Patents

Literature

191results about How to "Fast thermal response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

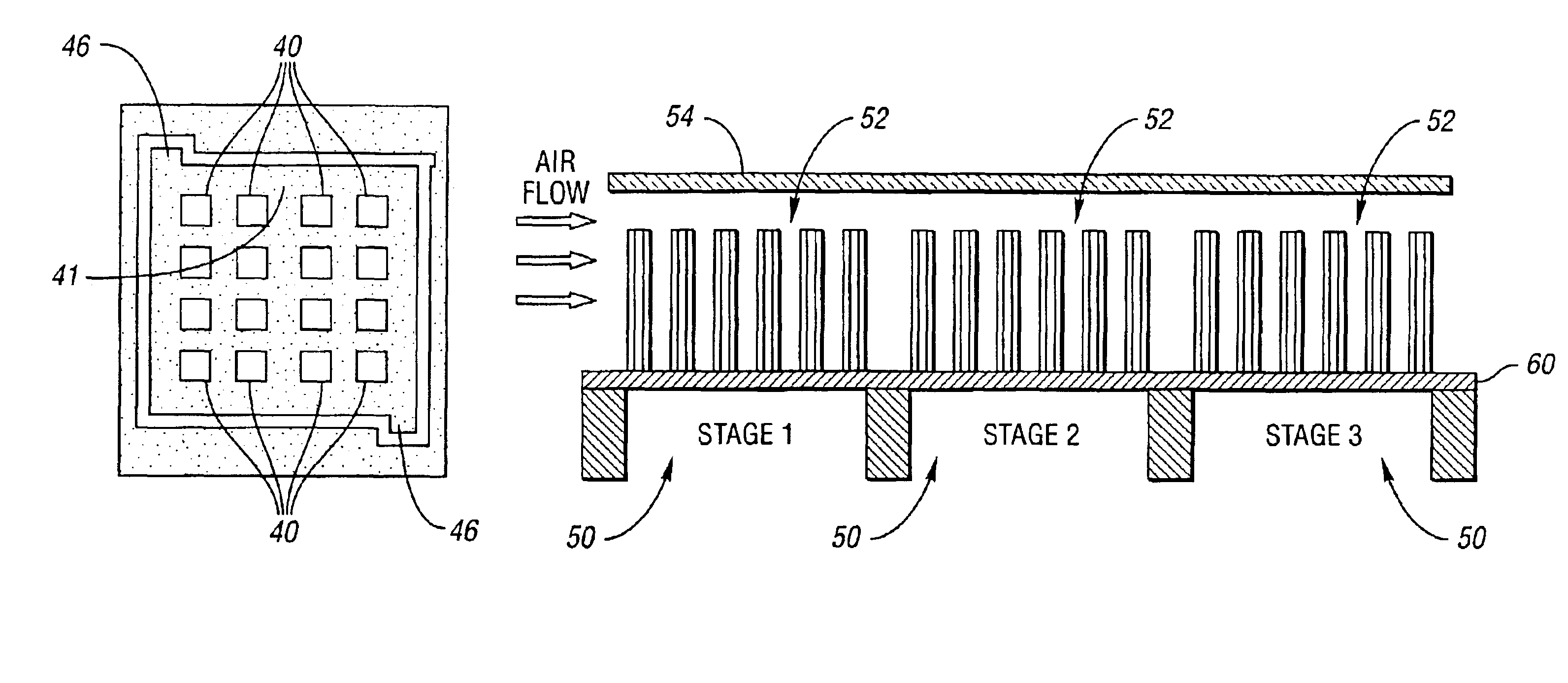

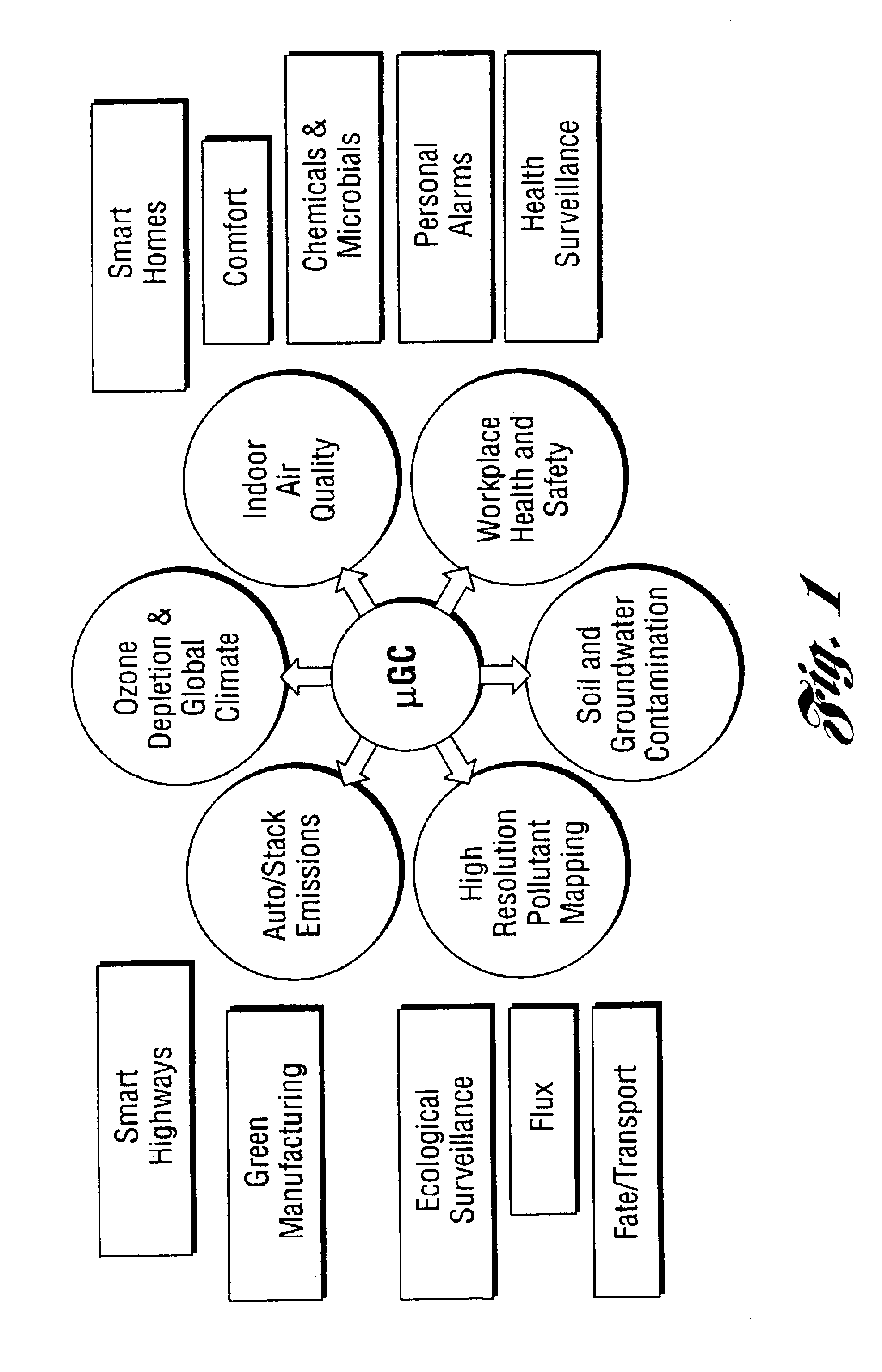

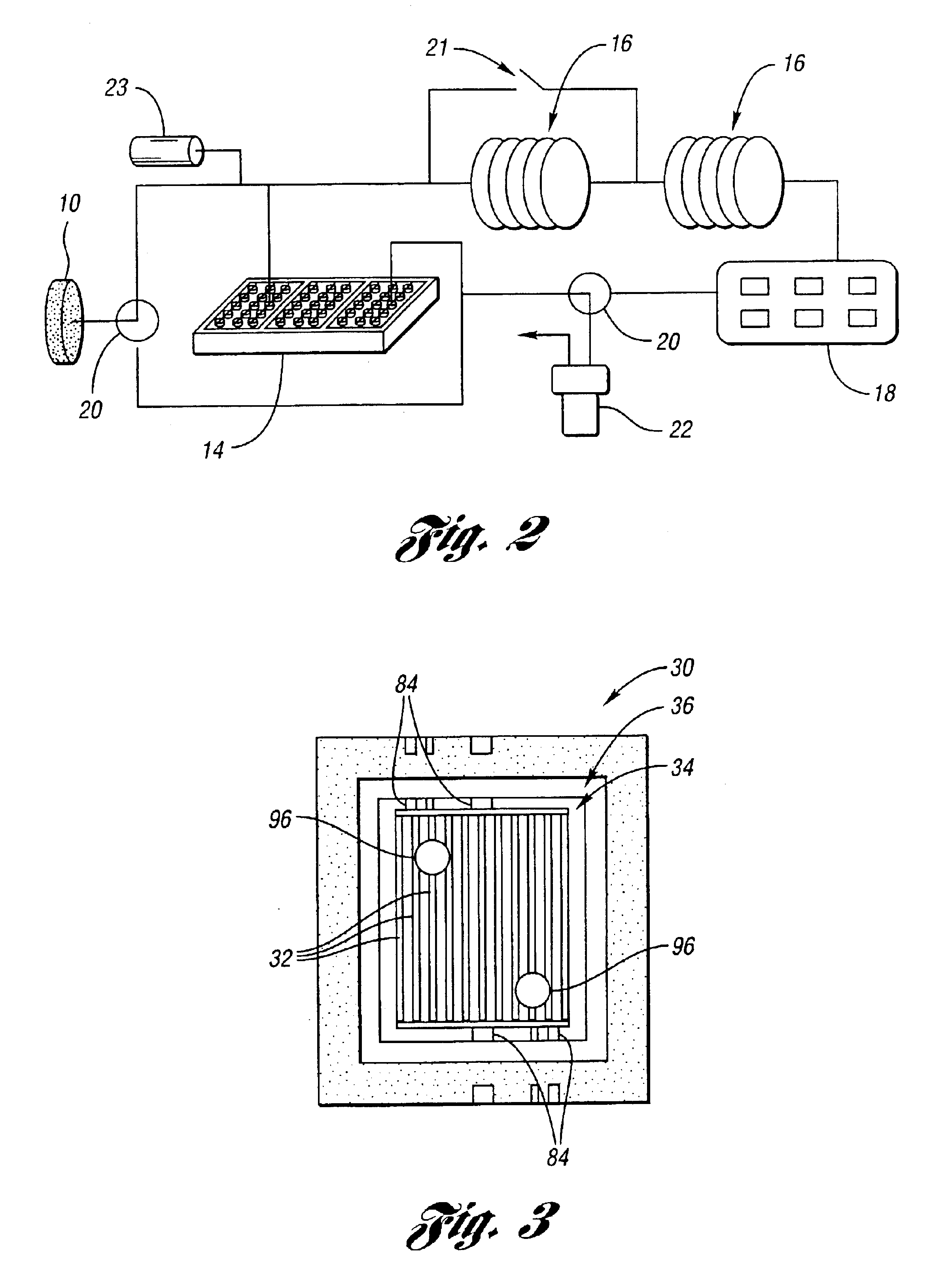

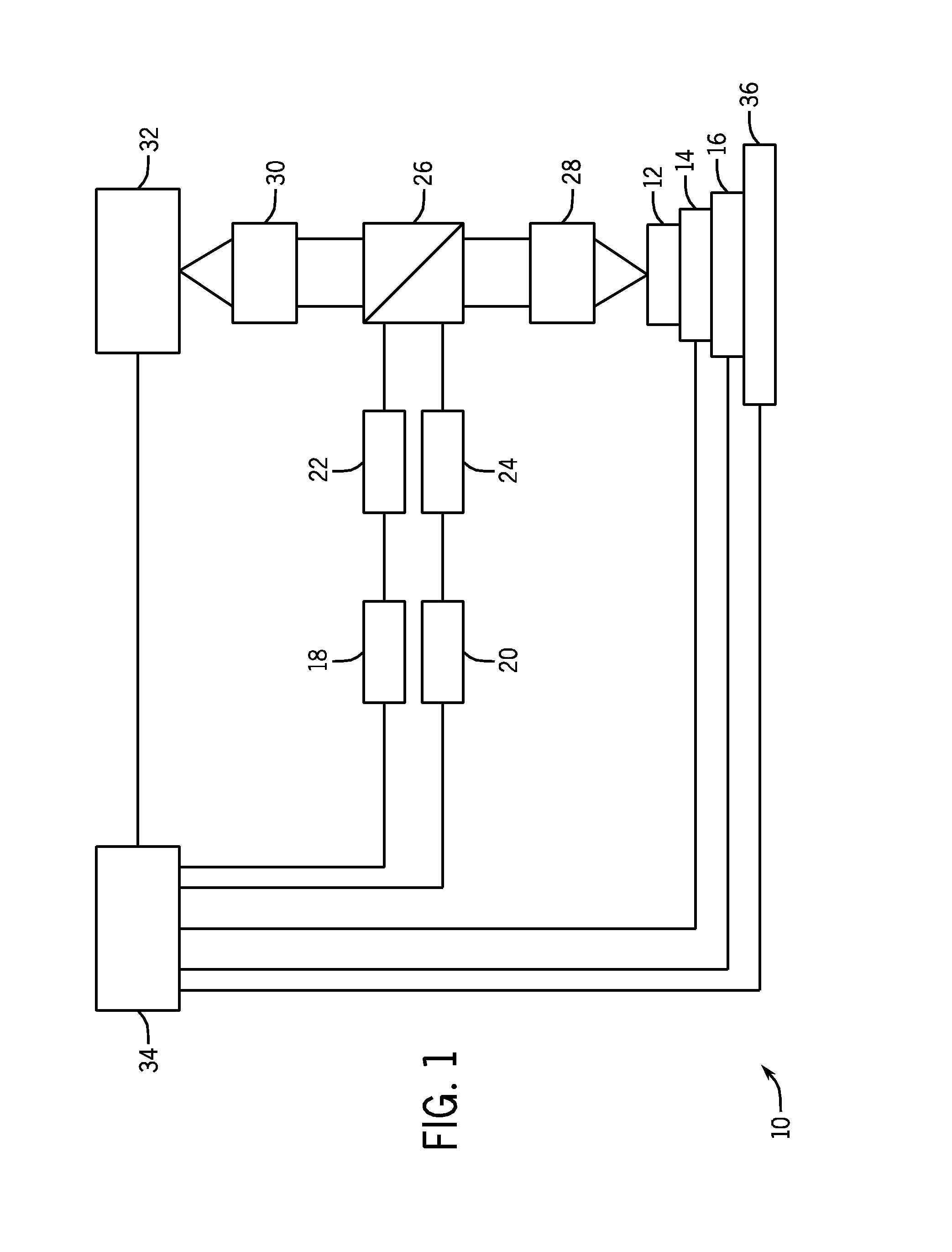

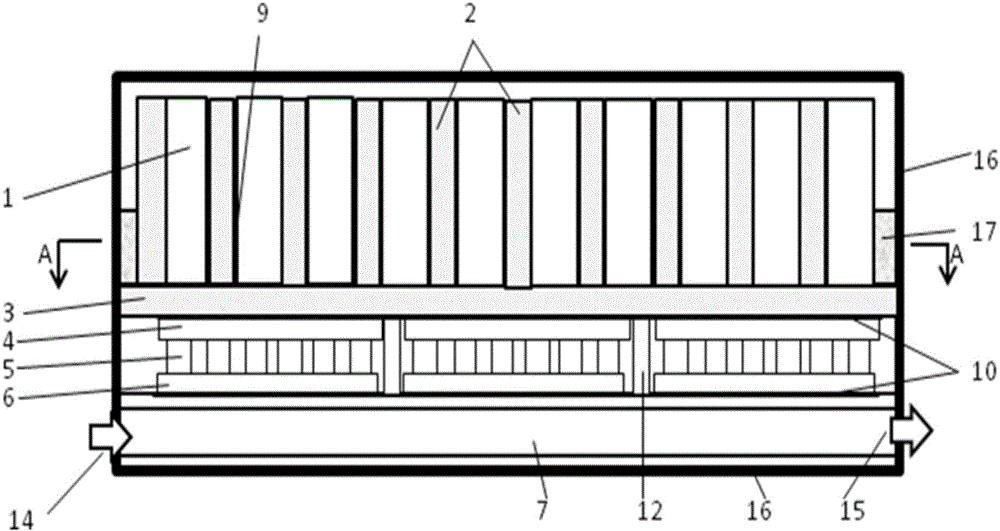

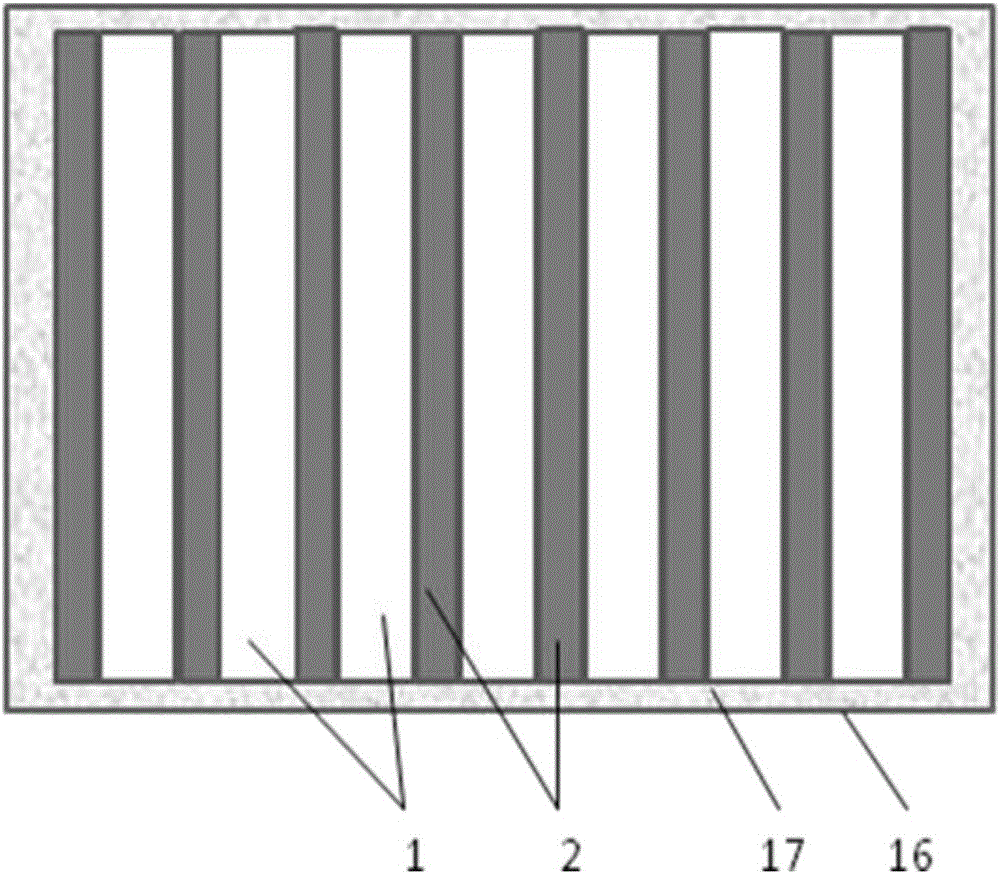

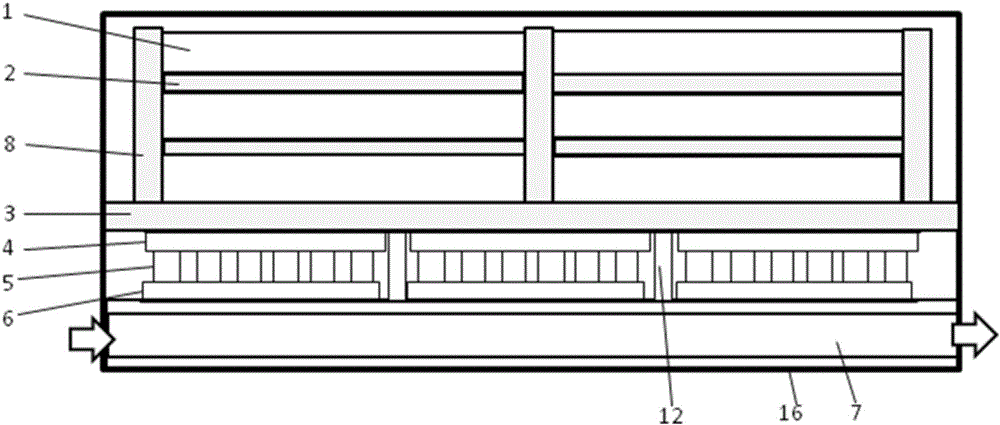

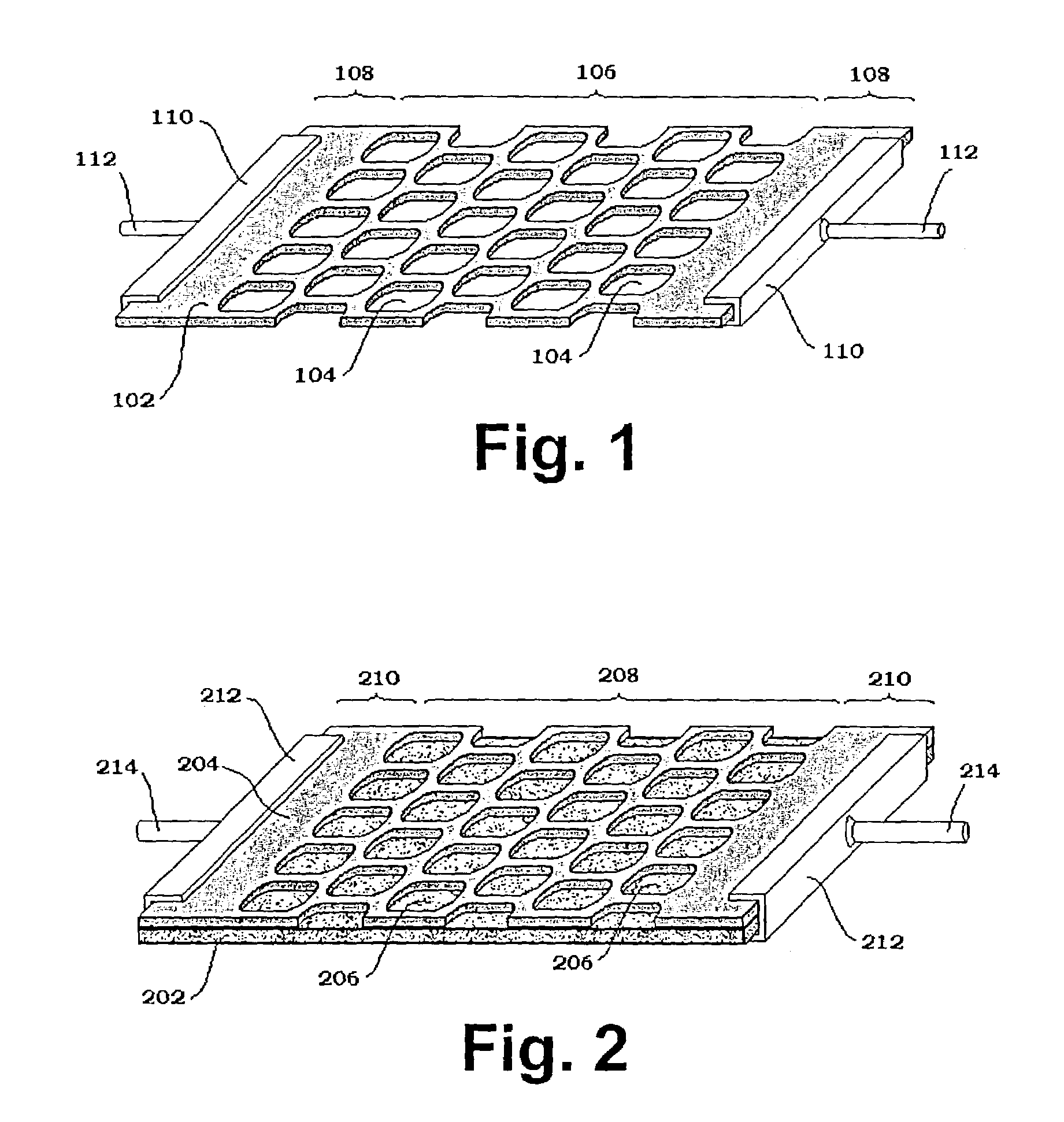

Microelectromechanical heating apparatus and fluid preconcentrator device utilizing same

InactiveUS6914220B2High porosityIncrease surface areaComponent separationBaking ovenThermal isolationEngineering

A microelectromechanical heating apparatus and fluid preconcentrator device utilizing same wherein heating elements of the apparatus are sized and spaced to substantially uniformly heat a heating chamber within a heater of the apparatus. Tall, thermally-isolated heating elements are fabricated in Si using high aspect ratio etching technology. These tall heating elements have large surface area to provide large adsorbent capacity needed for high efficiency preconcentrators in a micro gas chromatography system (μGC). The tall heating elements are surrounded by air gaps to provide good thermal isolation, which is important for a low power preconcentrator in the μGC system.

