A Fused Deposition Modeling 3D Printing Method for PVDF with High β Crystal Content

A technology of fused deposition modeling and 3D printing, applied in 3D object support structures, coating devices, manufacturing tools, etc., can solve the problems of inability to realize complex three-dimensional structure construction, no electrical activity, poor molding quality, etc., and achieve low cost , Piezoelectric conversion performance improvement, and the effect of improving the dimensional stability of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

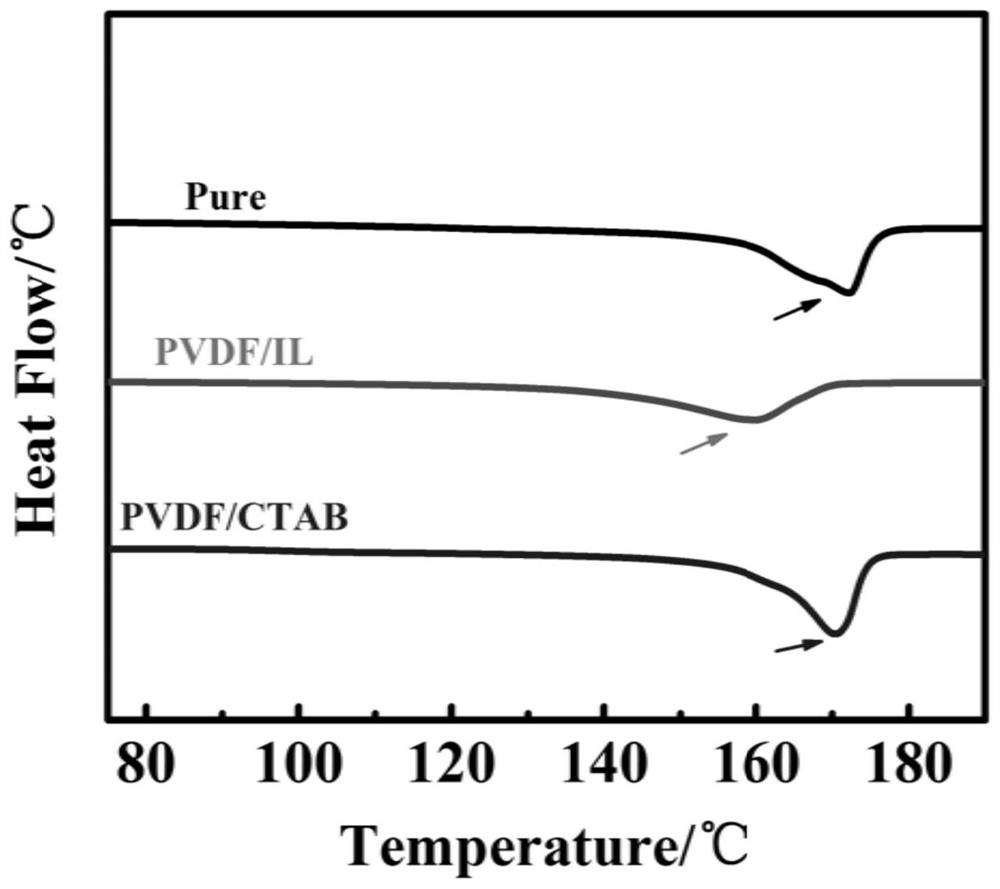

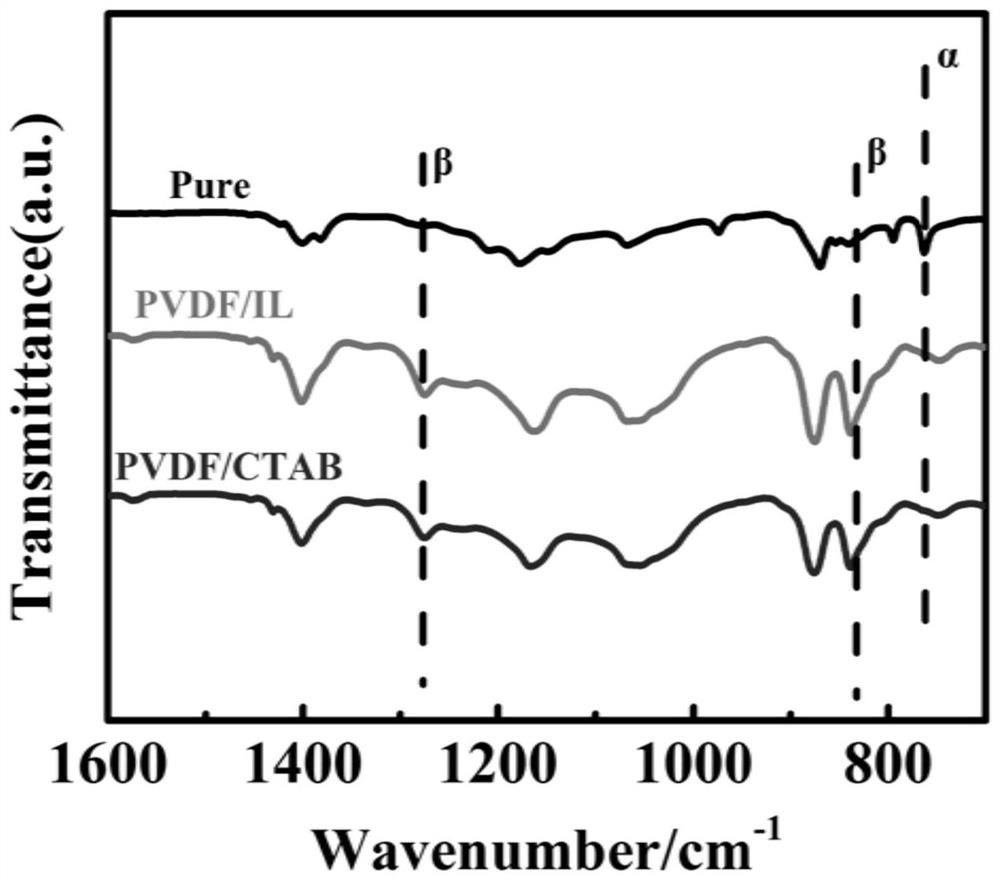

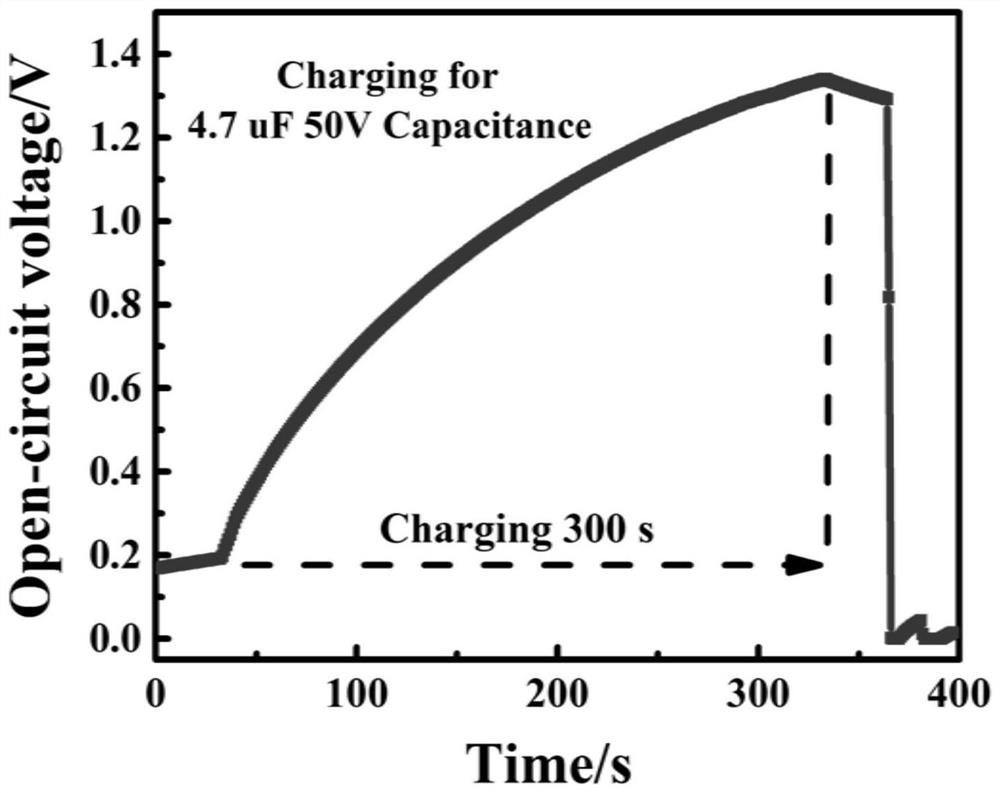

[0037] A preferred embodiment of the present invention provides a fused deposition modeling 3D printing method for PVDF with high β-crystal content, the specific steps are as follows:

[0038] First, 1-ethyl-3-methylimidazolium tetrafluoroborate is evenly dispersed in 250ml of N,N-dimethylformamide (DMF) solvent, and then poured into 100g of PVDF particles, keeping the temperature at 60°C , rotating at 520r / min, stirring for 4 hours until PVDF is completely dissolved in DMF solvent, then baked at 70°C until the solvent is completely removed; then cut into small particles, extruded through a single-screw extruder to obtain filaments, extruder The rotation speed is 22rpm, the temperature is 200°C, and the filament diameter is 1.75mm. During the extrusion process, an adjustable-speed tractor is used for traction and a measuring instrument is used to measure the filament diameter in real time. Finally, the filament is placed into the FDM 3D printer and passed through the printing n...

Embodiment 2

[0040] A preferred embodiment of the present invention provides a fused deposition modeling 3D printing method for PVDF with high β-crystal content, the specific steps are as follows:

[0041] First, evenly disperse 1-methylimidazole nitrate in 250ml of dimethylacetamide (DMAc) solvent, then pour 100g of PVDF particles, keep the temperature at 60°C, rotate at 520r / min, stir for 4h, until the PVDF is completely Dissolve in DMAc solvent, then bake at 75°C until the solvent is completely removed; then cut into small particles, extrude through a single-screw extruder to obtain filaments, the extruder speed is 20rpm, the temperature is 220°C, and the diameter of the filaments is 1.75 mm, during the extrusion process, an adjustable-speed haul-off machine is used for traction and a measuring instrument is used to measure the diameter of the filament in real time. Finally, the filament is placed in the FDM 3D printer and extruded through the printing nozzle according to the preset mode...

Embodiment 3

[0043] A preferred embodiment of the present invention provides a fused deposition modeling 3D printing method for PVDF with high β-crystal content, the specific steps are as follows:

[0044] Firstly, 1-ethyl-3-methylimidazolium diethyl phosphate salt is evenly dispersed in 250ml of dimethyl sulfoxide (DMSO) solvent, and then poured into 100g of PVDF particles, keeping the temperature at 60°C and rotating speed of 520r / min, stirred for 4 hours, until PVDF was completely dissolved in the DMF solvent, and then baked at 65°C until the solvent was completely removed; then cut into small particles, extruded through a single-screw extruder to obtain filaments, the speed of the extruder was 25rpm, and the material The temperature is 240°C and the diameter of the filament is 1.75mm. During the extrusion process, an adjustable-speed tractor is used for traction and the measuring instrument is used to measure the diameter of the filament in real time. Finally, the filament is placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com