High-precision five-shaft multi-dimensional ultrasonic polishing device

A polishing device, high-precision technology, applied in the direction of grinding/polishing equipment, surface polishing machine tools, grinding machine parts, etc., can solve the problems of increased surface roughness, particle layering, precipitation, low productivity, etc. Achieve the effects of increasing residence time, increasing removal efficiency, and improving effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

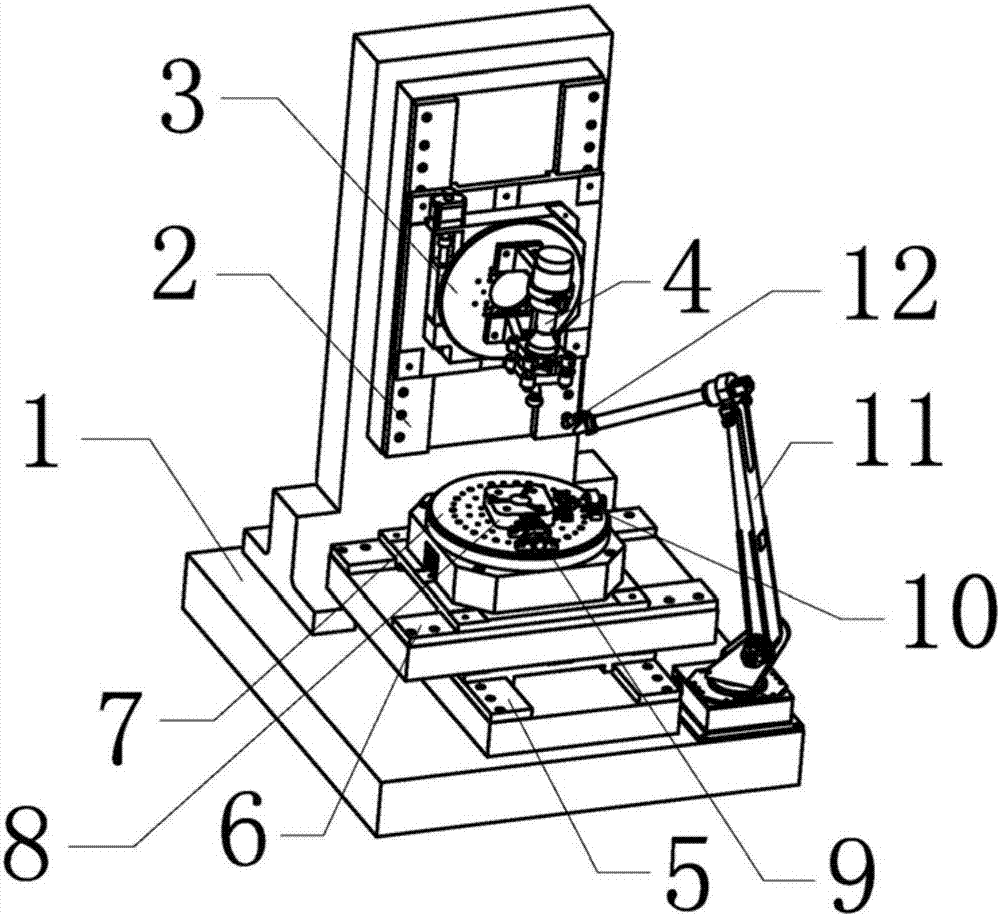

[0038] A high-precision five-axis multi-dimensional ultrasonic polishing device, the high-precision five-axis multi-dimensional ultrasonic polishing device includes an L-shaped base 1;

[0039] The top of the L-shaped base 1 is provided with a vertical guide rail 2, and the vertical guide rail 2 is provided with a vertical turntable 3, and the vertical turntable 3 can move up and down on the vertical guide rail 2. The vertical rotary table 3 is provided with a polishing tool head vibrator assembly 4;