Owner:RGT UNIV OF MICHIGAN

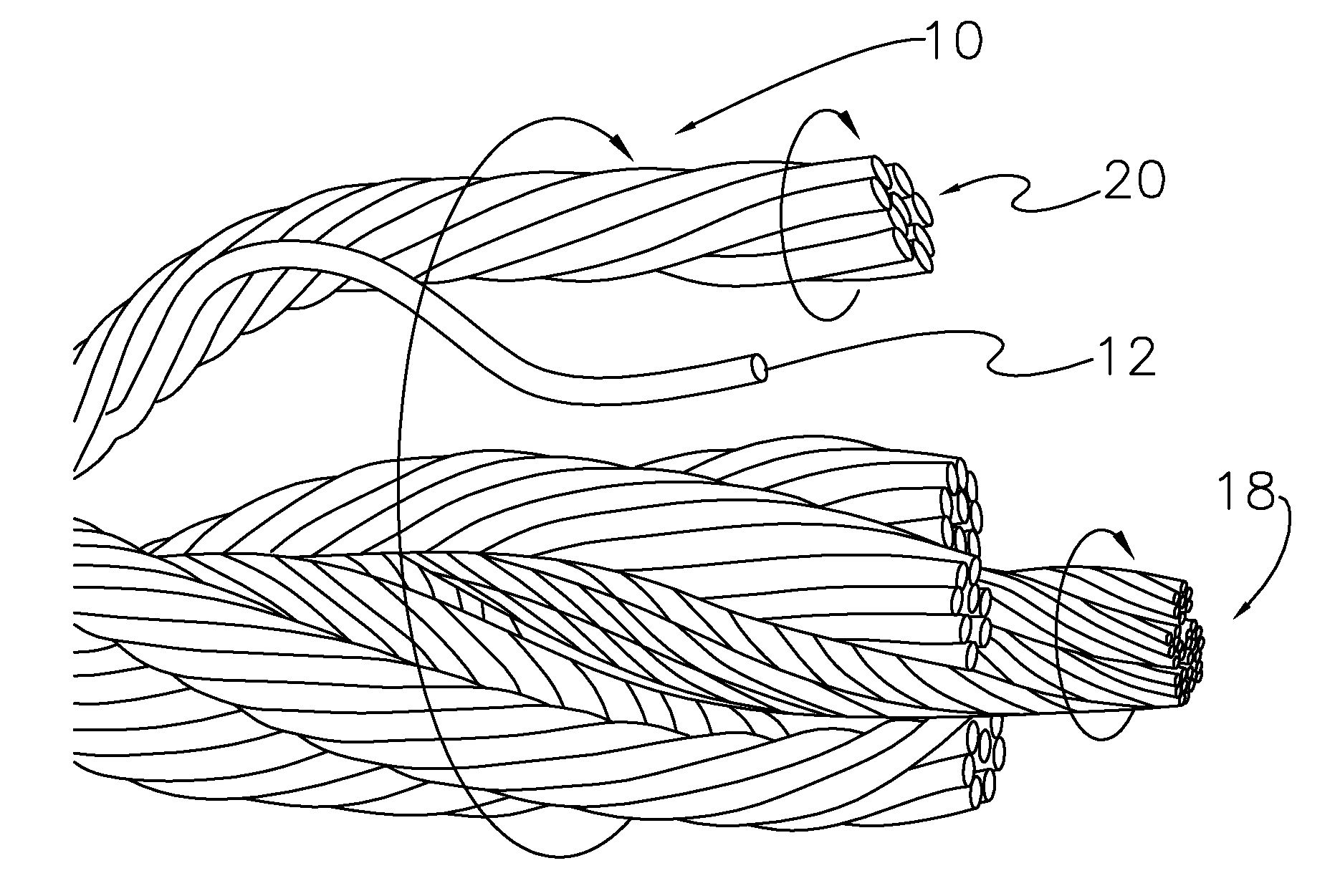

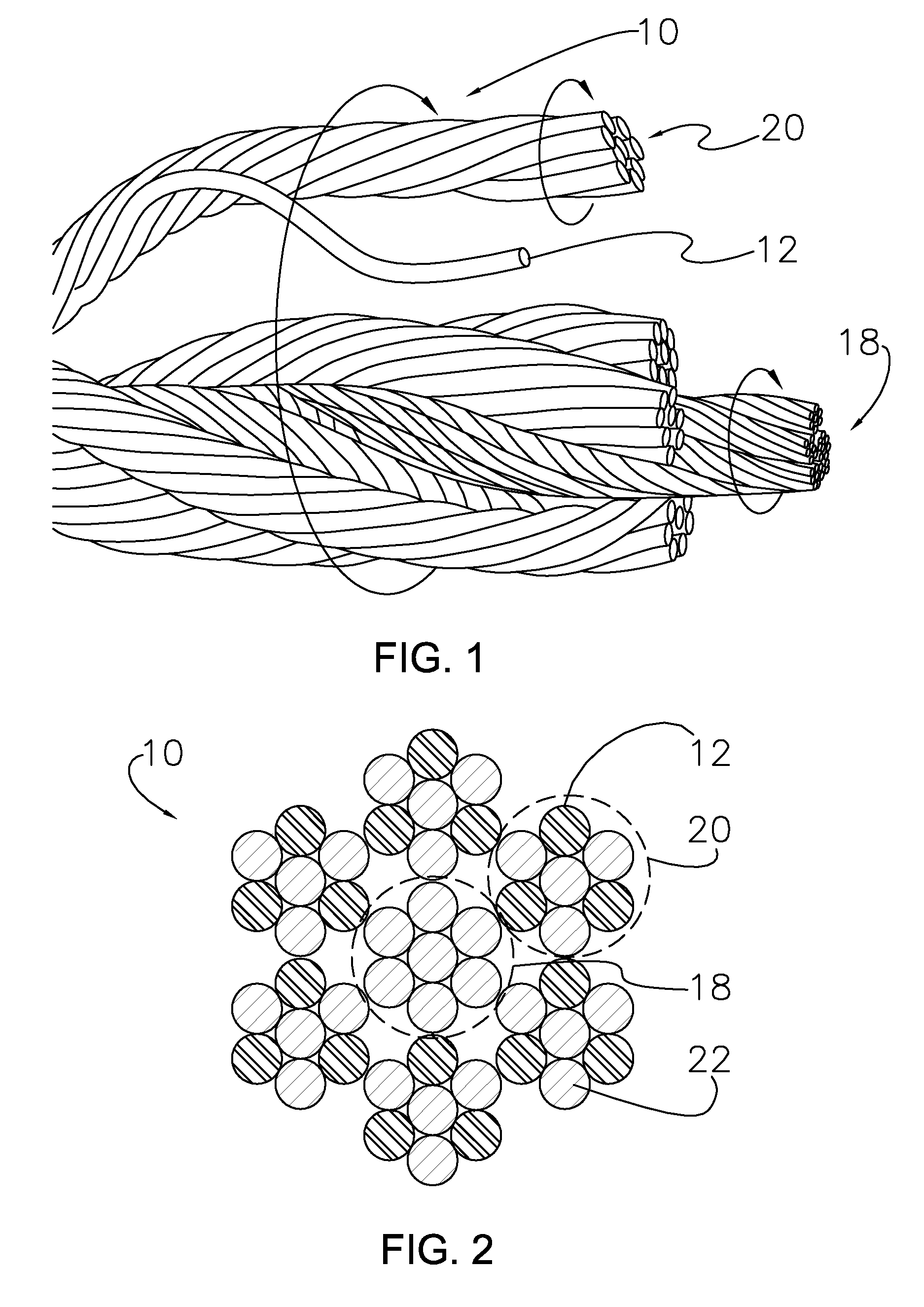

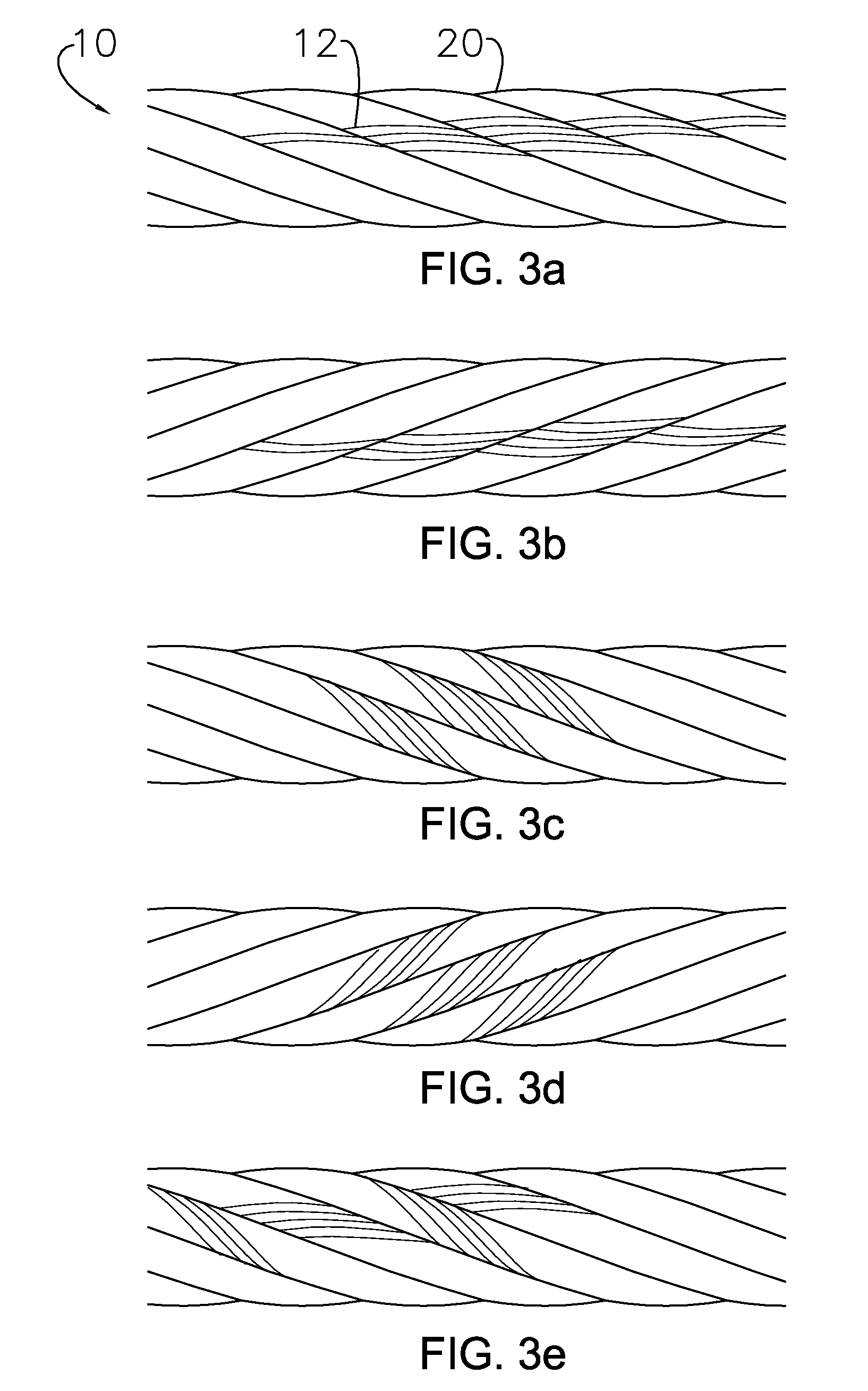

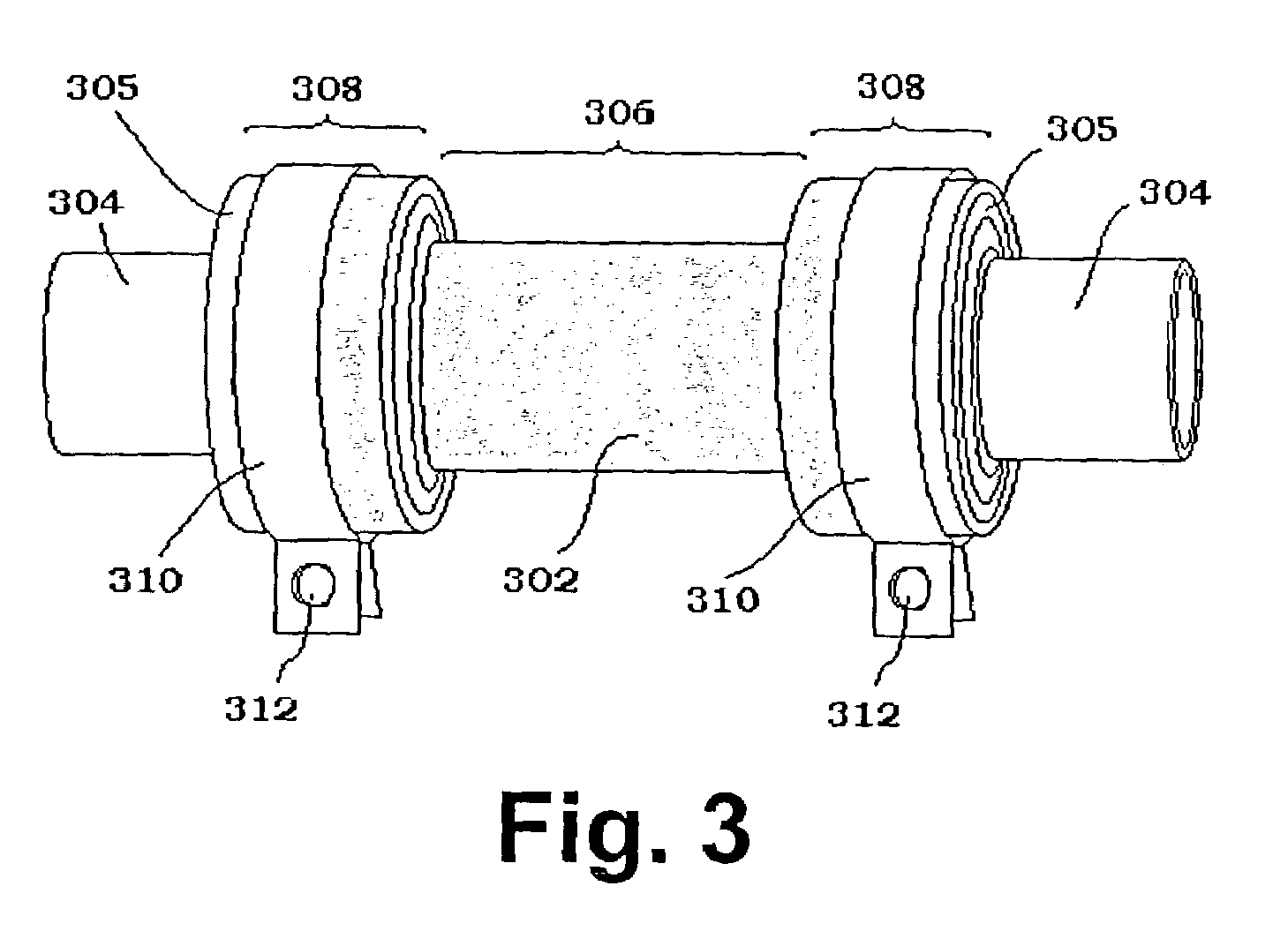

Shape memory alloy cables

ActiveUS20090226691A1Improve fatigue resistanceFlexible in bendingSampled-variable control systemsElectrical apparatusShape-memory alloyActuator

A cable adapted for use as an actuator, adaptive structural member, or damper, includes a plurality of longitudinally inter-engaged and cooperatively functioning shape memory alloy wires.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

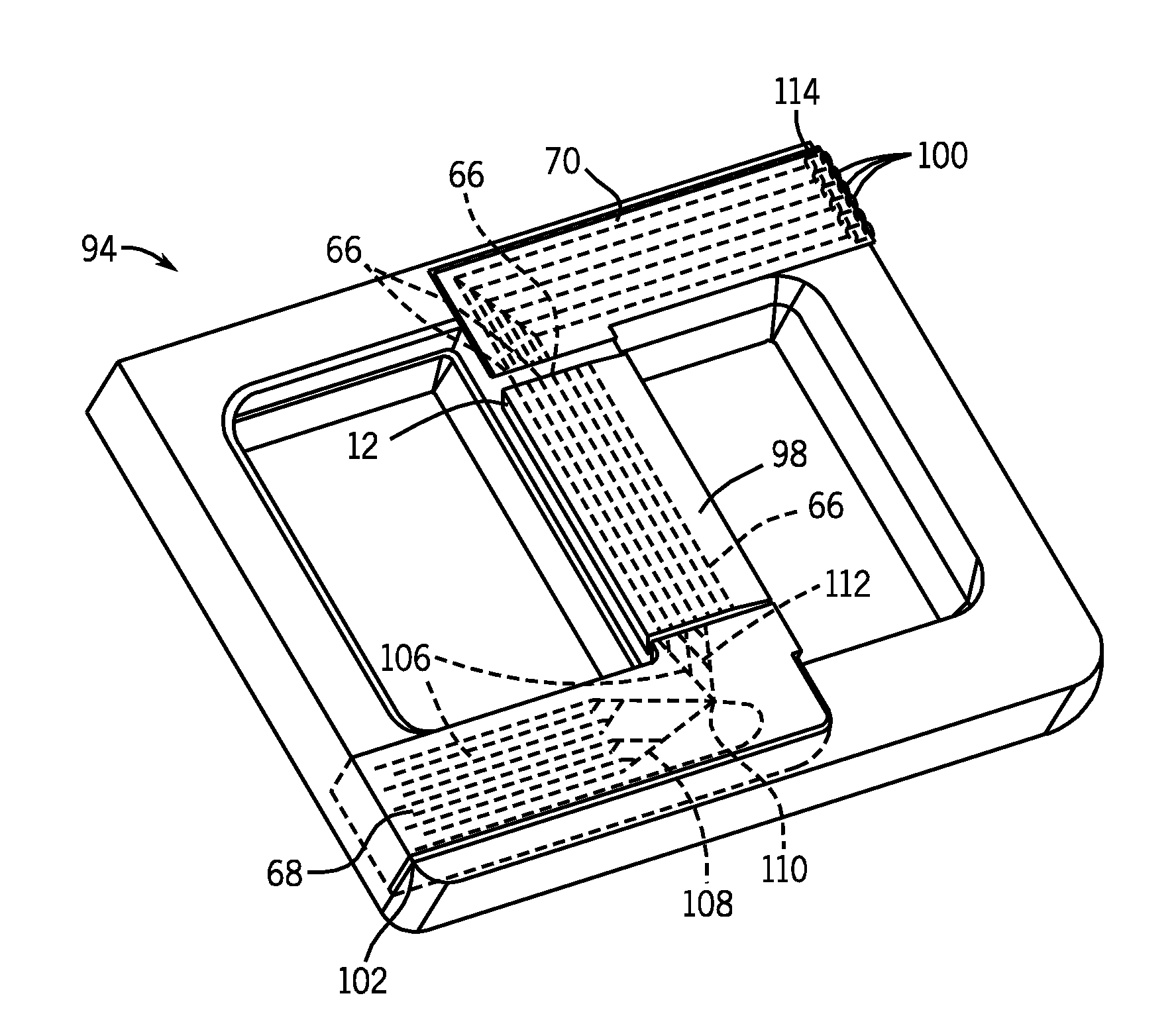

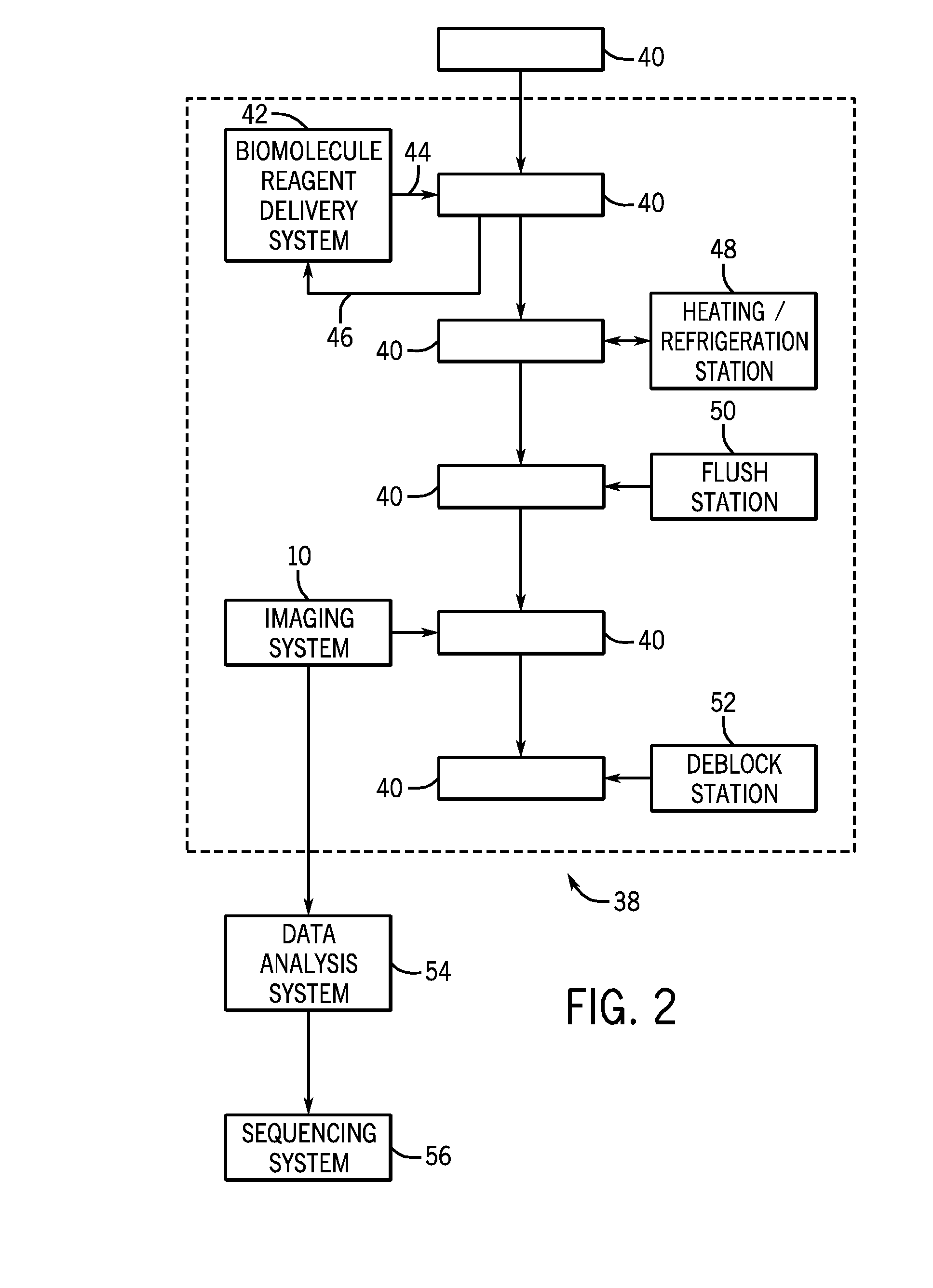

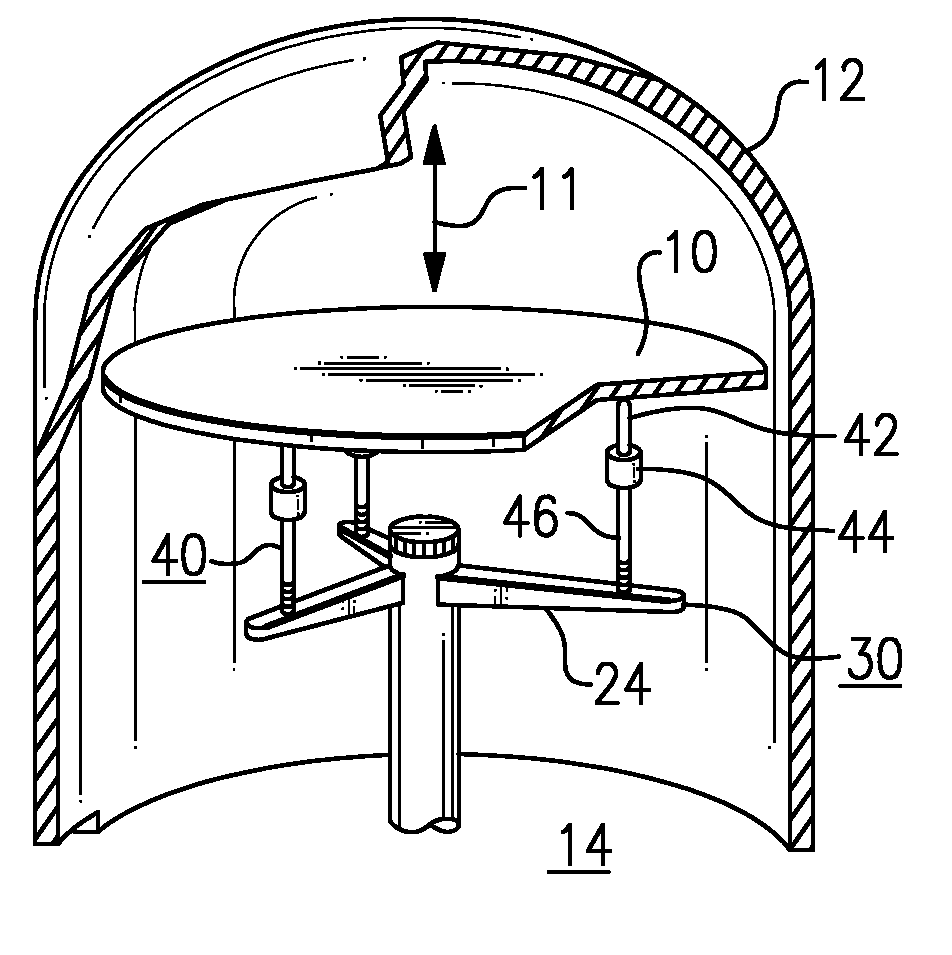

Biological sample temperature control system and method

InactiveUS20100087325A1Remove heatSlow responseHeating or cooling apparatusLibrary screeningTemperature controlTotal internal reflection

The present invention provides a novel approach for controlling the temperature of biological samples on a support structure. The support structure may, for instance, be a flow cell through which a reagent fluid is allowed to flow and interact with biological samples. A thermoelectric heat exchange device, such as a Peltier device, may be used to heat or cool the biological samples on the support structure. In addition, a fluid circulating heat exchange device, such as a water heating or cooling system, may be used to heat or cool the thermoelectric heat exchange device. In general, the support structure may be located on top of the thermoelectric heat exchange device which, in turn, may be located on top of the fluid circulating heat exchange device. The thermoelectric heat exchange device and fluid circulating heat exchange device may be integrated into a holder bench which may be part of a station within an imaging processing system. The holder bench may be configured to hold multiple support structures at a time. In addition, the support structures may be configured to be evaluated and imaged using both epifluorescent and total internal reflection (TIRF) excitation techniques.

Owner:ILLUMINA INC

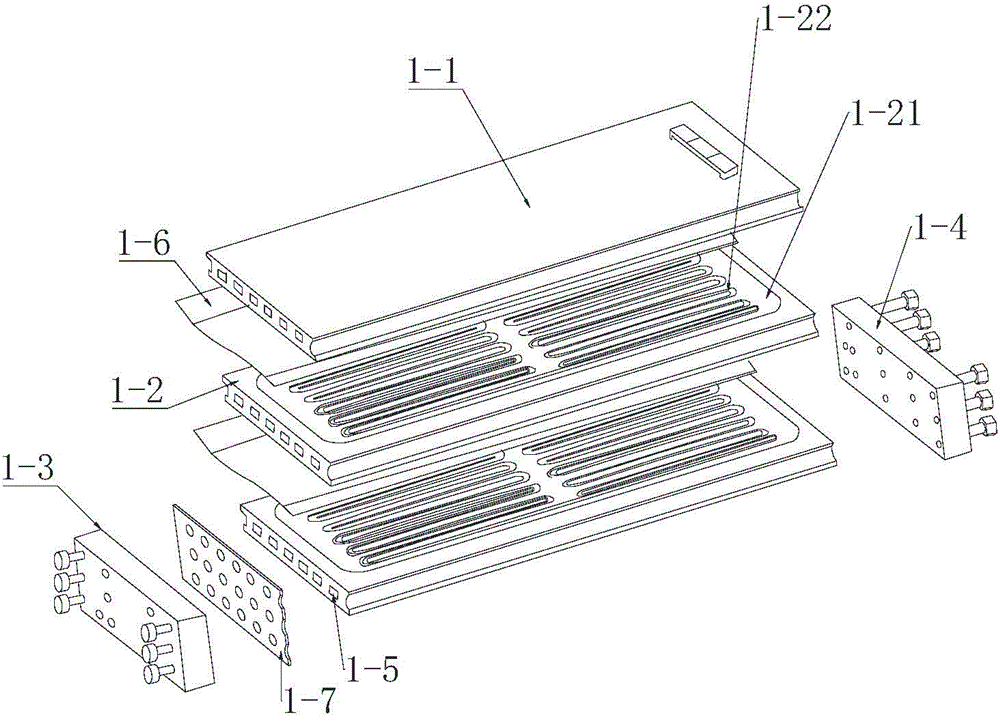

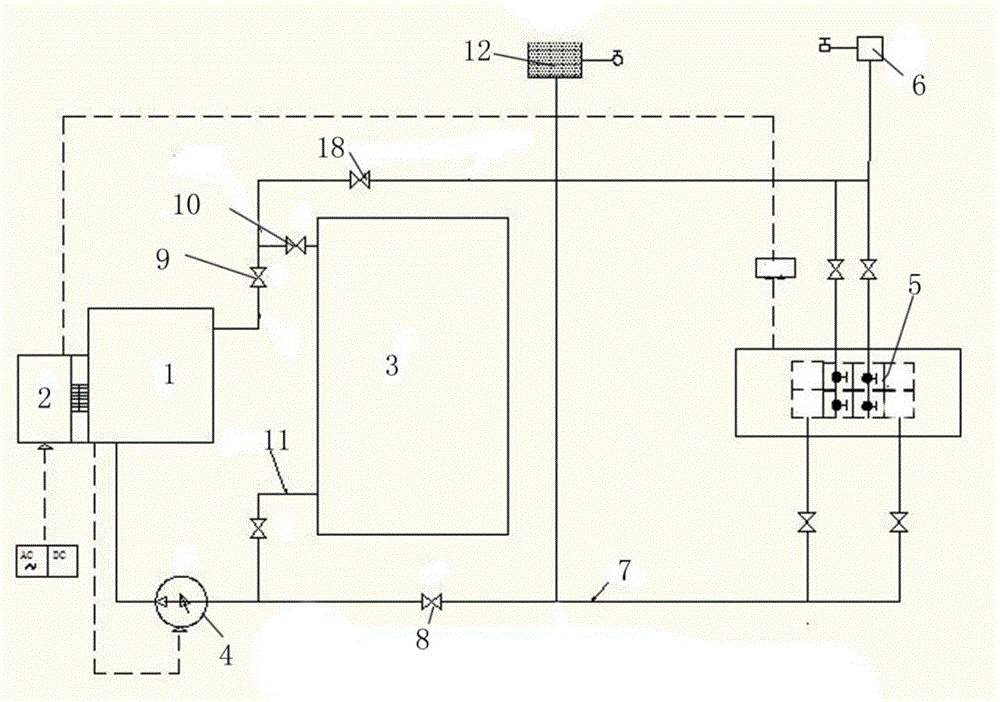

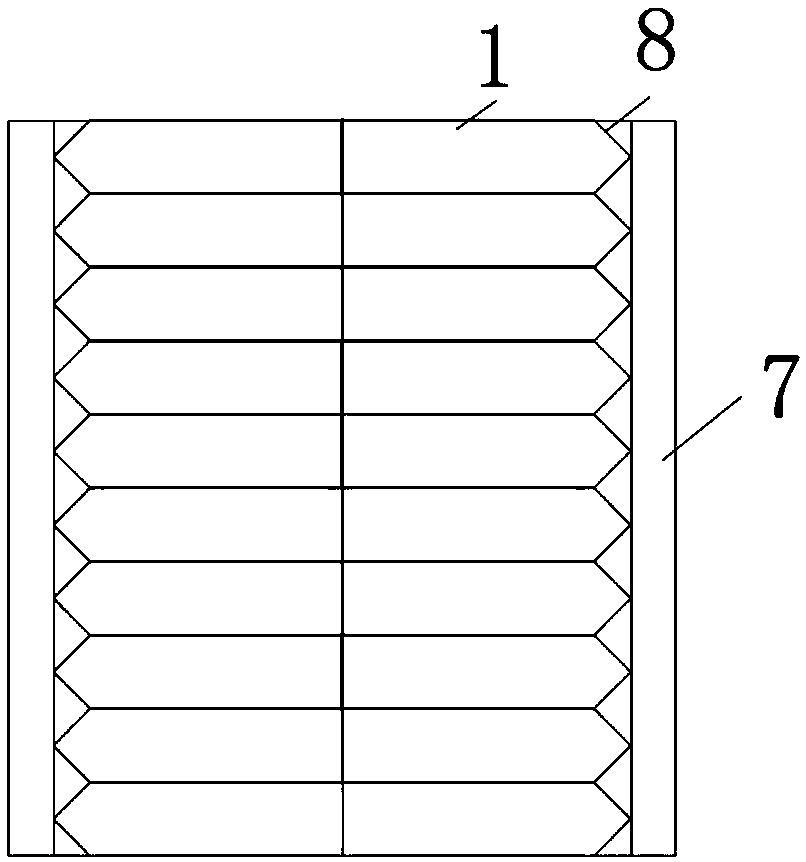

Battery module heat management method and apparatus based on thermo-electric effect

ActiveCN106374162AImprove heat transfer coefficientFast thermal responseSecondary cellsElectrical batteryOperating temperature range

The invention discloses a battery module heat management method and apparatus based on a thermo-electric effect. A battery module, heat conductors, semiconductor thermal-electric assemblies and a liquid heat conducting channel form a heat conducting path in a battery pack box; the battery module heat management method comprises two working modes, including a refrigerating mode executed in a high-temperature environment and a heating mode executed in a low-temperature environment, wherein in the refrigerating mode, the temperature of the upper part of each semiconductor thermal-electric assembly is reduced to be lower than the environment temperature to form a refrigerating surface; the temperature of the lower part of the semiconductor thermal-electric assembly is increased to form a heat dissipation surface; the generated heat is discharged through the liquid heat conducting channel; in the heating mode, the temperature of the upper part of each semiconductor thermal-electric assembly is increased to form a heating surface; the battery module is heated through the heat conduction of the heat conductors to achieve a normal working temperature range; and meanwhile, the temperature of the lower part of each semiconductor thermal-electric assembly is reduced to form a heat absorption surface. The battery module heat management method and apparatus, by integrating refrigerating and heating into one body, is compact in structure and efficient in heat exchange, thereby ensuring that the battery can constantly work in the optimal temperature environment; and therefore, the battery module heat management method and apparatus have high application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

