Fibers and fabrics made from ethylene/ alpha-olefin interpolymers

A technology of olefin interpolymers and interpolymers, applied in fabrics, fiber processing, filament/thread forming, etc., can solve problems such as difficult manufacturing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0247] where T x Is the preparation ATREF elution temperature (preferably expressed in K (Kelvin)) of the i fraction, P X is the ethylene mole fraction of fraction i, which can be measured by NMR or IR as described above. P AB is the ethylene mole fraction of the bulk ethylene / α-olefin interpolymer (before fractionation), which can also be measured by NMR or IR. T A and P A is the ATREF elution temperature and ethylene mole fraction of the pure "hard segment" (which refers to the crystalline segment of the interpolymer). If the actual value of the "hard segment" is not available, then as a first approximation, T A and P A Values are set to those of high density polyethylene homopolymer. For the calculations performed in this application, T A is 372°K, P A it's 1.

[0248] T AB are of the same composition and have P AB ATREF temperature of random copolymers of ethylene mole fractions. T AB can be calculated from the following equation:

[0249] Ln P AB =α / T A...

Embodiment

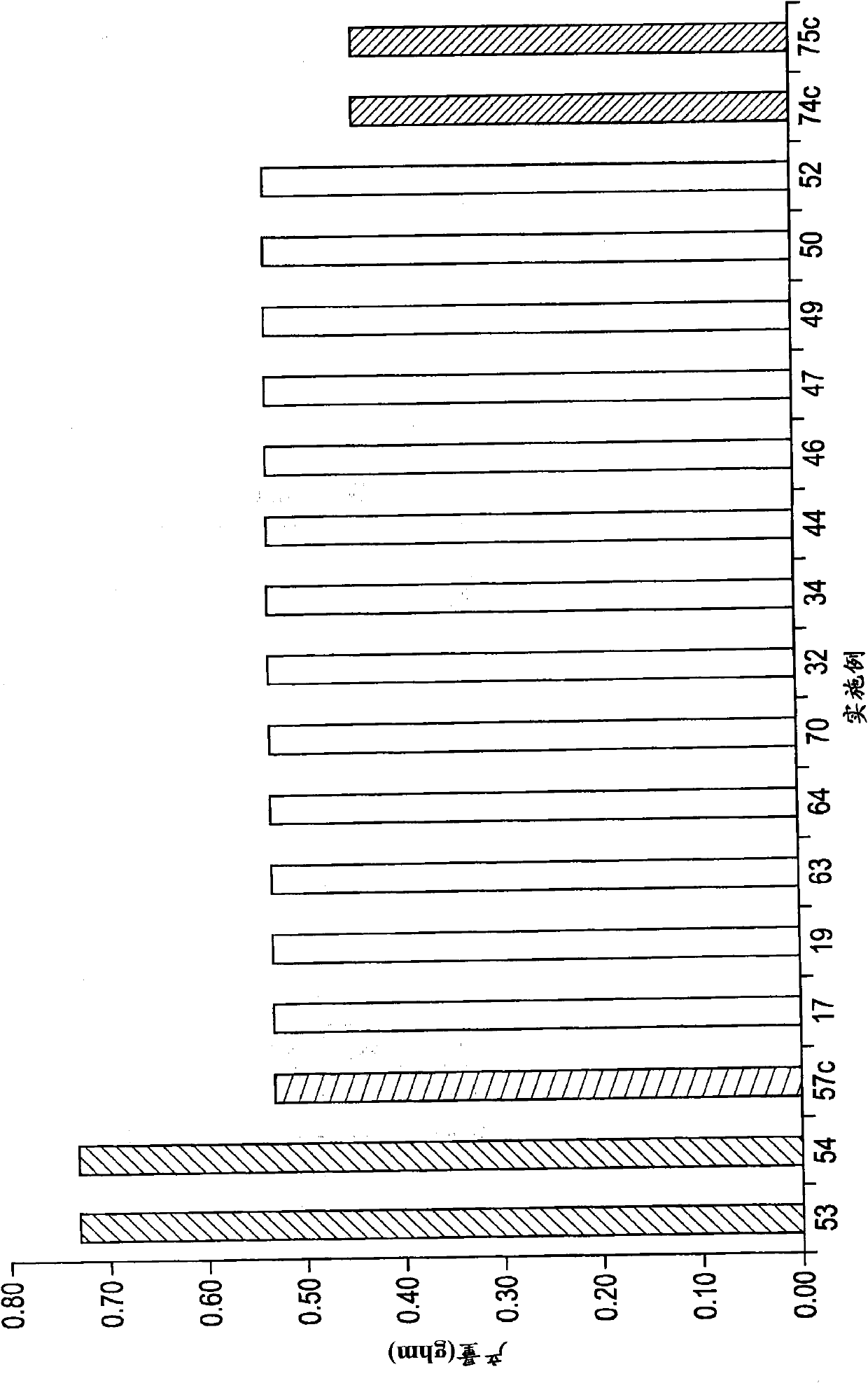

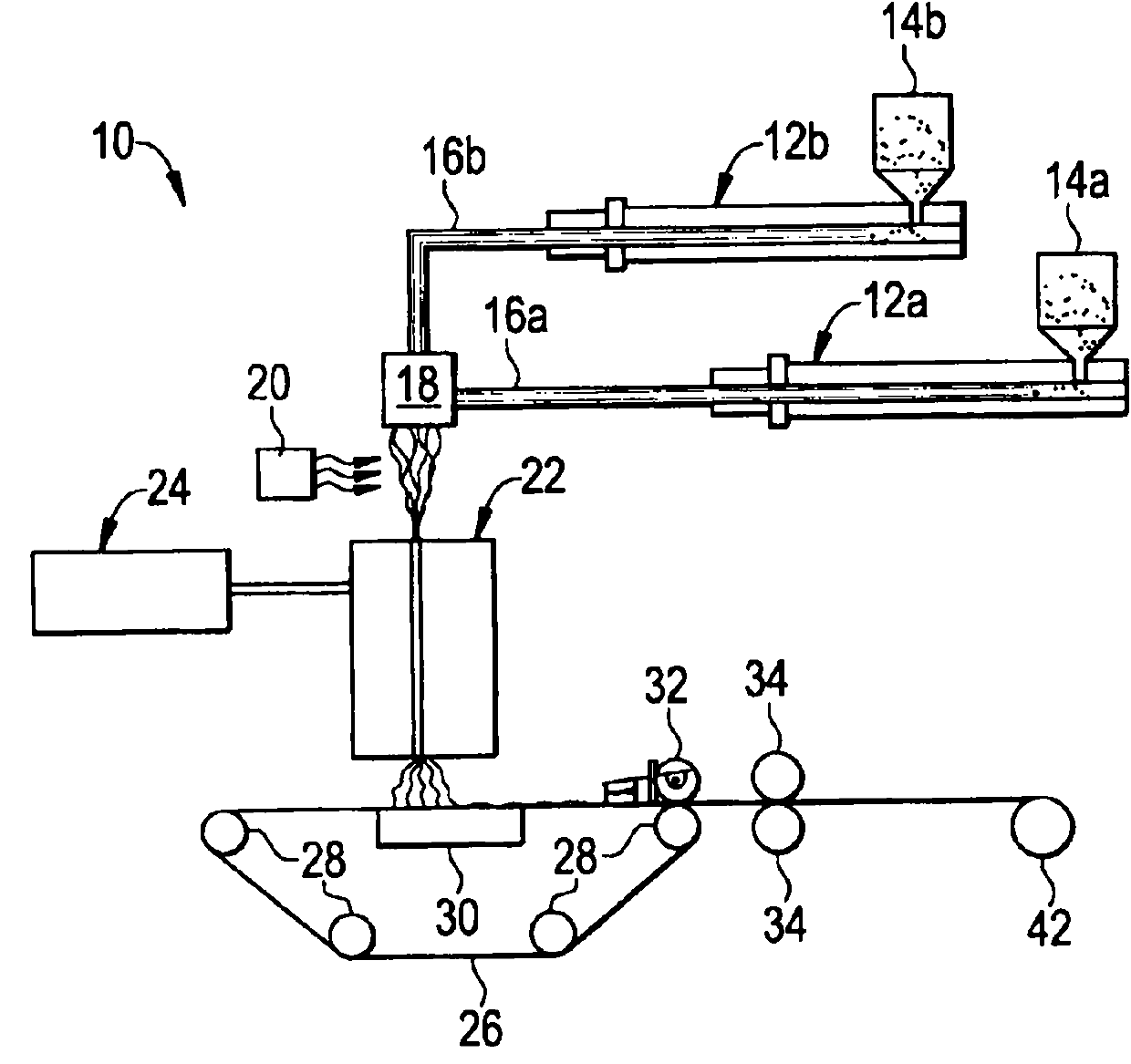

[0415] Spunbond nonwoven fabric samples consisting of Examples 1 through 81c in Table IV, Table V, and Table VI were prepared using Reicofil's Reicofil 4 spunbond technology. The technology consists of a 1.2 meter wide spunbond line with two independent extruders providing a bicomponent spin beam configuration and a separate spin pump for each extruder.

[0416] Spunbond nonwovens are manufactured by melting the polymer via an extruder maintained at a constant pressure of 60 bar, into a melt pump that delivers the melt frontward to a polymer melt die A spin beam consisting of dies for delivering a homogeneous melt to a distribution plate and spinnerets under constant pressure. The spinneret design in this test had 6827 holes per meter, a hole diameter of 0.6mm and an L / D ratio of 4. Yields are 0.44ghm to 0.72ghm and fiber deniers are 1.6denier to 2.2denier.

[0417] Molten polymer exits the spinneret (6827 fibers per meter) and is then accelerated drawn via air streams to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com