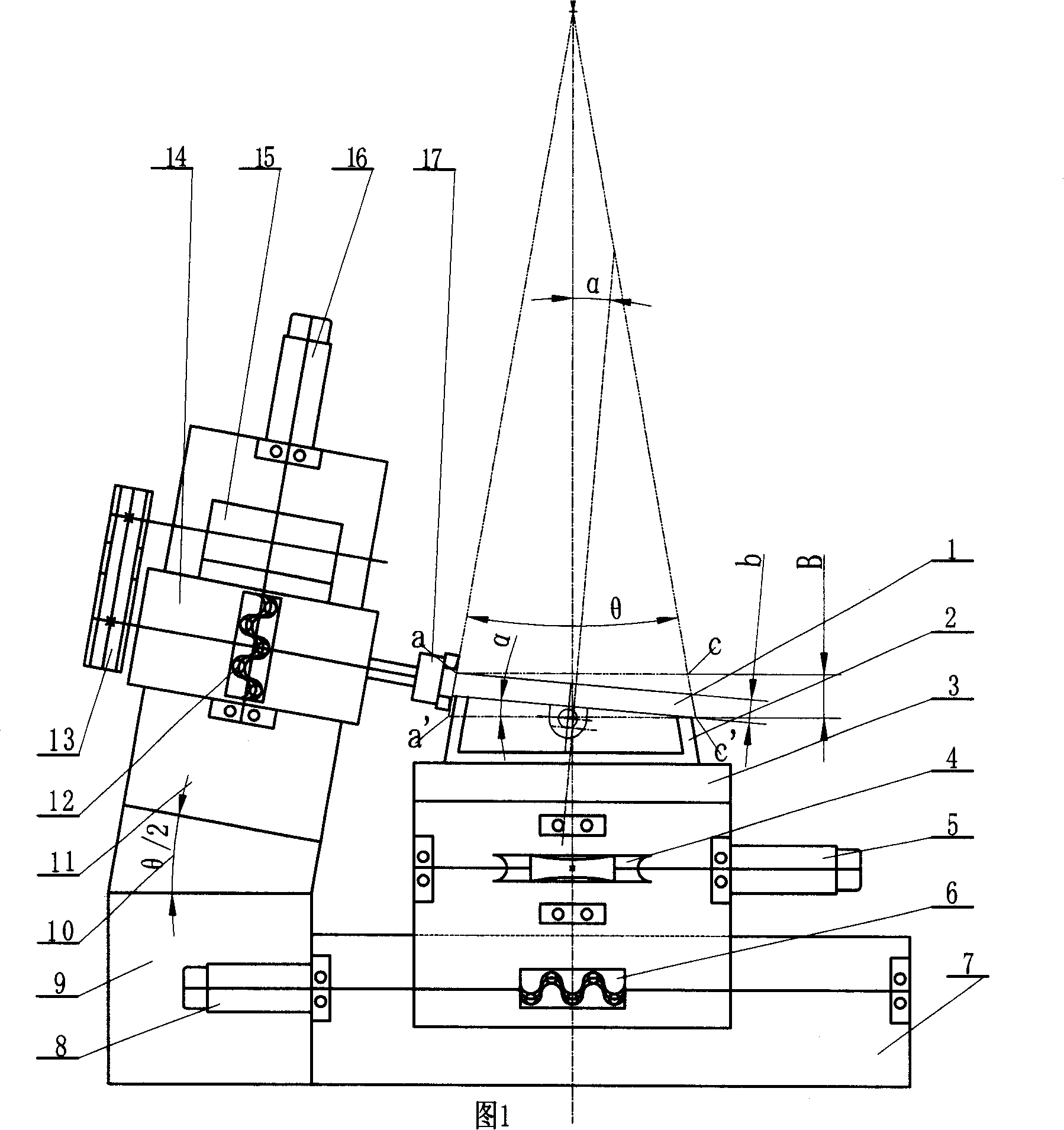

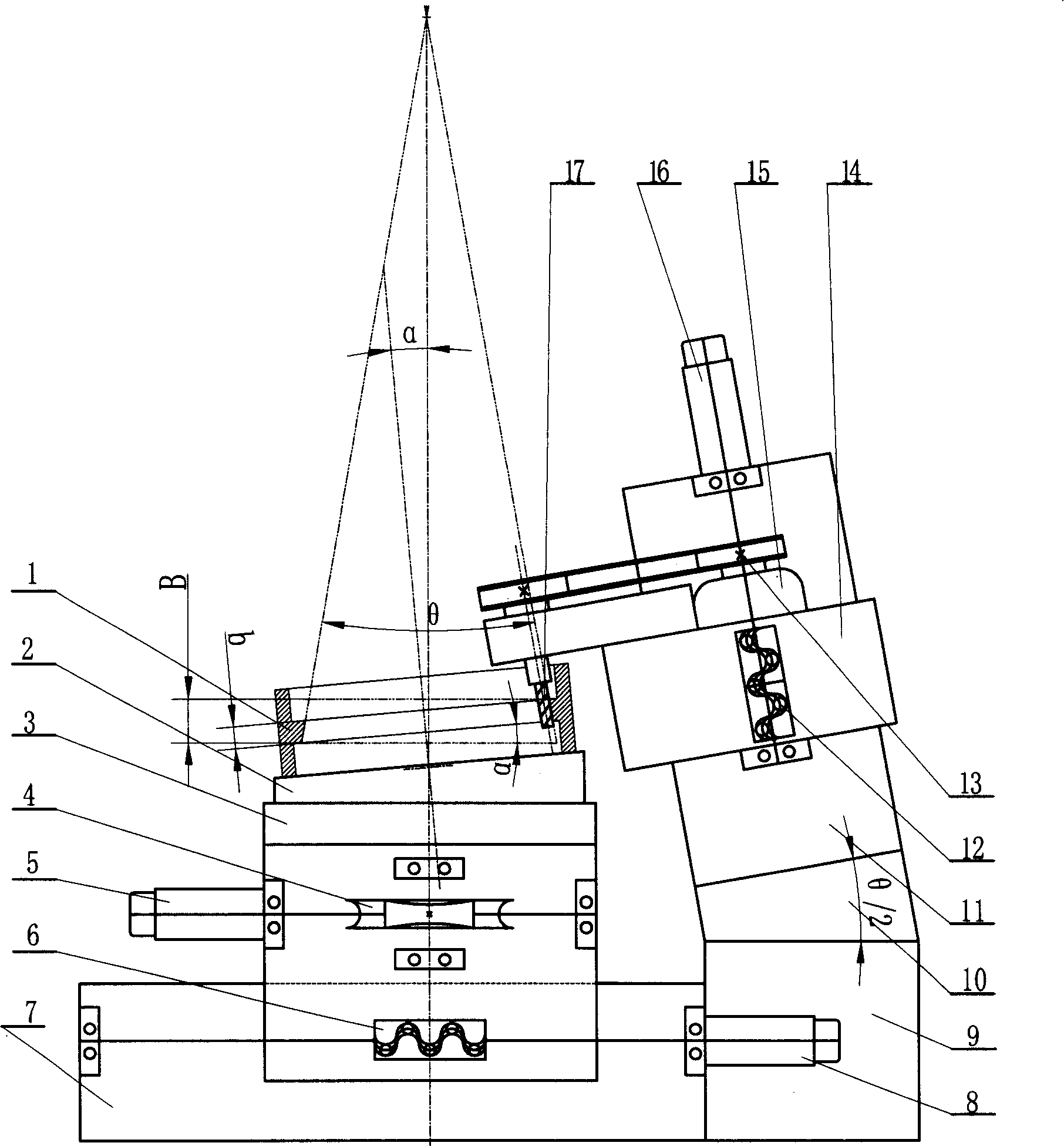

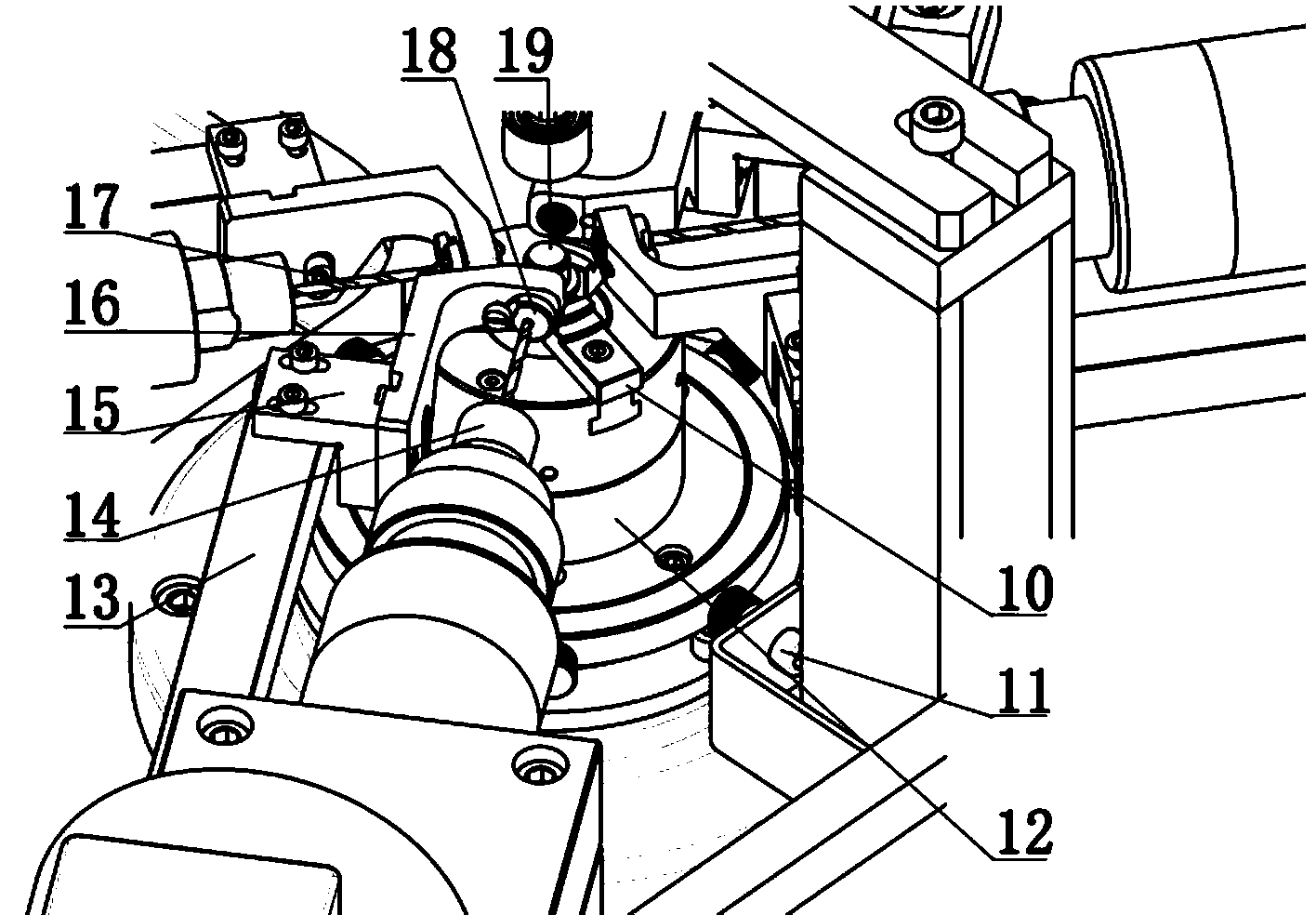

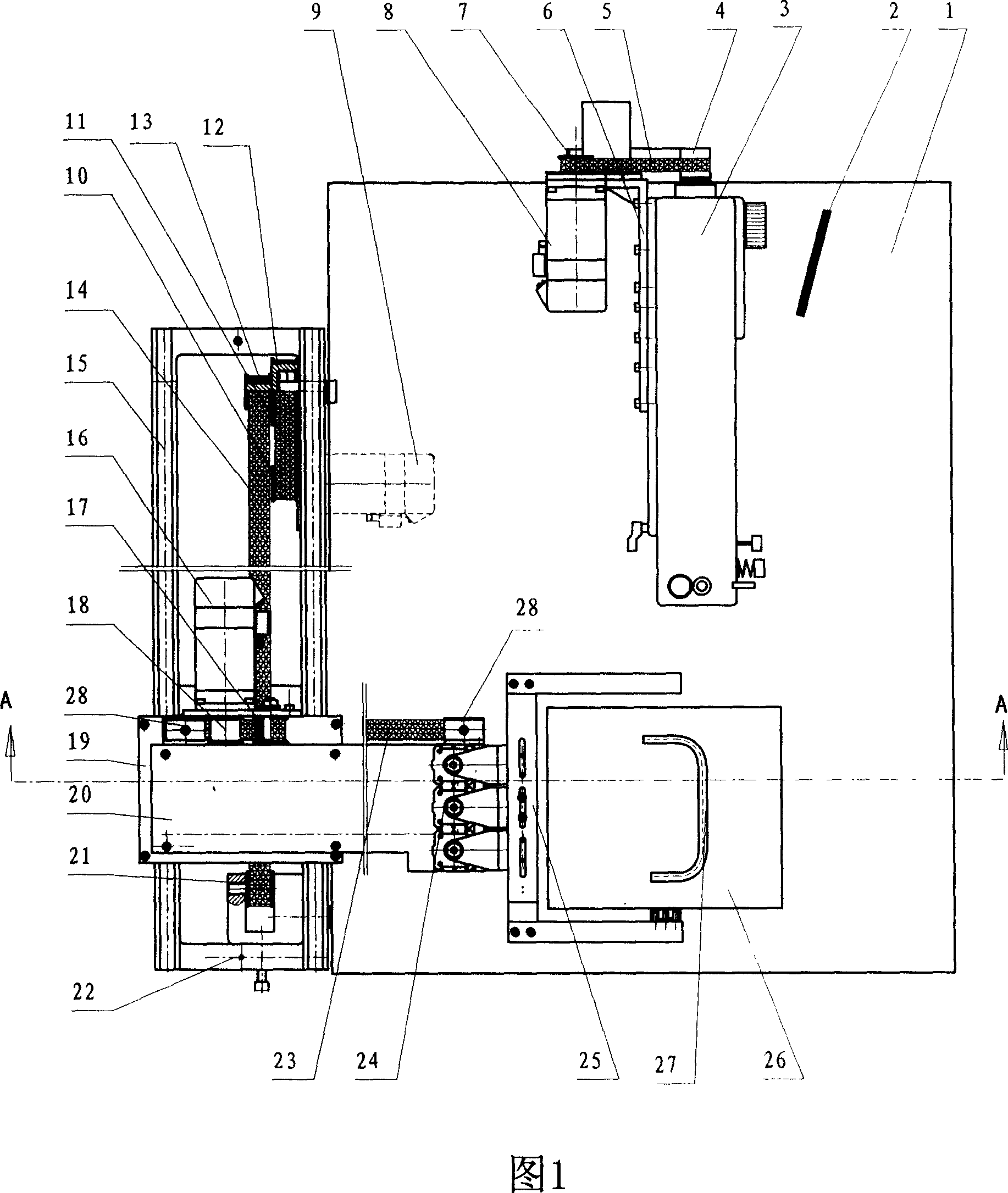

Long U-shaped tube bender

ActiveCN102139301ASimple structurePrecise positioningShaping toolsMetal-working feeding devicesPipe fittingEngineering

The invention relates to a long U-shaped tube bender, in particular to the long U-shaped tube bender capable of processing two tubes in different pipe diameters. The long U-shaped tube bender comprises a base, a stand, a rounding and straightening device, a feeding device, a cutting device, a feeding path, a bending device, a receiving device and a controller, wherein the rounding and straightening device comprises two sets of rounding and straightening mechanisms; the stand is provided with a position switching mechanism for adjusting positions of the two sets of rounding and straightening mechanisms; the feeding device comprises two kinds of feeding channels for conveying pipe fittings in different pipe diameters; a position switching part for adjusting the positions of the two feeding channels is arranged on the stand; the bending device comprises two kinds of bending channels for bending pipe fittings in different pipe diameters; and a bending bracket is arranged on the stand and is provided with a position switching part for adjusting the positions of the two bending channels. The long U-shaped tube bender has a simple and reasonable structure, is accurately positioned, is convenient to operate and easy for manufacture. On the basis of no dismount and replacement of main parts, the long U-shaped tube bender can be used for processing the pipes in different pipe diameters and has wide processing range.