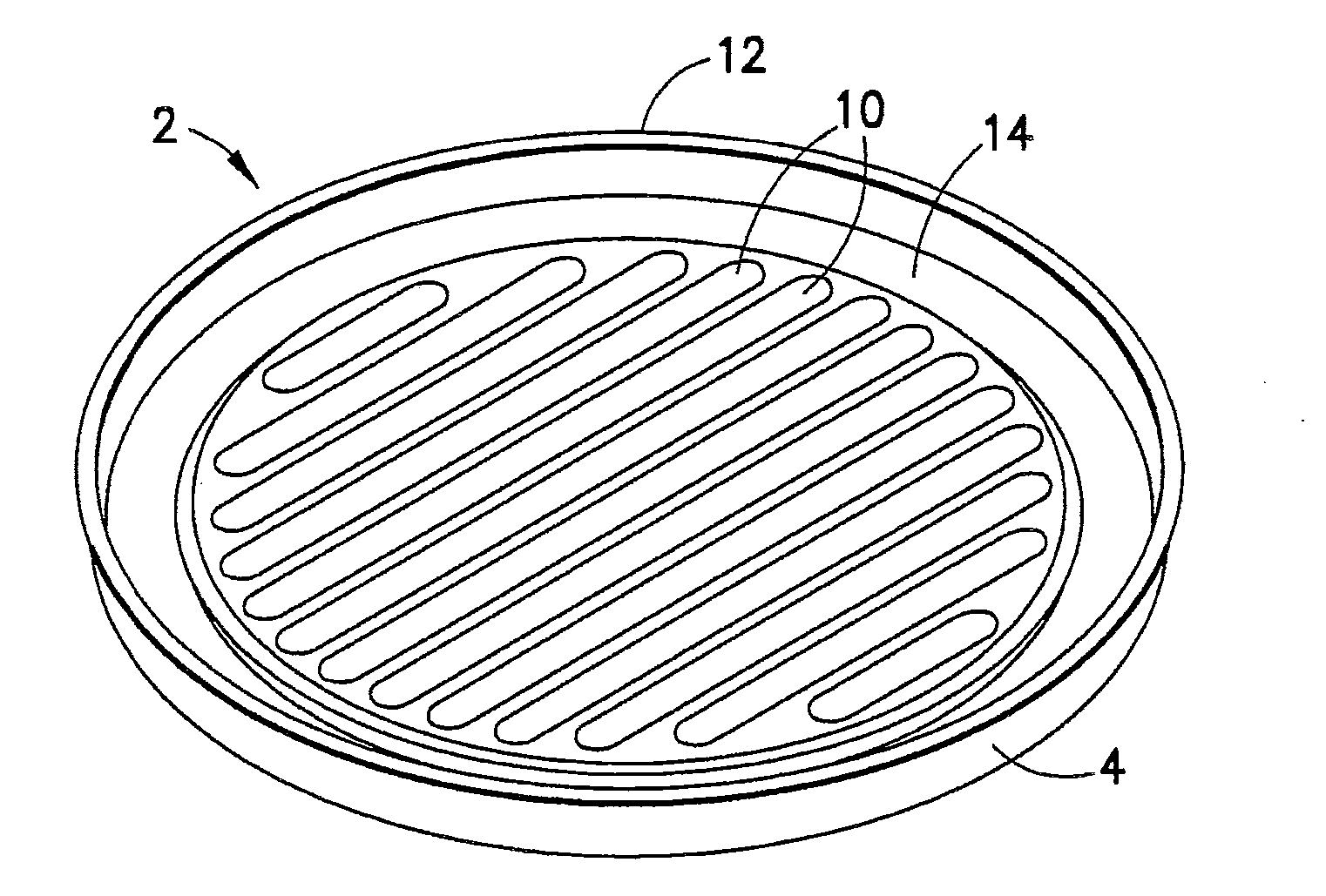

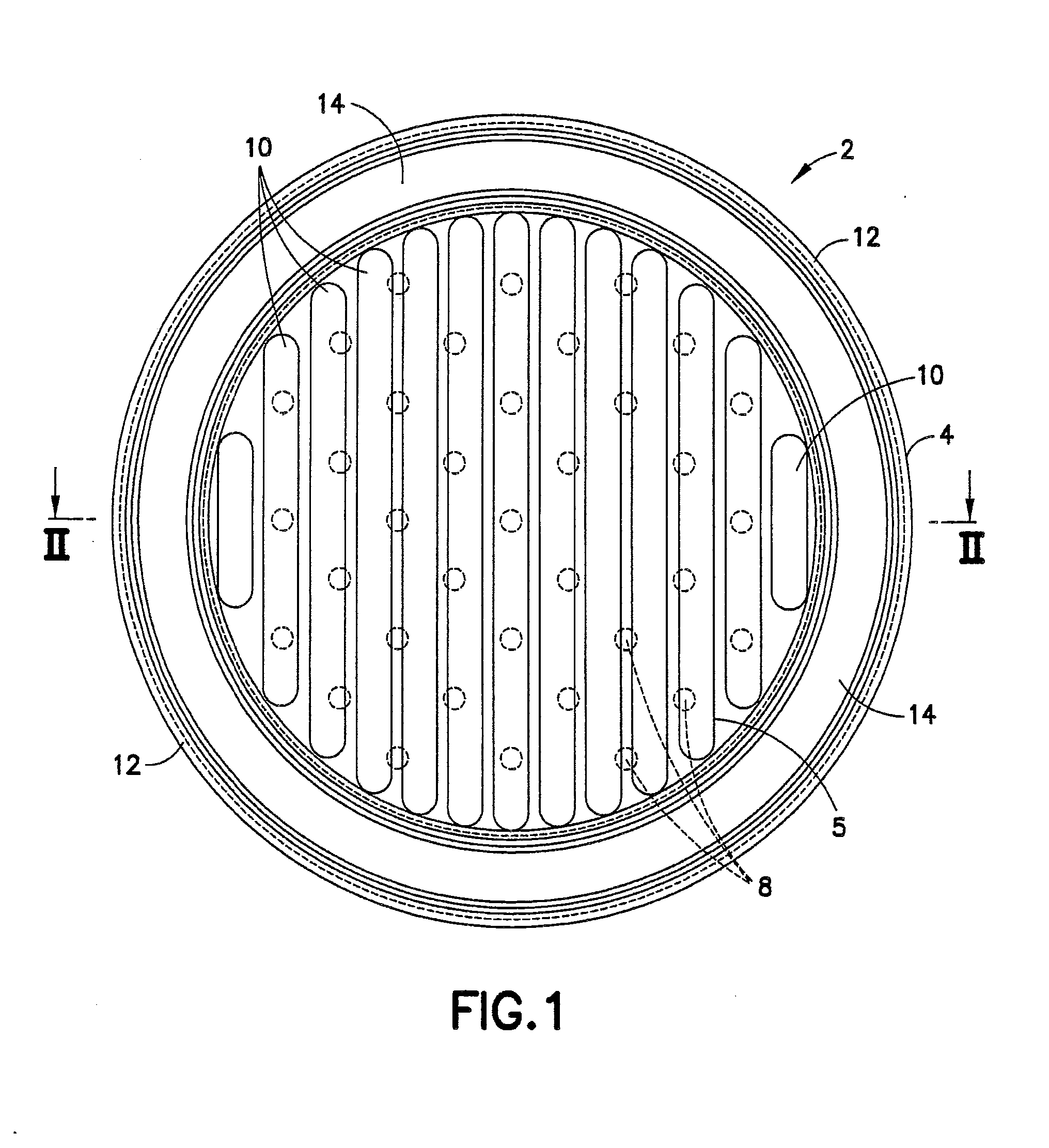

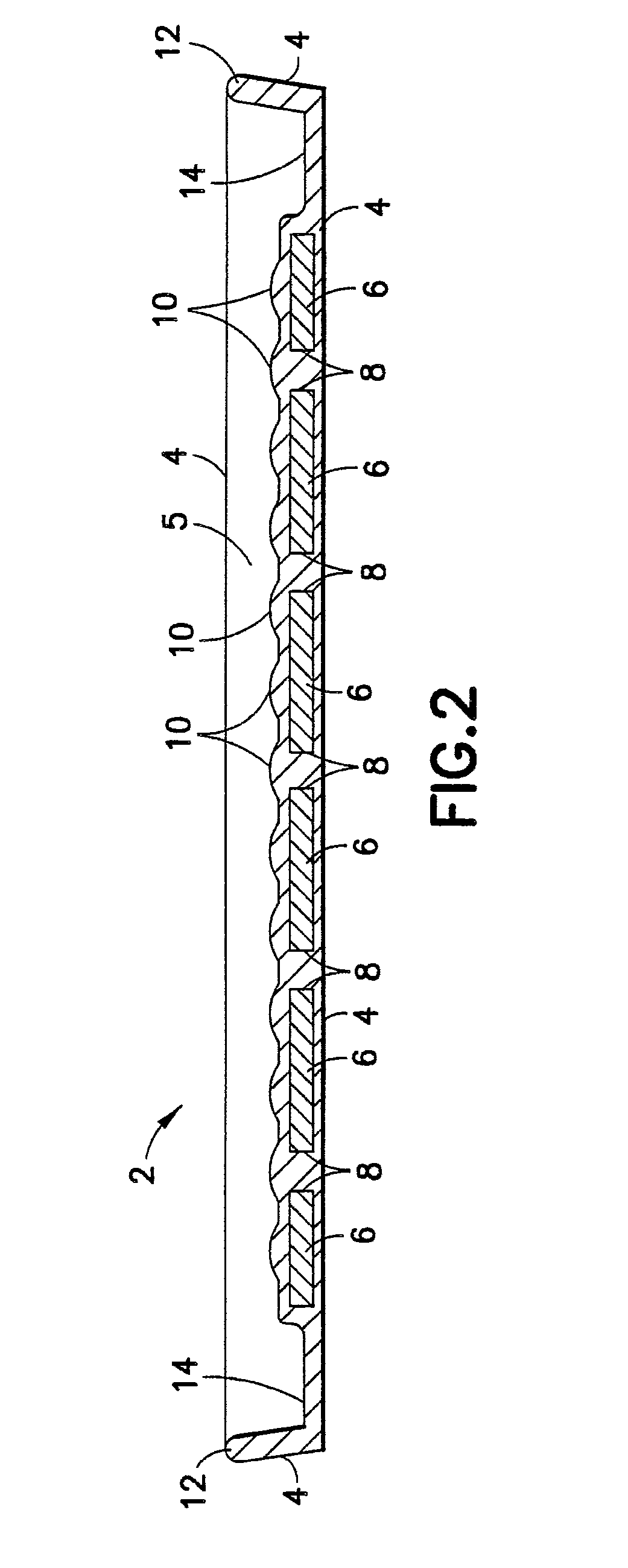

Graphite encapsulated cookware

ActiveUS20110041708A1Fast thermal responseUniform temperature distributionCooking-vessel materialsFoundry mouldsGraphiteMetal

Owner:CLAD METALS

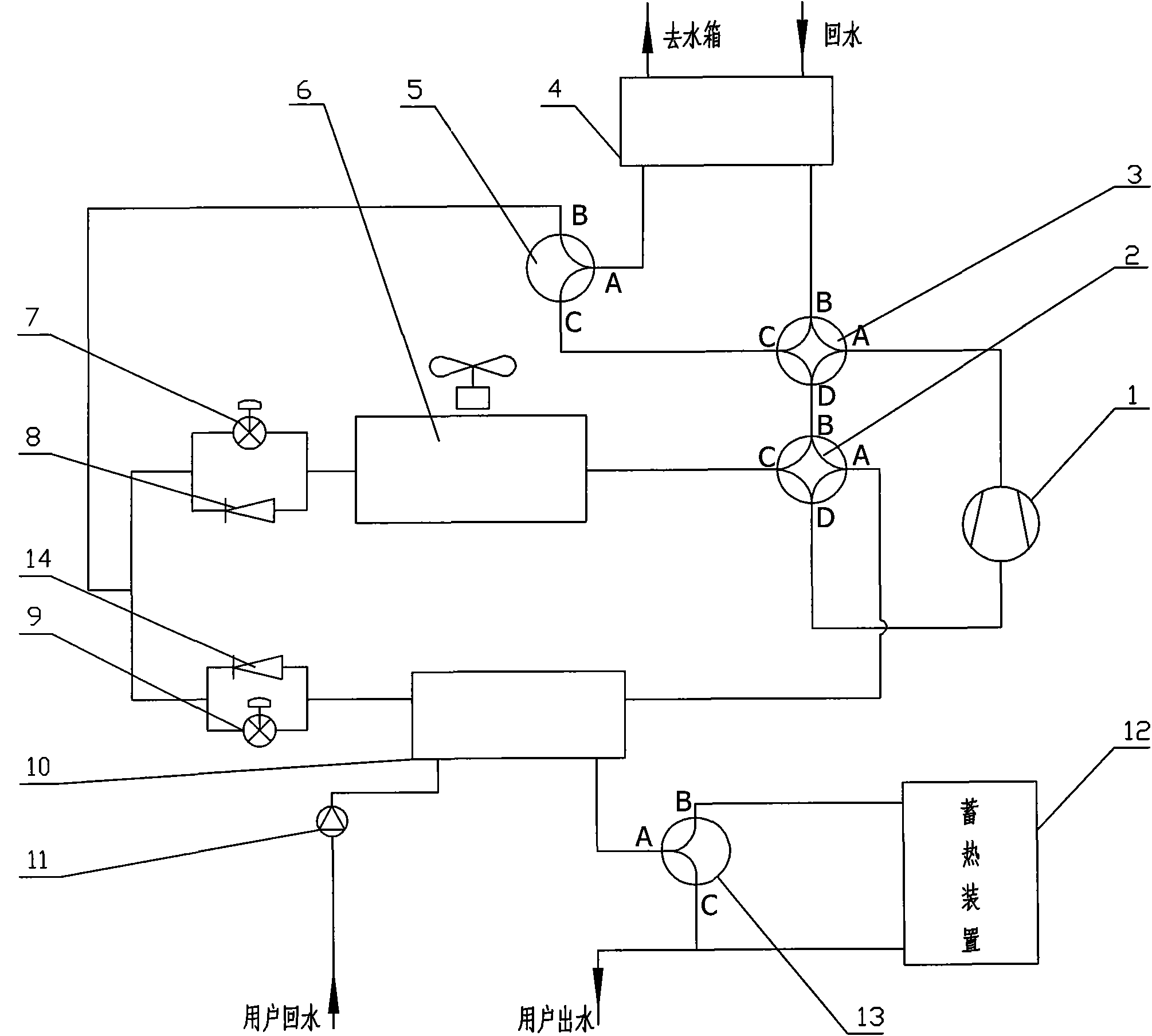

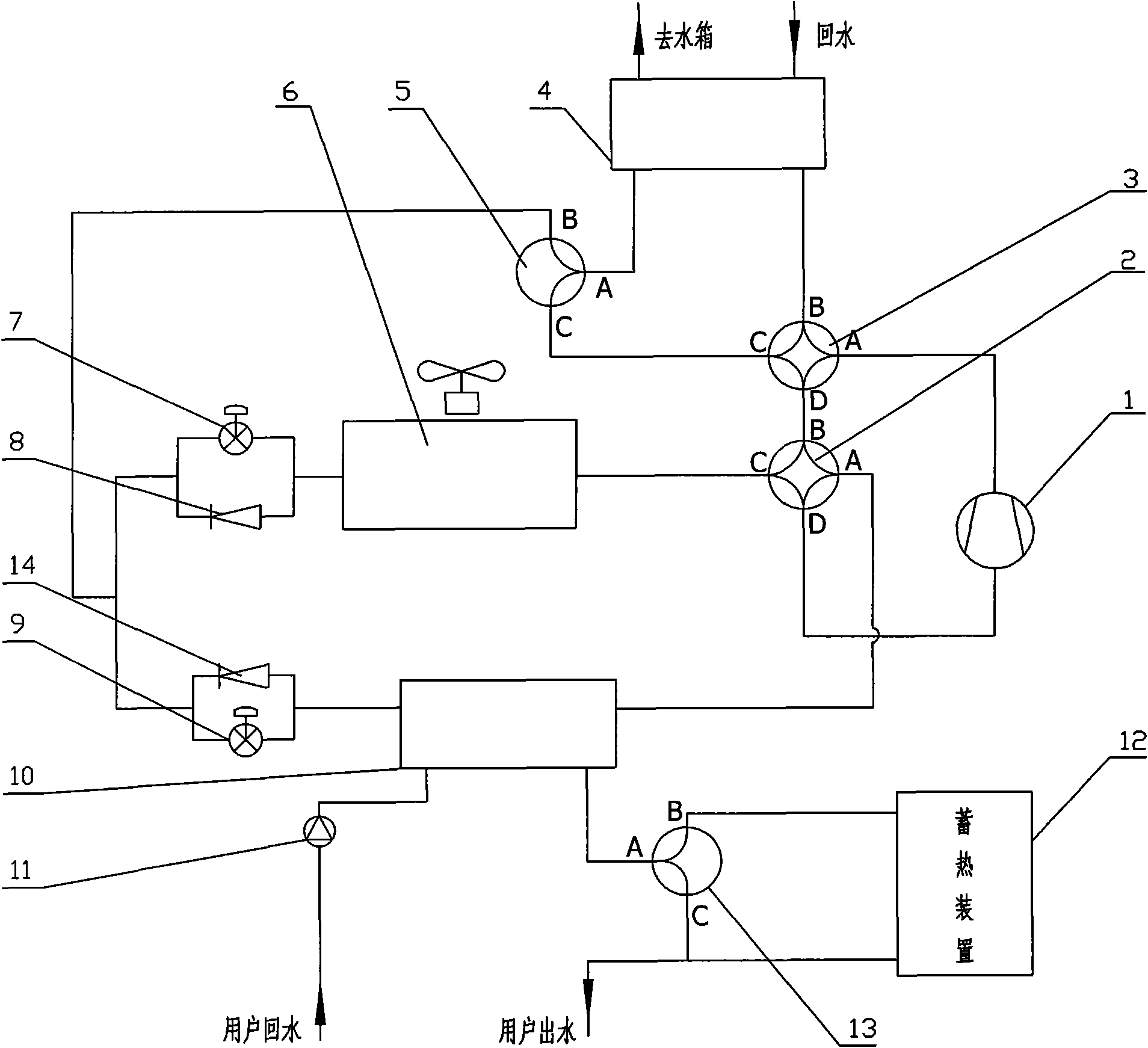

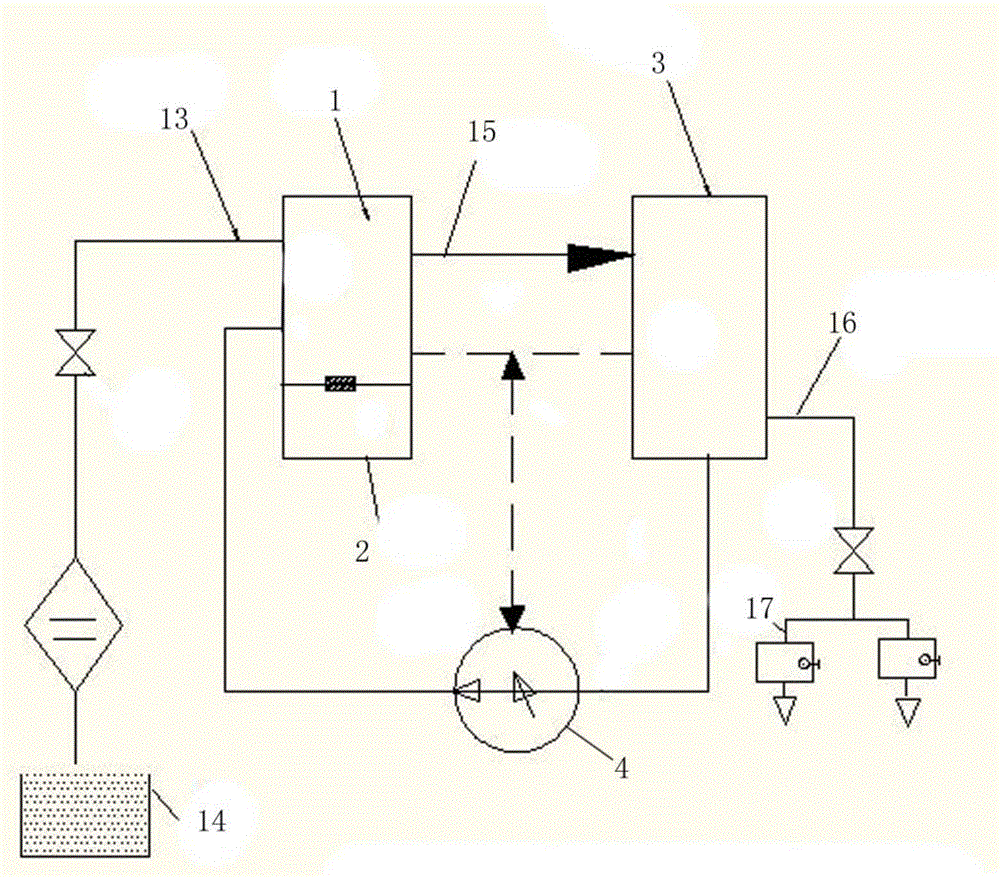

Energy-saving air-conditioning/hot water triple-supply system

InactiveCN101813401AOvercome efficiencyOvercome stabilityEnergy industryHeating and refrigeration combinationsBusiness efficiencyWater quality

The invention discloses an energy-saving air-conditioning / hot water triple-supply system, comprising a compressor (1), a hot water heat exchanger (4), an air heat exchanger (6), an air conditioning heat exchanger (10) and other parts; using main components of a heat pump system, the system adopts a structure with three heat exchangers interconnected in a mixed manner and double four-way reversing valves and has four working modes including refrigeration and water heating, water heating, heating and water heating, and defrosting, thus the triple supply of refrigeration, heating and clean hot water can be realized; the system has high heat exchange efficiency and simultaneously enhances energy efficiency ratio of system as well; by adopting the heat pipe exchangers, the system solves the problem that the heat exchanger is liable to leakage so as to pollute water, and overcomes the deficiency of large resistance when a plurality of heat exchangers are connected with each other in series.

Owner:江乐新

Gel capable of injecting temperature sensitive complex and its preparation method

InactiveCN1593385AMaintain salt contentHigh strengthPharmaceutical delivery mechanismSalt resistanceHydrogen

The invention provides a gel capable of injecting temperature sensitive complex and its preparation method, wherein the constituent percentage by weight of the composition includes chitosan 1.0-2.0, glycerin phosphate 1.9-4.5, disodium hydrogen phosphate 0-0.5, gelatin 0-1.25, 0.1mol / l HCL solution or acetic acid solution 86.4-89.0, distilled water 8.1-10. The gel can be used for encapsulating medicaments and cells with weak salt resistance.

Owner:TIANJIN UNIV

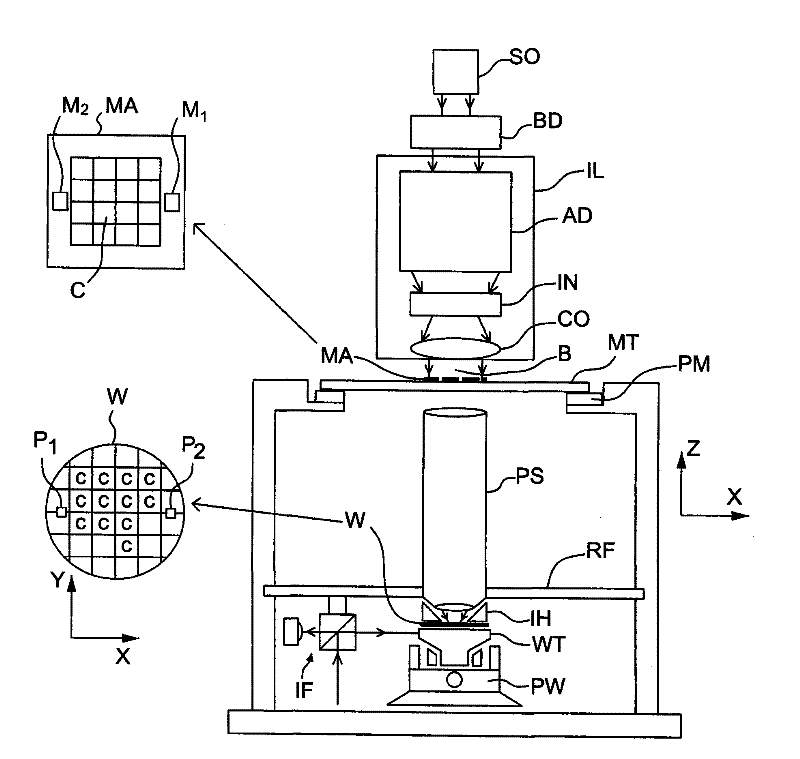

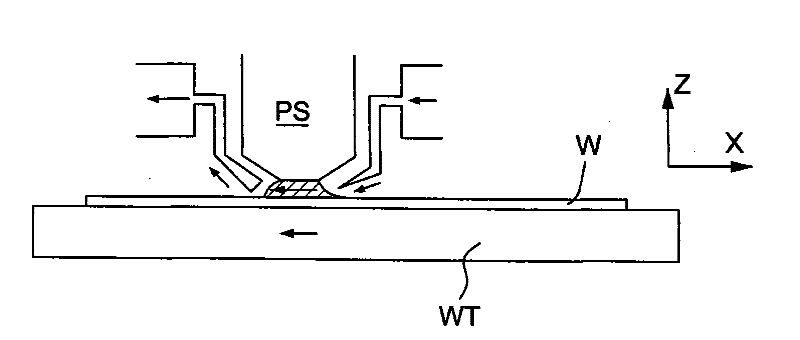

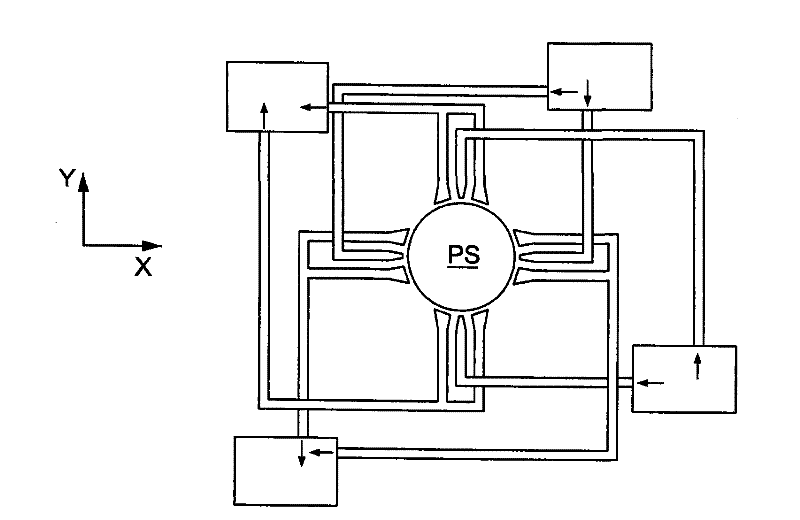

Lithographic apparatus and method

ActiveCN102193331AFast thermal responseSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringLithography

Owner:ASML NETHERLANDS BV

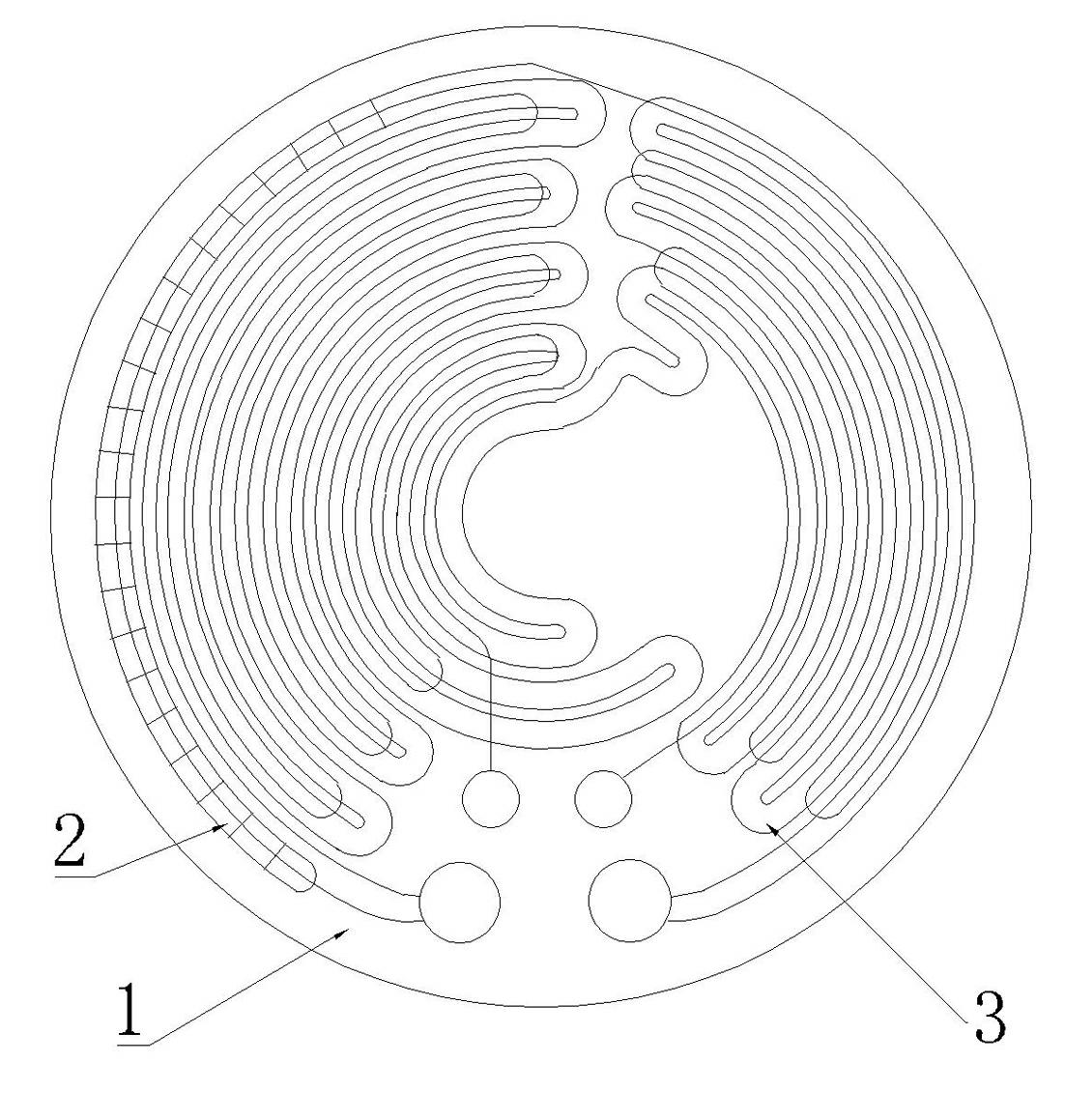

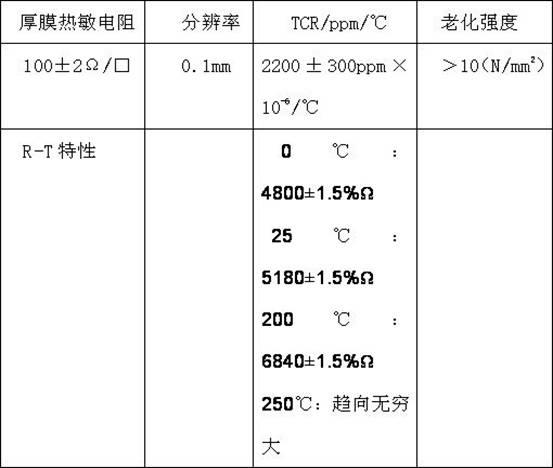

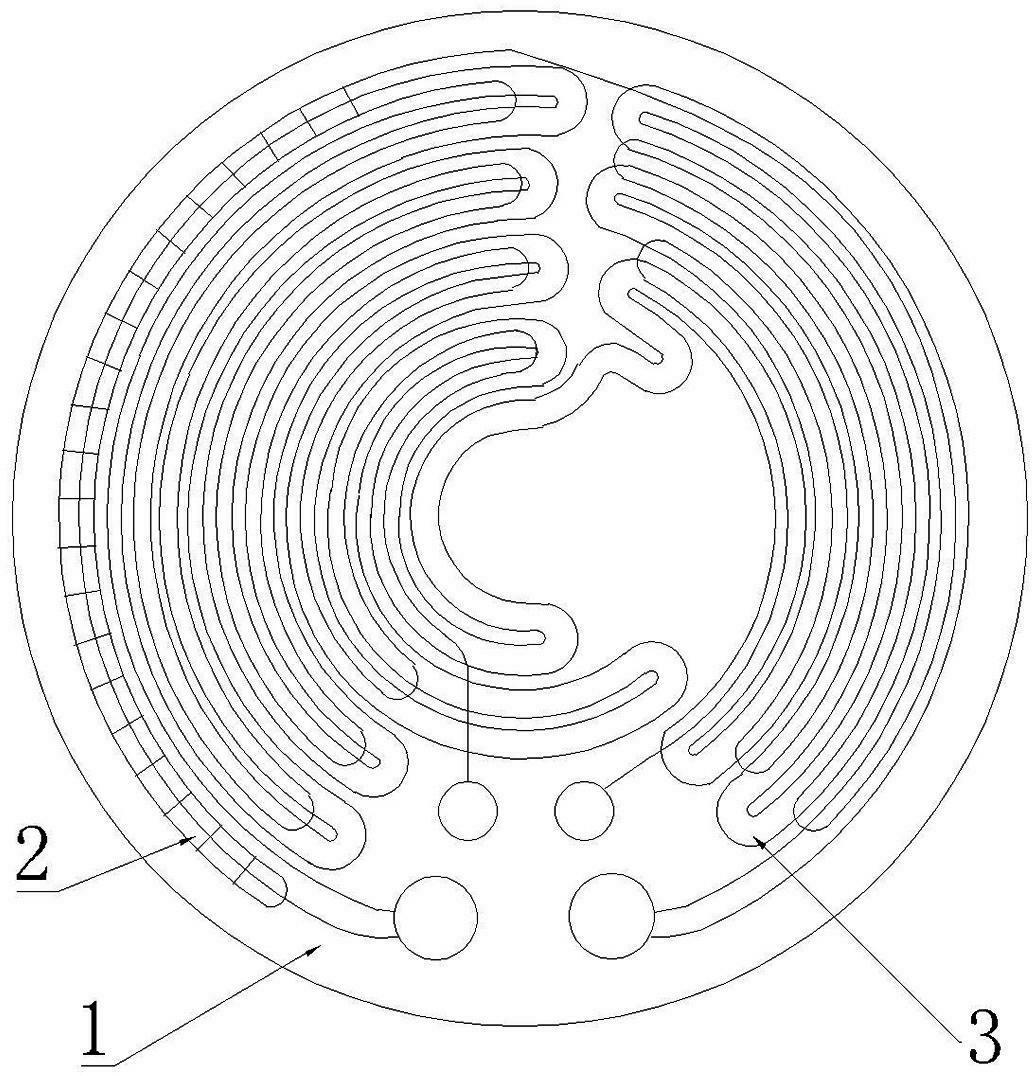

Intelligent electric-heating element with PTC (Positive Temperature Coefficient) rare-earth thick film circuit and preparation method thereof

