Melting processing method for polyvinyl alcohol composite material

A polyvinyl alcohol, melt processing technology, applied in the processing field of polyvinyl alcohol composite materials, can solve the problem of not meeting the thermal stability requirements of polyvinyl alcohol melt processing, affecting the stability and structure of blown film processing, and using water as a plasticizer Poor thermal stability and other problems, to achieve obvious plasticizing effect, good appearance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

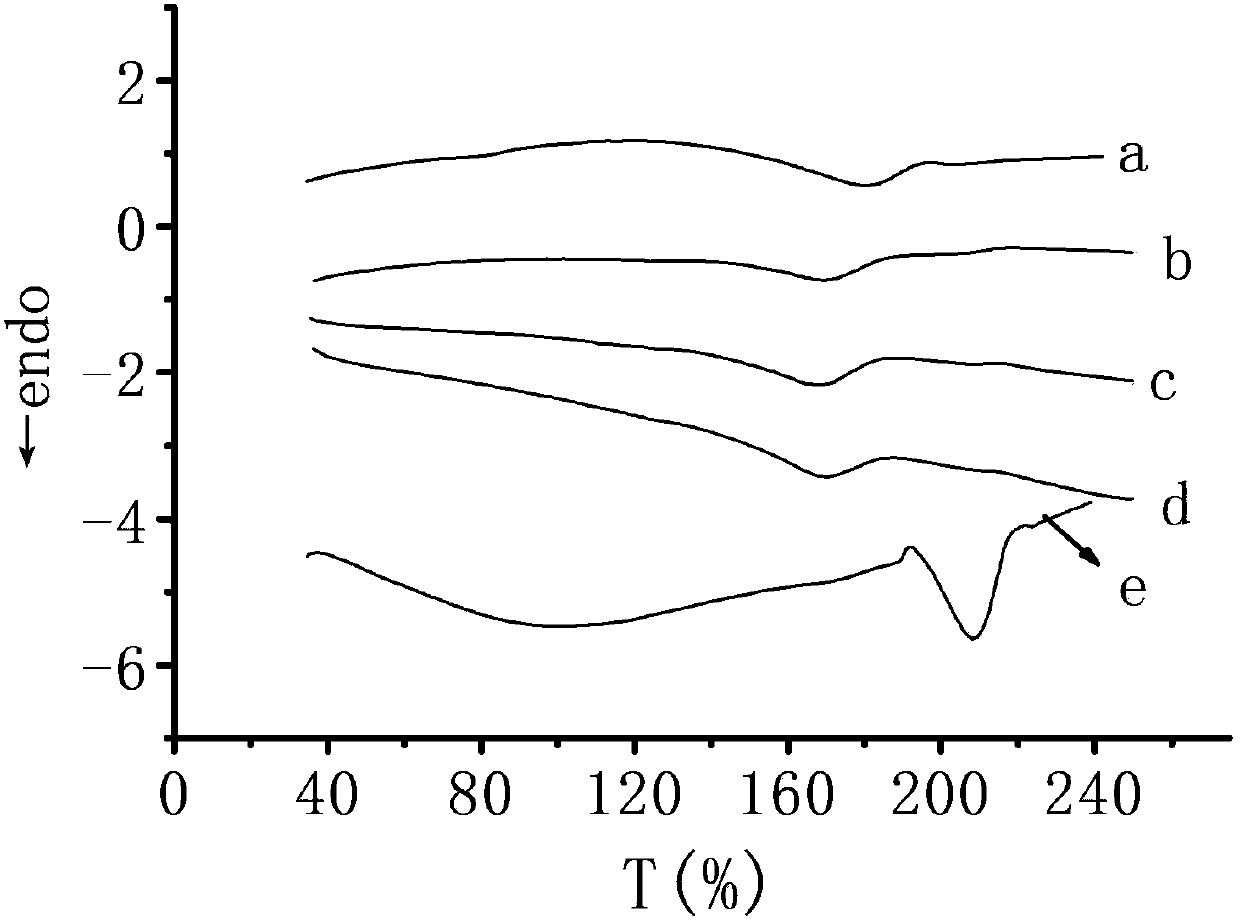

Image

Examples

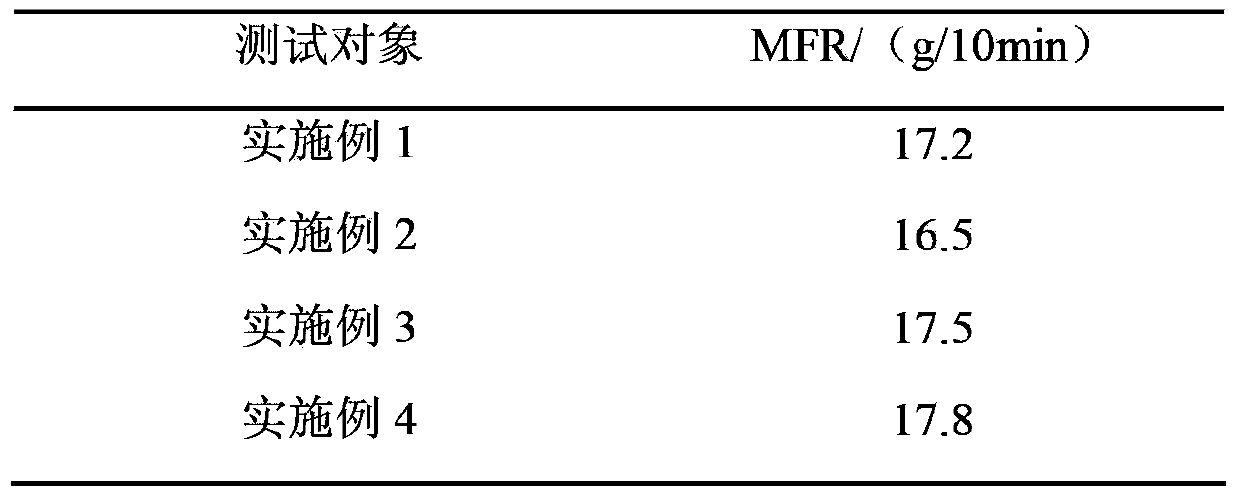

Embodiment 1

[0023] Mix 70 parts by mass of PVA1788 and 30 parts by mass of PVA0588 in a high-speed mixer at 70-100°C for 5 minutes, then add 20 parts by mass of dihydroxyacetone and mix at 80-120°C for 10 minutes, then add 5 parts by mass of glycerin and 0.5 parts by mass of liquid paraffin, mixed in a high-speed mixer at 70-85 ° C for 10-20 minutes, cooled to room temperature, extruded and pelletized in a twin-screw extruder, the barrel temperature is 130-200 ° C, the screw speed 110 rpm. The extruded pellets are injection-molded in an injection machine, the injection temperature is 170-190° C., and the injection pressure is 60-90 MPa. The measured tensile strength of the PVA composite sample was 28MPa, and the elongation at break was 450%.

Embodiment 2