Owner:OMS MASCH CO LTD

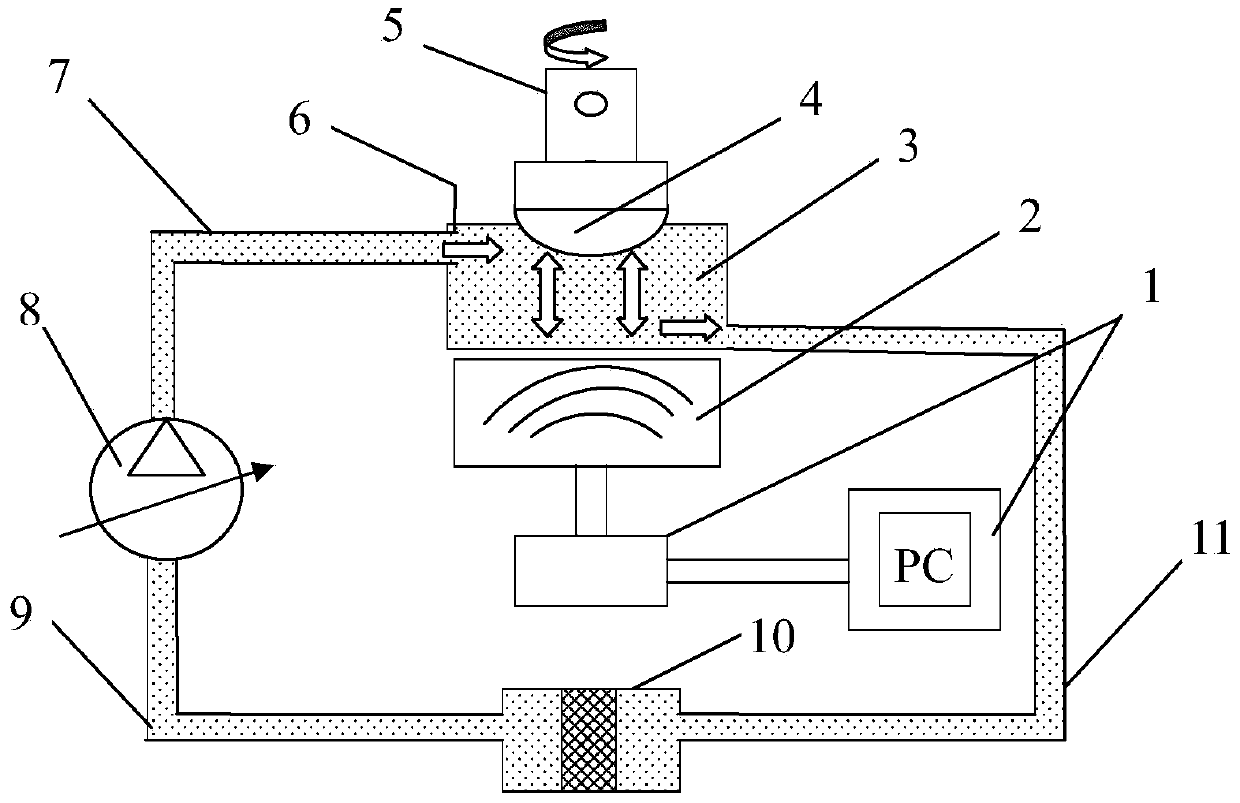

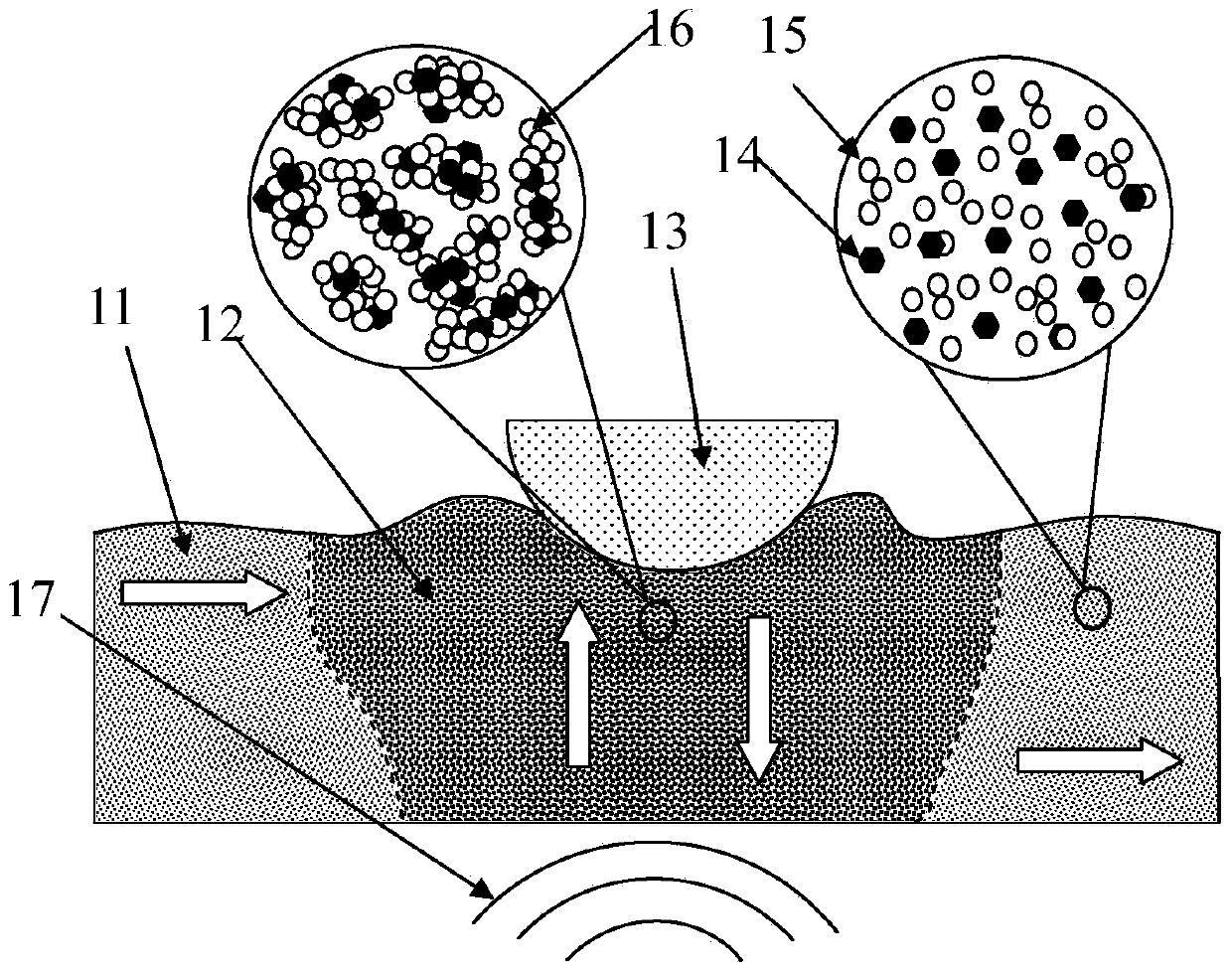

Ultrasonic control shear thickening and polishing method and device

An ultrasonic control shear thickening and polishing method comprises the following steps of 1 adding a non-Newtonian fluid polishing solution mixed with abrasive particles and having the shear thickening effect into a polishing pond and fixing a workpiece on a clamp, wherein the clamp is located above the polishing pond; 2 starting a polishing solution circulating system to enable the non-Newtonian fluid polishing solution to be circularly pumped out of the bottom of the polishing solution and fed into the upper portion of the polishing pond; 3 starting an ultrasonic wave generating device, and meanwhile setting the vibration frequency and vibration amplitude to enable the non-Newtonian fluid polishing solution in the polishing pond to rapidly vibrate and produce a strong shear thickening phenomenon; 4 adjusting the clamp to enable the workpiece to perform relative motion, wherein the abrasive particles having the polishing effect produce the micro-cutting effect or chemical mechanical effect on the workpiece to remove materials on the workpiece surface, and accordingly the workpiece surface polishing is achieved. The invention further provides an ultrasonic control shear thickening and polishing device. The ultrasonic control shear thickening and polishing method and device is high in polishing efficiency and low in cost.

Owner:ZHEJIANG UNIV OF TECH

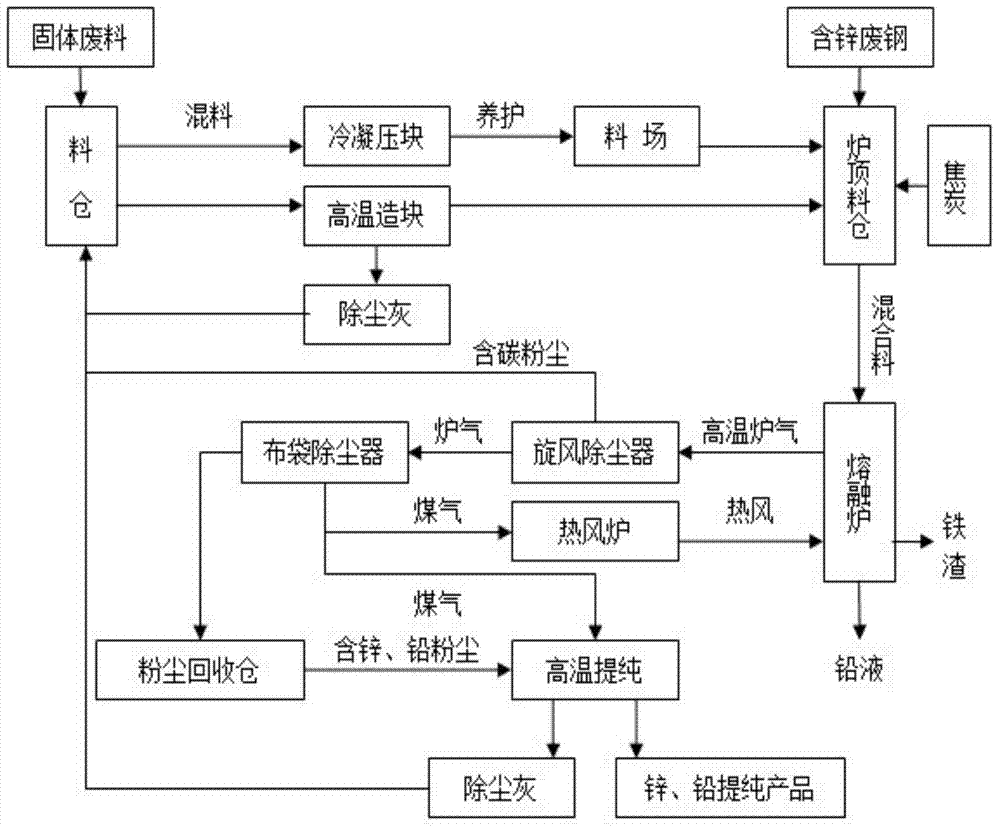

Process method for processing solid waste of steelworks by utilizing smelting furnace

The invention relates to a process method for processing iron-containing solid waste of steelworks by utilizing a smelting furnace. The process method comprises the following steps: with blast furnace dust containing zinc and lead, revolving furnace sludge, electric furnace fly ash, slag metal, waste metal and the like as principal raw materials, carrying out condensation agglomeration and high-temperature agglomeration, and carrying out operations such as maintaining or cooling and granulation so as to obtain finished agglomerates; after mixing the finished agglomerates with coke, sending the mixture into the smelting furnace to be subjected to high-temperature smelting, simultaneously adding the waste such as zinc-containing waste into the smelting furnace in a certain proportion to finally generate high-temperature mixed gas, separating elements such as carbon from the mixed gas by utilizing a cyclone dust collector at the top of the furnace, recycling carbon-containing dust again, further separating the residual mixed gas by utilizing a bag-type dust collector so as to obtain zinc-rich and lead-rich dust, and recycling the zinc-rich and lead-rich dust and applying the zinc-rich and lead-rich dust to the high-temperature agglomeration, the hot air preheating of the smelting furnace and a smelting furnace purification process; then purifying the collected zinc-rich and lead-rich dust, so as to obtain high-purity zinc and lead products; regularly opening a lead discharging hole in the bottom of the smelting furnace, and collecting lead liquid so as to simultaneously obtain wet lead and products such as molten iron and furnace slag.

Owner:卢龙宏赫废料综合利用有限公司

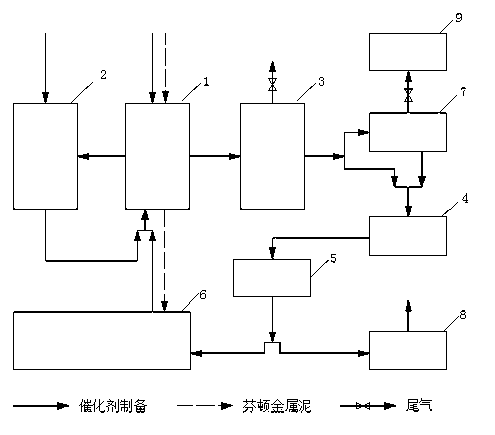

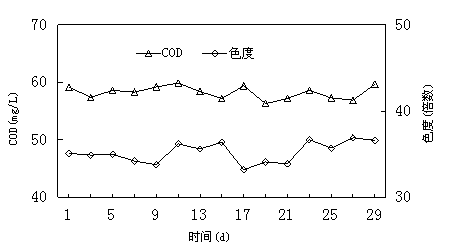

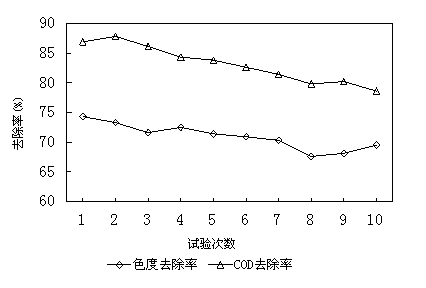

Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

ActiveCN103007937ANo pollution in the processReduce manufacturing costOther chemical processesCarbon compoundsActivated carbonIndustrial waste water

The invention discloses a catalytical ozonization catalyst prepared by utilizing multi-source sludge and an application thereof, and establishes a method for preparing a sludge group active carbon catalyst for catalytical ozone oxidation organic industrial waste water. The method comprises the following steps of: utilizing multi-source sludge such as surplus sludge generated by urban sewage factory biochemical treatment and a metal sludge generated by a Fenton oxidation method, preparing a skeleton which is a sludge group active carbon through steps such as organic substance adding, actification, dehydration, drying, mixing, roasting and screening, wherein a surface layer contains a solid catalyst of metallic oxide, and the ratio of the sludge group active carbon and the metallic oxide in parts by weight is 1:(0.3-0.5). The catalyst is used for catalyzing ozone oxidation treatment organic industrial waste water and has higher catalytic activity and stability, the processing range is wide, the realization and popularization and application are easy, and the economic benefits are improved in an organic industrial waste water processing procedure.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

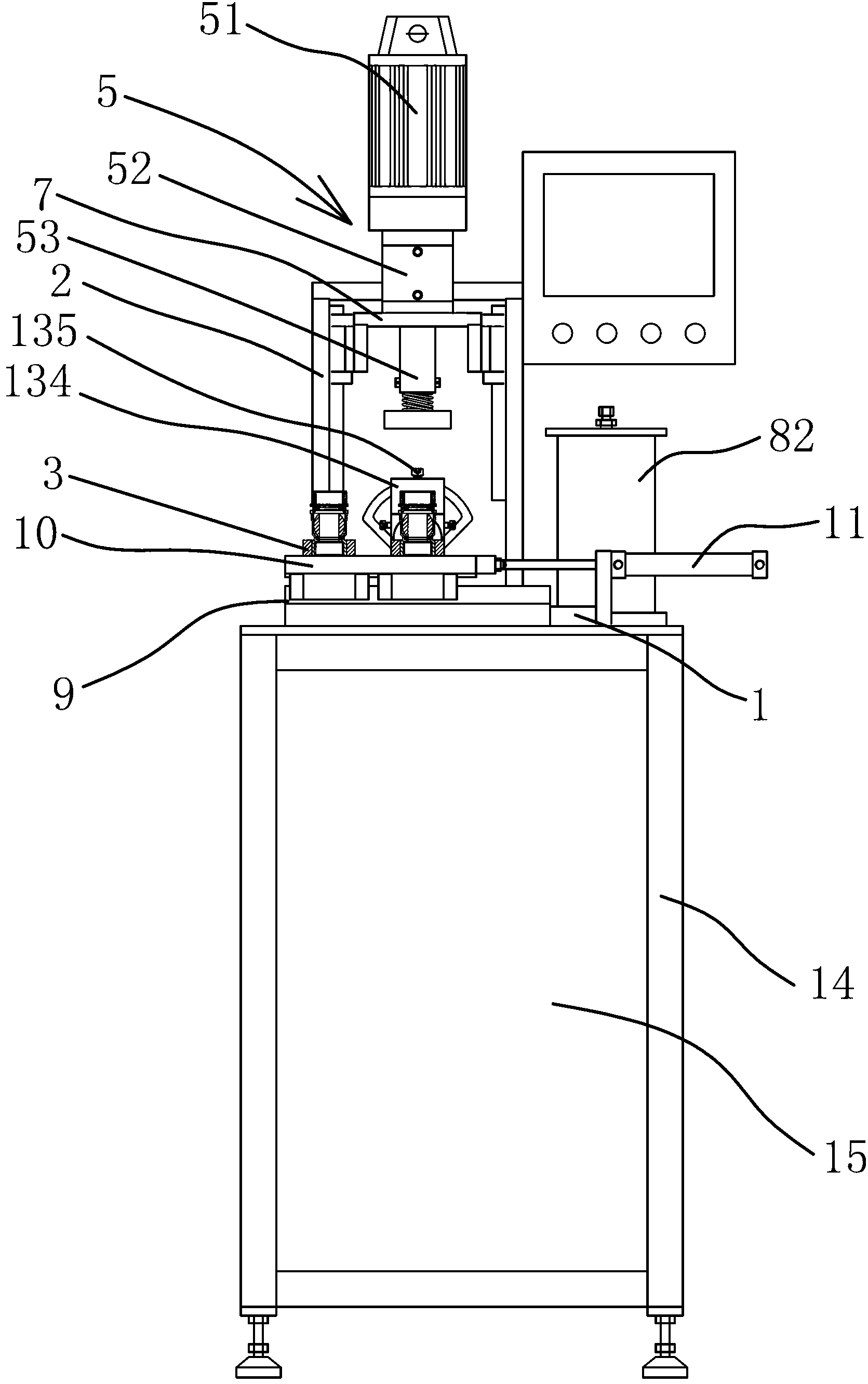

Valve body and bonnet connection torsion dispensing assembly machine

InactiveCN103231241AUniform coatingImprove the firmness of the connectionLiquid surface applicatorsAssembly machinesEngineeringPiston rod

The invention provides a valve body and bonnet connection torsion dispensing assembly machine, belongs to the technical field of valve production devices and solves problems that the existing valve body and bonnet connection assembly machine cannot achieve automatic gluing. The valve body and bonnet connection torsion dispensing assembly machine comprises a worktable and a support fixed on the worktable, wherein a lower die body is arranged on the worktable, an upper die body is arranged right above the lower die body and is fixed on the lower portion of a torsion control mechanism used for controlling rotating of the upper die body, a lifting cylinder is fixedly connected onto the support, a lifting sliding table is fixedly connected at the end of a piston rod of the lifting cylinder, the torsion control mechanism is fixed on the lifting sliding table, and a dispensing mechanism is arranged on the side portion of the lower die body. The valve body and bonnet connection torsion dispensing assembly machine has the advantages of having double functions of valve bonnet screwing and gluing, being high in automation and work efficiency and the like.