ActiveCN102685942AThe heating temperature field is uniform and self-controllable in stagesFast thermal responsePositive temperature coefficient thermistorsHeating element materialsFilm resistanceElectric heating

The invention discloses a PTC (Positive Temperature Coefficient) rare-earth thick-film-circuit intelligent electric-heating element and a preparation method thereof. The intelligent electric-heating element is characterized by comprising a metal substrate as well as a PTC thick film circuit thermistor and a rare-earth thick film resistance circuit which are arranged on the metal substrate, wherein the PTC thick film circuit thermistor is arranged in a thick film circuit way to be overlapped or positioned in a same plane with the rare-earth thick film resistance circuit to control the temperature of the thick-film-circuit electric-heating element, so that the control precision and sensitivity are improved substantially; or the PTC thick film circuit thermistor can be independently made into the controllable electric-heating element in the form of a thick film circuit. The intelligent electric-heating element disclosed by the invention can be started by low and high voltages as well as alternating and direct currents at present, is small in size, large in surface thermal load, high in thermal efficiency, quick in warm start, excellent in heat-conducting property, strong in thermal shock capacity and easy to process, green, low-carbon and environment-friendly as well as safe and reliable, has a far infrared function; moreover, the temperature fields are uniform and self-controlled level by level; therefore the intelligent electric-heating element is widely applied to series products of novel intelligent electric-heating elements, such as solar cells, wind power cells, lithium ion cells and the like, with new energy requirements.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Cellular metal screen catalyst for selective catalytic reduction of nitrogen oxide and preparation method thereof

InactiveCN101391214AWill not blockBlocked channelDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHoneycomb likeCalcination

Disclosed is a selective catalytic reduction nitrogen oxide honeycomb metallic sieve catalyst as well as a preparation method thereof, relating to a catalyst as well as a preparation method thereof. The invention solves the problems of poor thermal shock resistance, poor mass transfer performance, slow thermal response, poor catalytic performance and high treatment cost of the catalyst in common use in the existing SCR process technique. The selective catalytic reduction nitrogen oxide honeycomb metallic sieve catalyst is composed of a wire mesh, a carrier depositing on the wire mesh as well as V2O5 and MoO3 loading on the carrier. The method comprises: a. material pretreatment; b. preparing an electrophoretic liquid; c. electrophoretic deposition; d. making an Al2O3 / wire mesh; e. making a TiO2 / Al2O3 / wire mesh; and f. weaving a honeycomb metallic sieve, then obtaining the selective catalytic reduction nitrogen oxide honeycomb metallic sieve catalyst after dipping, drying and calcinations. The invention has advantages of good catalyst catalytic performance, low cost, good thermal shock resistance, good mass transfer performance and fast thermal response.

Owner:HARBIN INST OF TECH

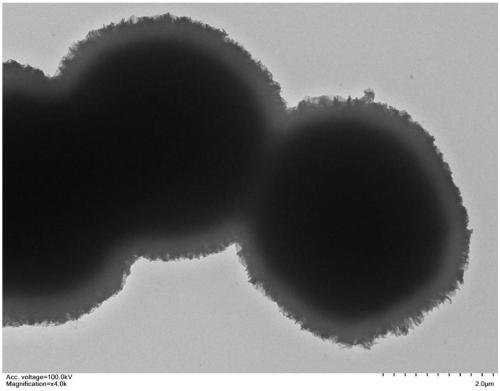

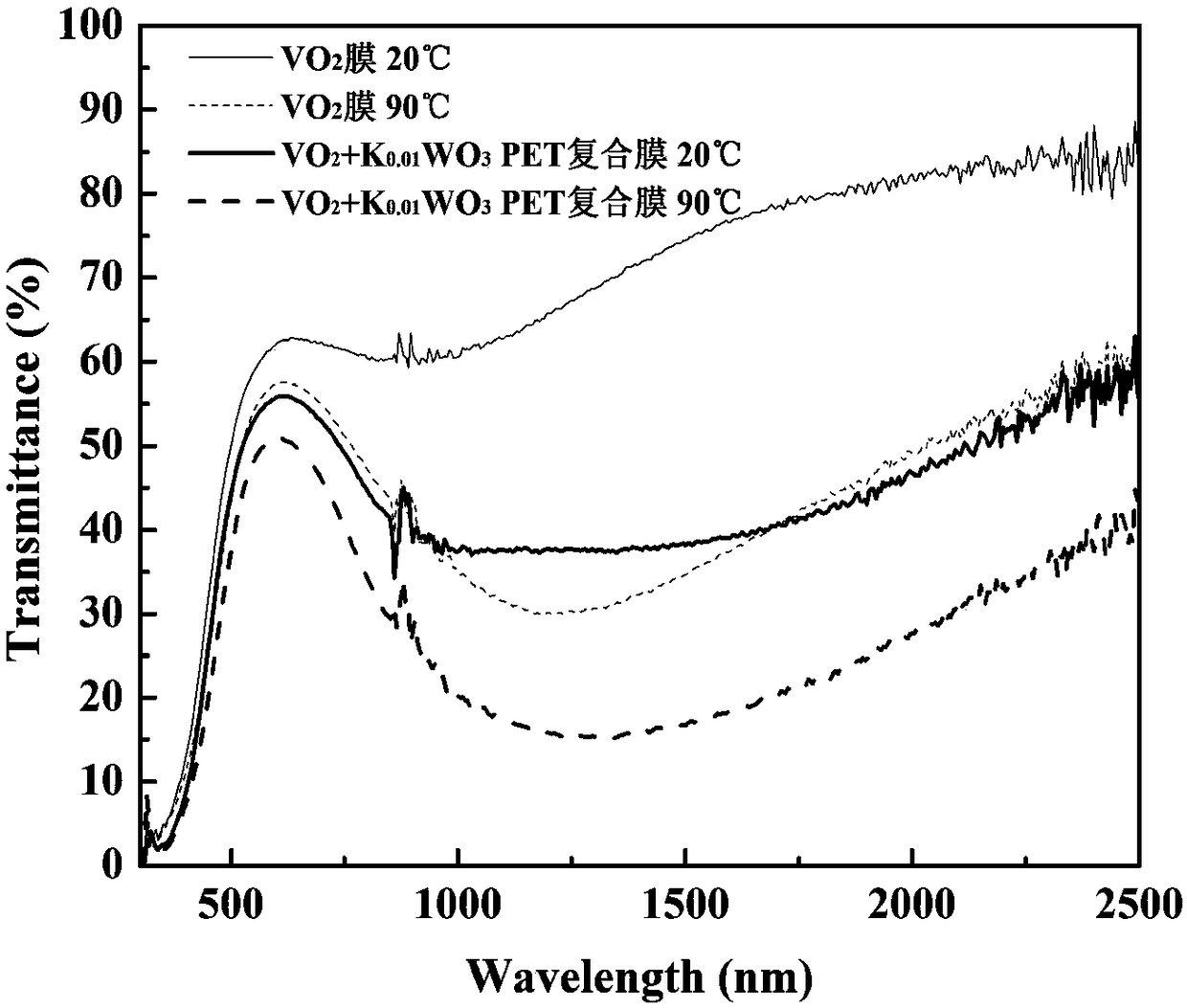

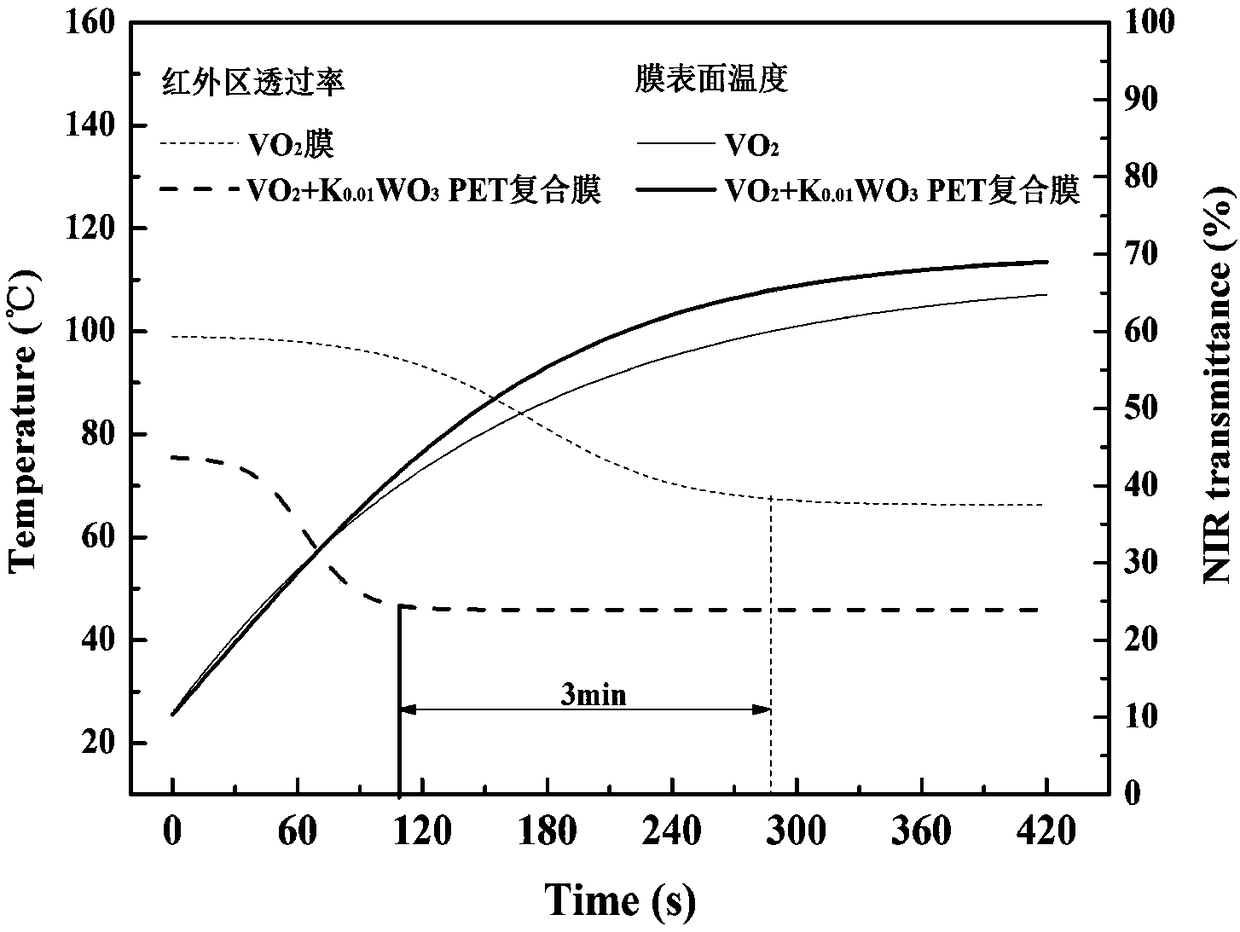

High-efficiency thermochromic nano composite powder with core-shell structure and preparation method thereof

ActiveCN108659812AHigh visible light transmittanceWill not affect daylightingMaterial nanotechnologyNanoopticsVanadium dioxideThermochromism

The invention discloses a high-efficiency thermochromic nano composite powder with a core-shell structure. The composite powder takes a VO2 layer as a core layer and a tungsten bronze compound layer as a shell layer; the VO2 layer is vanadium dioxide nano-powder, the smallest dimension in three-dimensional dimensions of the VO2 layer is not more than 100nm, and the tungsten bronze compound layer is MxWO3, wherein M is selected from any one of NH4+, Cs+, K+, Na+ or Li+; the value of x ranges from 0.01 to 0.8; and the thickness of the tungsten bronze compound layer is less than 60nm, an infraredabsorption characteristic of a tungsten bronze material is utilized to enable the shell layer to absorb heat, and the heat is quickly transferred to VO2 particles in the core layer through the closely connected core-shell structure, which results in the temperature rise and phase change of VO2, so as to reduce the ambient temperature required by the phase change of VO2, improve the thermal response speed of VO2, shorten the phase change reaction time and achieve an effect of efficient thermochromism.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Piezoresistance with alloy type temperature fuse

ActiveCN1925072AEasy to installFast thermal responseVaristor coresOvervoltage protection resistorsElectrical resistance and conductanceSafety wire

This invention relates to alloy temperature safety wire pressure sensitive resistance suitable for zin oxidation pressure sensitive resistance for over voltage protection. This invention comprise pressure sensitive resistance, which locates the resistance and safety wire into one compact chamber with near surface and with leg extending outside chamber with alloy melt agent. This invention locates one resistance and alloy temperature wire into compact chamber with legs extending outside and wire is set into other chamber with alloy assistant agent.

Owner:XIAMEN SET ELECTRONICS

High temperature heating element for preventing contamination of a work piece

InactiveUS20080041836A1Accurately closely controlledAccurately determineMuffle furnacesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceWorking temperature

A modular heating element that facilitates removal and replacement without disassembly of a furnace provides a precisely controllable process temperature in the range 1000-1400 degrees centigrade. The configuration of the heating element is linear rather than coiled, and the temperature is monitored directly by measuring the electrical resistance of KANTHAL®, or other like Fe Cr Al wire encased in an aluminum ceramic sleeve that provides mechanical support and seals the heating element wire against oxidation, thereby increasing operational temperature and prolonging service life.

Owner:SOLAICX

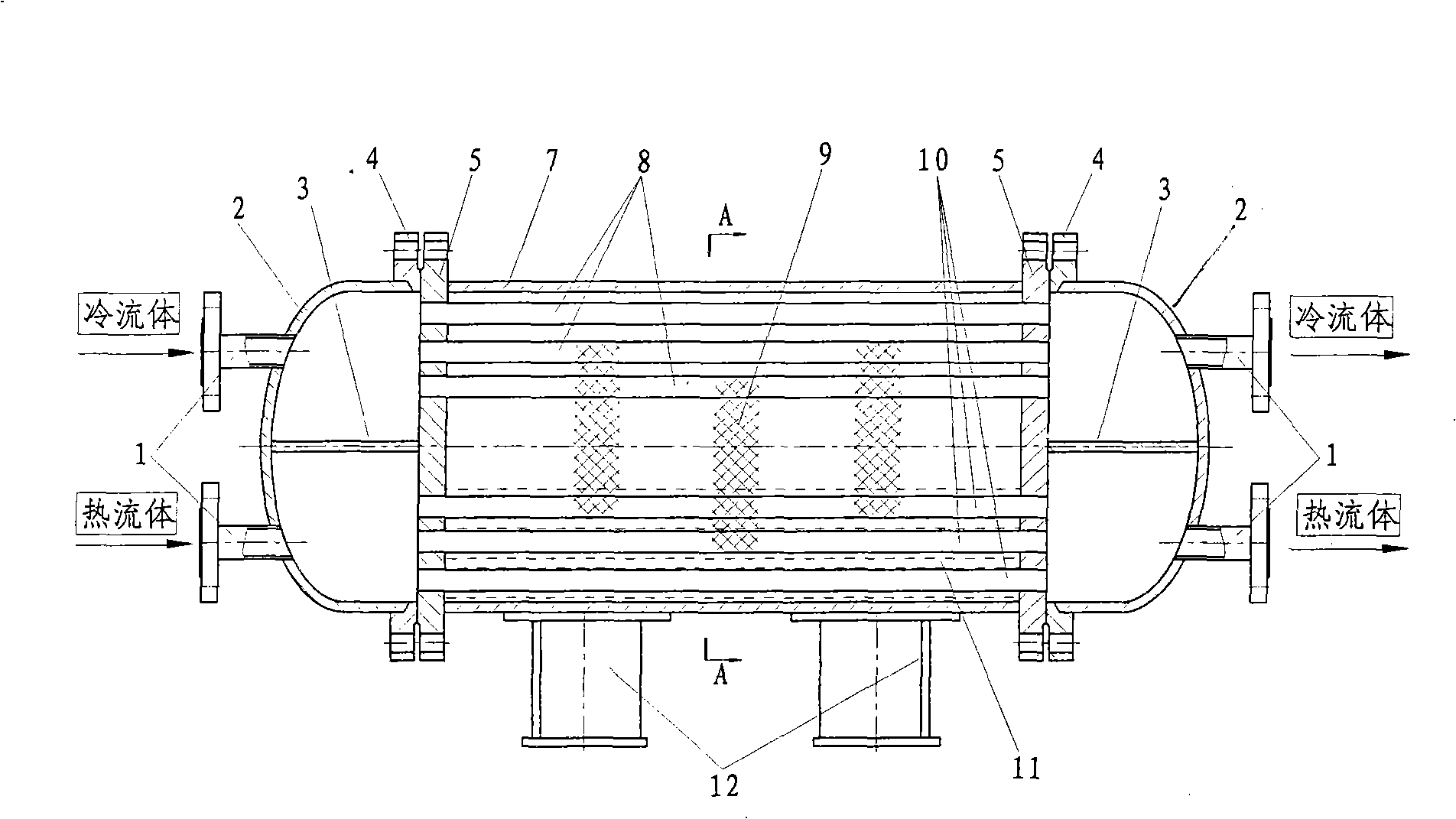

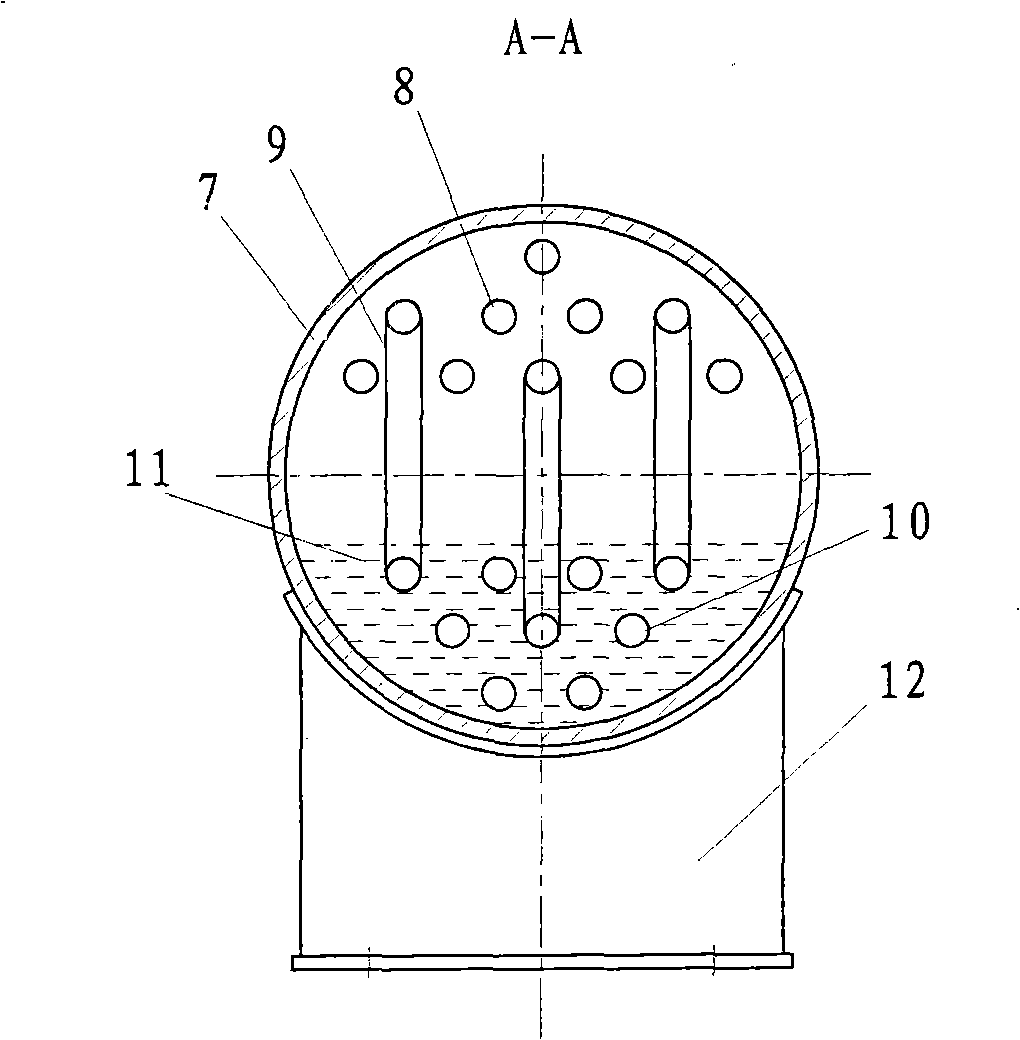

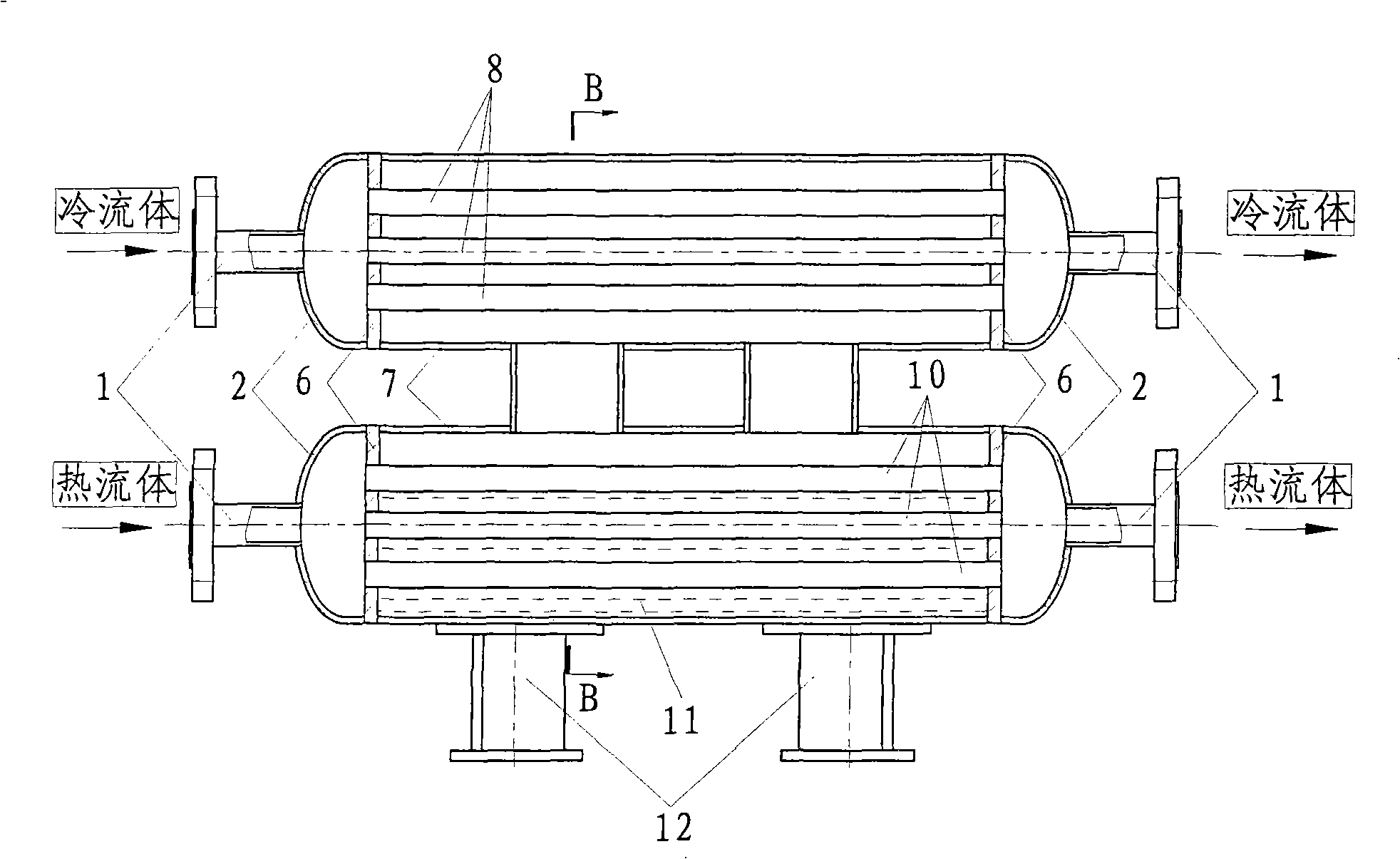

Enclosed cavity type heat exchanger

InactiveCN101245971AIncreasing the thicknessEfficient heat transferStationary tubular conduit assembliesHeat transmissionClosed chamber

The invention provides a closed chamber typed heat exchanger, belonging to the heat energy exchange technical field. The closed chamber typed heat exchanger is characterized in that a hole plate is sealed with two ends and the circumference of a cylindrical shell which is horizontally arranged; a cold fluid heat exchange pipe bundle and a hot fluid heat exchange pipe bundle pass through the hole plate and are sealed to form a chamber body; the cold fluid heat exchange pipe bundle and the hot fluid heat exchange pipe bundle are respectively arranged in the upper space and the lower space of the chamber body; a vacuum-shaped closed chamber is filled with working media; the internal chambers of the cold fluid heat exchange pipe bundle and the hot fluid heat exchange pipe bundle are communicated with a cover with a connecting pipe at two ends so as to respectively form an independent fluid passage; an installation supporter is welded externally below the cylindrical shell; the closed chamber of the cylindrical shell can be provided with a plurality of structural types such as single body, double bodies or three bodies; the closed chamber typed heat exchanger has the active effects that the heat exchanger is not a pipe shell typed heat exchanger in traditional meaning and has the advantages of simple structure, fast response, convenient heat control, high heat transmission efficiency and obvious energy-saving effect. The heat exchanger can be applied to heat transmission places with low, middle and high temperature, and is an extremely practical invention.

