Polyvinyl alcohol/high amylose biodegradable material and melting preparation method thereof

A high-amylose and biodegradable technology, which is applied in the field of melt preparation of polyvinyl alcohol/high-amylose biodegradable composite materials, can solve the problems of difficult to meet the market demand, poor mechanical properties of starch, unsatisfactory mechanical properties, etc., and achieve good Processability and biodegradability, low crystallinity, and obvious plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

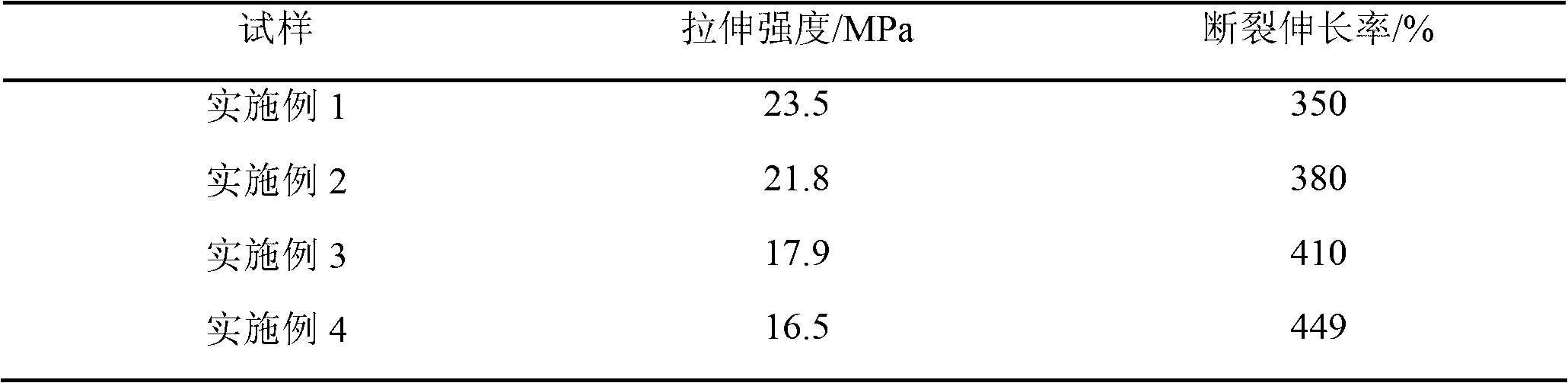

[0030] Mix 85 parts of PVA1788 and 15 parts of high amylose starch, 0.3 parts of zinc stearate, 0.3 parts of calcium stearate, and 1.5 parts of modified montmorillonite in a high-speed mixer at 70-100 °C for 20 minutes, Then add 10 parts of dihydroxyacetone, 20 parts of diethanolamine and 0.5 part of liquid paraffin, mix in a high-speed mixer at 70-85°C for 20 minutes, cool to room temperature and extrude and granulate in a twin-screw extruder. The temperature is 130-190°C, and the screw speed is 210 rpm.

[0031] The measured tensile strength of the composite material sample is 23.5MPa, and the elongation at break is 350%. The soil burial method is used for its degradation test, and the period is 4 months, and the weight loss rate of the material is 37%.

Embodiment 2

[0033] Mix 80 parts of PVA1788, 20 parts of high amylose starch, 0.2 parts of zinc stearate, 0.2 parts of calcium stearate, and 1 part of nano silicon dioxide in a high-speed mixer at 70-100 ° C for 20 minutes at high speed, and then add 10 parts of a Diglycerol, 20 parts of diethanolamine, and 0.5 parts of PE wax were mixed in a high-speed mixer at 70-85°C for 15 minutes. The mixture is extruded and granulated in a twin-screw extruder, the barrel temperature is 130-190° C., and the screw speed is 240 rpm.

[0034] The tensile strength of the composite sample was measured to be 21.8MPa, and the elongation was 380%. The degradation experiment was carried out by soil burial method, the period was 4 months, and the weight loss rate of the material was 43%.

Embodiment 3

[0036] Mix 70 parts of PVA1788, 30 parts of high amylose starch, 0.4 parts of zinc stearate, and 2 parts of modified montmorillonite in a high-speed mixer at 70-100°C for 15 minutes, then add 20 parts of dihydroxyacetone, 10 1 part of diethanolamine and 0.3 part of PE wax are mixed in a high-speed mixer at 90-110°C for 15 minutes at high speed, cooled to room temperature and extruded into pellets in a twin-screw extruder with a barrel temperature of 130-190°C and a screw speed of 220 rpm.

[0037] The measured tensile strength of the composite sample was 17.9MPa, and the elongation was 410%. The degradation experiment was carried out by soil burial method, the period was 4 months, and the weight loss rate of the material was 53%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com