Owner:ZHEJIANG VALOGIN TECH

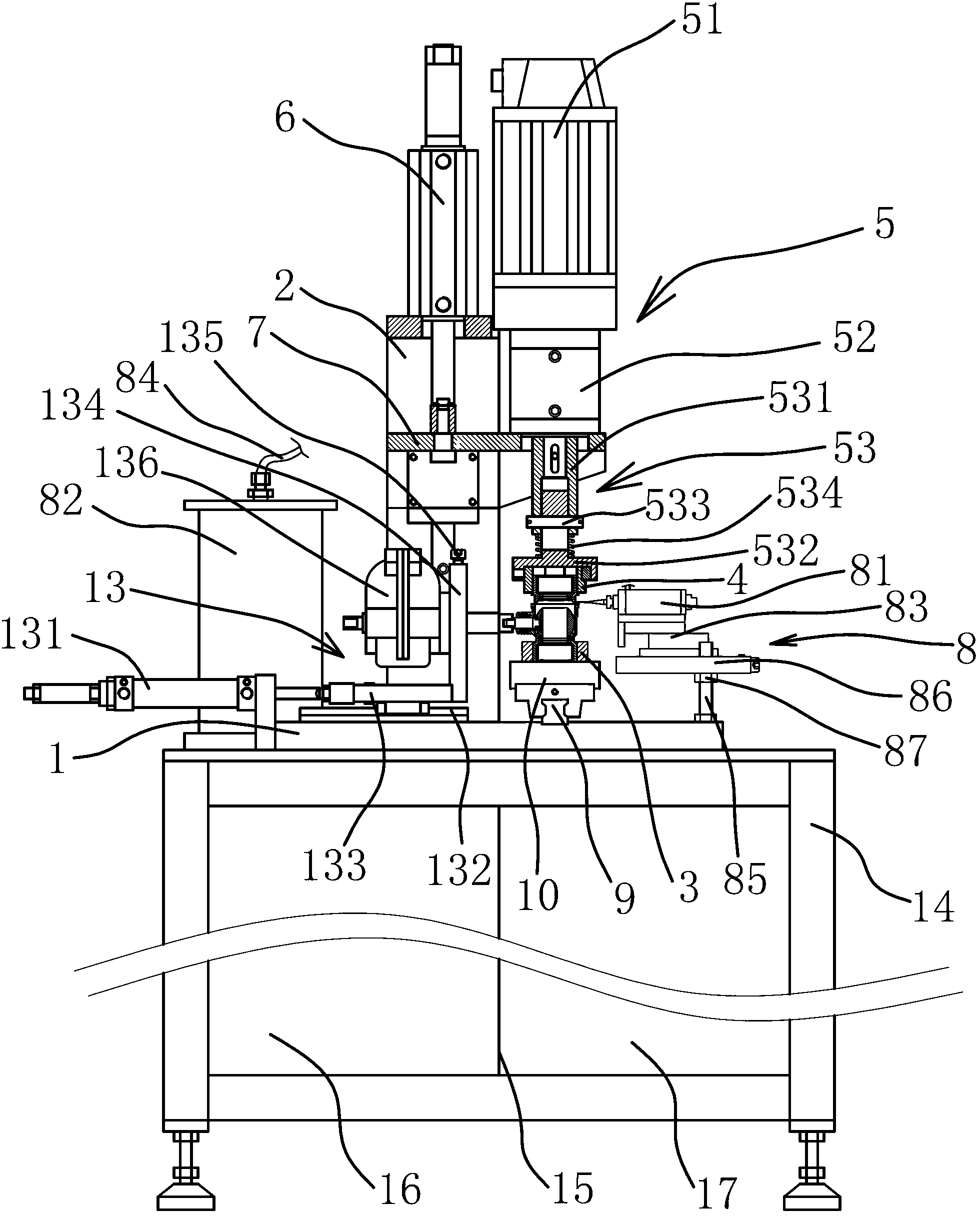

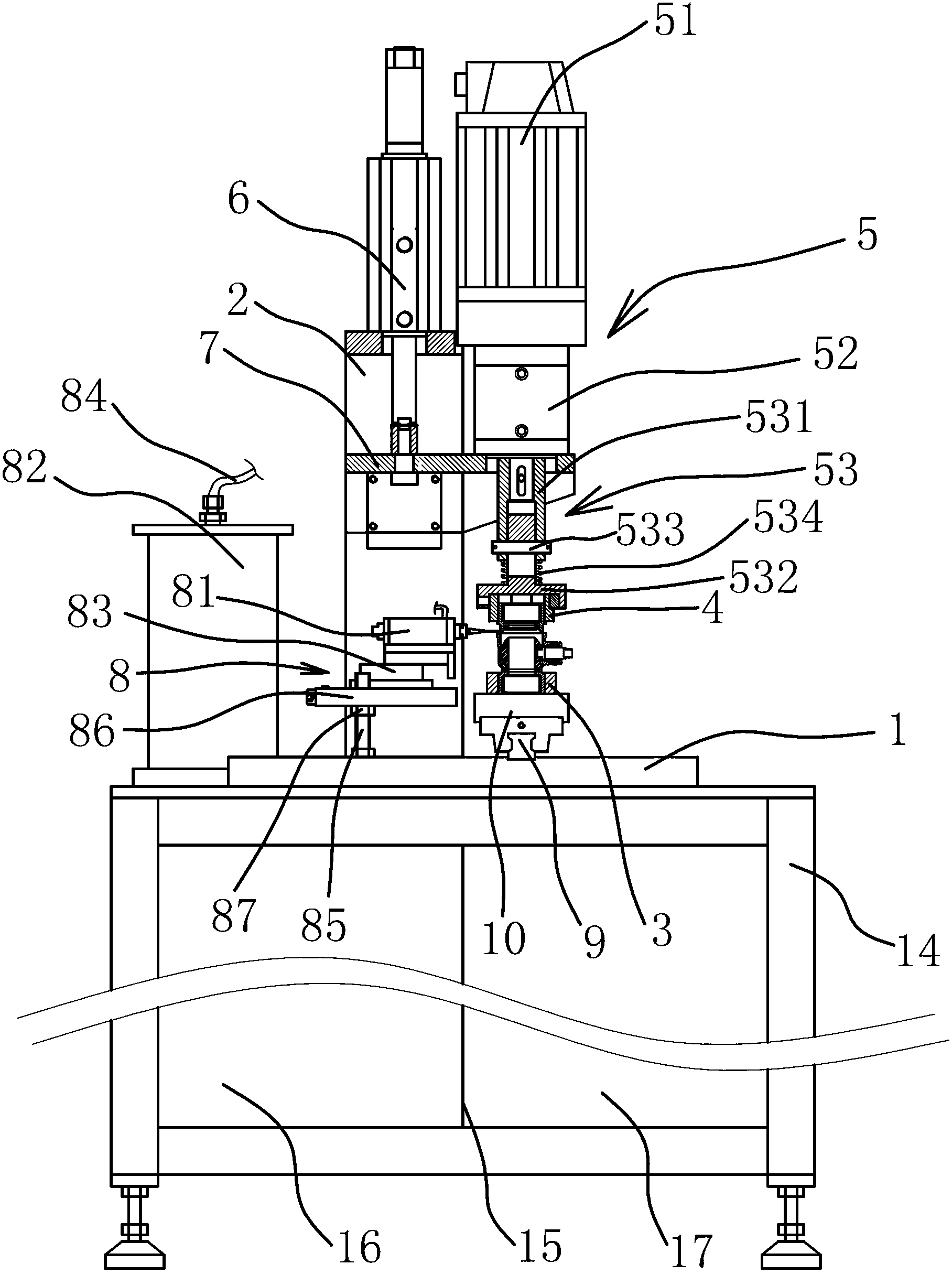

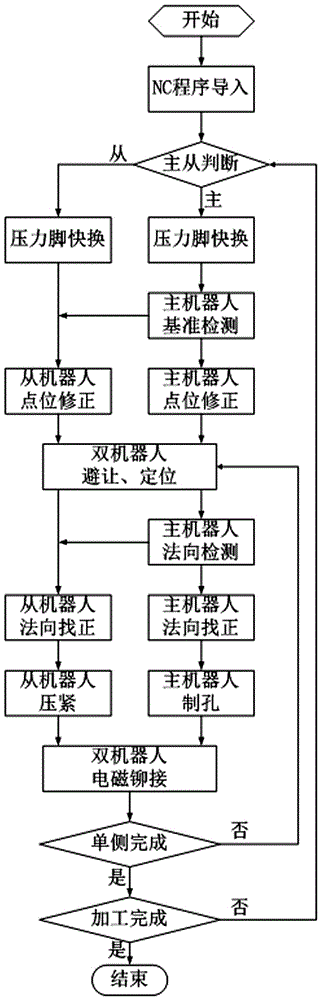

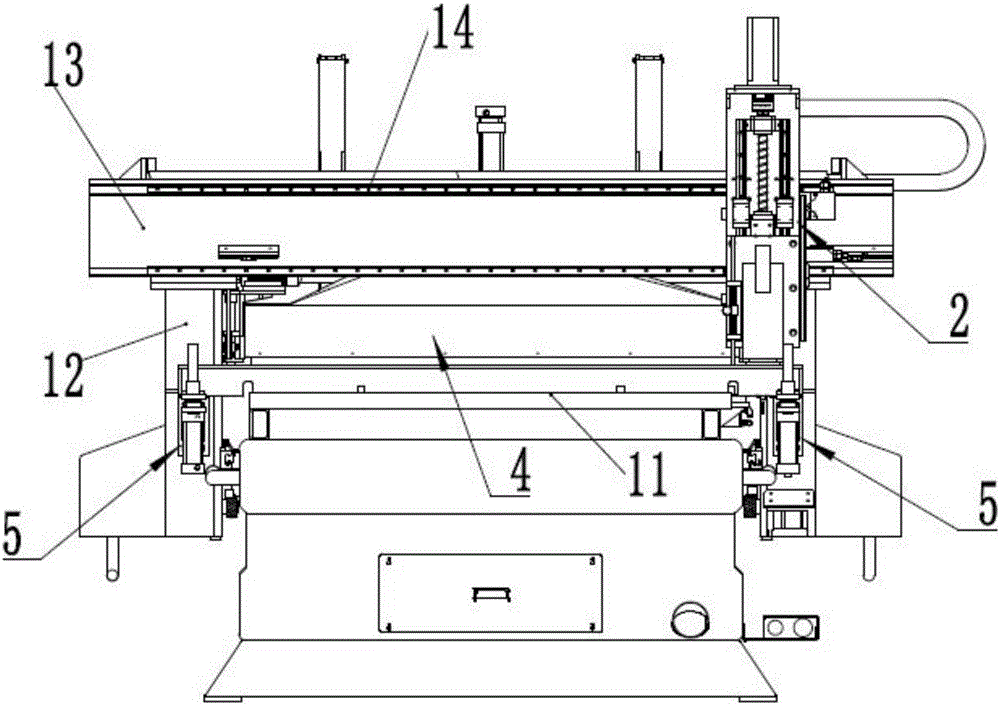

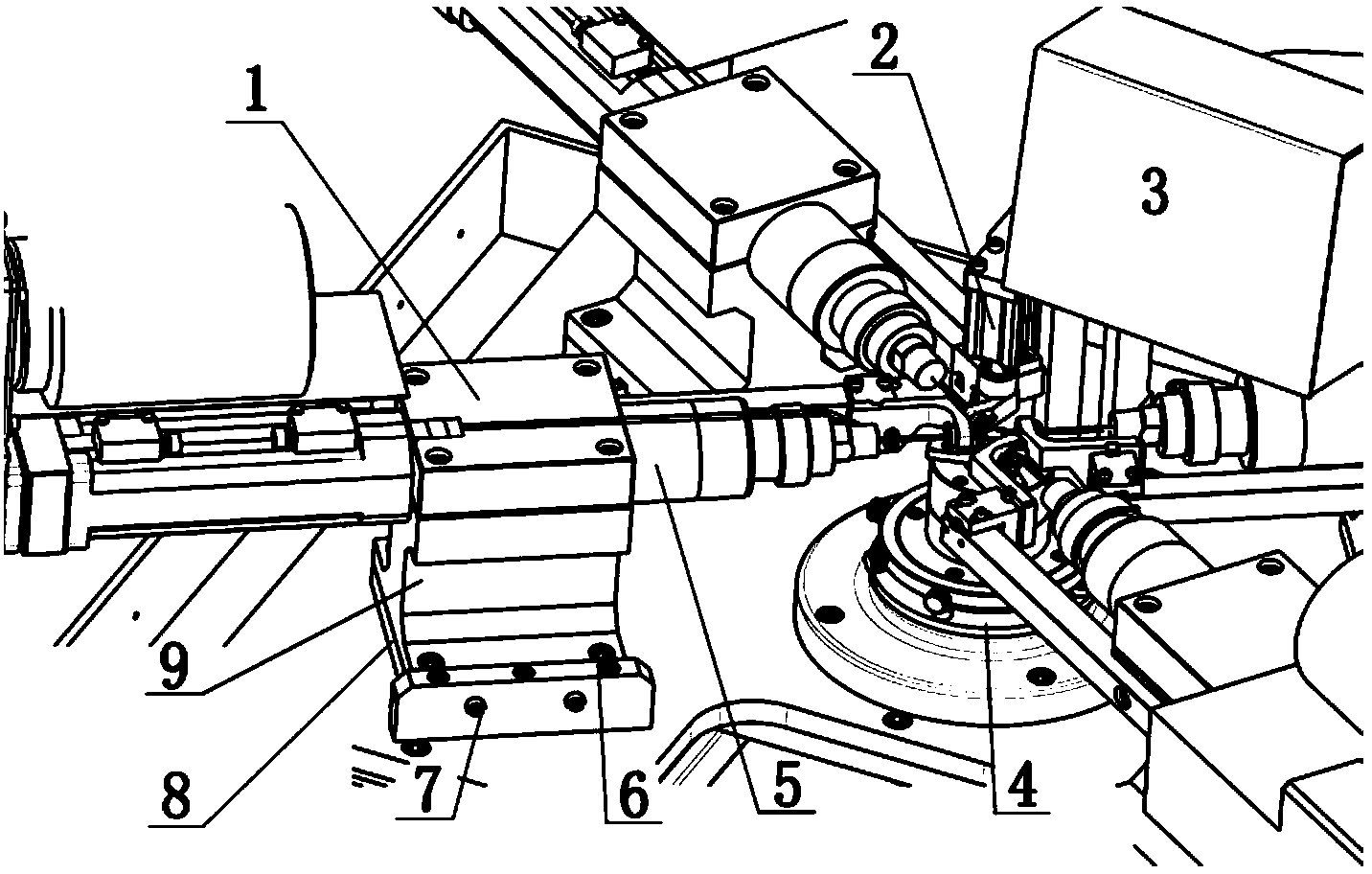

Intelligent flexible production line with double robot cooperative automatic assembling and operation method for same