Owner:上海释皆通生物科技有限公司

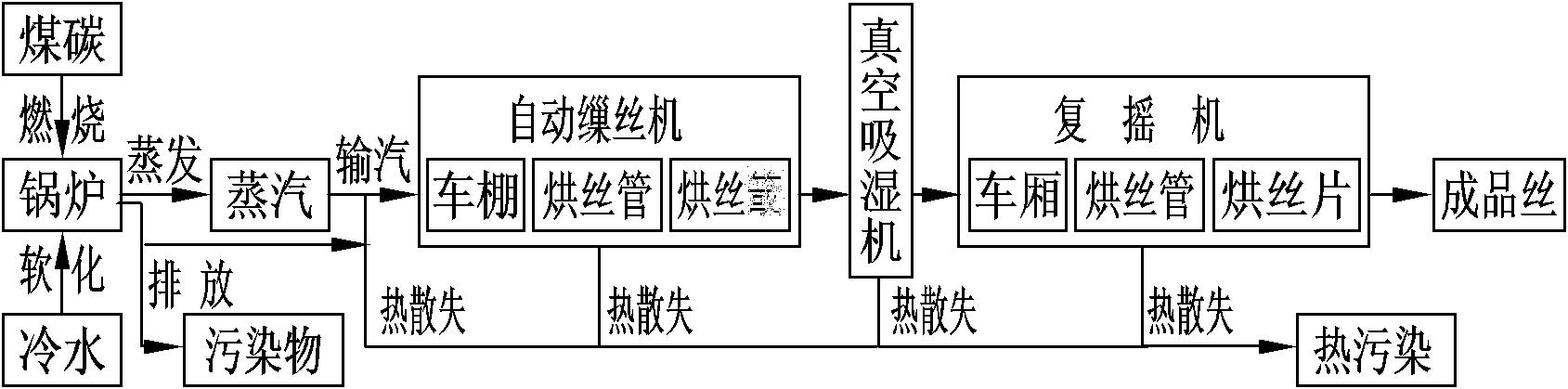

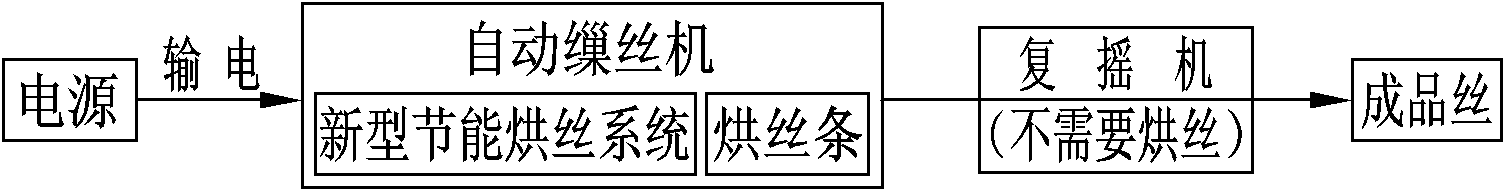

Novel energy-conservation silk drying system of automatic silk reeling machine

ActiveCN101984156AImprove production efficiency and product qualityReduce manufacturing costArtificial filament washing/dryingSilk reelingProcess engineeringEnergy loss

The invention relates to an automatic silk reeling machine in the technical field of raw silk production in the silk reeling industry, in particular to a novel energy-conservation silk drying system of an automatic silk reeling machine. The novel energy-conservation silk drying system comprises a compensation drum wheel, a traverse rod, a silk arranging drum wheel and a small silk-collecting tool. The technical scheme of the invention is as follows: a silk drier inlet drum wheel is arranged at the silk outlet of the compensation drum wheel, a far infrared silk drier is arranged adjacent to the silk drier inlet drum wheel, a photoelectric automatic silk moving mechanism is arranged at the silk outlet of the far infrared silk drier, and the silk outlet of the photoelectric automatic silk moving mechanism is provided with the silk arranging drum wheel. In the invention, less air is heated to heat wet raw silks, the raw silks are evenly dried at a high speed, and silk drying can be finished in the silk reeling machine once, thus the novel energy-conservation silk drying system not only saves energy, but also is favorable for lowering the workshop temperature, the silk reeling operation environment is improved, the problems of multiple working procedures, large energy loss and high workshop temperature of the traditional silk steam drying system for silk reeling production can be thoroughly solved, and according to incomplete statistics, the silk reeling energy consumption is greatly reduced compared with the silk coal-fired steam drying process.

Owner:SICHUAN RES INST OF SILK SCI

Process for the rapid fabrication of composite gas cylinders and related shapes

ActiveUS8858857B2Reduce the possibilityReduce tensionPressure vesselsDomestic articlesGas cylinderPlastic materials

A method of fabricating a composite vessel encompassing rapid manufacturing that is applicable to composite hydrogen and other gas storage tanks, both for high-pressure cylinders, as well as low-pressure conformal tanks. The process of fabrication includes using a liner, of metal or plastic materials, over which a braided or developed preform is wrapped. The dry fiber wrapped liner is placed in a mold and resin injected into the cavity formed between the liner and the mold outer walls. The liner is flooded with heated and / or cooled pressurized fluid thus enabling complete and independent process control from within the liner for both the resin injection and the cure phases. Fiber placement control is determined through combined biaxial and triaxial braid / preform design, and by wrapping at controlled tension onto the supporting liner. Fiber tension control is further enhanced by the methodology of mold loading whereby tensioning forces are enacted during actual load and close. The process may use thermoset or thermoplastic resins and any of a variety of fibrous reinforcements such as carbon, boron, glass, natural, aramid or other fibers.

Owner:A&P TECH

Method for preparing lithium battery current collector by plasma spraying polymer composite positive temperature coefficient (PTC) powder

InactiveCN103794801AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsManufacture by sprayingState of artReaction speed

The invention discloses a method for preparing a lithium battery current collector by plasma spraying polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through a plasma spraying device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coated in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. Compared with the prior art, the method has the advantages that the processing process is simple and convenient, the production efficiency is improved, the yield is increased, the product thickness consistency is high, the product quality reliability is high, the thermosensitive reaction speed is high, and capacity adjustment is accurate and convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

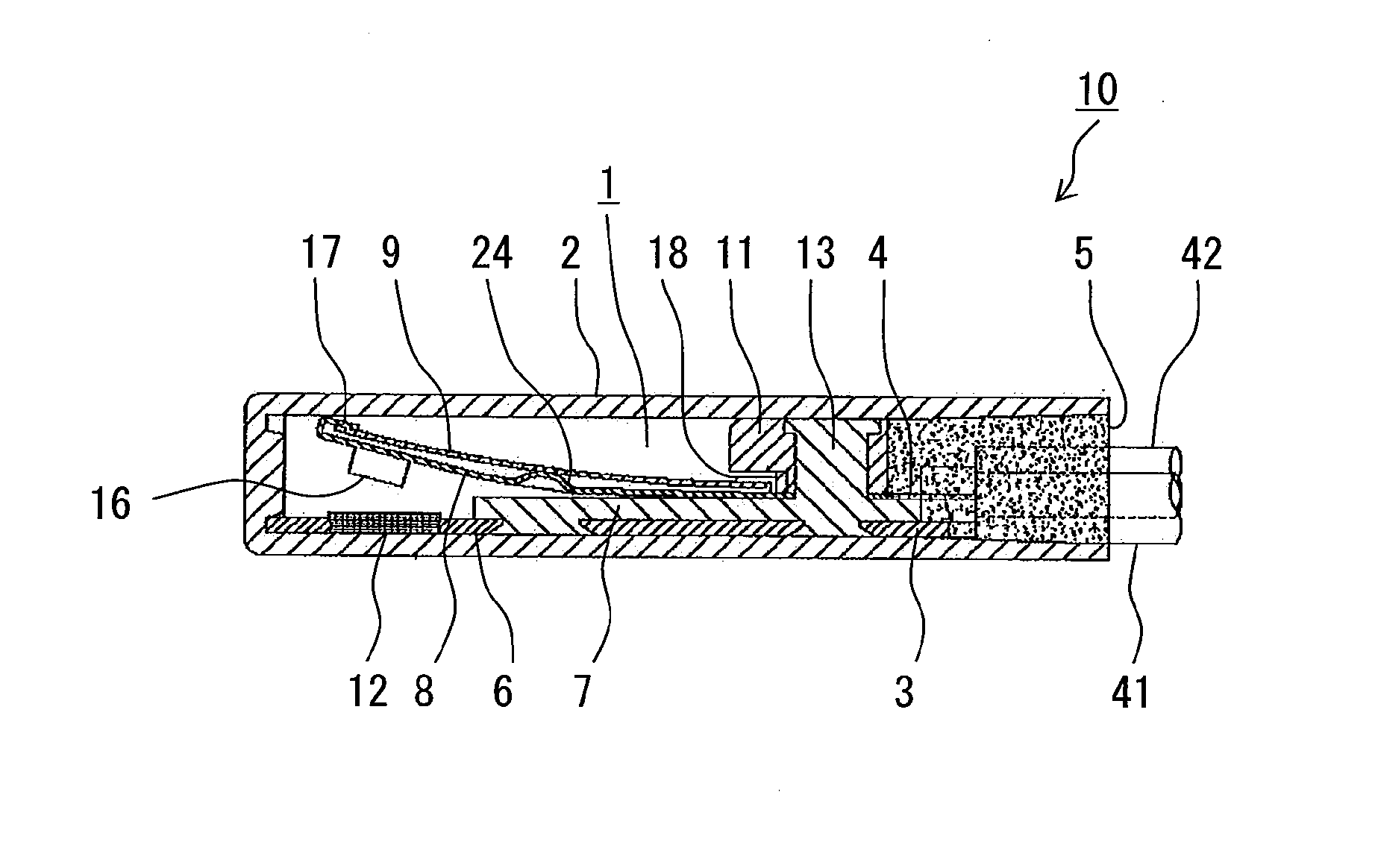

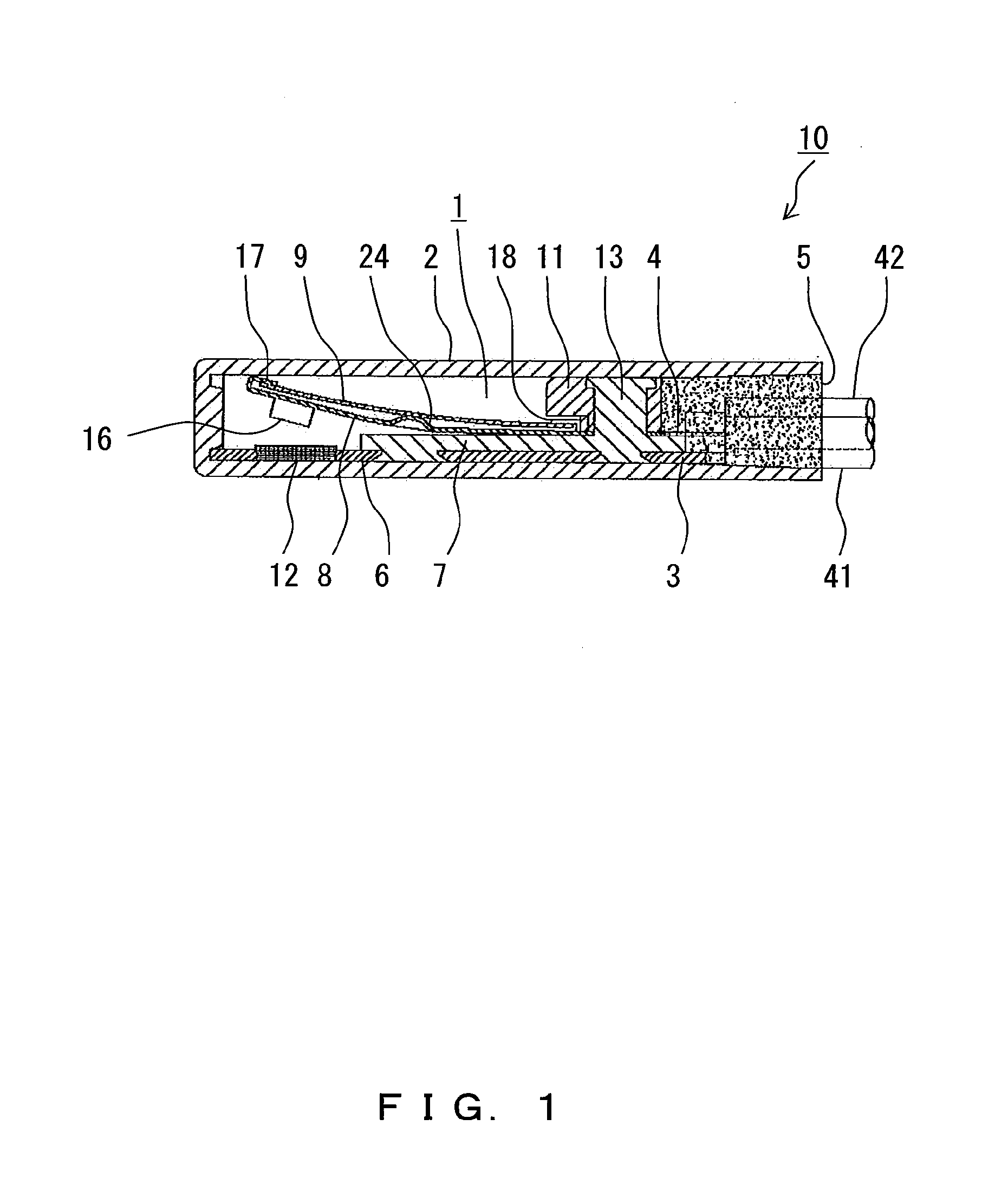

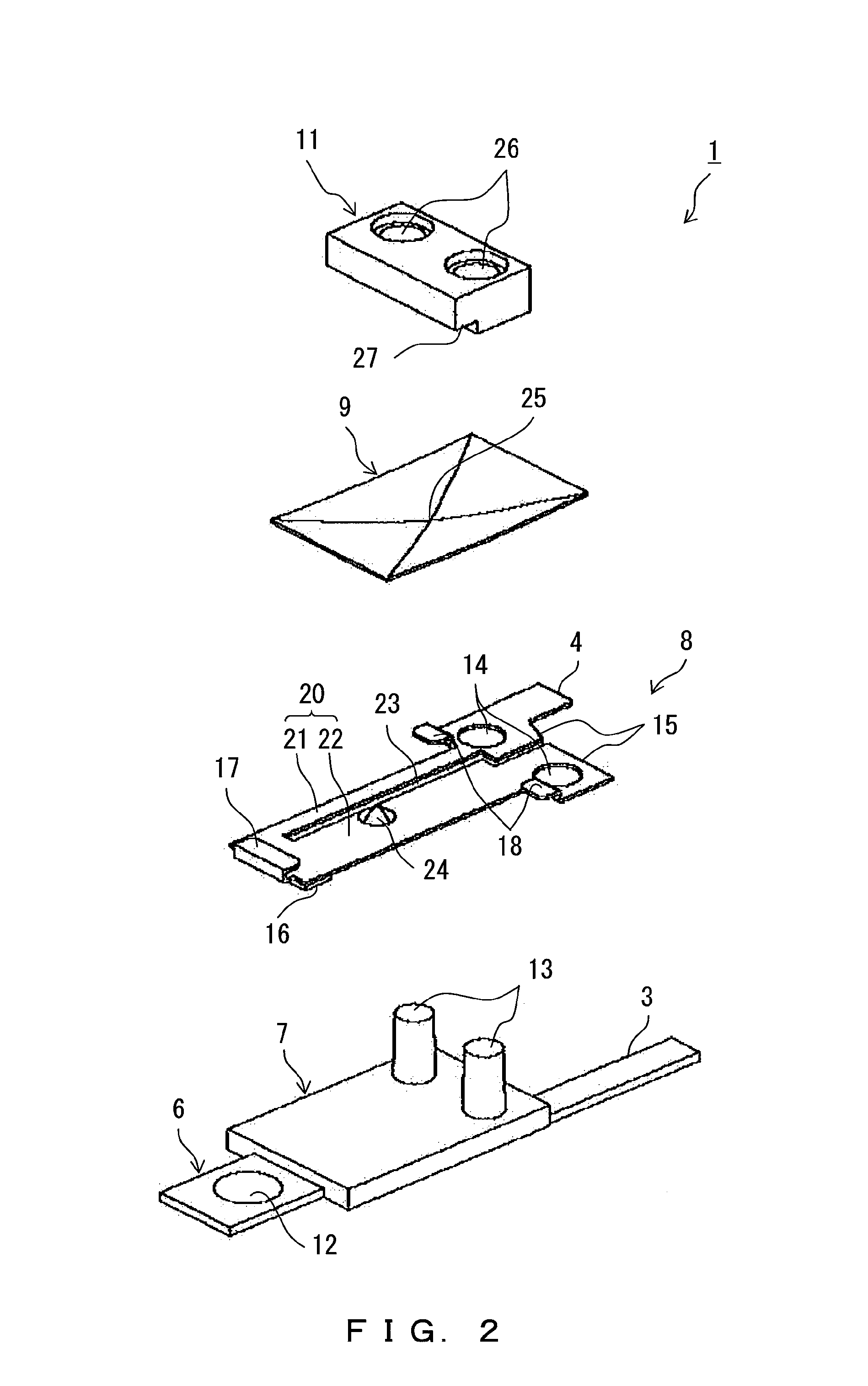

Thermal switch

InactiveUS20120001721A1Reduce heatReduce total powerThermal switch detailsEmergency protective arrangements for limiting excess voltage/currentCurrent limitingHeat sensitive

A movable plate 8 is partitioned by a slim hole 23 into a narrow-width part 21 and a wide-width part 22. When a contact is closed as a thermal switch 10, the narrow-width part 21 produces heat with an applied current branched via a first terminal 3 and a second terminal 4, which short-circuits both ends of the current limit resistor, and the heat of a bimetal 9 is retained with a small amount of local heat to self-hold the non-restoration state, so that the current limit resistor is quickly cooled down. When the power supply switch is turned off, the heat produced by the narrow-width part 21 is quickly cooled down to restore the thermal switch 10 in a short time. Also when the power supply is again turned on in a short time, the current limit resistor is made to function efficiently.

Owner:UCHIYA THERMOSTAT

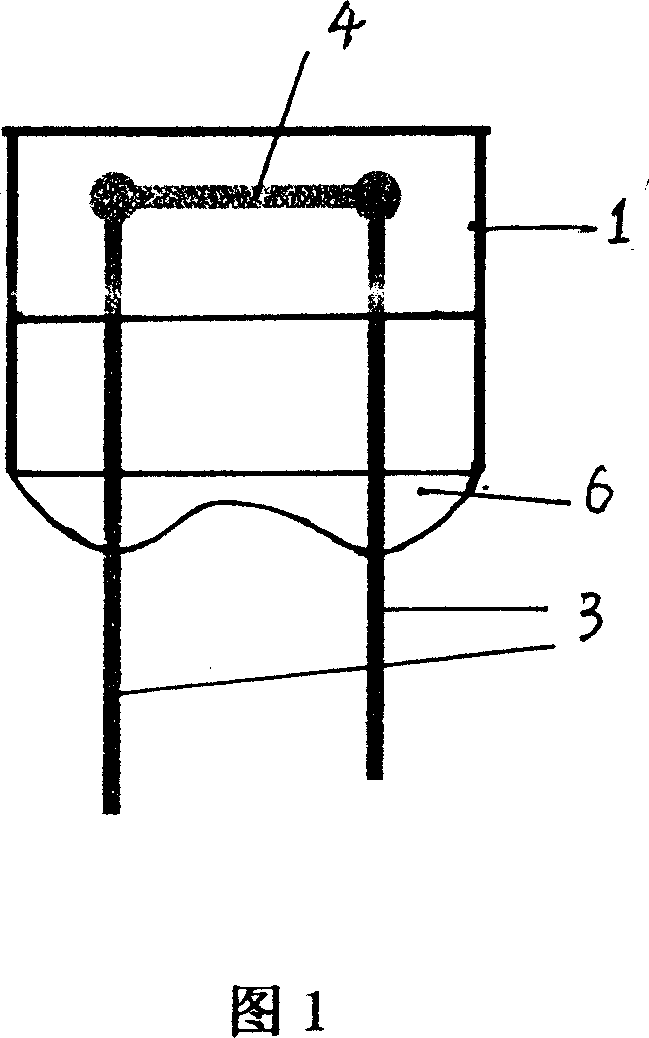

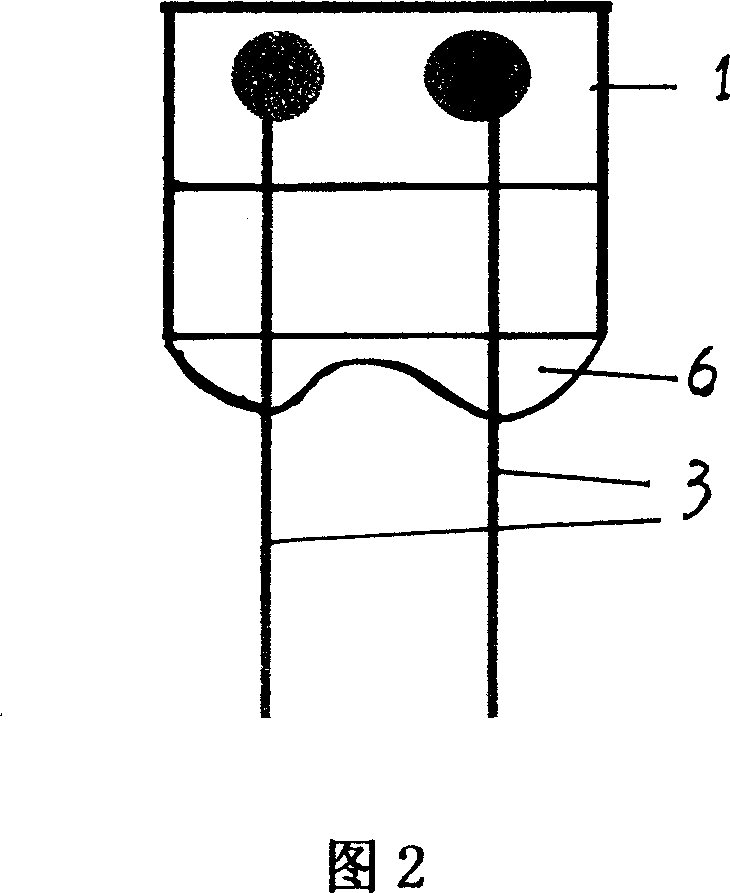

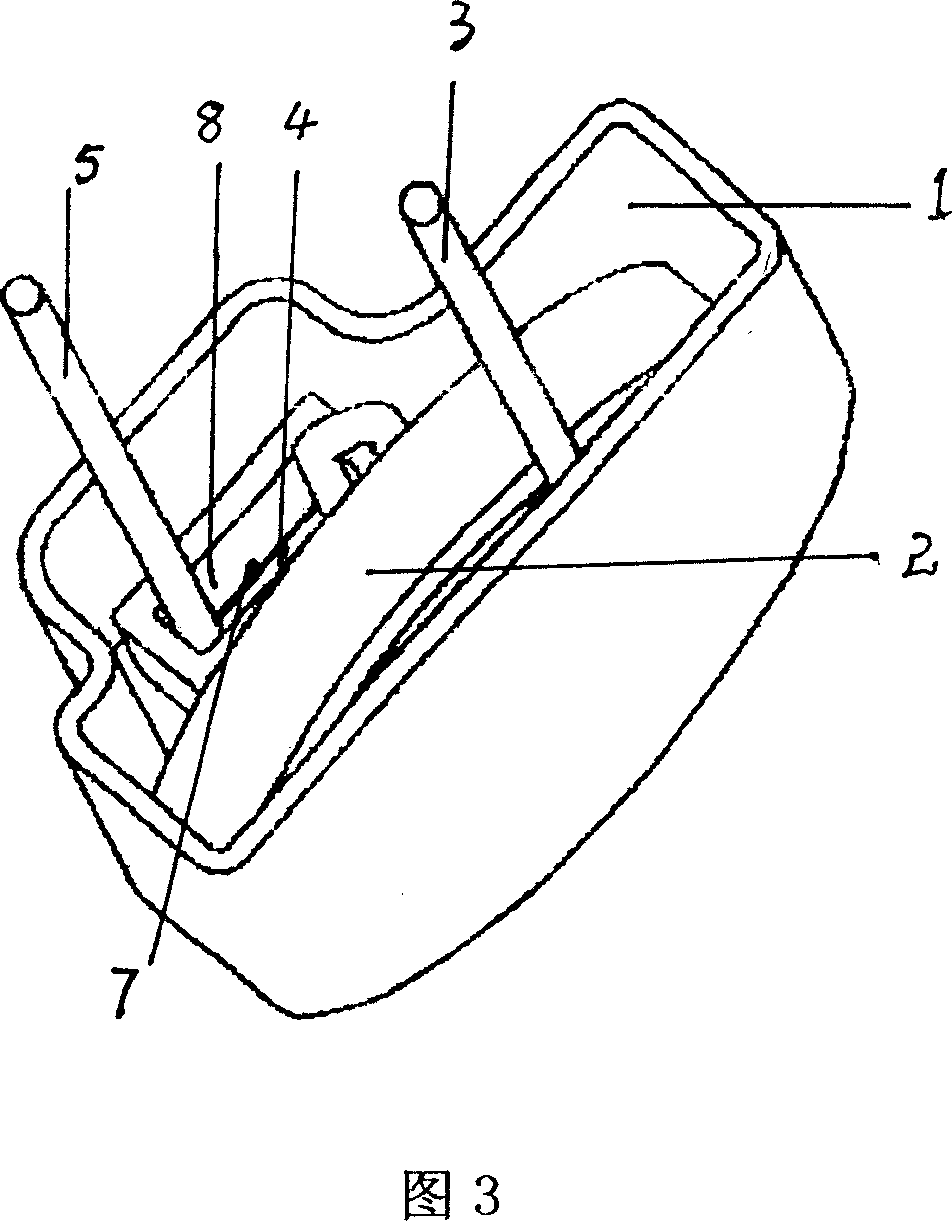

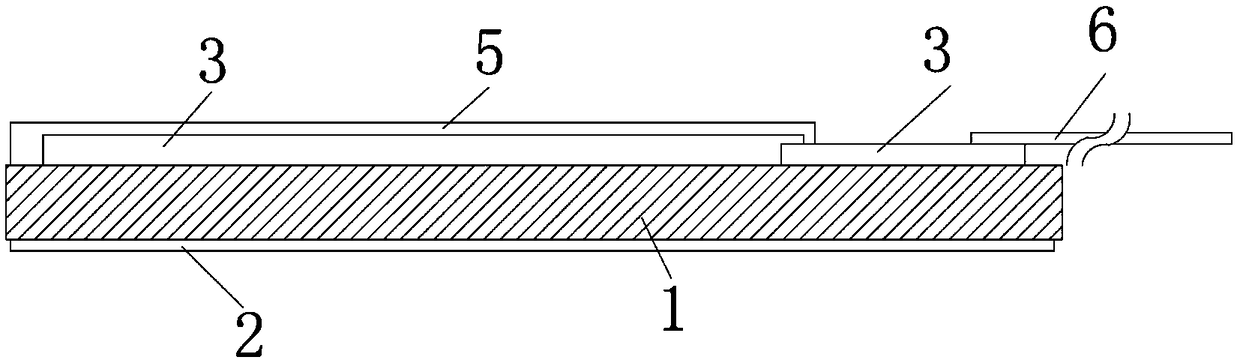

Thermal physiotherapy device

ActiveCN102038569AImprove heating efficiencyFast thermal responseMaterial nanotechnologyTherapeutic coolingCarbon nanotubeEngineering

The invention relates to a thermal physiotherapy device. The thermal physiotherapy device comprises an insulation base, a plurality of line electrodes and a plurality of row electrodes as well as a plurality of heating units, wherein the insulation base is provided with one surface; the line electrodes and the row electrodes are mutually crossed and arranged on the surface of the insulation base, each two adjacent line electrodes and each two adjacent row electrodes crossed with the line electrodes form a grid, and the line electrodes and the row electrodes are electric-insulated; each heating unit is arranged corresponding to one grid, and each heating unit comprises a first electrode, a second electrode and a heating element; the first electrode and the second electrode are arranged at interval and are electrically connected with the line electrodes and the row electrodes respectively; the heating unit is electrically connected with the first electrode and the second electrode; and the heating element comprises a carbon nano periosteum structure and a flexible macromolecule substrate, the flexible macromolecule substrate is provided with a surface close to the insulation base, and the carbon nano periosteum structure is arranged in the flexible macromolecule substrate and is adjacent to the surface of the macromolecule substrate close to the insulation base.