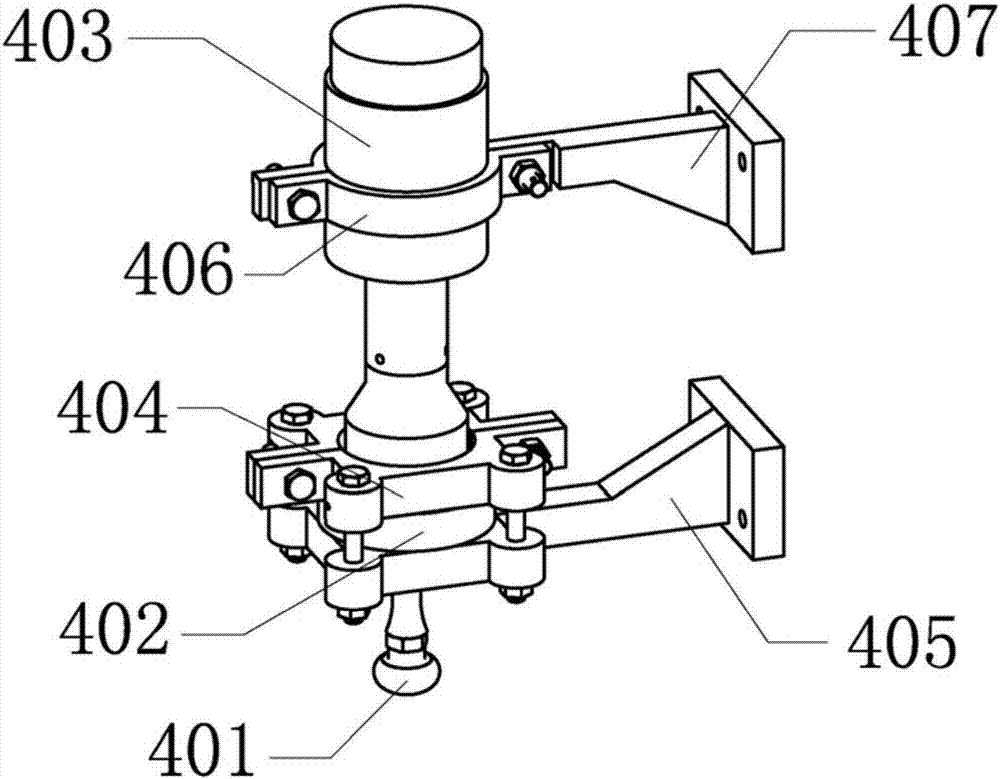

[0040] The polishing tool head vibrator assembly 4 includes a polishing tool head 401, an ultrasonic horn III 402, and an ultrasonic transducer III 403, and one end of the ultrasonic horn III 402 is connected to the polishing tool head 401 through a stud and a lock nut , the other end of the ultrasonic horn III402 is connected to the ultrasonic transducer III403,

[0041]The vibration node of the ultrasonic horn III 402 is fixed on the four-ear composite flange 404, the four-ea...

Embodiment 2

[0048] The method of using the high-precision five-axis multi-dimensional ultrasonic polishing device described in Example 1 is as follows:

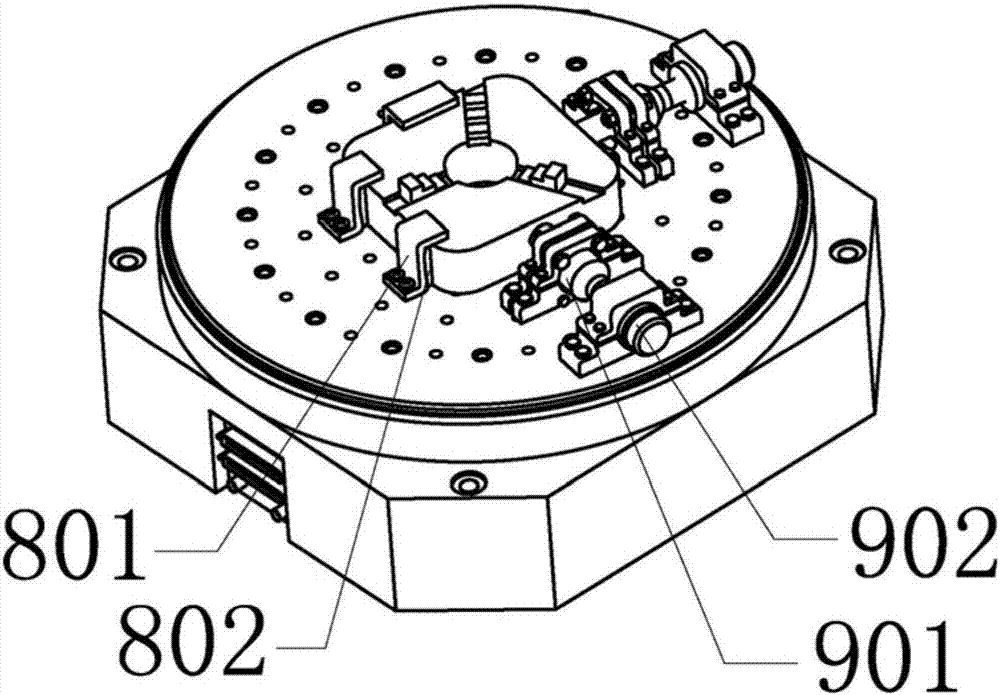

[0049] For a specific processing object, first use the 8 jaws of the workpiece fixture to position and clamp the workpiece, then adjust the polishing tool head 401 to the specified pressure, and at the same time adjust the ultrasonic atomizing nozzle 12 to the specified position, and then convert the set path into a numerical control The code is input into the numerical control system, the machine tool is turned on, and the machine tool moves in a five-axis linkage manner. The ultrasonic atomizing nozzle 12 tracks the position of the polishing tool head 401 and evenly sprays the polishing liquid to perform efficient polishing operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com