[0025] Mix 70 parts by mass of PVA1788 and 30 parts by mass of PVA0588 in a high-speed mixer at 70-95°C for 5 minutes at high speed, then add 5 parts by mass of glycerin and 15 parts of 2-hydroxyacetamide and mix in a high-speed mixer at 70-120°C After 10-20 minutes, add 5 parts by mass of dihydroxyacetone and 1 part by mass of liquid paraffin and mix in a high-speed mixer at 60-85° C. for 10 minutes at high speed. The mixture is extruded and granulated in a twin-screw extruder, the barrel temperature is 130-200° C., and the screw speed is 150 rpm. Finally, the pellets are injection-molded in an injection machine, the injection temperature is 170-190° C., and the injection pressure is 60-90 MPa. The measured tensile strength of the PVA composite sample is 29.8MPa, and the elongation is 380%.

Embodiment 3

[0027] Mix 60 parts by mass of PVA1788 and 40 parts by mass of PVA0588 in a high-speed mixer at 70-95°C for 5 minutes, then add 20 parts by mass of dihydroxyacetone and mix in a high-speed mixer at 90-110°C for 10 minutes. Then add 5 parts by mass of 2-hydroxyacetamide, 0.5 parts by mass of dimethyl silicone oil and mix at 70-115°C for 10-15 minutes, cool to room temperature and extrude into pellets in a twin-screw extruder, the barrel temperature is 130- 200°C, the screw speed is 130 rpm. Finally, the pellets are injection-molded in an injection machine, the injection temperature is 170-190° C., and the injection pressure is 60-90 MPa. The measured tensile strength of the PVA composite sample is 27.9MPa, and the elongation is 450%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com