Owner:TSINGHUA UNIV +1

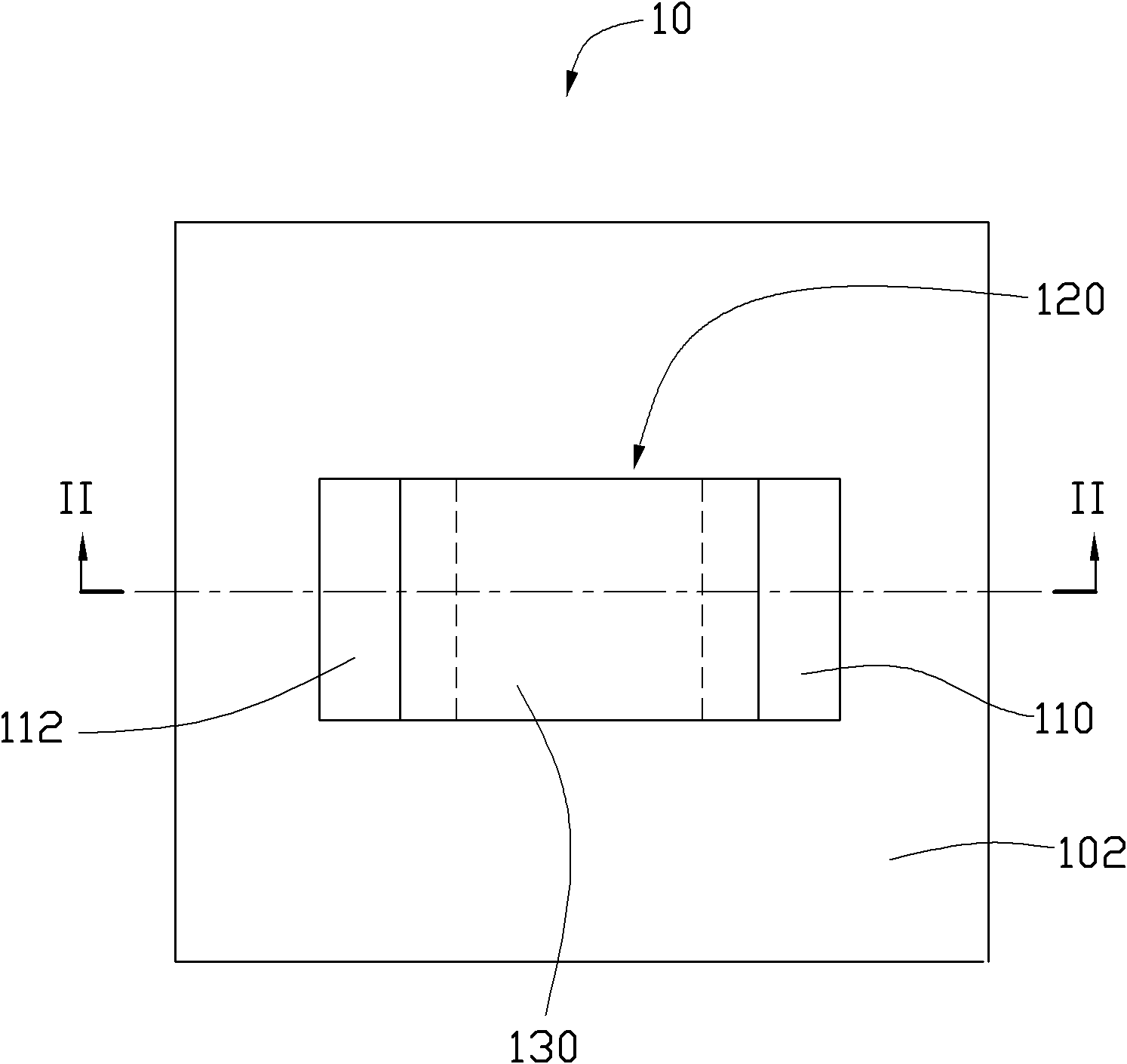

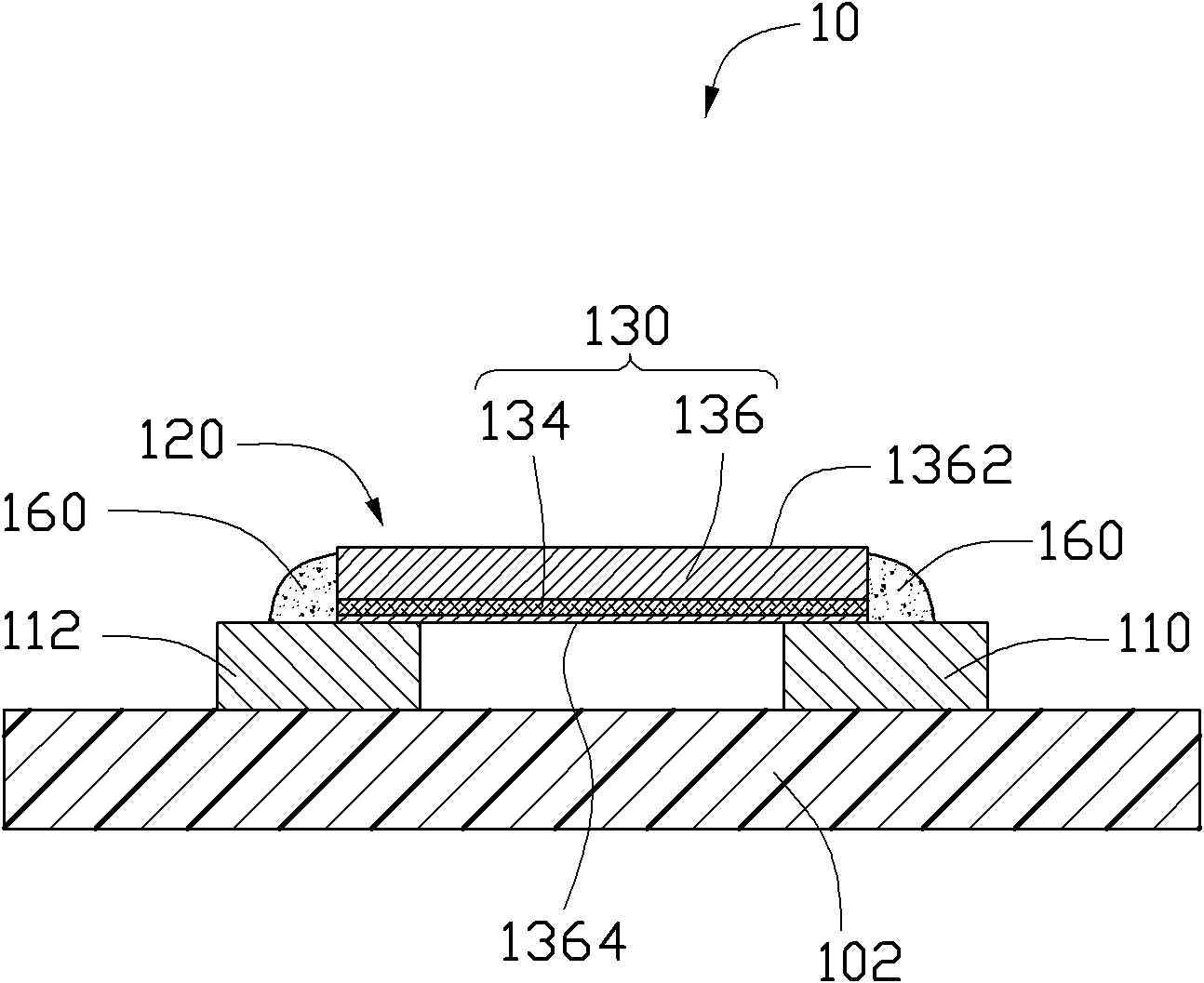

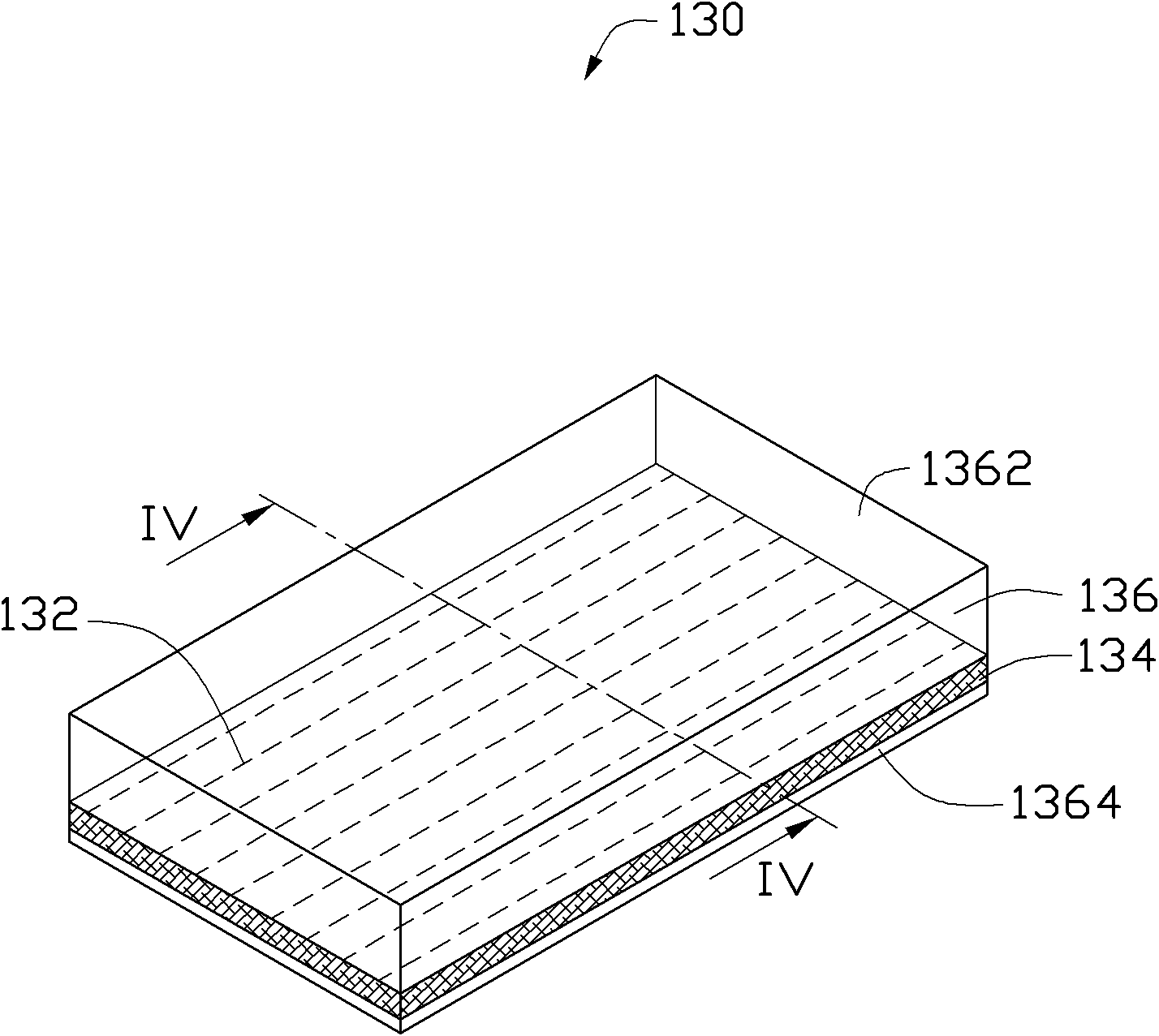

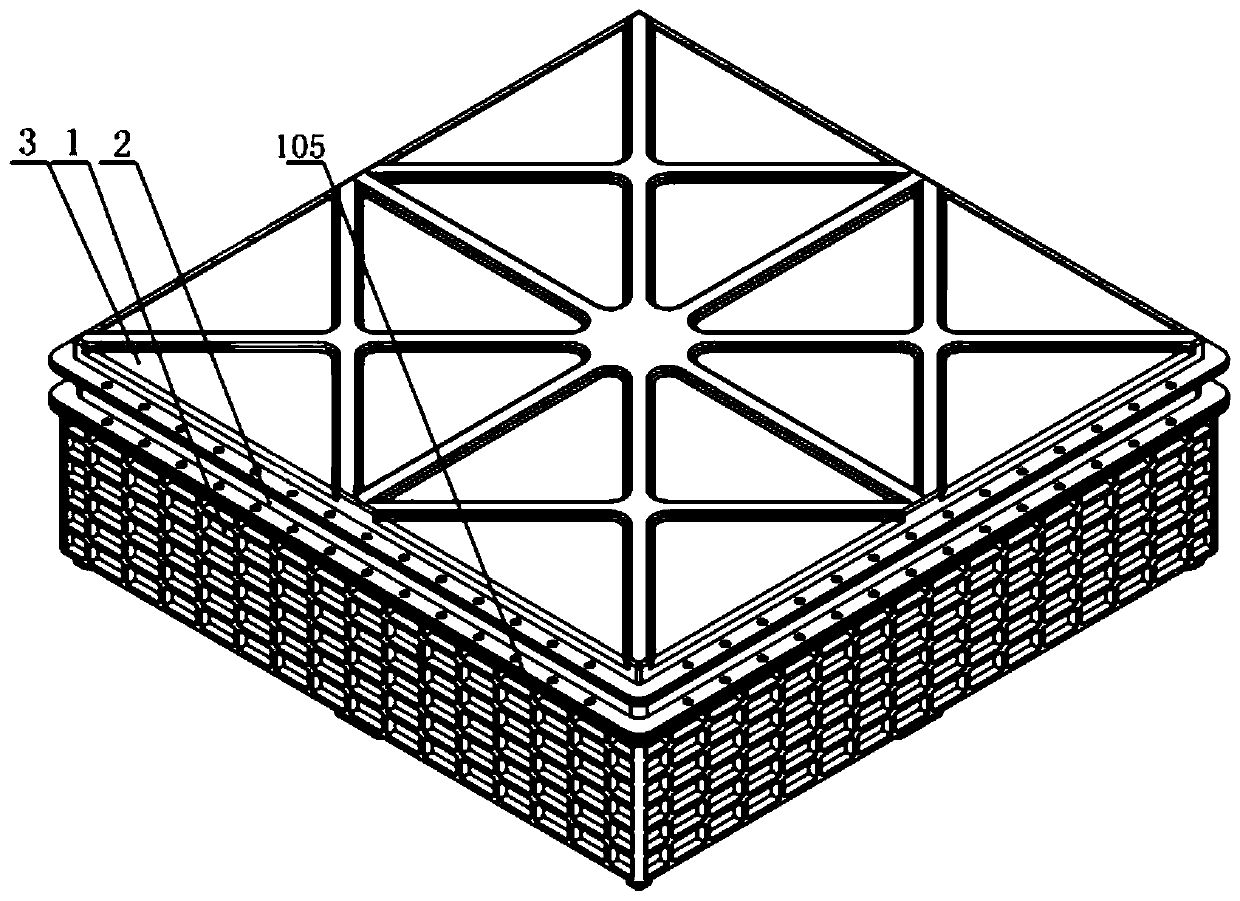

Battery pack based on Peltier effect and heat pipe cooling and heat management method thereof

ActiveCN109802194AImprove stabilityImprove reliabilitySecondary cellsTemperature controlHeat management

The invention discloses a battery pack based on a Peltier effect and heat pipe cooling and a heat management method thereof. A thermoelectric cooler is disposed on the upper part of a battery module in a battery pack case. Heat conduction gaskets and heat conduction fins having high thermal conductivity and the batteries form a heat conduction path of battery module-heat conduction gaskets-heat conduction fins-heat conduction support plate and a heat conduction path of battery module-heat conduction gaskets -heat conduction fins- heat conduction support vertical plate-heat conduction support plate. Different working modes can be performed in a high-temperature environment, a low-temperature environment and a normal environment. Advantages of fast thermal response, high thermal conductivity, accurate temperature control, no noise and the like are achieved. The battery individual modules in the battery module are increased in heat transfer coefficients when uniformly heated, thereby further ensuring the stability, reliability and high efficiency of the battery operation. The battery pack is compact in overall structure and small in size, and provides a space for the structural arrangement of the whole vehicle.

Owner:CHONGQING UNIV

Modularized combined intelligent heat collector system

ActiveCN104832967AImprove thermoelectric conversion efficiencyReduce manufacturing costWaste gas energySpace heating and ventilation detailsCollector deviceEngineering

The invention discloses a modularized combined intelligent heat collector system, which is characterized in that the system comprises a PTCR-xthm electric heating chip heat source host, a data control template, a constant-temperature and constant-pressure device and a variable frequency pump, wherein the variable frequency pump and the PTCR-xthm electric heating chip heat source host are connected with the data control template; the outlet end of the PTCR-xthm electric heating chip heat source host is connected with the constant-temperature and constant-pressure device; the outlet end of the constant-temperature and constant-pressure device is connected with the PTCR-xthm electric heating chip heat source host through the variable frequency pump; the PTCR-xthm electric heating chip heat source host directly leads out a user heating pipeline; and / or the PTCR-xthm electric heating chip heat source host leads out the user heating pipeline through the constant-temperature and constant-pressure device, and a heat exchanger connected with a user water heater. Source water is heated to a set temperature when passing through the PTCR-xthm electric heating chip heat source module once a machine is started, and waiting is not needed. The water temperature can be adjusted and controlled within 100 DEG C, the saturation temperature can be adjusted and controlled within 180 DEG C, and the device also has the advantages of general structure, zero pollution, zero emission, high efficiency, energy saving, safety, reliability, high cost performance, small size, low cost and intelligent control.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

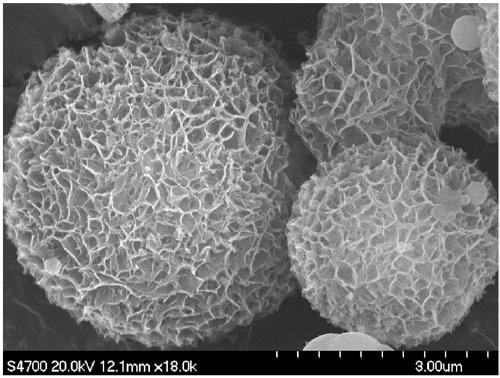

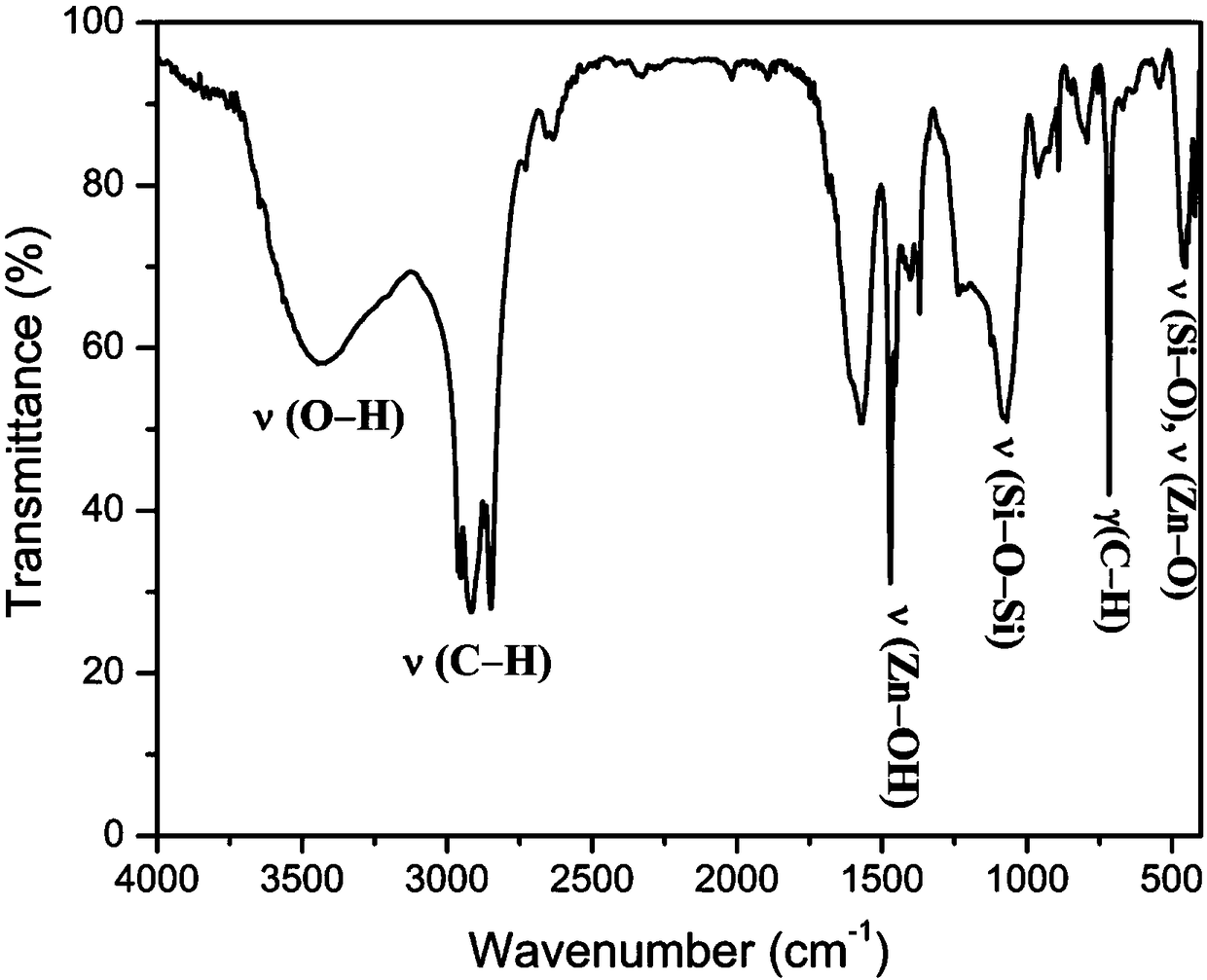

Superhydrophobic phase change energy storage material microcapsule and preparation method thereof

ActiveCN109499499AHas multiple functionsEasy to packEnergy storageHeat-exchange elementsThermal energyThermal energy storage

The invention relates to a superhydrophobic phase change energy storage material microcapsule and a preparation method thereof, belonging to the technical field of phase change energy storage materials. The microcapsule consists of an organic phase change material core, an inorganic oxide inner layer shell and a nano flower-like zinc oxide outer shell layer, and has a 'core-shell' structure; the preparation method comprises the steps of preparing an organic phase change material microcapsule coated with the inorganic oxide inner layer shell by using an emulsion template interfacial polymerization method; then, under the action of a surfactant, a structure inducer and a pH regulator, constructing a rough surface formed by the nano flower-like zinc oxide outer shell layer by means of hydrolysis of a zinc source and by inducing zinc ions to nucleate and crystallize on the surface of the inner shell layer of the microcapsule; modifying the surface of the nano flower-like zinc oxide outer shell layer with a halogen-free low surface energy modifier so as to obtain a superhydrophobic property with a static water contact angle of 160 degrees or more. The phase change material microcapsuleprovided by the invention is used for thermal energy storage, thermal temperature regulation and thermal management, and has the characteristics of being self-cleaning, anti-fouling, efficient in lubrication and environmentally-friendly, and the like.

Owner:BEIJING UNIV OF CHEM TECH

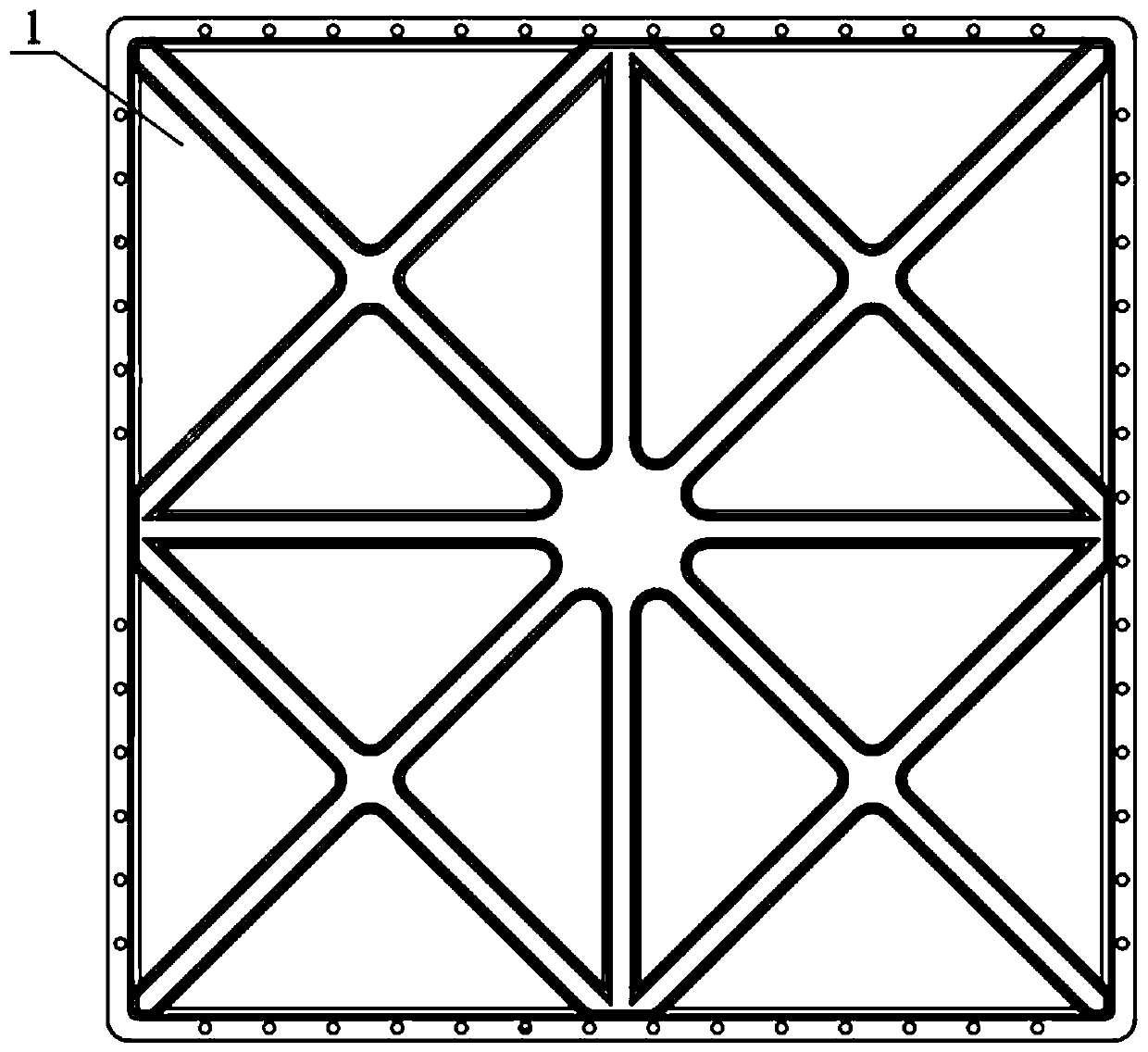

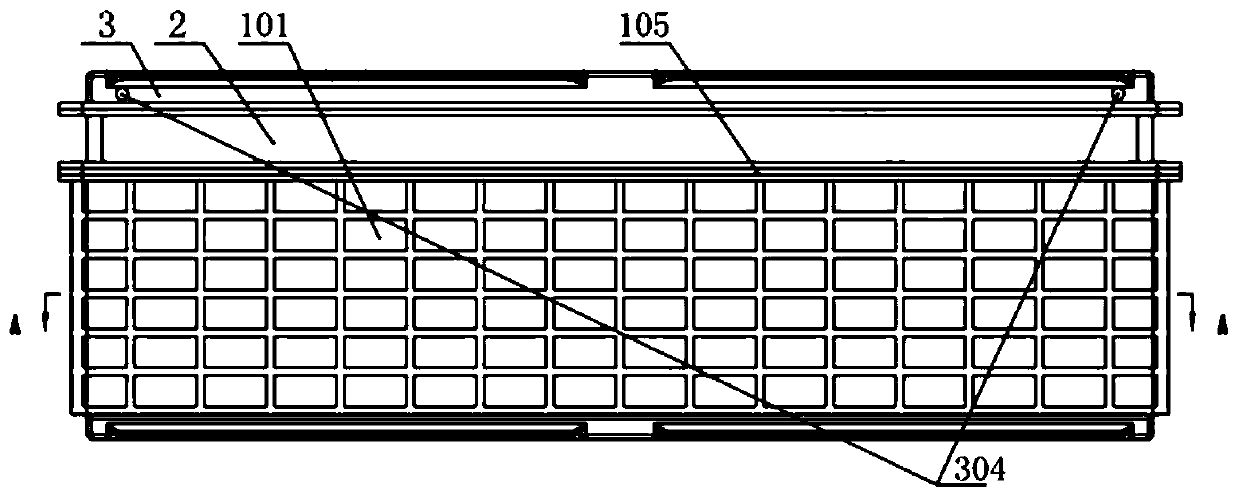

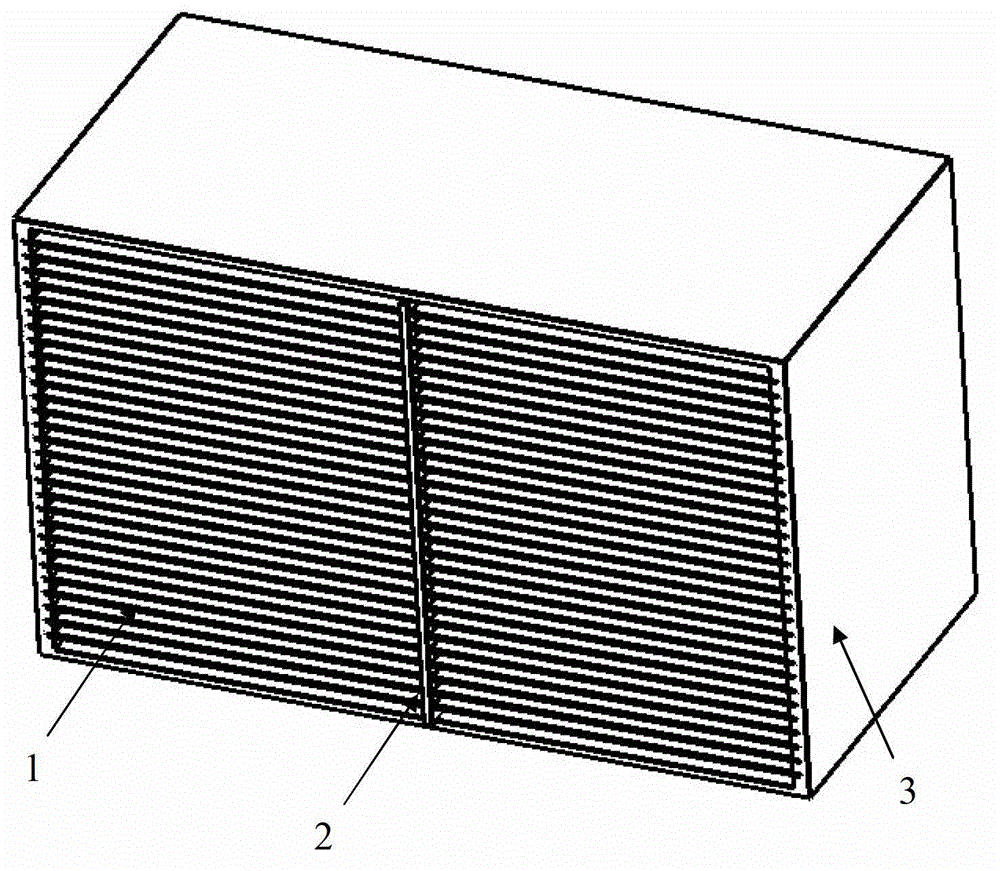

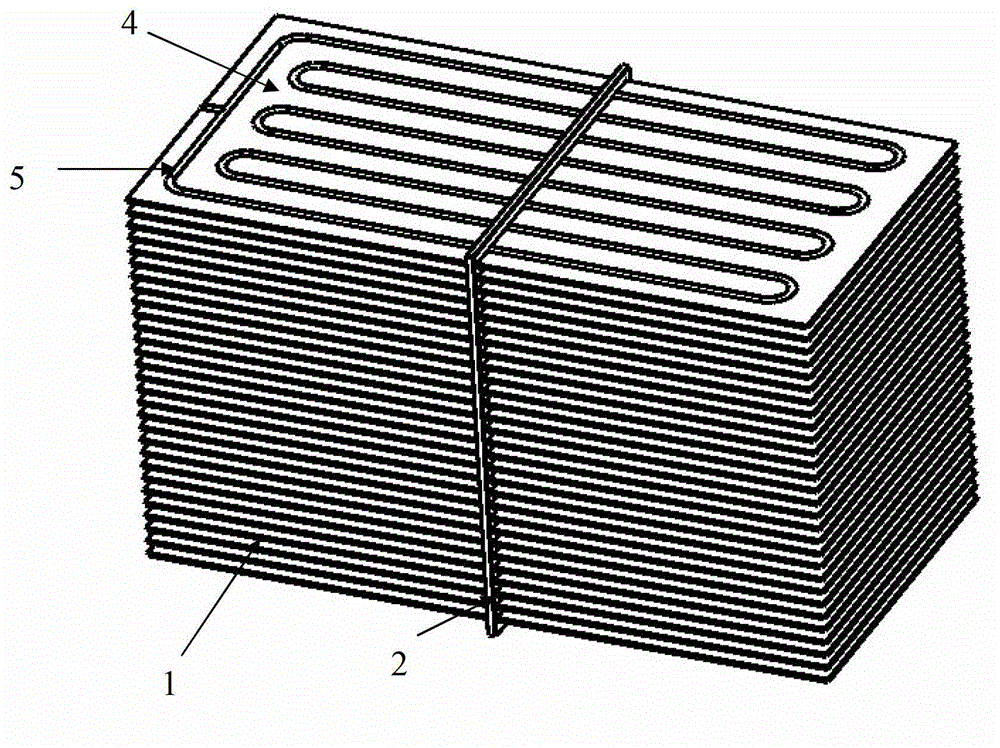

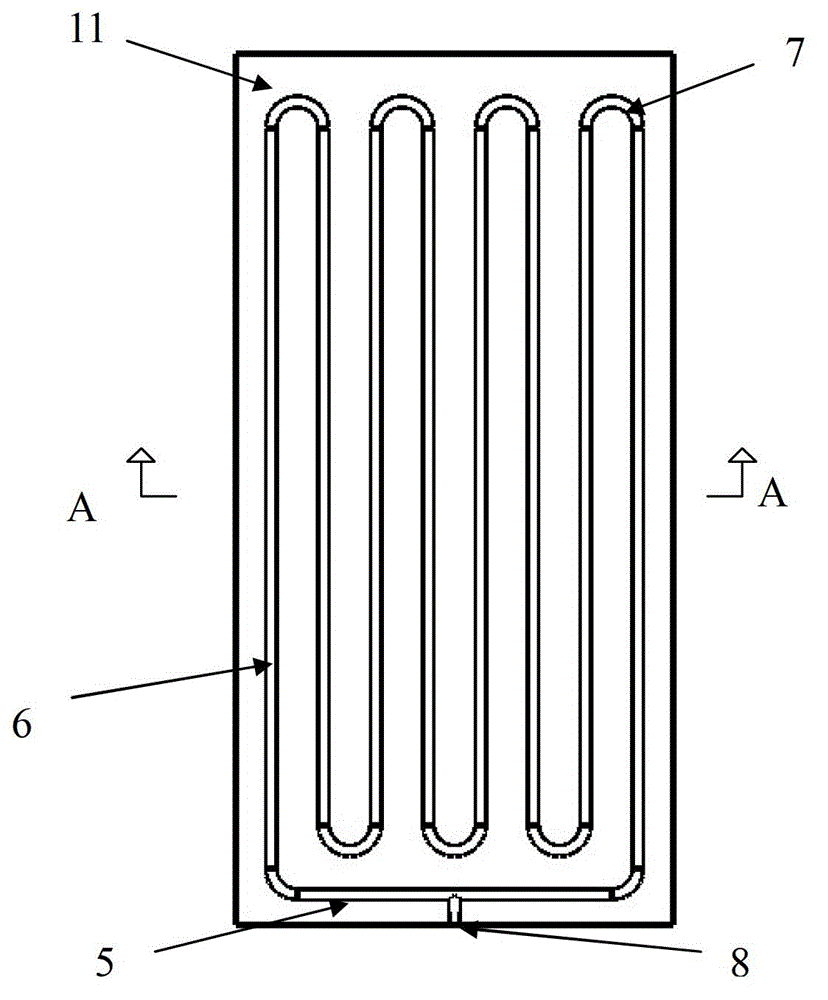

Plate type pulsating heat pipe fresh air heat regenerator

InactiveCN102944052AGuaranteed uptimeAvoid the problem of changing direction in changing seasonsEnergy recovery in ventilation and heatingIndirect heat exchangersEngineeringAir conditioning

The invention relates to a plate type pulsating heat pipe fresh air heat regenerator, which consists of a heat exchanger casing, a separating plate and a plate type pulsating heat pipe heat exchange plate group, wherein the heat exchanger casing is a square-shaped hollow casing with openings at the front and the back, a plurality of horizontal side wall slots are symmetrically are arranged in the left inner wall and the right inner wall of the hollow casing, the separating plate is vertically arranged in the right center of the heat exchanger casing and divides an inner cavity of the heat exchanger into a left part and a right part, a plurality of rectangular through holes in positions corresponding to the side wall slots are arranged in the separating plate, the plate type pulsating heat pipe heat exchange plate group comprises a plurality of plate type pulsating heat pipe heat exchange plates, the plate type pulsating heat pipe heat exchange plates pass through the rectangular through holes of the separating plate, and in addition, two ends of the plate type pulsating heat pipe heat exchange plates are respectively inserted into the side wall slots of the heat exchanger casing. The operation of the plate type pulsating heat pipe fresh air heat regenerator is not influenced by the gravity field, the problem of reversing need during season change is avoided, and the plate type pulsating heat pipe fresh air heat regenerator has the advantages that the heat exchange efficiency is high, the heat exchange quantity is great, and fresh and old air cannot be polluted. The plate type pulsating heat pipe fresh air heat regenerator is suitable for a fresh air heat exchange system of an air conditioning system.