The invention discloses an intelligent flexible production line with double robot cooperative automatic assembling and operation method for the same. The production line comprises an industrial control computer, a double track moving platform, double industrial robots, a control cabinet, a nail feeding system, a vacuum chip absorbing device, a knife trying station and a flexible tool. With a double-robot cooperative drilling-riveting work mode, the double-robot systems are distributed on two sides of a product, and information is detected by one-side robot to achieve robot pose correction; master-slave distribution of the robots can be dynamically realized during the work; pressure feet can be quickly exchanged upon master-slave switch; a master robot drills and conduct front compression and a slave robot compresses on the back surface of the product; and at last after drilling completion, electromagnetic riveting can be conducted to the double robots. Double-robot cooperative drilling-riveting work can be conducted with high intelligent degree; double-sized drilling and single-sided riveting operations can be completed; burrs can be prevented; and the intelligent flexible production line with double robot cooperative automatic assembling possesses high riveting quality, wide processing range, high flexibility and is suitable for various products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

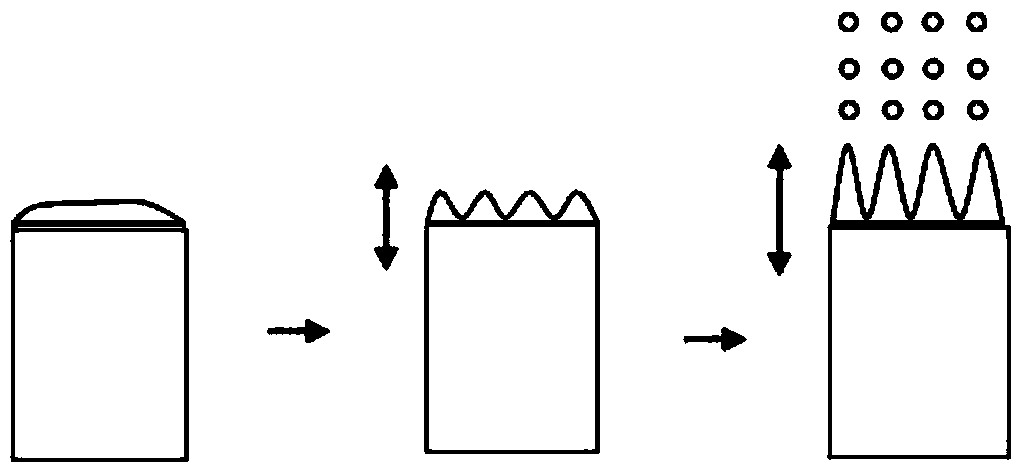

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

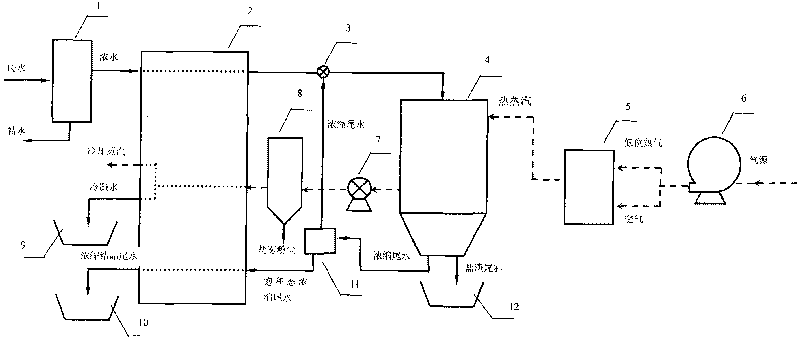

Method for spraying and desalting through residual pressure of reverse osmosis concentrated water

InactiveCN101712521ASave powerSimple structureGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater vaporReverse osmosis

The invention establishes a method for treating waste concentrated saltwater of reverse osmosis systems. The method mainly comprises the following steps that: the residual pressure of concentrated water produced by the self of a reverse osmosis system during water production is utilized to form high-salt spray so as to save power needed by conventional atomization; tiny water droplets quickly evaporate in floating air so as to separate water, salt and other impurities; meanwhile, organic matter contained by the water is oxidized to be carbon dioxide; vapor is input into a condensing chamber to turn into pure water, while salt and high-power tail water fall to the bottom of a separation chamber; the tail water and initial inflow water are mixed and circulated and then continue to be atomized and concentrated to a saturation state; the contained salt is subjected to heat-exchange condensation and then crystallization and precipitation; and water purification and salinity removal of reverse osmosis concentrated water are finally realized. The desalting and pollutant-reducing method for reverse osmosis concentrated water is suitable for the separation of the waste concentrated saltwater produced by every type of reverse osmosis systems.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

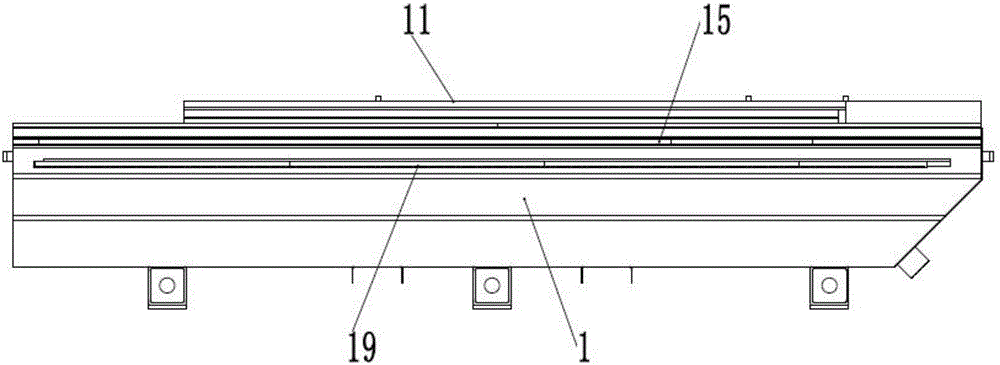

Wide-width aluminum strip double-axis coiling and longitudinal splitting machine

ActiveCN104150266AGuaranteed uptimeAdjustable distanceArticle deliveryWebs handlingLongitudinal splittingEngineering

The invention discloses a wide-width aluminum strip double-axis coiling and longitudinal splitting machine. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine comprises an uncoiling machine, an adjustment device and a main machine. The uncoiling machine, the adjustment device and the main machine are arranged in one plane and sequentially connected according to the order. The uncoiling machine comprises an uncoiling base and an uncoiling driving device. The uncoiling driving device is arranged on the top face of the uncoiling base. The adjustment device comprises a first base, a pair of steering mechanisms, an adjustment mechanism and a centering detection device. The steering mechanisms are fixedly arranged at the two ends of the top face of the first base respectively. The adjustment structure is arranged in the position right between the steering mechanisms. The centering detection device is arranged on the side face of one of the steering mechanisms. The main machine comprises a machine frame, a pair of rocker arm devices, a guide rail supporting device, a pair of winding devices and a splitting device. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine is stable in running, wide in machining range, high in universality, low in cost and high in efficiency.

Owner:镇江龙源铝业有限公司

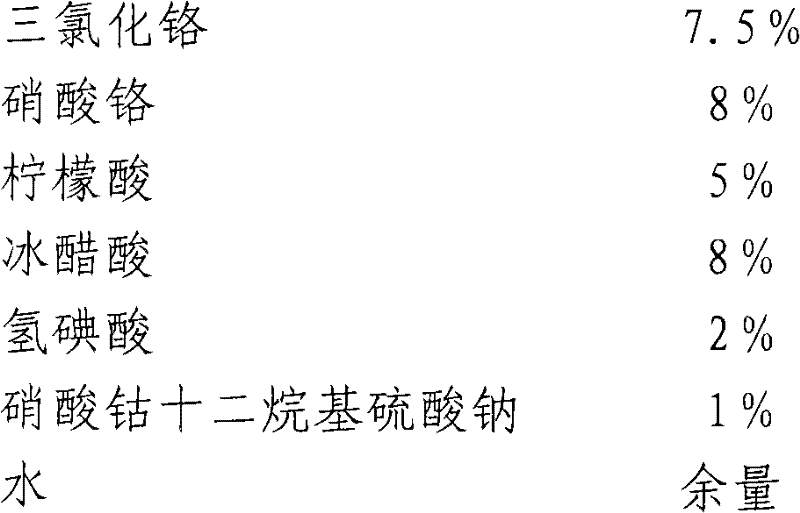

A kind of trivalent chromium multicolored passivator

InactiveCN102260867AGood salt spray performanceReduce the use temperatureMetallic material coating processesHexavalent chromiumHolding time

A trivalent chromium multicolored passivator belongs to the technical field of surface treatment. This passivating agent is used for trivalent chromium multicolored passivating agent after passivation treatment after various electroplating galvanizing processes, and hexavalent chromium will not appear during use. It can prevent the aging of the passivation film and last for a long time through the detection by boiling method. Time to keep the passivation film bright, excellent corrosion resistance. The passivating agent is composed of: 15-30% trivalent chromium composite main salt, 10-25% composite chelating agent, 3-8% reducing agent, 3-10% salt spray resistance additive, 1-3% surfactant, etc. , and the balance is composed of water.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

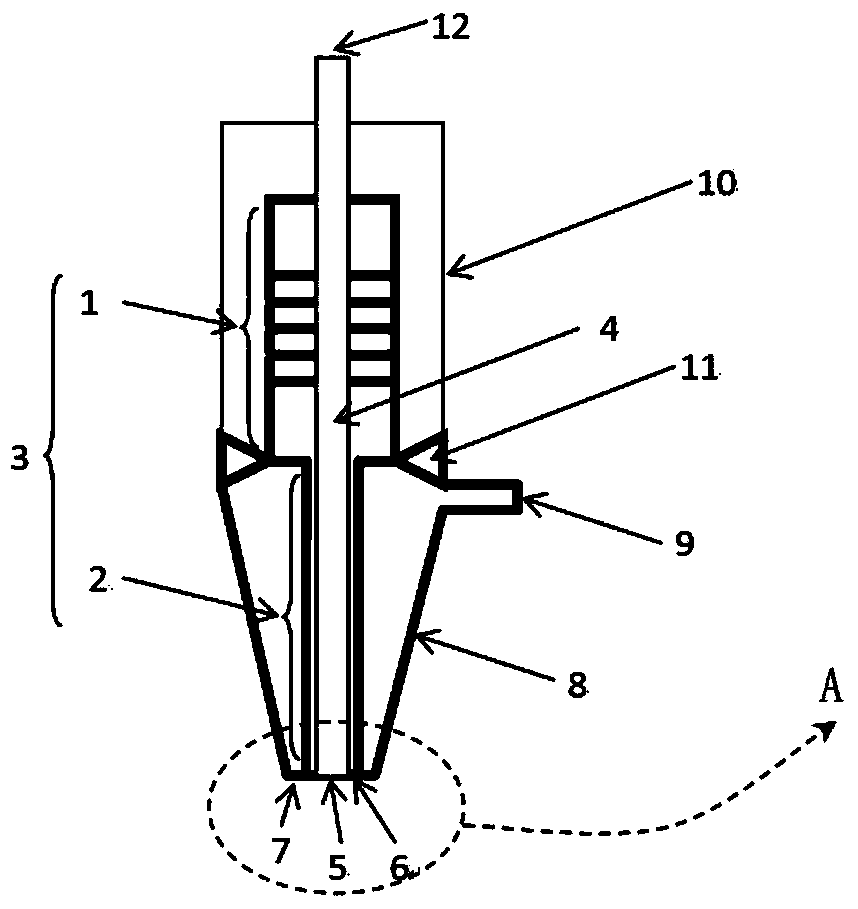

Natural focusing type ultrasonic atomization nozzle

ActiveCN104324839AReduce volumeEvenly distributedLiquid spraying apparatusPrintingTransformerEngineering

