Method for enrichment of vanadium in vanadium-containing stone coal and V-concentrating phase regulation

A technology of vanadium-containing stone coal and enrichment phase is applied in the field of vanadium pre-enrichment, which can solve the problems of low recovery rate of vanadium, and achieve the effects of low pollution, good adaptability and wide treatment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to verify the feasibility of the present invention, the content of the present invention will be further described with examples below, but the content of the present invention is not limited to the following embodiments. Simple modifications made according to the essential content of the present invention should all fall within the protection scope of the present invention.

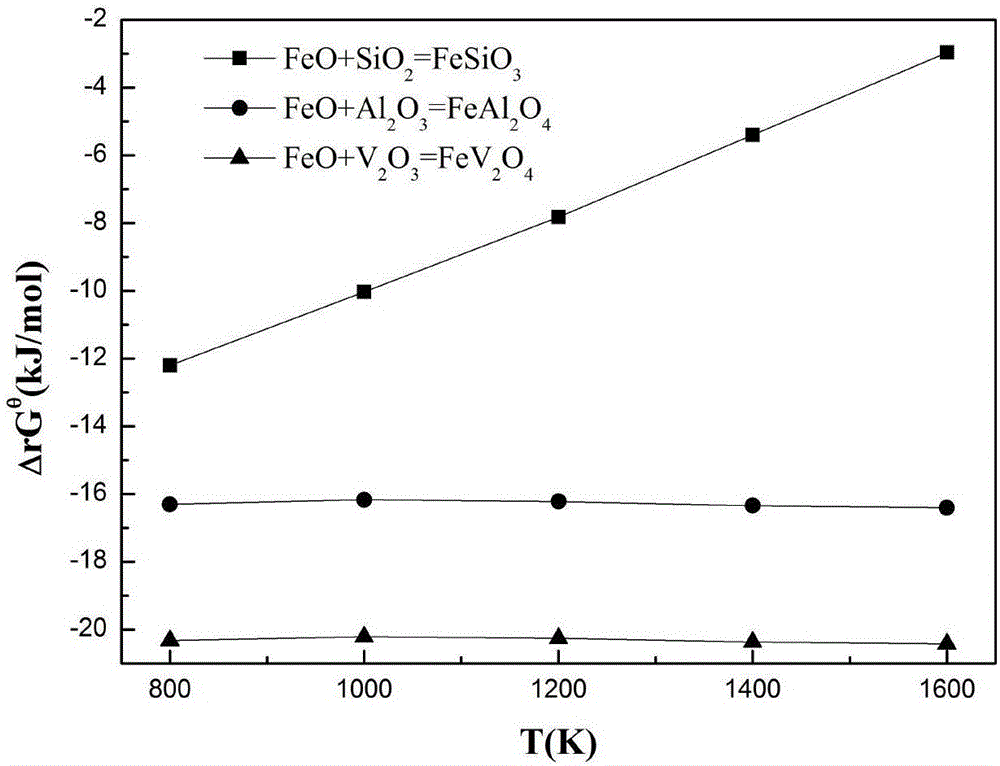

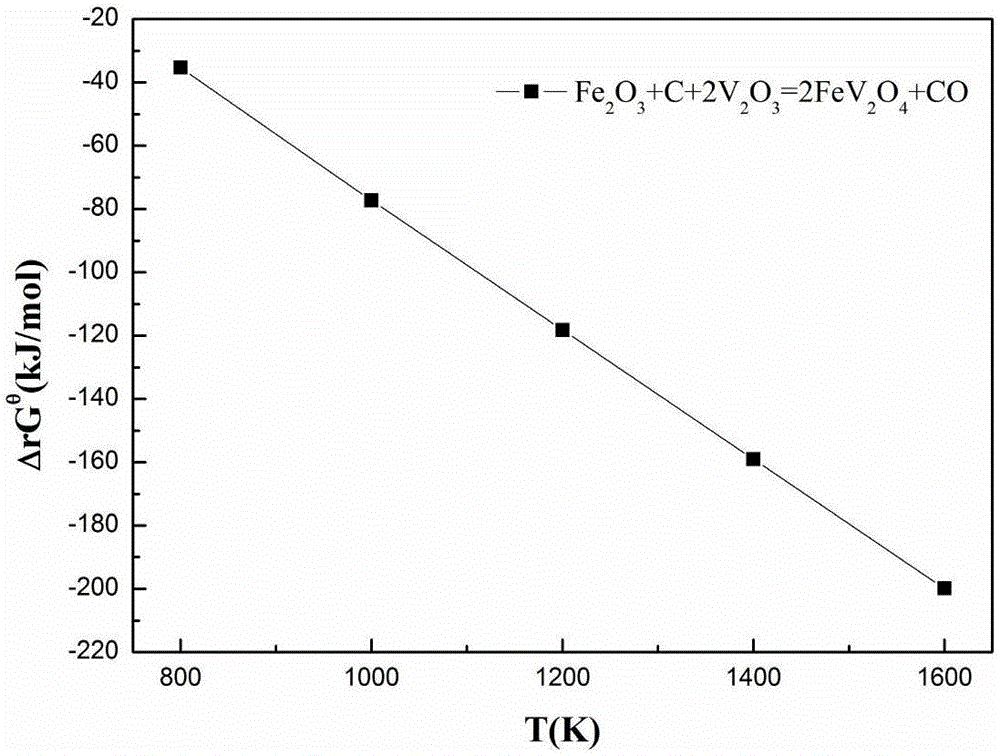

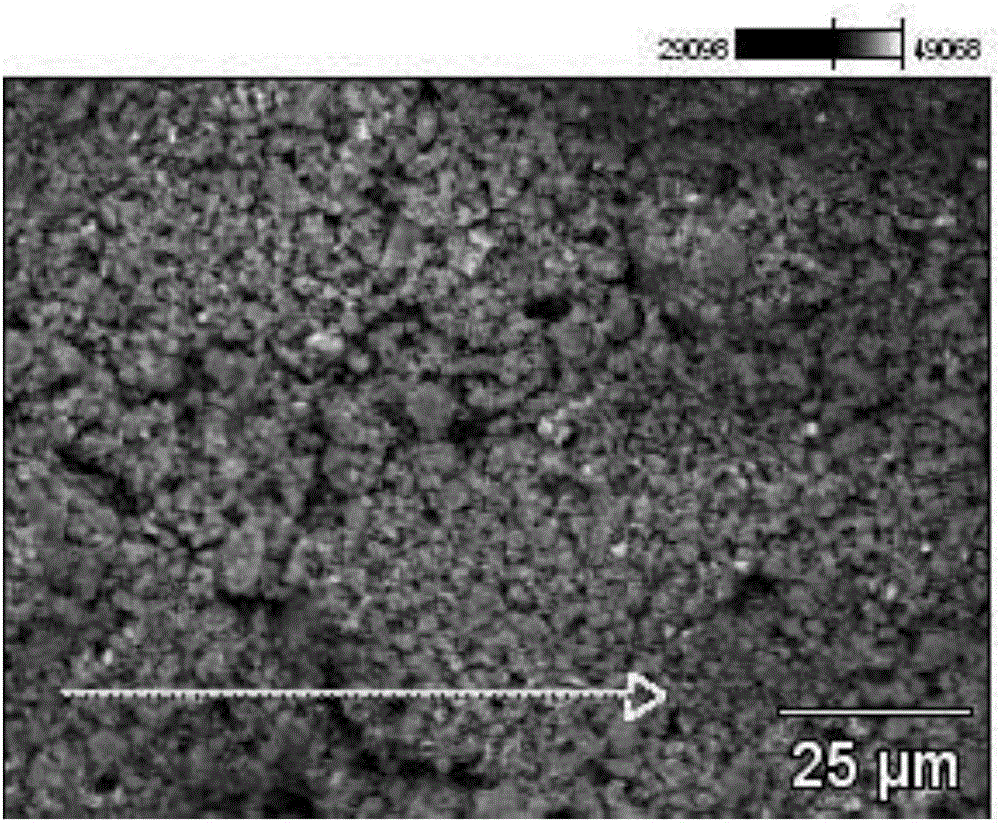

[0033] The raw material selected in this example is a vanadium-containing stone coal mine in Yichang, Hubei. The content of vanadium in the ore is about 0.5% to 0.7%, vanadium is mainly distributed in mica minerals, and mica minerals account for about 20% to 30% of the minerals. The content of C in the ore is 5.75%, of which 5.02% is in the form of carbonate, and amorphous carbon only accounts for 0.73%, and it is in close symbiosis with the quartz in the ore. The calculation from reaction (5) shows that when the mass of vanadium-containing stone coal added is x(g), the added Fe 2 O 3 The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com