Owner:SHANGHAI JIAO TONG UNIV

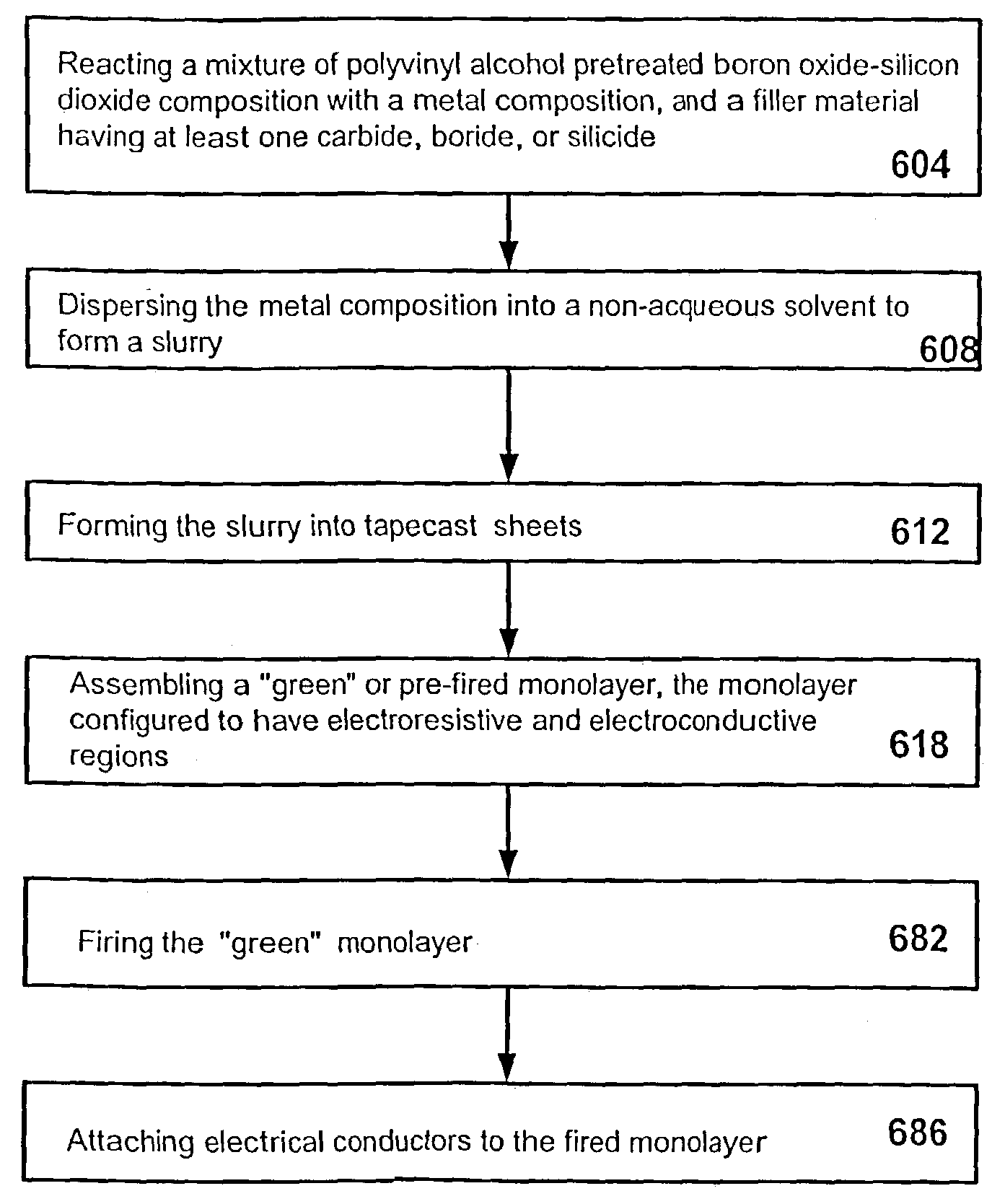

Tapecast electro-conductive cermets for high temperature resistive heating systems

InactiveUS7189342B2Low costImprove performanceNon-metal conductorsConductive materialElectrical resistance and conductanceChemical composition

This invention relates to novel chemical compositions and manufacturing methods for producing electro-conductive, metal-ceramic materials having improved structural stability to operate at high temperatures in oxidizing atmospheres.