Owner:千藤(南京)环保科技有限公司

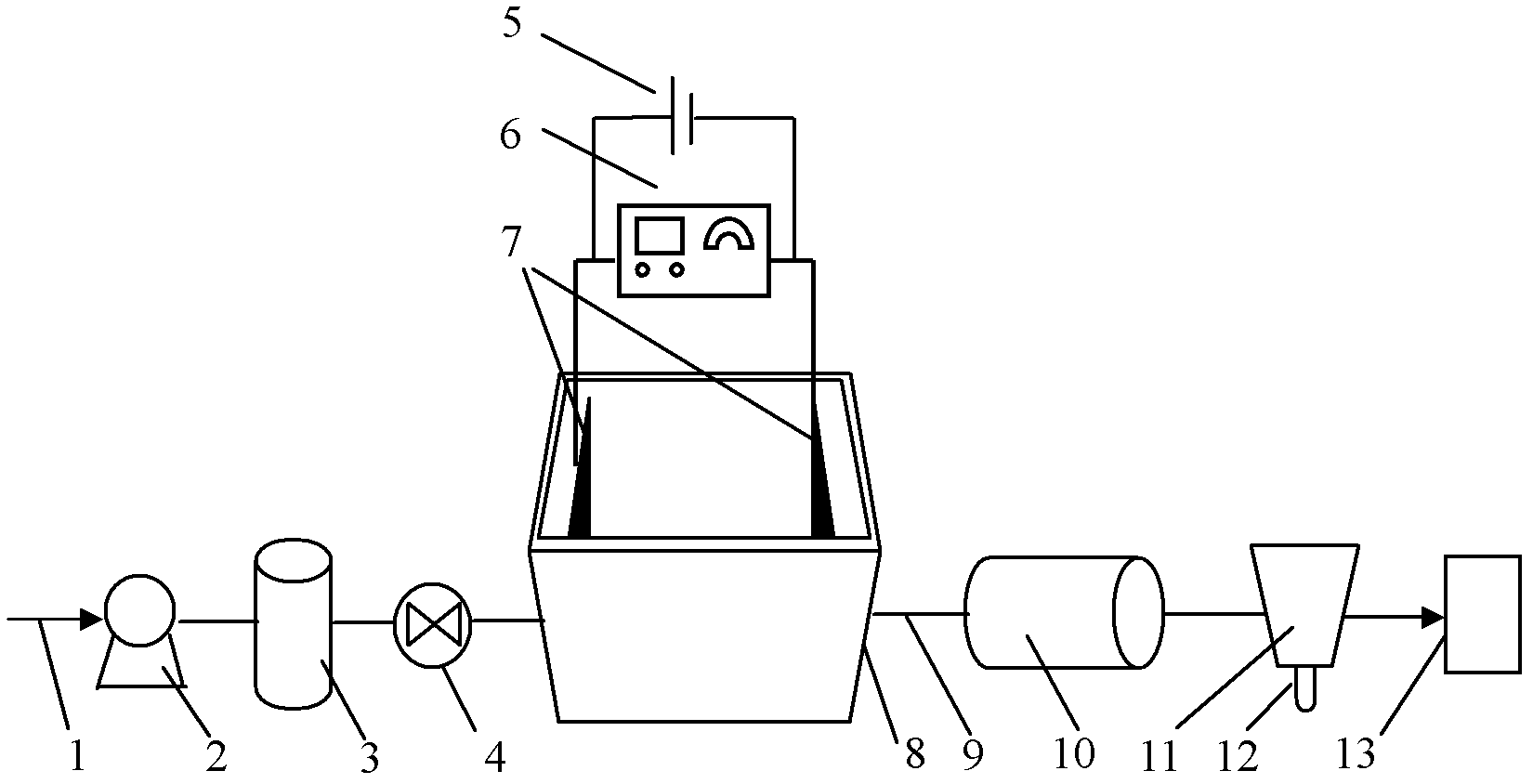

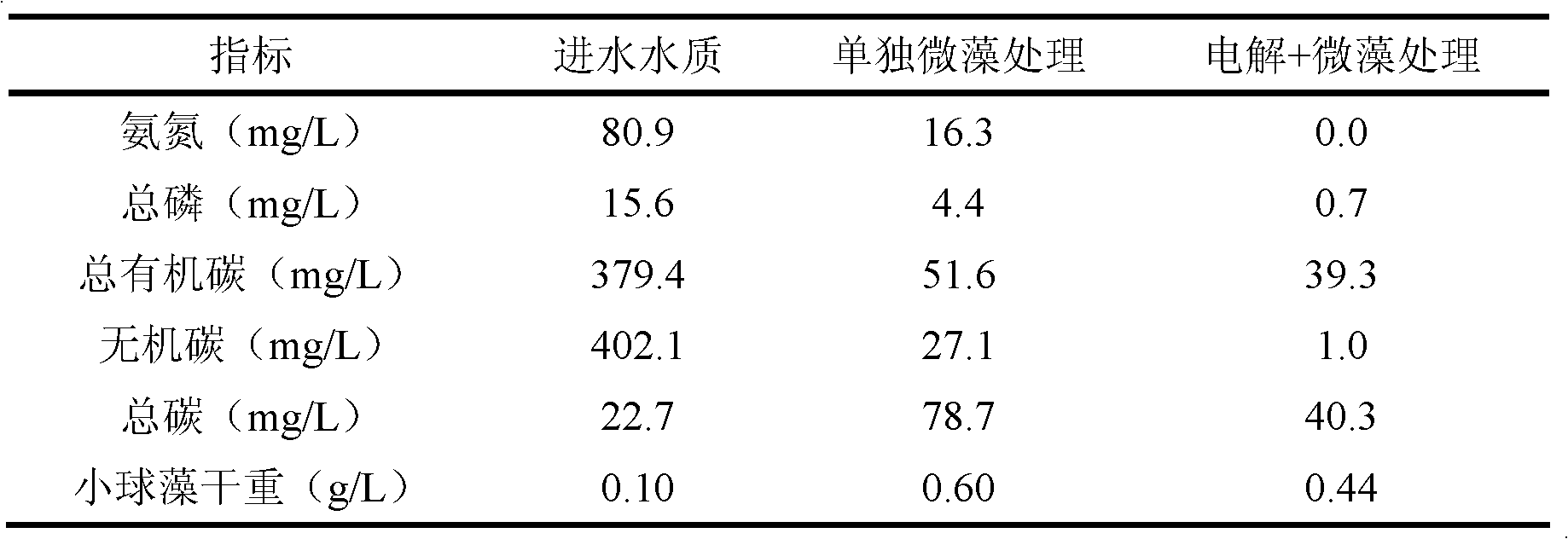

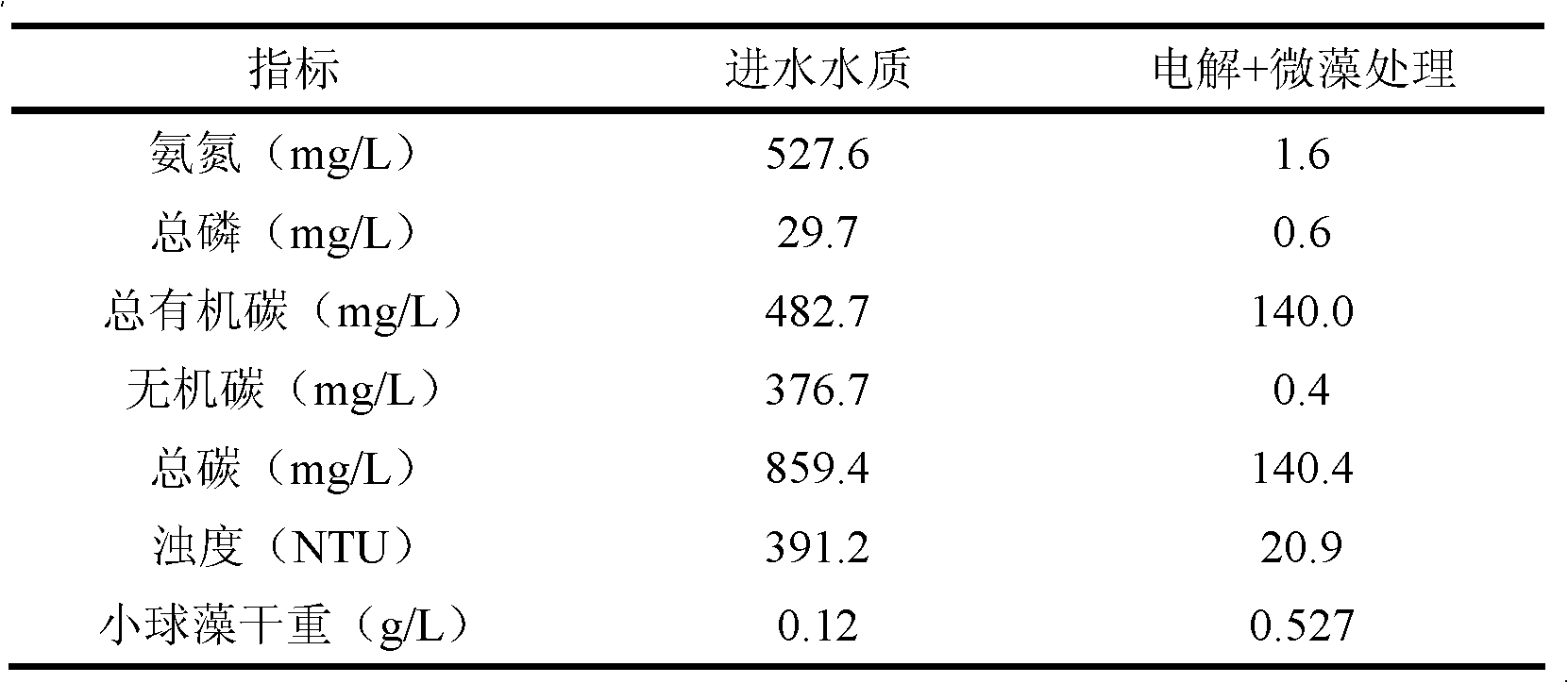

High-concentration sewage treatment method

InactiveCN102642987AImprove biodegradabilityReduce the concentration of pollutantsEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationHydrogen

The invention discloses a high-concentration sewage treatment method. The method includes the steps: firstly, using an electrochemical oxidation method for pretreatment of sewage to obtain pretreated sewage; and secondly, adjusting the pH (potential of hydrogen) value of the pretreated sewage to range from 7.0 to 9.0, inoculating microalgae into the sewage, and subjecting the sewage to microalgaebiological treatment so as to purify the sewage, wherein the microalgae biological treatment operating conditions include: the temperature ranges from 25 DEG C to 30 DEG C, the light dark period is 12:12, the illumination intensity ranges from 40001ux to 60001ux, and the steps include aerating or mechanically stirring and continuously culturing for ten to twenty days. By the high-concentration sewage treatment method, sewage treatment cost is reduced, pollutant removal efficiency is improved. Further, the high-concentration sewage treatment method is wide in sewage treatment range, free of secondary pollution and flexible and controllable in operation mode, and environment-enhancing energy is realized.

Owner:CHINA AGRI UNIV

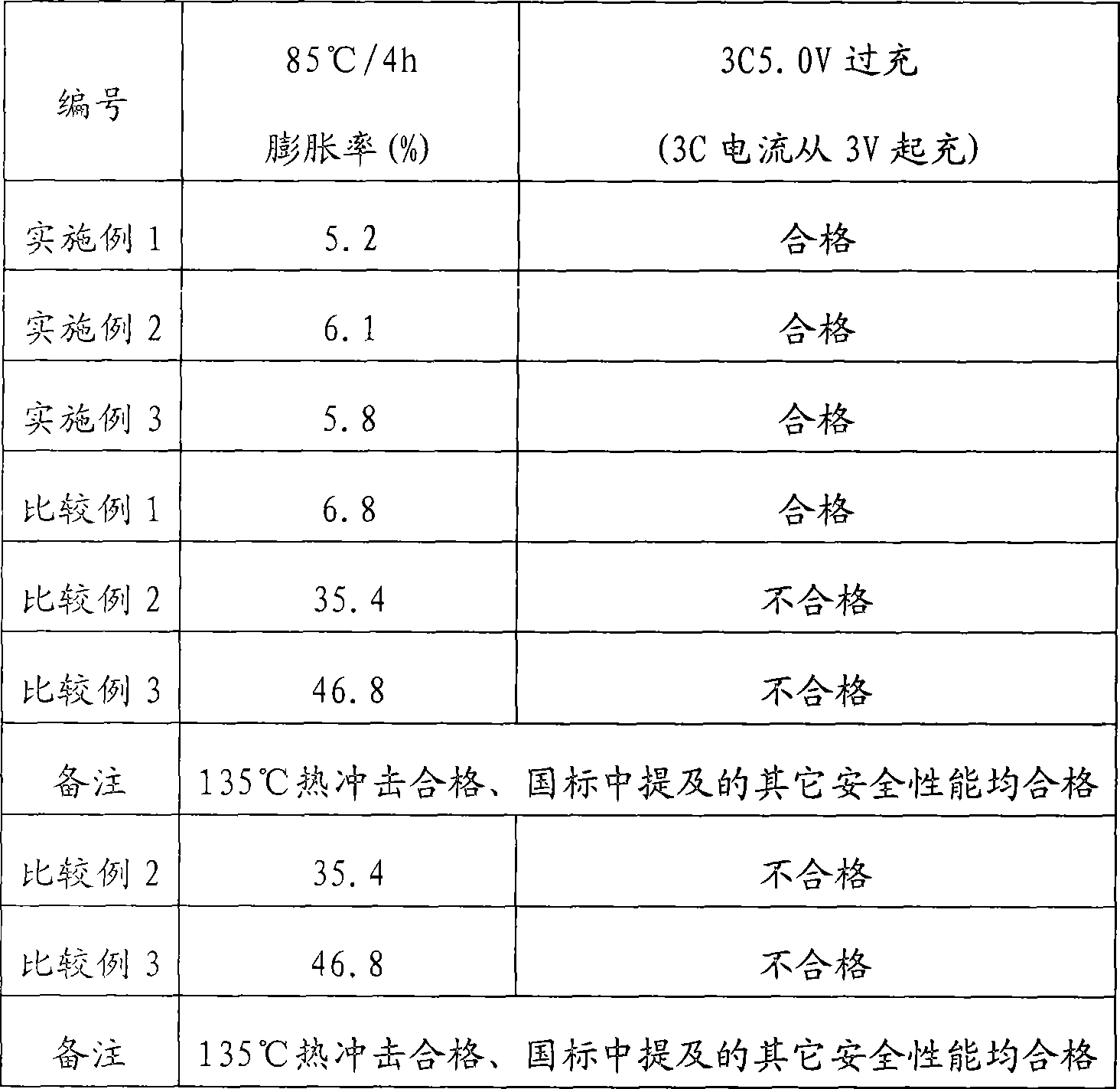

Anode material of lithium ion cell and preparation method thereof

ActiveCN101436666AImprove distributionEvenly distributedElectrode manufacturing processesCobalt compoundsLithium carbonatePhysical chemistry

The invention discloses a method for preparing lithium cobaltate positive pole material for a lithium ion cell and the obtained lithium cobaltate positive pole material. The method comprises the following steps: adopting a multiple-step synthesizing process; in a first synthesis, adopting excessive lithium so as to obtain larger lithium cobaltate particles at lower temperature; and before a second synthesis, adhering mixed powder of cobalt carbonate and lithium carbonate with small particle size and larger specific surface area to the one-step synthesized lithium cobaltate large particles through a mechanical granulation mode. The method can effectively improve the particle size and the tap density of the lithium cobaltate positive pole material so as to improve the compacted density and the volume specific capacity of the positive pole material.

Owner:广东风华新能源股份有限公司

Novel numerical control cutting machine

InactiveCN105773734AImprove processing efficiencyImprove machining accuracyProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlEngineering

The invention discloses a novel numerical control cutting machine which comprises a rack, wherein a working table used for supporting a workpiece is arranged on the rack. The novel numerical control cutting machine further comprises a cross beam capable of moving on the rack, a processing component used for processing the workpiece on the working table, a material sucking device used for loading materials, a dust collection device used for cleaning chips on the surface of the workpiece on the working table, and a material pushing device used for pushing the processed workpiece away from the working table. According to the novel numerical control cutting machine, the processing efficiency is high, the processing accuracy is high, the automation degree is high, the operation is convenient, a straight line edge can be processed on the workpiece, an arc edge can be processed, the processing range is wide, and the processing flexibility is high.

Owner:GUANGDONG SANDAR CNC MACHINERY CO LTD

Process of zine pressure casting non cyanogen alkaline immersion plating copper

InactiveCN100999819AImprove bindingEliminate pollutionSuperimposed coating processCopper platingGluconic acid

The cyanide-free alkaline copper dip plating process for die cast zinc part includes the following steps: dewaxing die cast zinc part, deoiling, soaking in alkaline immersion liquid at 15-60 deg.c and pH 7.5-13.0 for 5 sec to 15 min to form replacing copper layer. The alkaline immersion liquid contains two-valent copper ion, and one or several kinds of inorganic or organic complexing agent selected from pyrophosphoric acid, tartaric acid, citric acid, gluconic acid, EDTA and HEDP acid radical ion a in the concentration of 1-150 g / L. The process of the present invention may be used to replace cyanide copper plating to form copper coating with high adhesion force without cyanide pollution.

Owner:GUANGZHOU UNIVERSITY

Fibers and fabrics made from ethylene/ alpha-olefin interpolymers

InactiveCN102016149AImprove wear resistanceReduce coefficient of frictionLayered productsFilament/thread formingFiberPolymer science

A bicomponent fiber is obtainable from or comprises an ethylene / alpha-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re >1481-1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics, such as spunbond, melt blown and spun-laced fabrics or webs can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

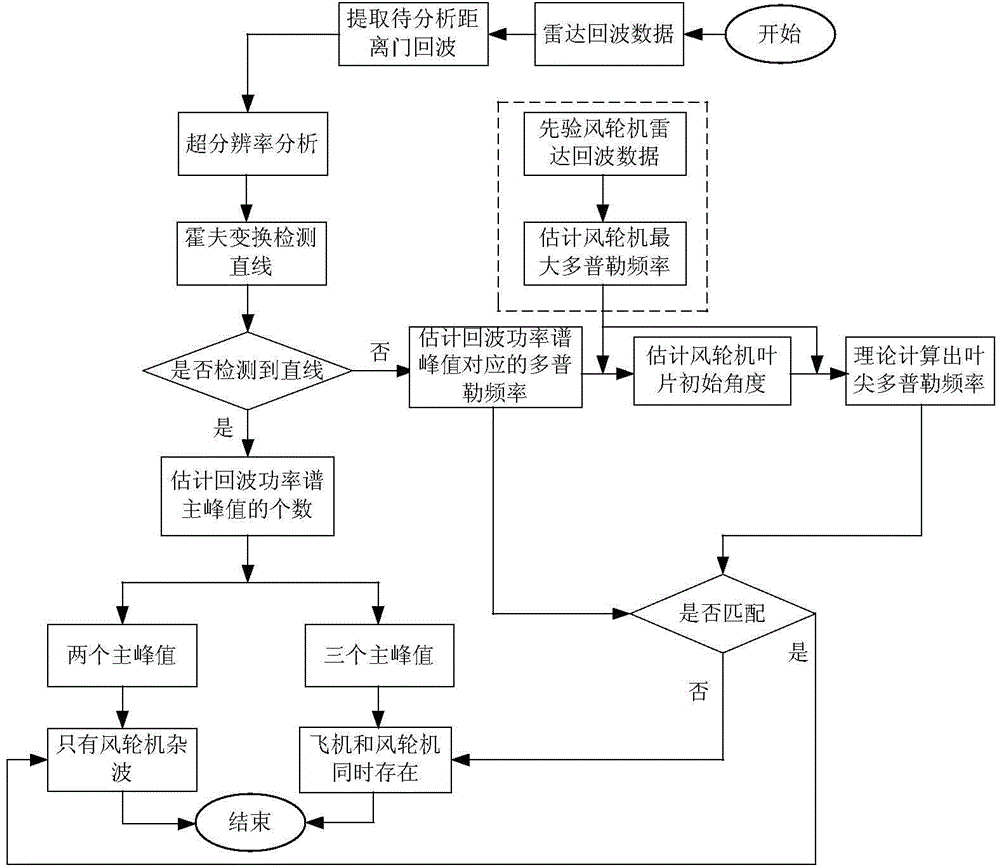

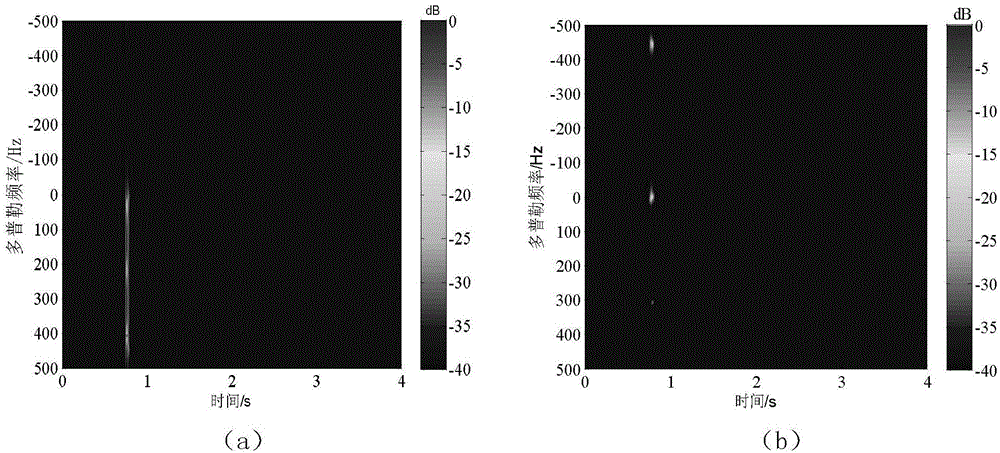

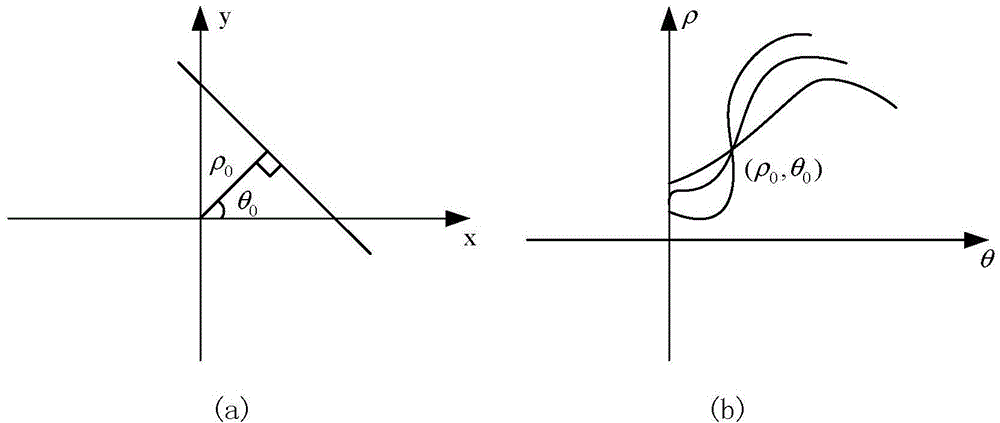

Aircraft target detection method under radar scanning mode in wind turbine clutter background

ActiveCN104931949AWide range of processingSimplified processing stepsWave based measurement systemsHough transformTurbine blade

The invention relates to an aircraft target detection method under a radar scanning mode in wind turbine clutter background. The method includes the following steps that: radar multi-scanning data of wind turbine clutter are obtained through utilizing apriori information, and the maximum Doppler frequency of wind turbine blades is estimated according to the data; super resolution technology is introduced for the obtained radar scanning data, so that frequency resolution can be improved; Hough transform is performed on radar echo data which have been subjected to super resolution processing, so that whether the wind turbine blades are vertical to radar beams can be detected, if the wind turbine blades are vertical to the radar beams, whether an aircraft target exists is further detected, otherwise, the possible Doppler frequencies of the tips of the wind turbine blades and the aircraft are estimated through utilizing the power spectrum of the radar echoes which have been subjected to the super resolution processing; the possible Doppler frequencies are compared with the calculated value of the Doppler frequency of the tips of the wind turbine blades; and whether the aircraft target exists in a range gate can be judged according to a comparison result. With the method of the invention adopted, a situation in which only wind turbine clutter exist and a situation in which aircraft and wind turbine clutter co-exists can be distinguished, and aircraft target detection under wind turbine clutter background with any blade initial angle can be realized.

Owner:CIVIL AVIATION UNIV OF CHINA

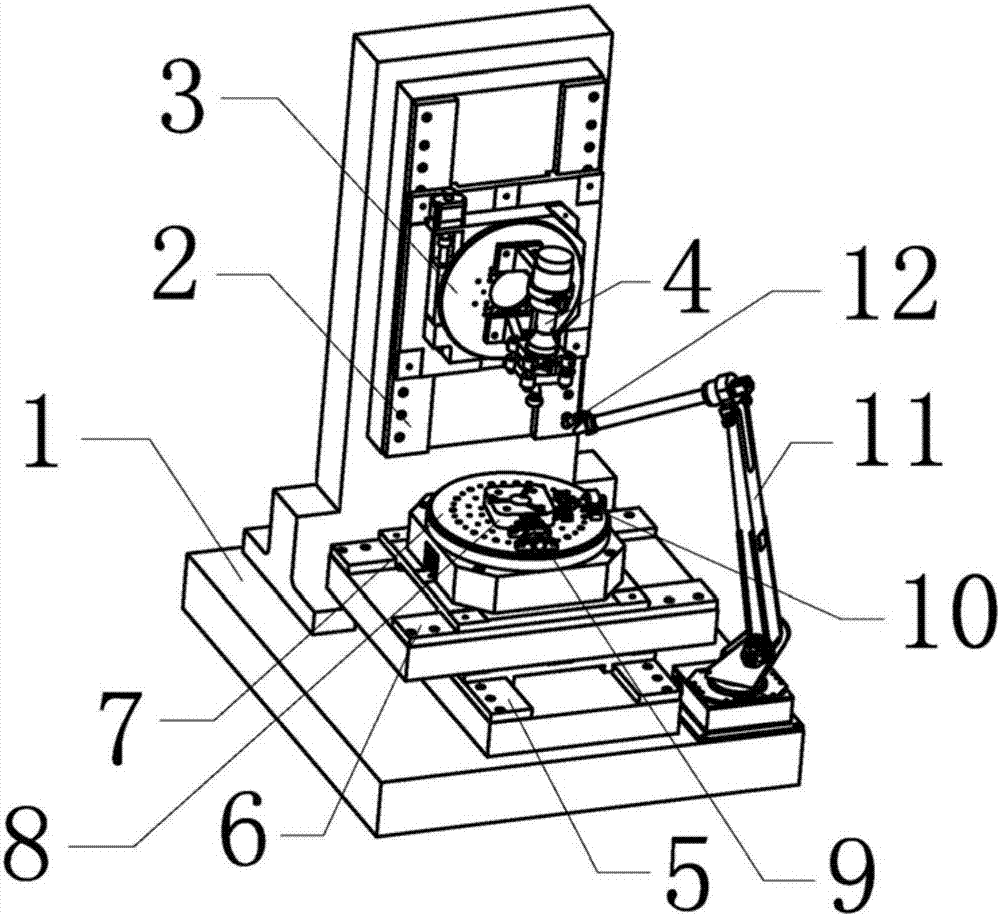

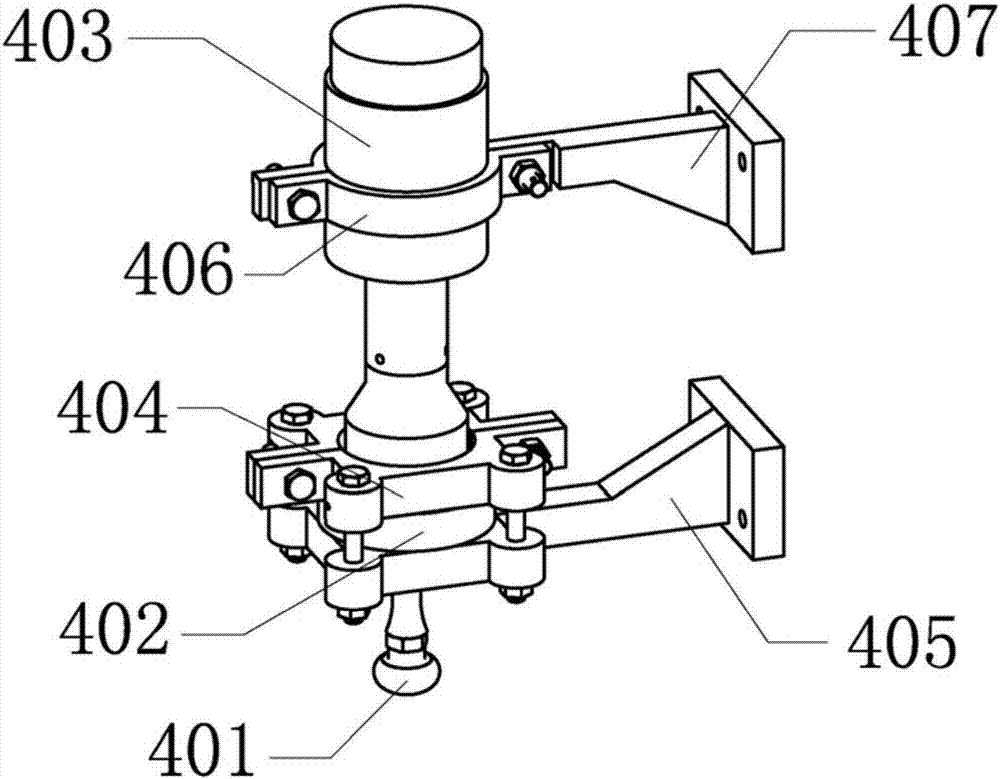

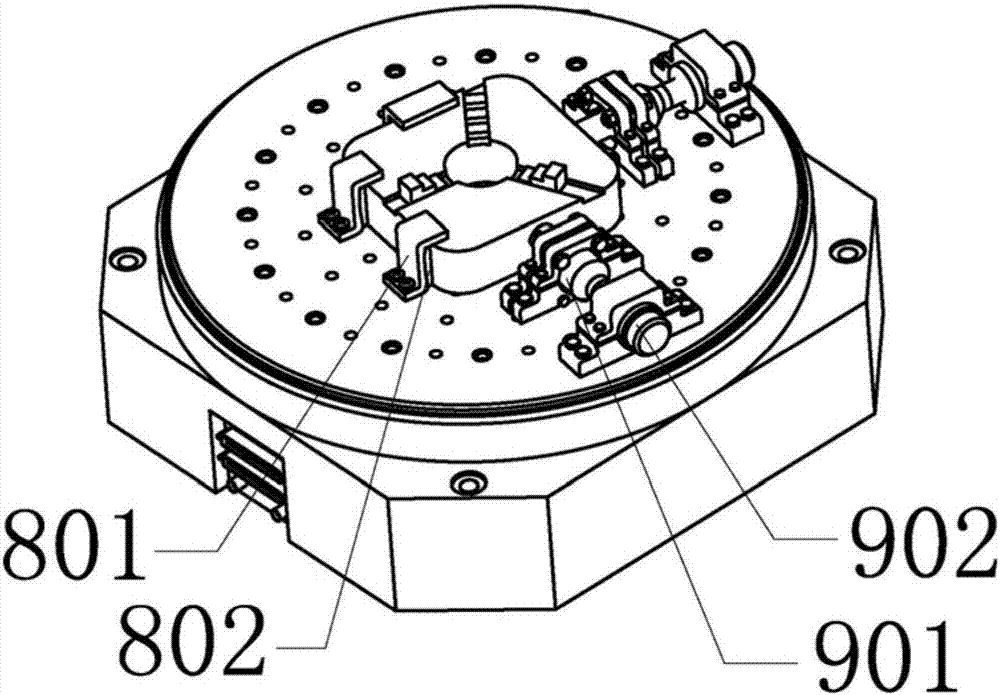

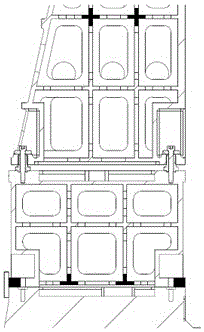

High-precision five-shaft multi-dimensional ultrasonic polishing device

PendingCN107009200AChange processing characteristicsSmooth vibrationGrinding carriagesPolishing machinesRotary stagePolishing

The invention relates to a high-precision five-shaft multi-dimensional ultrasonic polishing device, and belongs to the field of polishing of a complicated curved surface element which has high precision and is difficult to machine. An upright guide rail is arranged at the upper part of an L-shaped base; an upright rotary table capable of moving up and down is arranged on the upright guide rail; a polishing tool head vibrator assembly is arranged on the upright rotary table; a horizontal guide rail I is arranged at the lower part of the L-shaped base; a horizontal guide rail II capable of moving forwards and backwards is arranged on the horizontal guide rail I; a horihzontal rotary tool table capable of moving leftwards and rightwards is arranged on the horizontal guide rail II; the vibration radiation surfaces of ultrasonic vibration exciting assemblies I and II in the horizontal rotary tool table are respectively in contact with two mutually perpendicular side surfaces of a workpiece clamp; one end of a three-degree-of-freedom mechanical arm is connected to the lower part of the L-shaped base in a rotatable manner; and an ultrasonic atomization spraying head is arranged at the other end of the three-degree-of-freedom mechanical arm. The device comprises multiple guide rails and the rotary table, thus providing five degrees of freedom, and can realize polishing of a complicated curved surface to complete machining of a complicated part which is difficult to machine with an existing machine tool.

Owner:NORTHEASTERN UNIV LIAONING

Thermal deformation suppression middle type high-speed crown block gantry five-axis machining center

InactiveCN106736799AImprove machining accuracyWide range of processingFeeding apparatusLarge fixed membersStructural deformationThermal deformation

The invention discloses a thermal deformation suppression middle type high-speed crown block gantry five-axis machining center. A workbench is directly cast on a base; a left bridge and a right bridge are installed on the two sides of the base; linear guide rails are installed on the left bridge and the right bridge correspondingly; a cross beam is installed on the left bridge and the right bridge through X-axis sliding blocks on the two sides; the middle of the cross beam is hollowed-out; four guide rails are arranged on the upper side and the lower side of the cross beam; and a left sliding base and a right sliding base are installed in the middle of the cross beam through the sliding blocks. A left ram and a right ram are connected into a whole through a Y-axis sliding block and a connection board, four linear guide rails are arranged on the rams, and the rams are installed in the middle of the left sliding base and the right sliding base through Z-axis sliding blocks. The middle type design of the movement components in the thermal deformation suppression middle type high-speed crown block gantry five-axis machining center effectively conduct temperature rise generated by movement, so that structural deformation is uniform and influence of thermal deformation on the precision machining of products is reduced. The thermal deformation suppression middle type high-speed crown block gantry five-axis machining center is stable in operation and performance and suitable for precision machining in the automotive die field.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Embedding slice type composite tool and electrochemic mechanical composite processing device and its processing method

InactiveCN101342622AReal-time monitoring of processing statusReduce lossElectric circuitsElectrolysisControl system

The invention relates to an inserted sheet type composite tool and an electrochemical and mechanical composite machining device and a machining method thereof. The composite tool of the invention comprises an inserted sheet and a substrate. The inserted sheet is fixed on the substrate. The composite tool of the invention has the advantages of simple fabrication, easy replacement of the inserted sheet, adjusting the inter-electrode gap and the ratio of the electrolysis area and the grinding area of the machining process by adjusting the geometric parameter of the inserted sheet and the substrate, simultaneously adopting the little grinding particle as possible according to the material to be machined, and consequently achieving the higher surface roughness. The composite machining device of the invention comprises a mechanical movement mechanism, a control system and an electrolyte supply system, wherein the mechanical movement mechanism comprises a mechanism enabling the composite tool to do the self-rotation motion, and a mechanism enabling the composite tool to do the upward and downward, front and back, and left and right motion relative to the workpiece. The machining process of the invention utilizes the principle of electrochemical anode dissolution and the mechanical film scraping to remove the metal. For the difficult-machining material, the machining method has the advantages of small tool loss, high machining efficiency and high machining accuracy.

Owner:GUANGDONG UNIV OF TECH

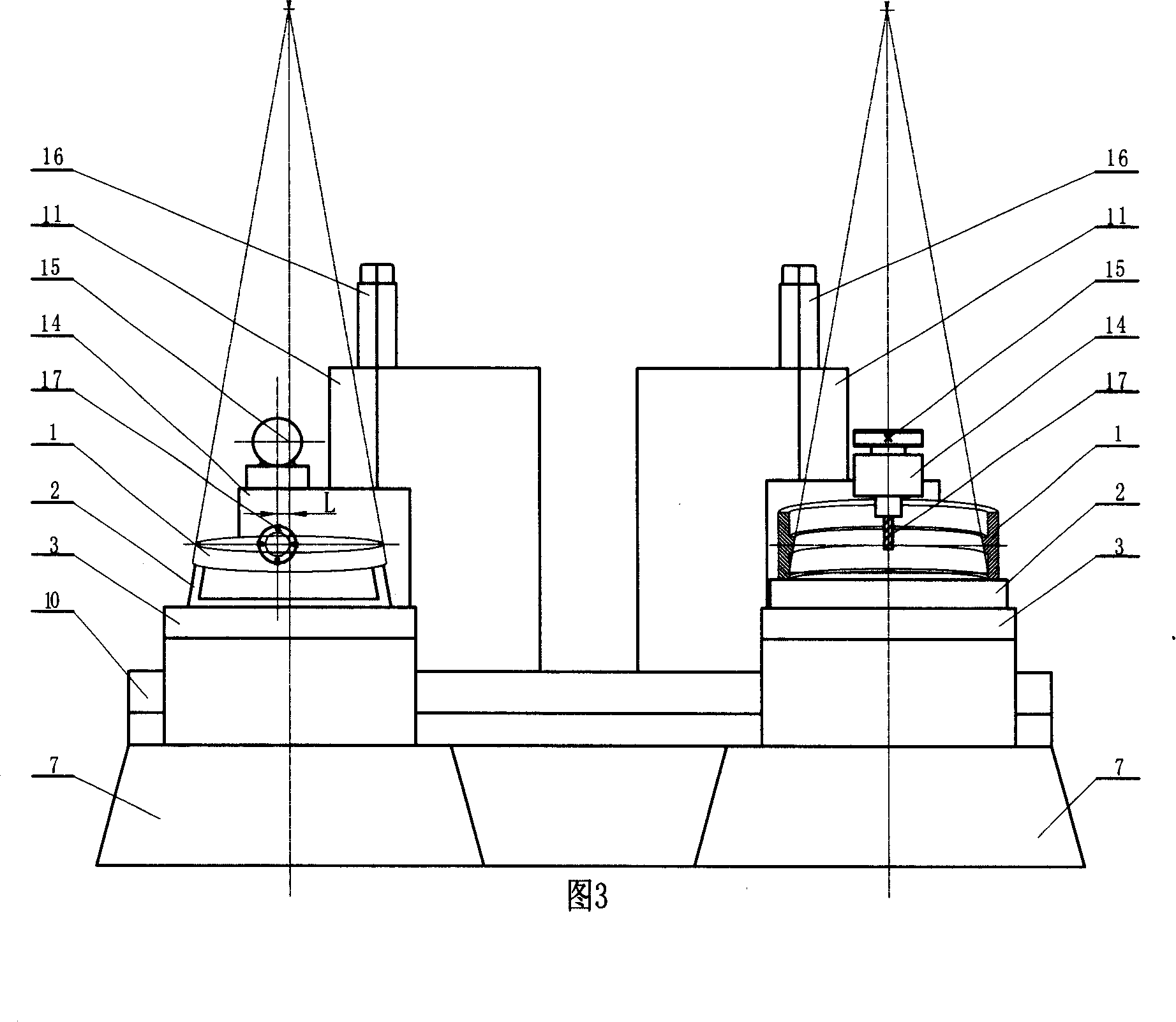

Valve tri-eccentric seal surface milling processing special numerical control combination machine

InactiveCN101200009AGuaranteed straightnessImprove efficiencyMilling machinesMilling equipment detailsControl systemHigh intensity

The invention discloses a special digital combined machine tool in tri-eccentric sealing surface milling a valve; two independent turning worktables can process two workpieces of a butterfly plate and a valve body simultaneously; two milling driving heads are arranged on a base with the same inclination through each own upright column, ensuring the conformability on conicity and accuracy of the workpiece sealing surface of the butterfly plate and the valve body. Because the configuration of the main shaft servo motor realizes high-speed heavy cut and the two axis coupled digital feed control system realizes high intensity continuous milling for inclined cut cone surface at three dimensional direction with automatic precision feeding, the machine tool has simple structure, excellent performance, convenient adjustment and maintenance. Comparing with the common machine tool of the traditional technique, this machine tool not only improves the dimensional processing precision and production efficiency; but also greatly reduces the production cost.

Owner:SHANGHAI MAUD GROUP

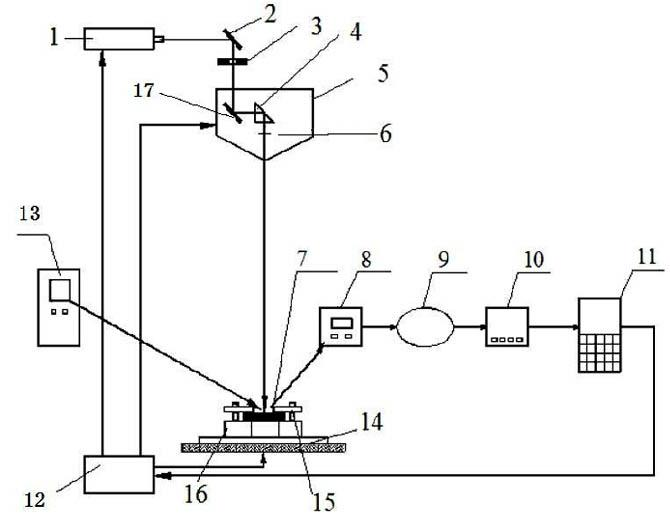

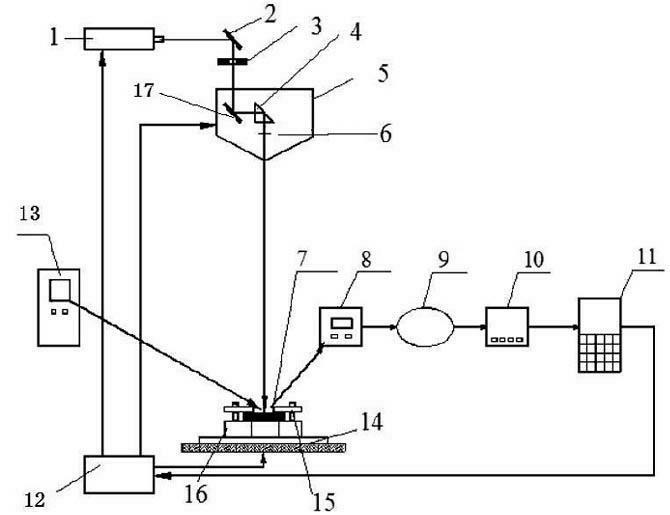

Device and method for laser micro shock dieless forming

The invention discloses a device for laser micro shock dieless forming device. The device comprises a laser, a light path guiding system, a tooling fixture system, a detection system and a control system, wherein laser beams emitted by the laser are transmitted to the surfaces of workpieces, which are arranged in the tooling fixture system and are attached with flexible absorption layers through the light path guiding system; the absorption layers are induced by laser to generate high-temperature and high-voltage plasmas; the plasmas sharply expand and burst to generate strong shock waves to press towards surface layers of the workpieces and internal tissue structures, so that the workpieces are quickly and plastically deformed; the detection system is used for detecting shock regions on the workpieces and transmitting the detected data to the control system; the control system is used for receiving the data, analyzing and calculating the received data, comparing the analyzed and calculated result with the theoretical deformation of the point and acquiring energy required by next laser shock according to the comparison result; in addition, the control system is used for controlling the energy of the laser beams emitted by the laser next time and also controlling the tooling fixture system to do three-dimensional motion towards the next shock position. The device for the laser micro shock dieless forming, which is disclosed by the invention, is suitable for micro forming of materials which are difficult to form or cannot be formed by using a conventional method.

Owner:SUZHOU UNIV OF SCI & TECH

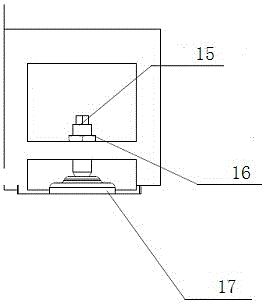

Multi-shaft precision drilling machine tool

InactiveCN103586503ARealize adaptive intelligent controlGuaranteed quality and accuracyPositioning apparatusMetal-working holdersCantileverMachine tool

A multi-shaft precision drilling machine tool comprises a machine frame and a working platform on the machine frame. The multi-shaft precision drilling machine tool is characterized in that the multi-shaft precision drilling machine tool further comprises two to six supports (9), two to six power heads (5), a dividing plate (4), a workpiece clamping mechanism and a drilling and covering clamping mechanism, wherein the supports (9) are fixed on the side portion of the working platform and are provided with sliding grooves, the power heads (5) are installed on the supports, and the dividing plate (4) is installed on the working platform; the workpiece clamping mechanism comprises a chuck (12) and a pressing air cylinder (2), wherein the chuck (12) is installed on the dividing plate (4) and rotates along with the dividing plate (4), and the pressing air cylinder (2) is used for pressing a workpiece (19); the drilling and covering clamping mechanism comprises a cantilever (13), a first holder (15) and a second holder (16), wherein the cantilever (13) can be adjusted in the horizontal direction of the sliding grooves of the supports (9), the first holder (15) is installed at one end of the cantilever (13) and can be adjusted in the transverse direction of the cantilever (13), and the second holder (16) is installed on the first holder (15) and can be adjusted in the vertical direction. The multi-shaft precision drilling machine tool has the advantages of being efficient, strong in rigidity, high in stability and machining precision, wide in application range and the like.

Owner:DALIAN MIX FLUID ENG & TECH

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

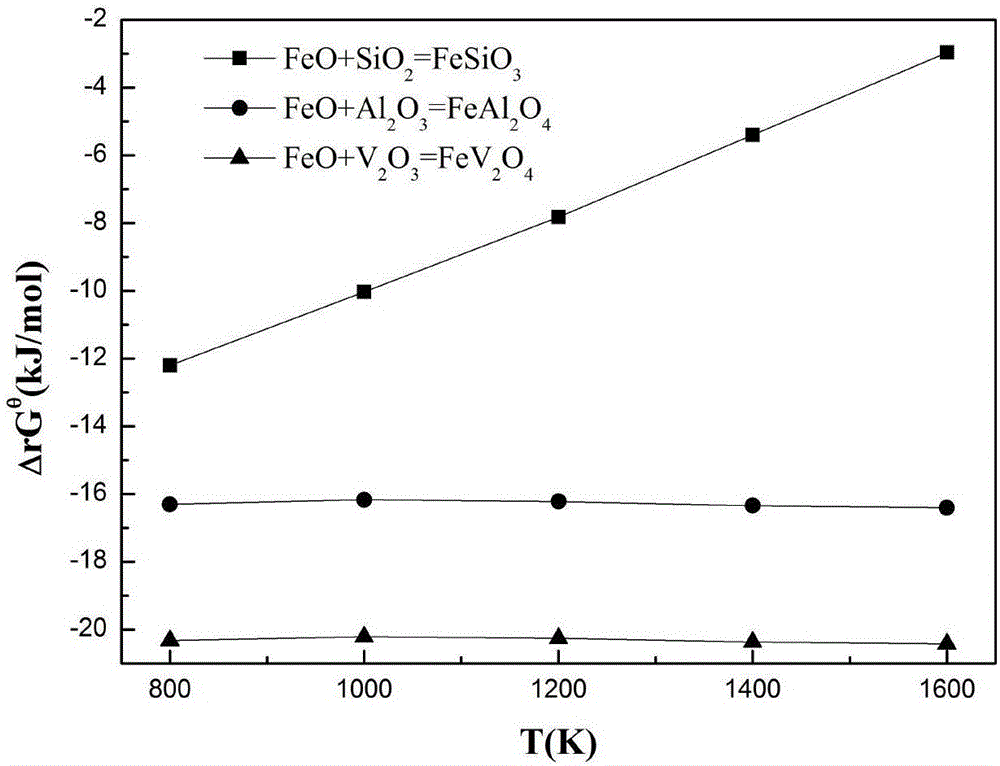

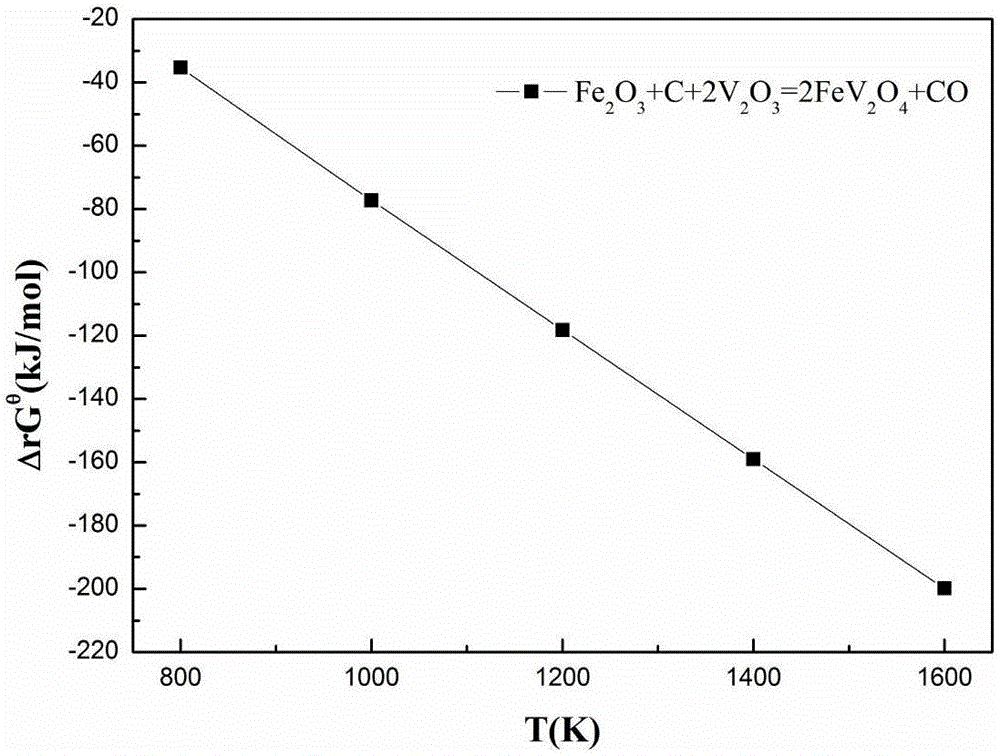

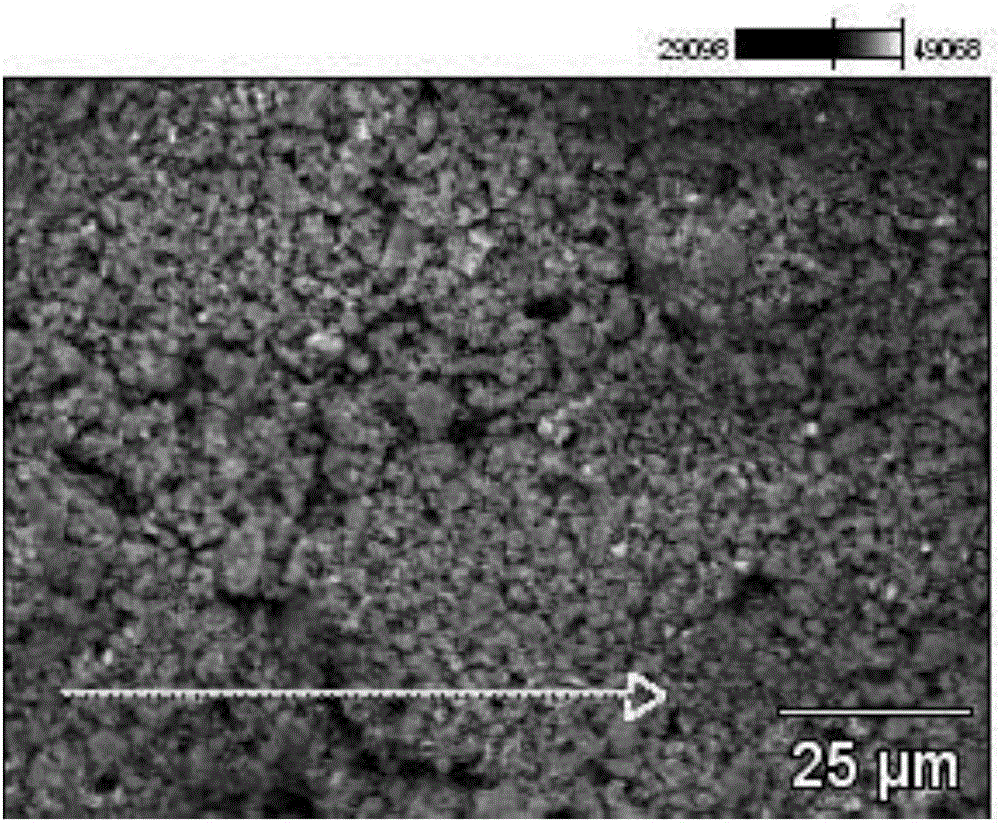

Method for enrichment of vanadium in vanadium-containing stone coal and V-concentrating phase regulation

The invention relates to a method for enrichment of vanadium in vanadium-containing stone coal and V-concentrating phase regulation. The method includes: taking stone coal vanadium ore as the raw material, using Fe2O3 and carbon powder as the additives; carrying out crushing and mixing to obtain pellets, performing roasting at a temperature of 900-1100DEG C so as to obtain a V-concentrating phase composed of Fe, V and O in stone coal. The method is characterized in that: (1) vanadium is enriched into the V-concentrating phase composed of Fe, V and O by a high temperature chemical process, and compared with the conventional physical beneficiation method, the enrichment efficiency is higher; (2) the adding amount of carbon powder can be adjusted according to the carbon content of stone coal, the adaptability is good, and the treatment scope is wider; and (3) by changing the roasting conditions, V-concentrating phase regulation can be realized. The method provided by the invention not only can the V-concentrating phase with high vanadium content and particle size suitable for subsequent separation, but also can control the V-concentrating phase, has the advantages of wide application range and high enrichment efficiency, and is suitable for application in the technical field of vanadium preconcentration in vanadium-containing stone coal.

Owner:UNIV OF SCI & TECH BEIJING

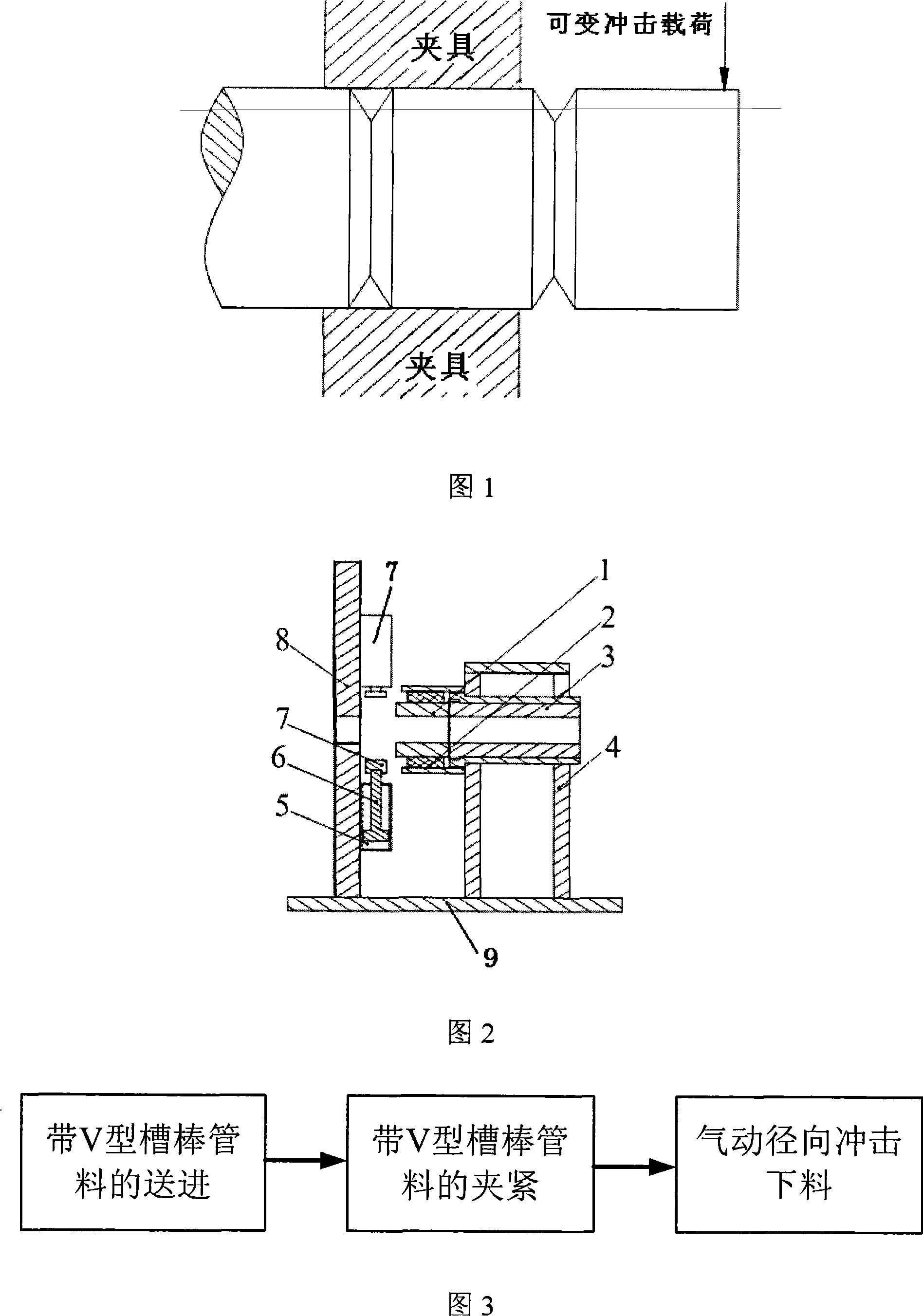

Bar stock pneumatic radial impact blanking method with high-efficiency and precision

The invention discloses a bar stock pneumatic radial impact high-efficiency precise blanking method. In the method, the bar stock is arranged on a pneumatic radial impact precise blanking device and the main working parts of the blanking device comprise a blanking sleeve, an elastic pad sleeve, a bar stock fixing sleeve, an impact cylinder, a piston and a blanking die. The impact cylinder works sequentially under the control of a control system and drives the blanking die to load the bar stock along the radial direction continuously; cracks are extended from the surface of the bar stock along the radial direction to the center of the circle by a fatigue breaking device of the bar stock, thus achieving the blanking and gaining good quality of the profile.

Owner:XI AN JIAOTONG UNIV

Digitally controlled multifunctional sewing machine

InactiveCN1932115ASimple mechanical structureEasy to operateSewing-machine control devicesControl systemElectric machinery

The digitally controlled multifunctional sewing machine belongs to the field of automatic sewing apparatus technology. The digitally controlled multifunctional sewing machine includes mainly one sewing machine body with control system on the working platform and motor, one X-Y skid platform mechanism and one presser foot mechanism. The X-Y skid platform mechanism consists of one Y skid platform pedestal with Y guide track, one Y skid platform motor with Y transmission mechanism, one Y skid platform connected to the Y transmission mechanism, one X skid platform motor with X transmission mechanism, one X skid platform connected to the X transmission mechanism, etc. The presser foot mechanism consists of one outer presser foot, presser foot, cylinder and other part. The digitally controlled multifunctional sewing machine can grasp fabric and move fabric automatically for sewing.

Owner:绍兴县奇功数控机械有限公司

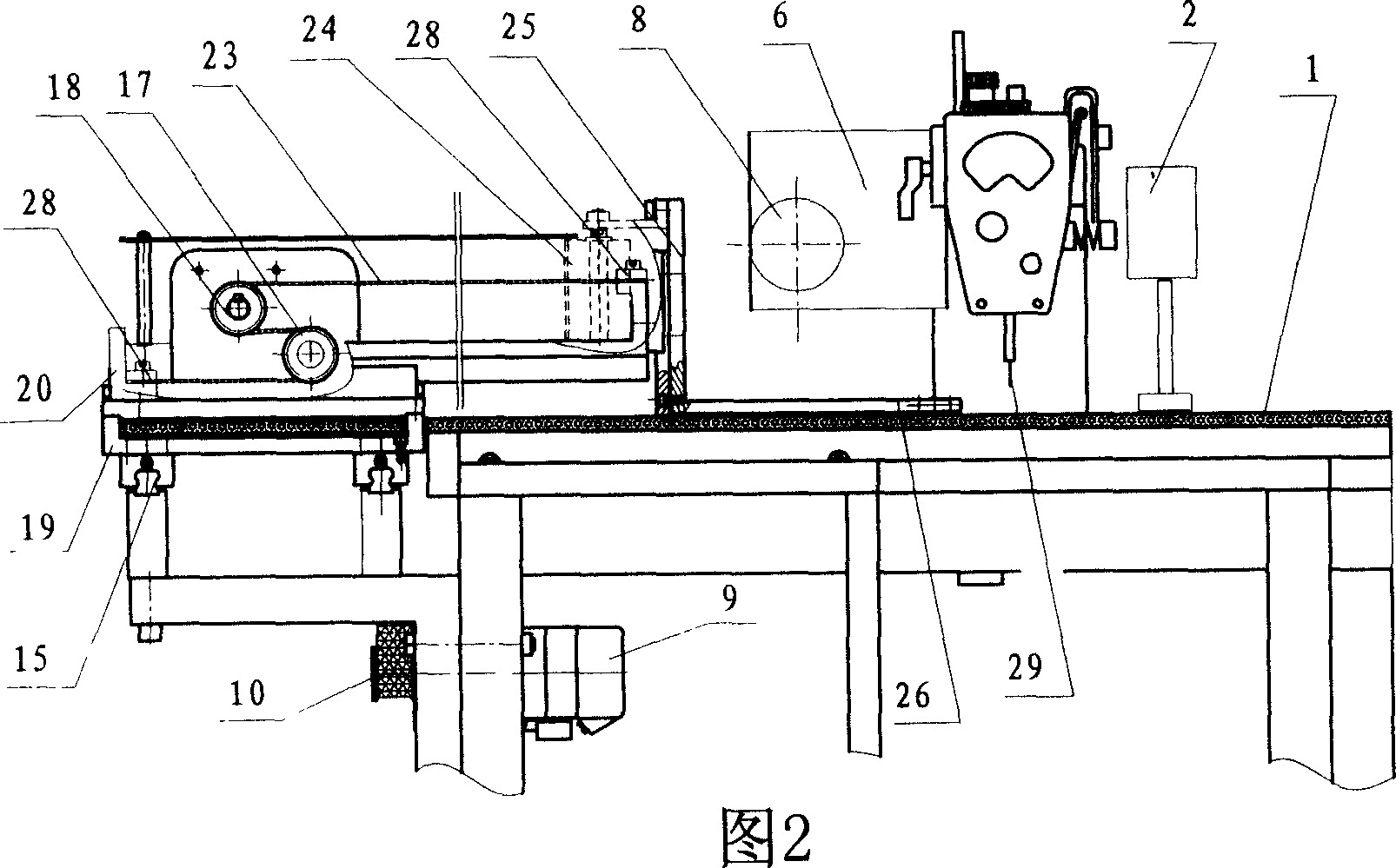

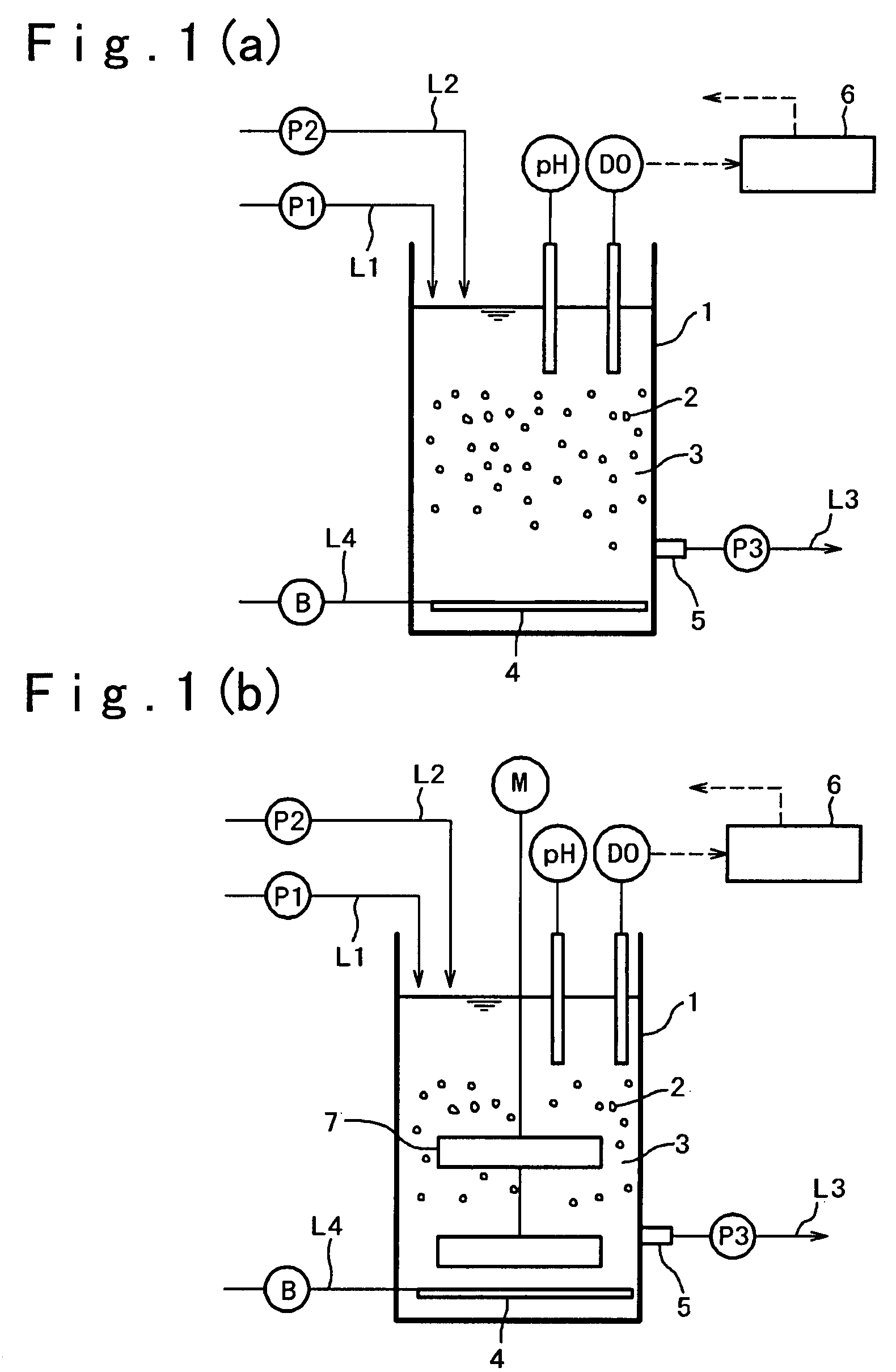

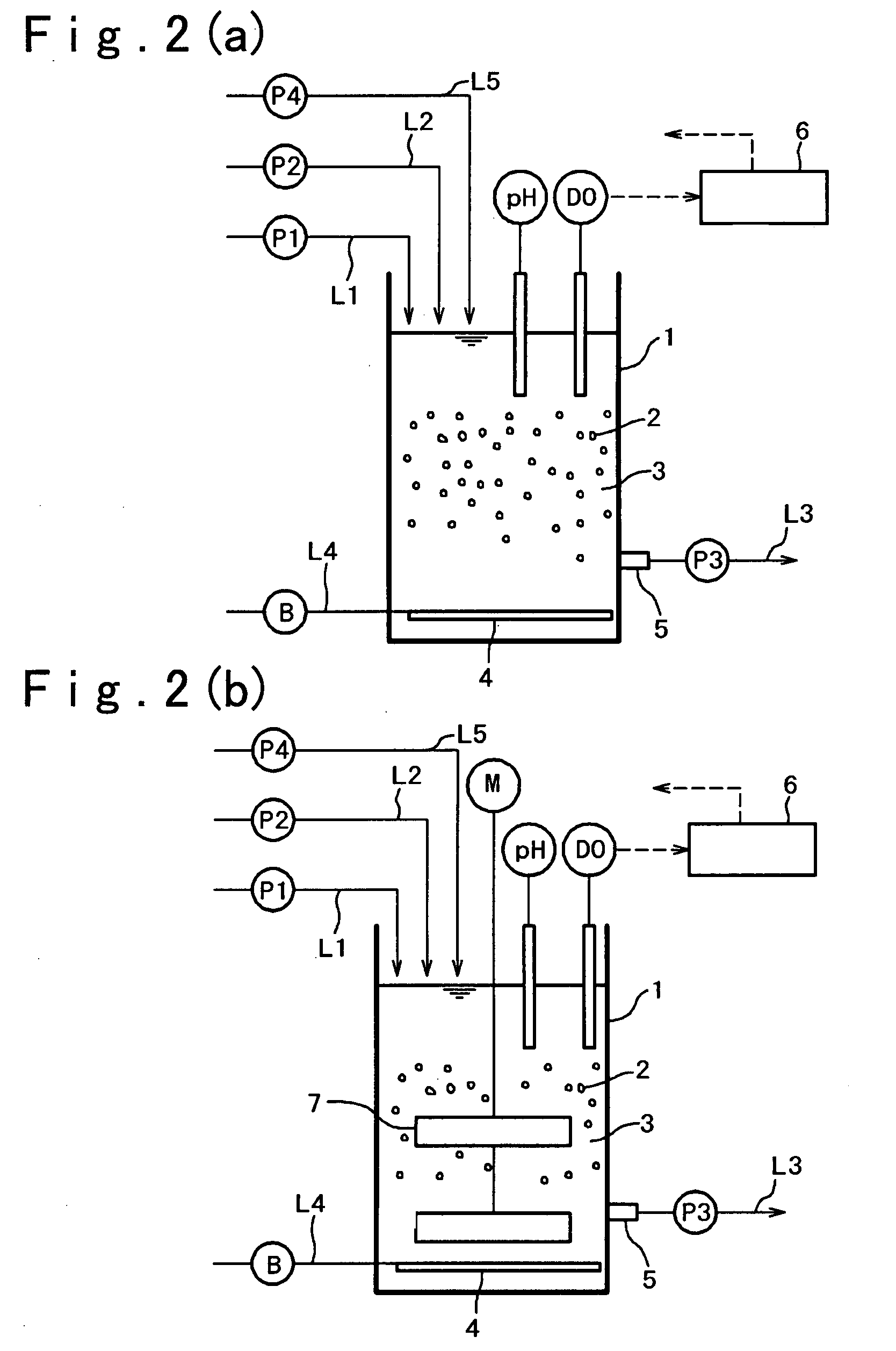

Process and Apparatus for Treating Nitrogeneous Liquor

InactiveUS20080245730A1Easy to controlImprove water qualitySemi-permeable membranesWater treatment parameter controlSludgeAmmonia-oxidizing bacteria

A process and apparatus for treating an aqueous nitrogeneous liquor by performing ammonia oxidation and denitrification using a biosludge comprising anammox bacteria and ammonia-oxidizing bacteria, which process and apparatus can serve to obtain treated liquor of high water quality at a high treating efficiency and a high yield of ammonium nitrogen removal with easy control of supply rate of oxygen-containing gas. The technique comprises the steps of charging a reaction vessel having stored therein a biosludge comprising anammox bacteria and ammonia-oxidizing bacteria present as a suspension with a definite amount of the liquor to be treated, supplying thereto an oxygen-containing gas at a rate not obstructing growth of the anammox bacteria to thereby cause ammonia oxidation of ammonium nitrogen into nitrite nitrogen by the ammonia-oxidizing bacteria and denitrification by the anammox bacteria simultaneously, or performing the denitrification in steps by charging the reaction vessel with a part amount of one treating batch of the liquor to be treated, whereupon supply of the oxygen-containing gas is stopped and the reaction liquor is replenished with the rest amount of the liquor to be treated. The supply of the oxygen-containing gas is stopped at a point of time at which the observed value of dissolved oxygen concentration or of ORP of the reaction liquor in the reaction vessel changes abruptly.

Owner:KURITA WATER INDUSTRIES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com