Owner:HARMONICS

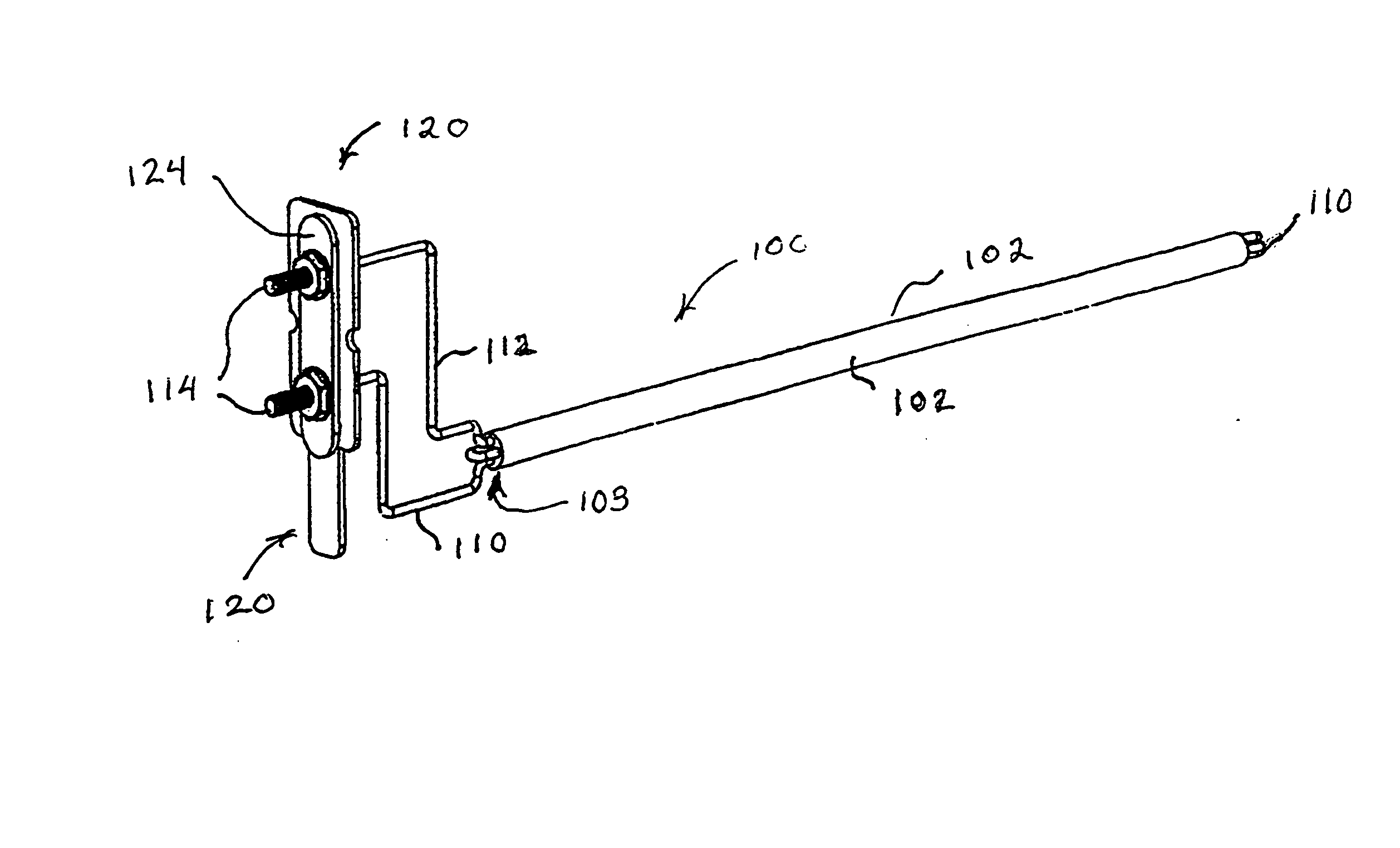

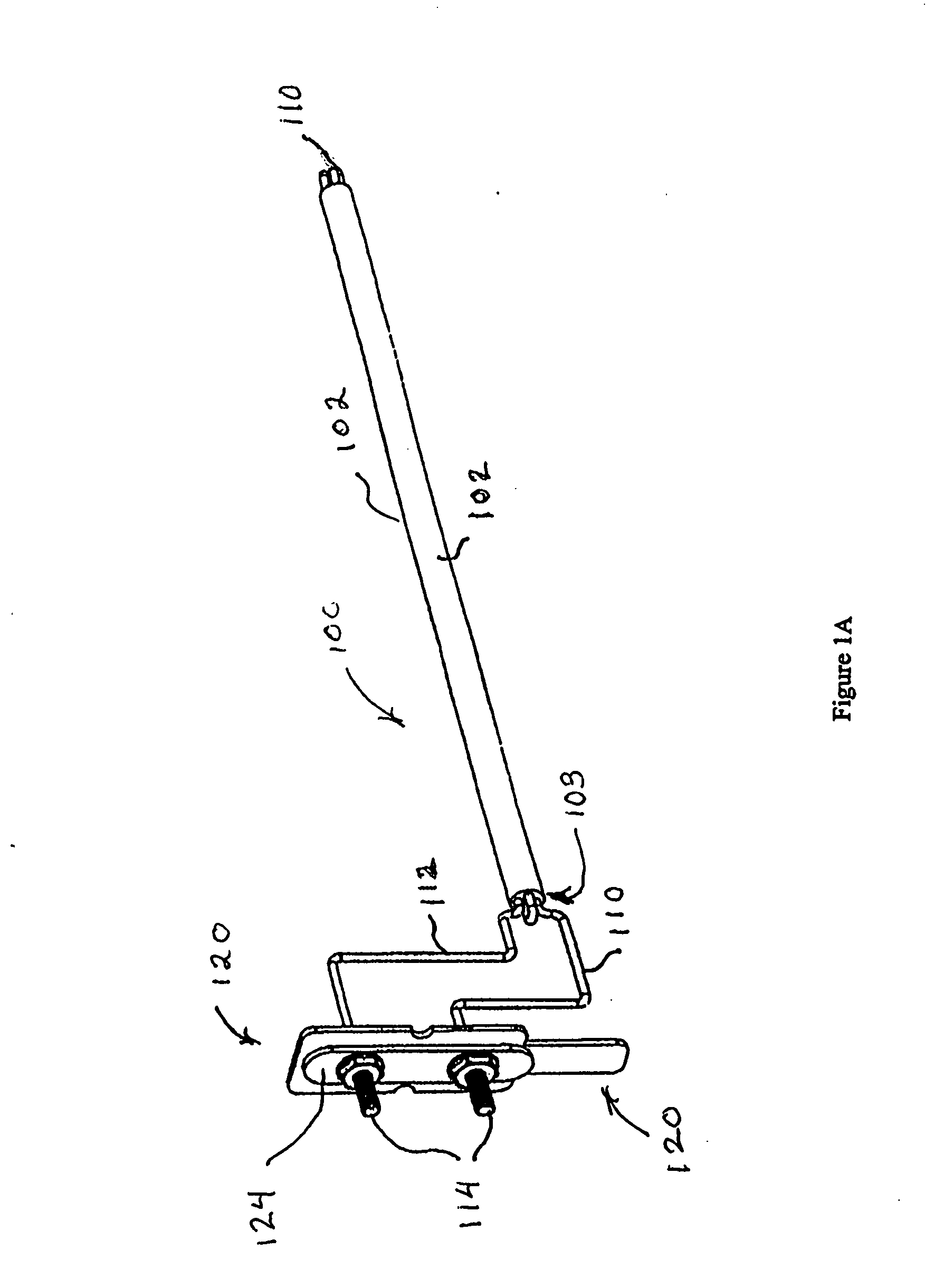

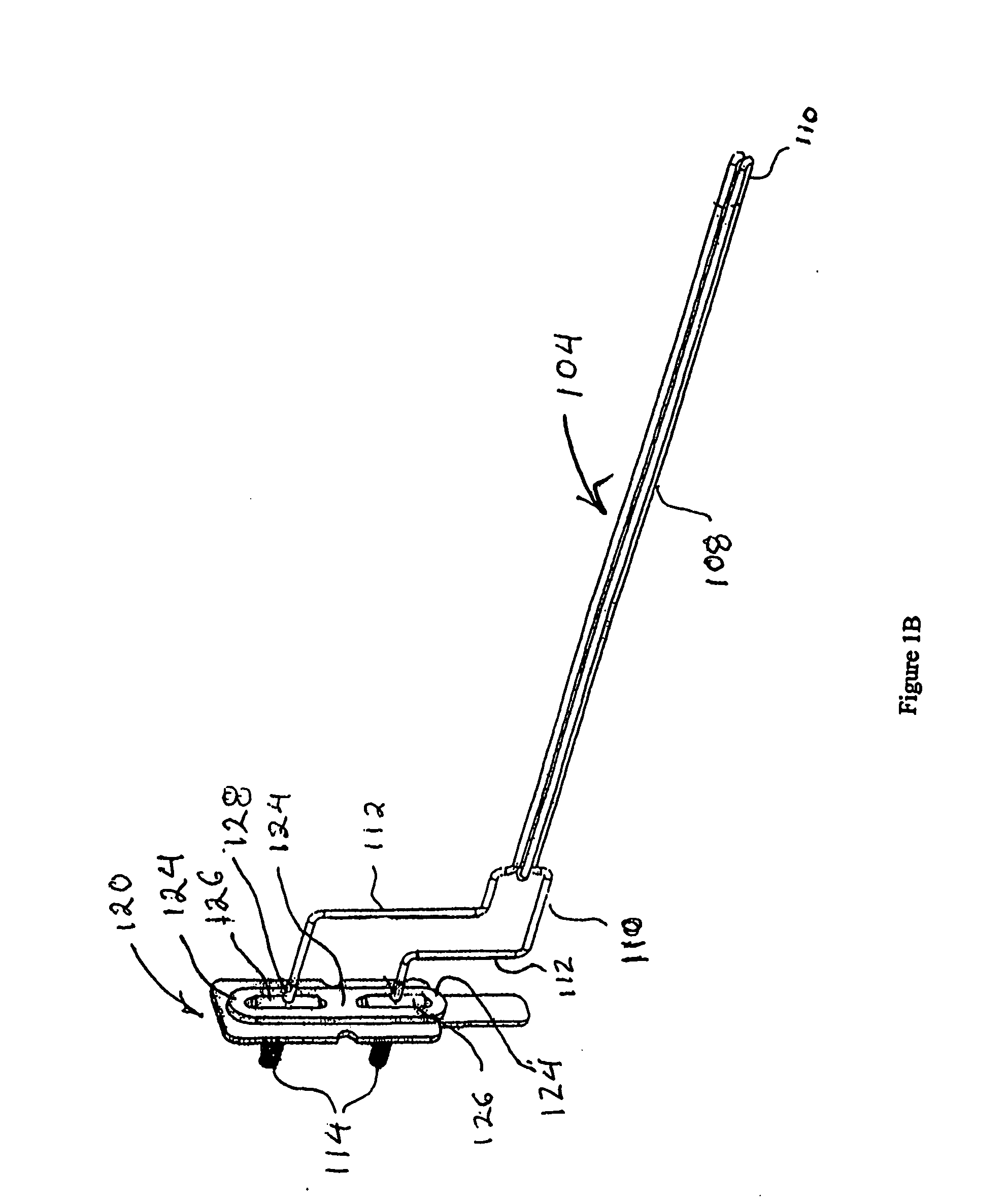

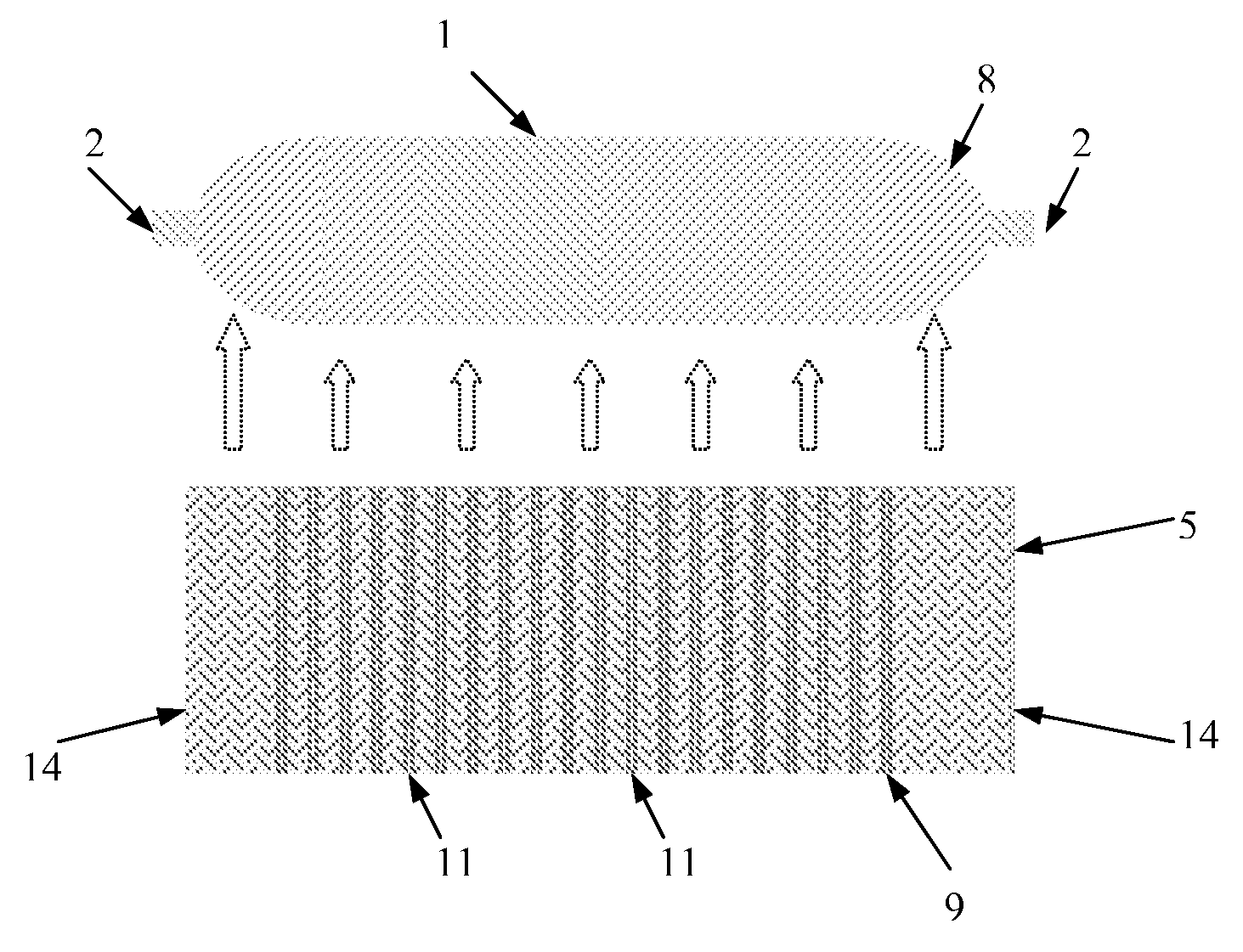

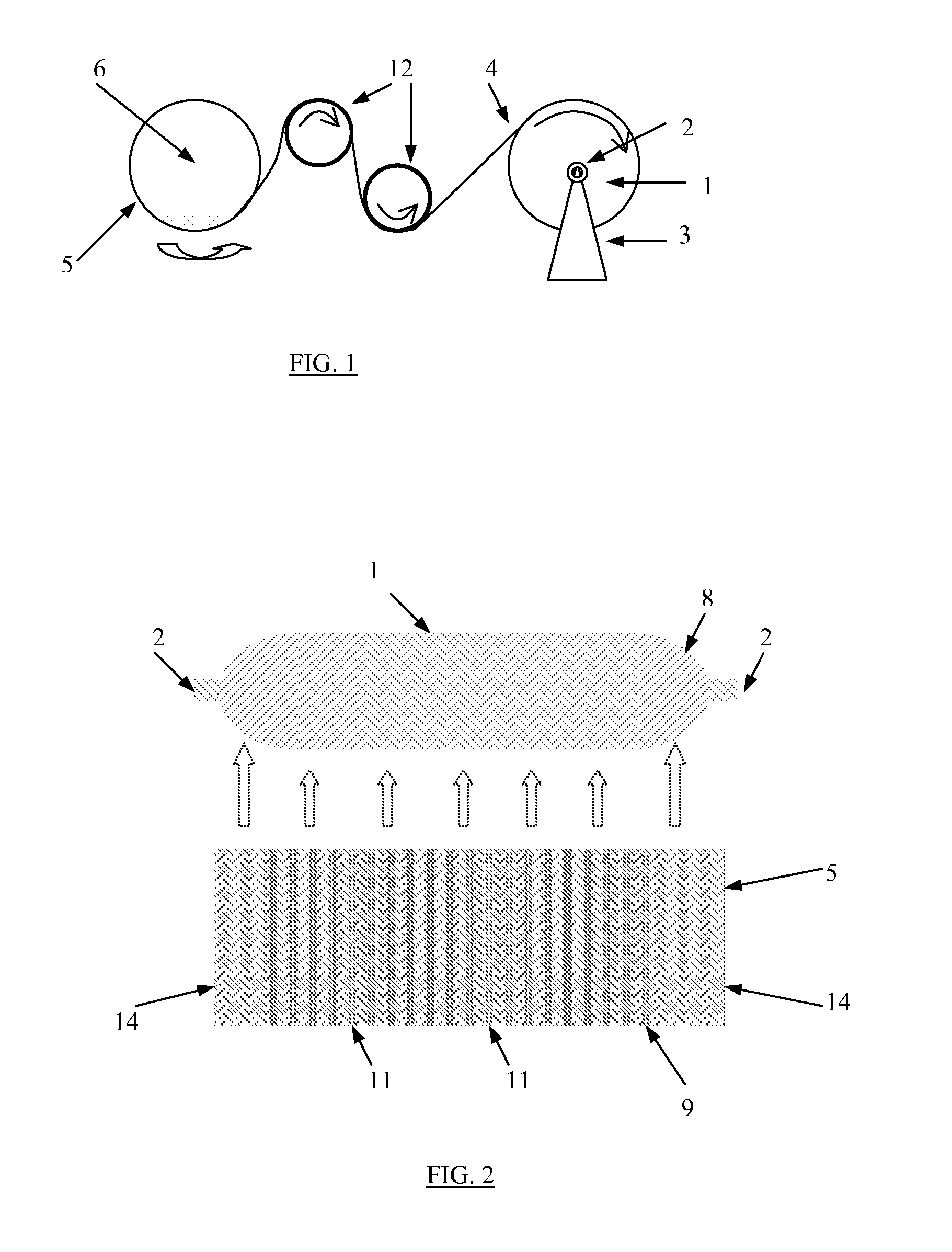

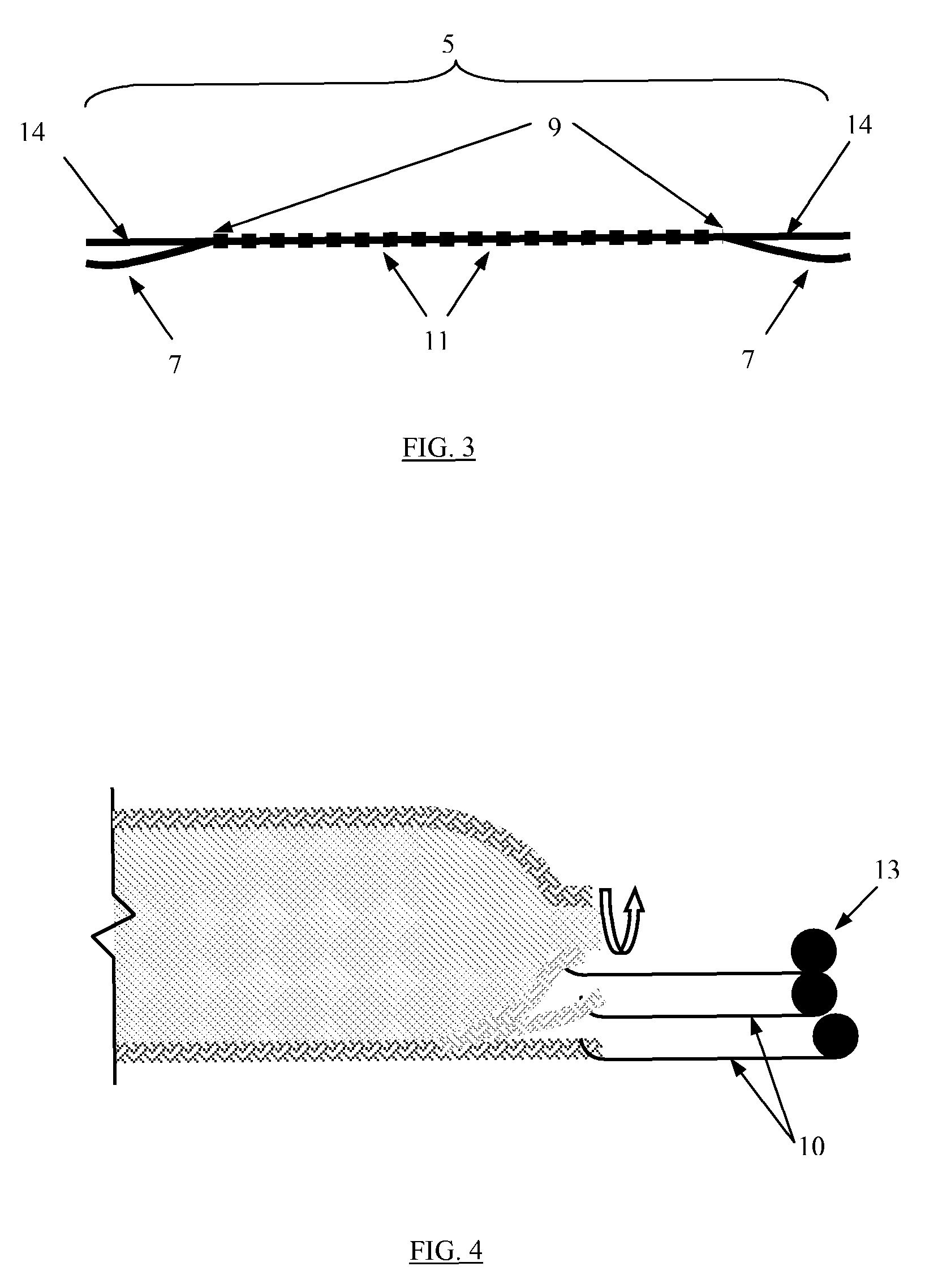

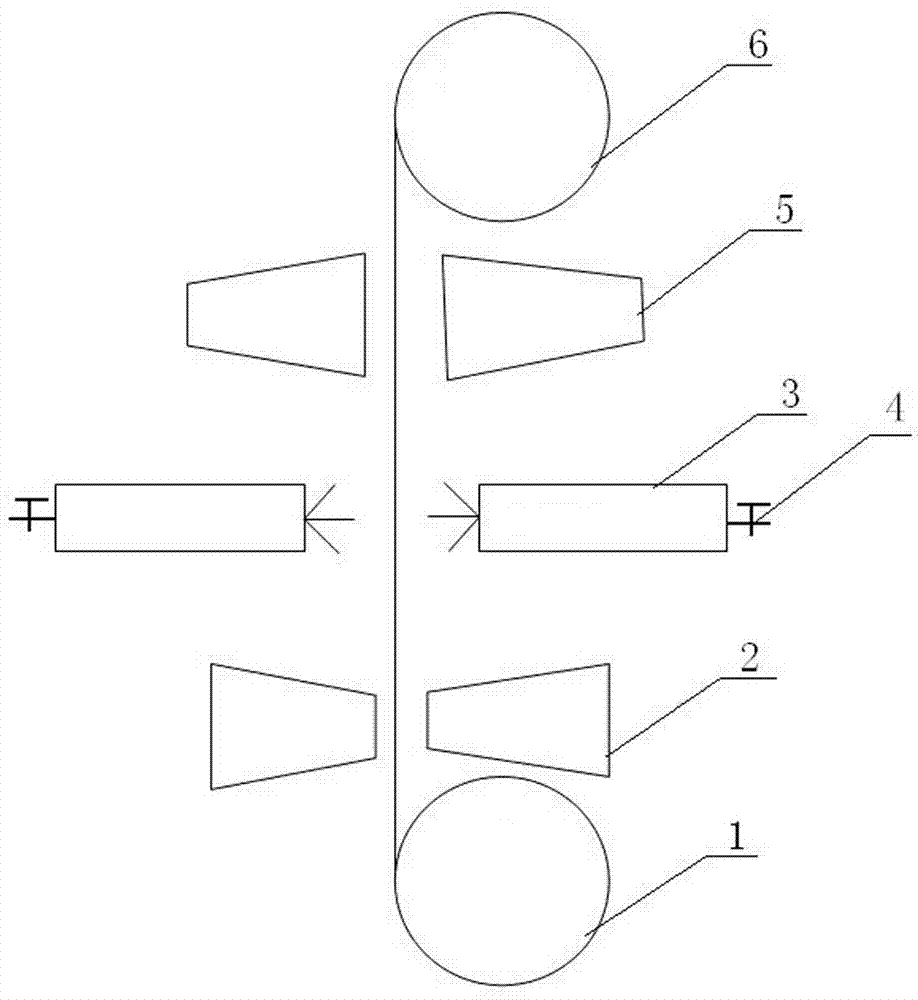

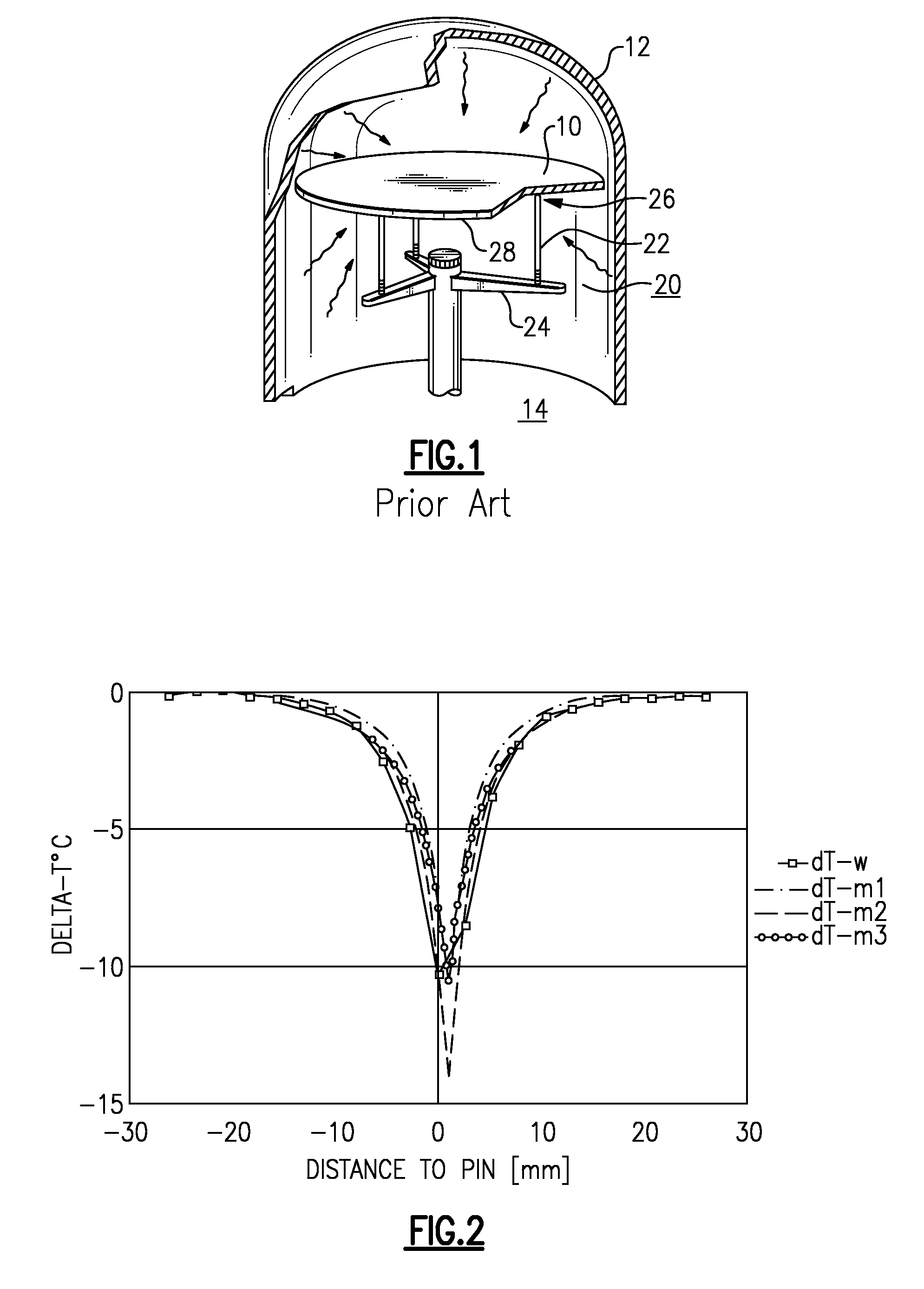

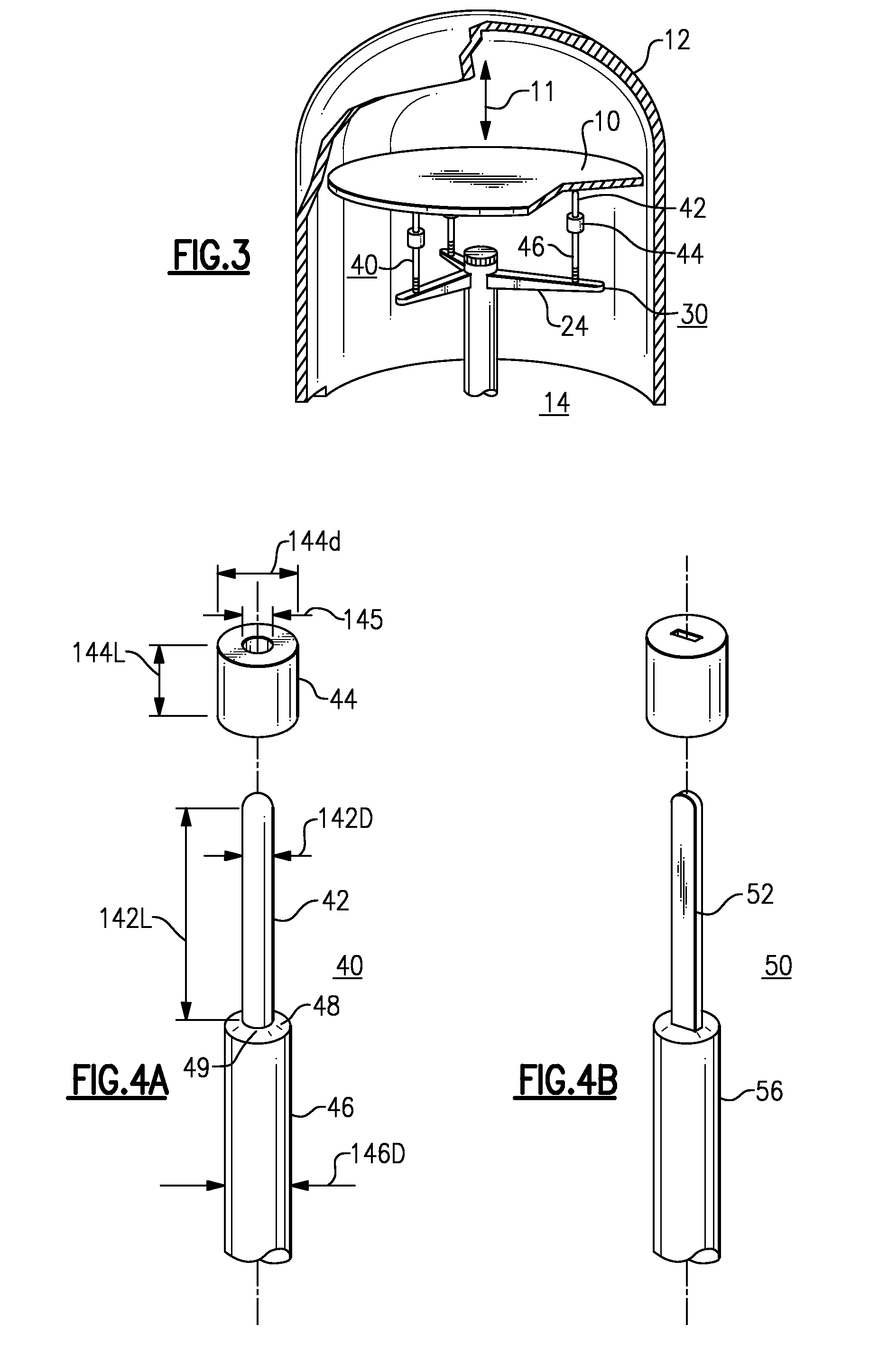

Method and structure to control thermal gradients in semiconductor wafers during rapid thermal processing

InactiveUS8107800B2Fast thermal responseDomestic stoves or rangesDrying solid materials with heatEngineeringMechanical engineering

An article supports a workpiece during thermal processing. At least three elongated support members, e.g., support pins, extend upwardly from an element such as support arms for supporting the workpiece. Each of the support members includes a first portion adjacent to the workpiece. A second portion extends downwardly from the first portion. The first portion can have a thermal response faster than the thermal response of the workpiece and the second portion can have a slower thermal response. A removable element may be mounted to the support member for adjusting the thermal response of the support member. With removable elements, the support members can be adjusted to cause no net transfer of heat to or from the workpiece.

Owner:ALSEPHINA INNOVATIONS INC

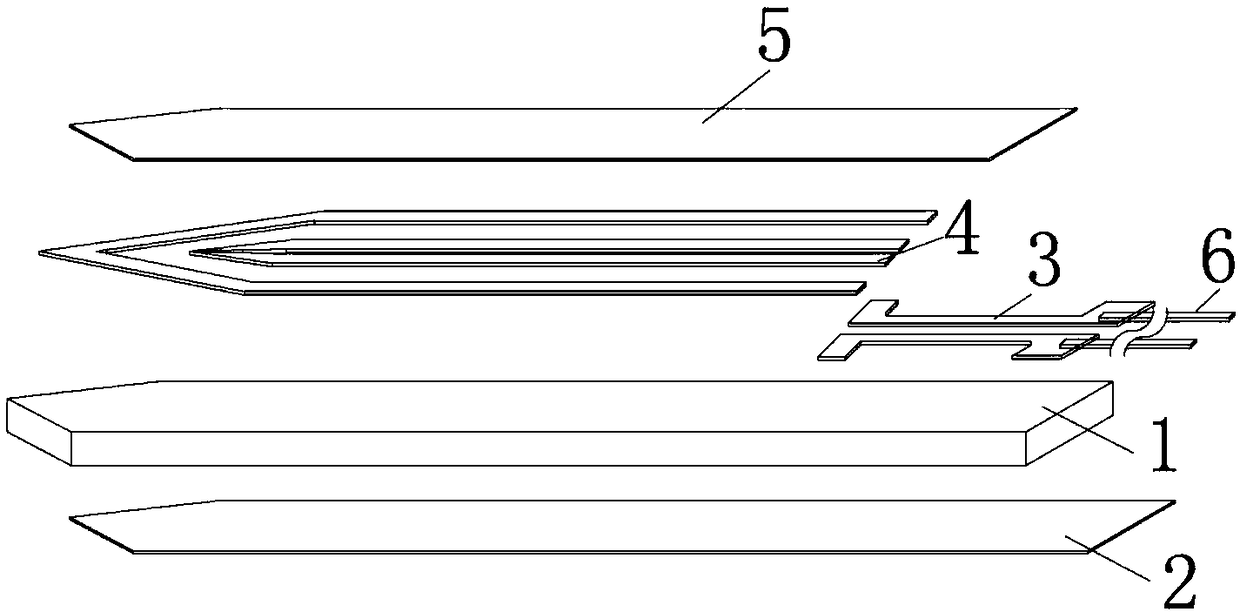

Yttrium-doped zirconia heating element for heating incombustible low-temperature cigarette and manufacturing method thereof

PendingCN108966382AImprove toughnessImprove heating efficiencyTobacco devicesOhmic-resistance heatingYttriumZirconia ceramic

The invention relates to the technical field of incombustible low-temperature cigarette heating, and particularly to a yttrium-doped zirconia heating element for heating incombustible low-temperaturecigarette. The yttrium-doped zirconia heating element comprises a yttrium-doped zirconia ceramic substrate. One surface of the yttrium-doped zirconia ceramic substrate is provided with an insulating film layer which is printed, and the other surface is provided with a lead pad film and a heating power resistance film. The heating power resistance film is connected with a lead on the lead pad film.The yttrium-doped zirconia heating element further comprises an insulating protecting layer which packages the heating power resistance film. The lead pad film is provided with lead pins which can beelectrically connected with an outer power supply. The yttrium-doped zirconia heating element has advantages of high temperature increase speed, high thermal compensation speed and high thermal response speed. Furthermore, the yttrium-doped zirconia heating element for heating the incombustible low-temperature cigarette has an advantage of easy operation.

Owner:东莞市东思电子技术有限公司

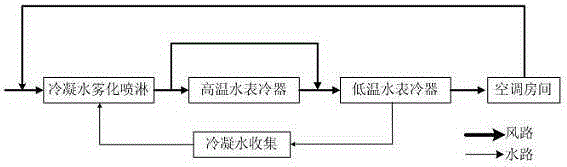

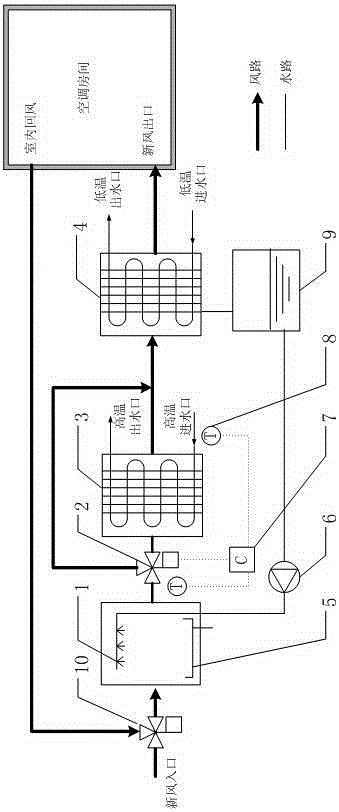

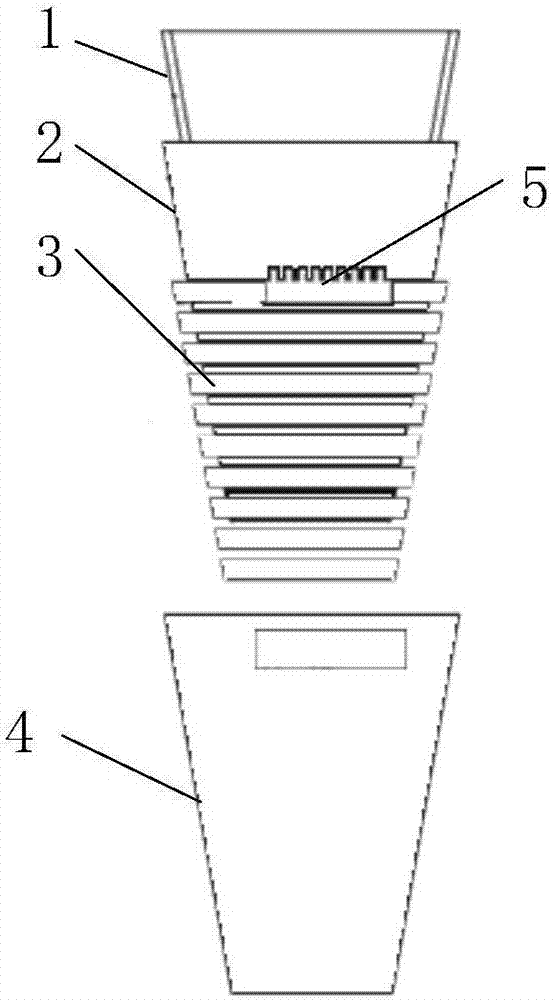

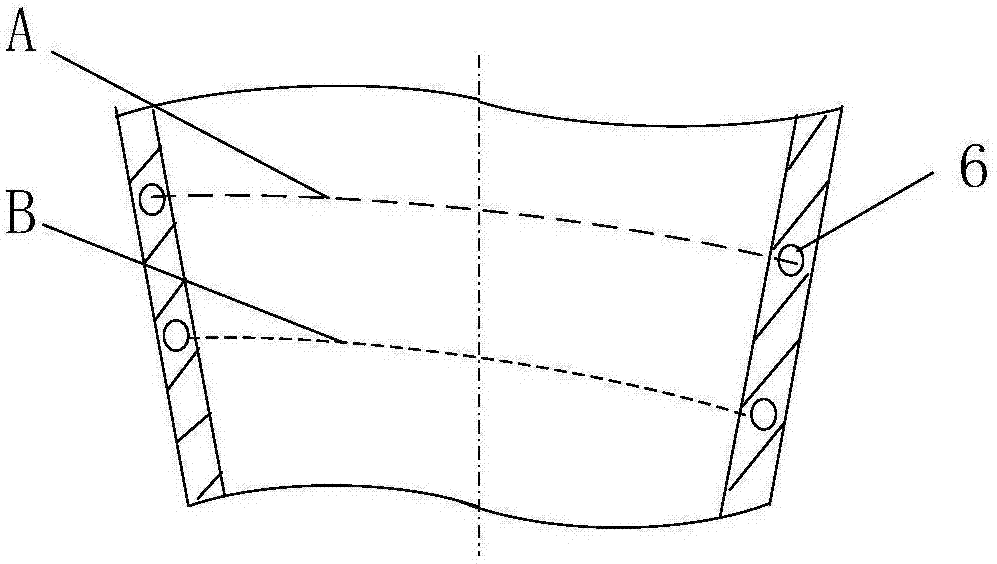

Fresh air energy-saving processing system and method in temperature and humidity independent processing air-conditioner system

ActiveCN105180317AEasy to evaporateImprove heat transfer efficiencyMechanical apparatusCondensate preventionTwo temperatureEngineering

The invention discloses a fresh air energy-saving processing system and method in a temperature and humidity independent processing air-conditioner system. The fresh air energy-saving processing system comprises an atomization spraying processing device (1), a first electric three-way air valve (2), a high-temperature water surface air cooler (3), a low-temperature water surface air cooler (4), a condensate water collection device (9), a booster pump (6), a controller (7) and two temperature sensors (8). A fresh air step processing circuit is determined through one control device; if the temperature obtained after preliminary spraying atomization processing is lower than the inlet water temperature of the high-temperature water surface air cooler, secondary processing of the high-temperature water surface air cooler is sequentially performed on processed fresh air, and finally the processed fresh air enters the low-temperature water surface air cooler for final processing. The temperature obtained after preliminary spraying atomization processing is higher than the inlet water temperature of the high-temperature water surface air cooler, the processed fresh air passes the bypass of the first electric three-way air valve and directly enters the low-temperature water surface air cooler for final processing, and local component resistance in the fresh air processing process is decreased.

Owner:NANJING UNIV OF TECH

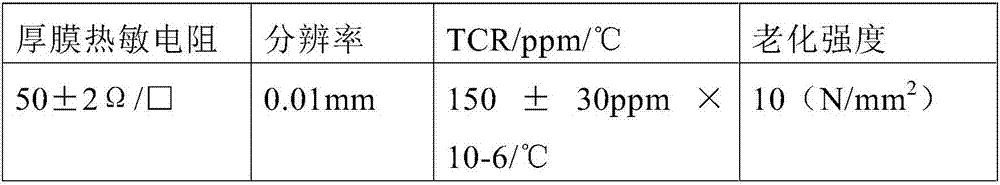

Electronic paste, preparation method thereof, thick-film circuit chip hot source and preparation method of thick-film circuit chip hot source

PendingCN107396466AGood workmanshipIncrease productivityHeating element materialsMicro nanoOrganic solvent

The invention relates to electronic paste for preparing a thick-film circuit. The electronic paste comprises a solid-phase constituent and an organic solvent carrier, wherein the weight ratio of the solid-phase constituent and the organic solvent is (65-90):(35-10), and the solid-phase constituent comprises graphene or the graphene and at least one rare-earth oxide. In the electronic paste for preparing the thick-film circuit, provided by the invention, a tiny amount of graphene or graphene particles are dispersed in a thick-film circuit layer and a thick-film dielectric layer, the electrical property, the thermal performance and the chemical performance of the thick-film circuit and the heat conductivity of a thermal interface in a thickness direction are improved at orders of magnitude by the micro fine lattices of the formed carbon micronano material, and the heat dissipation performance and the mechanical strength of a large-power thick-film integrated circuit are substantially improved.

Owner:王晨

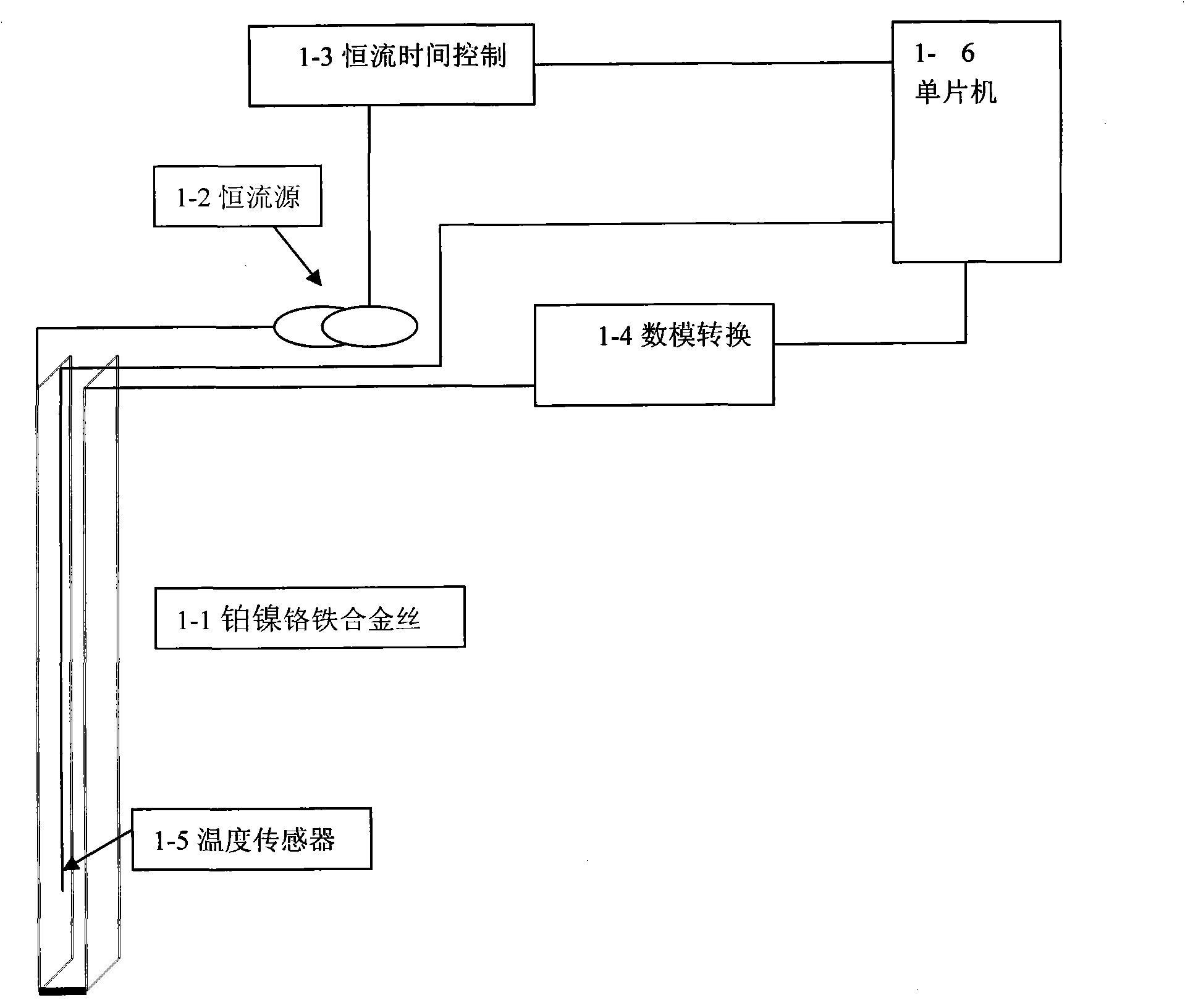

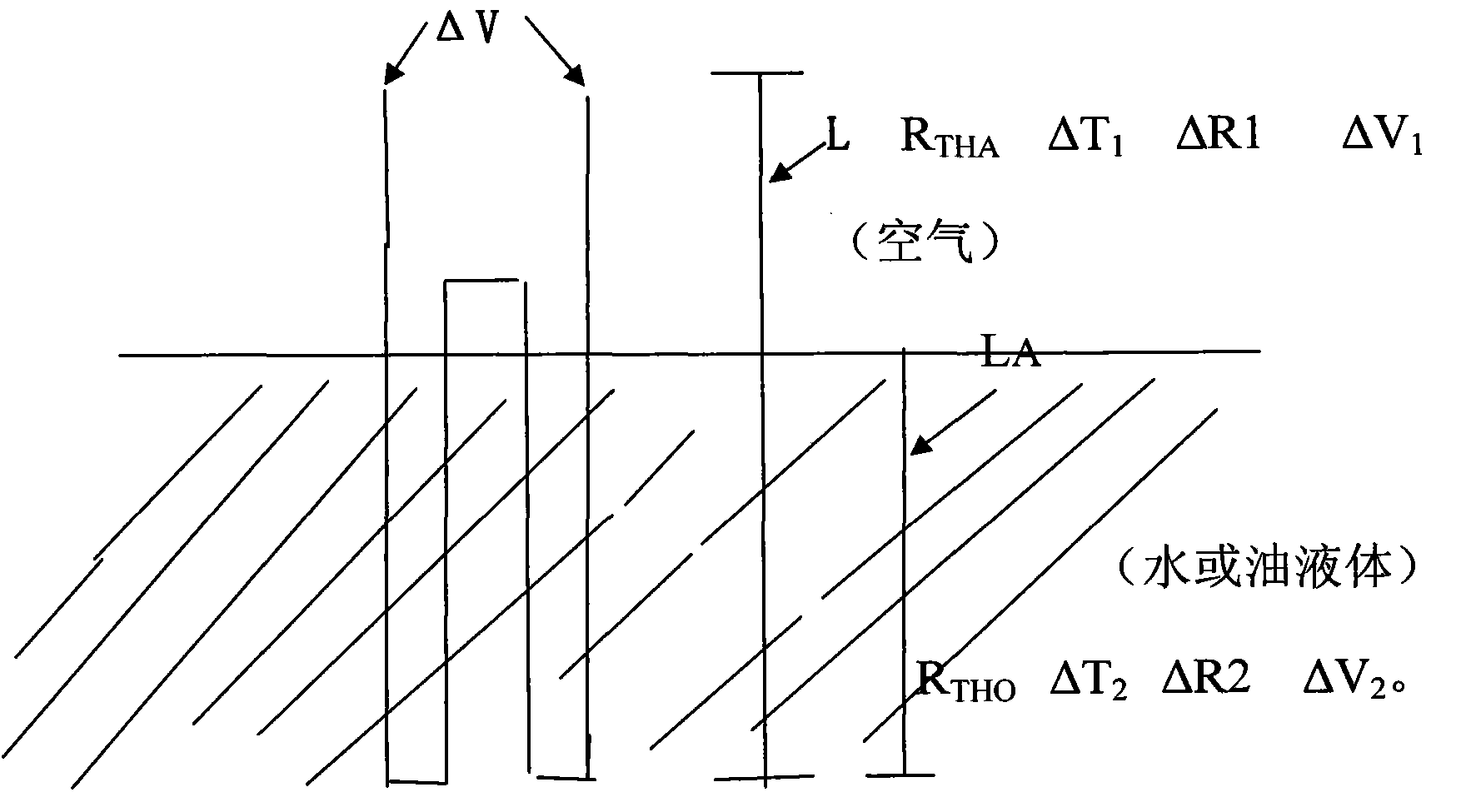

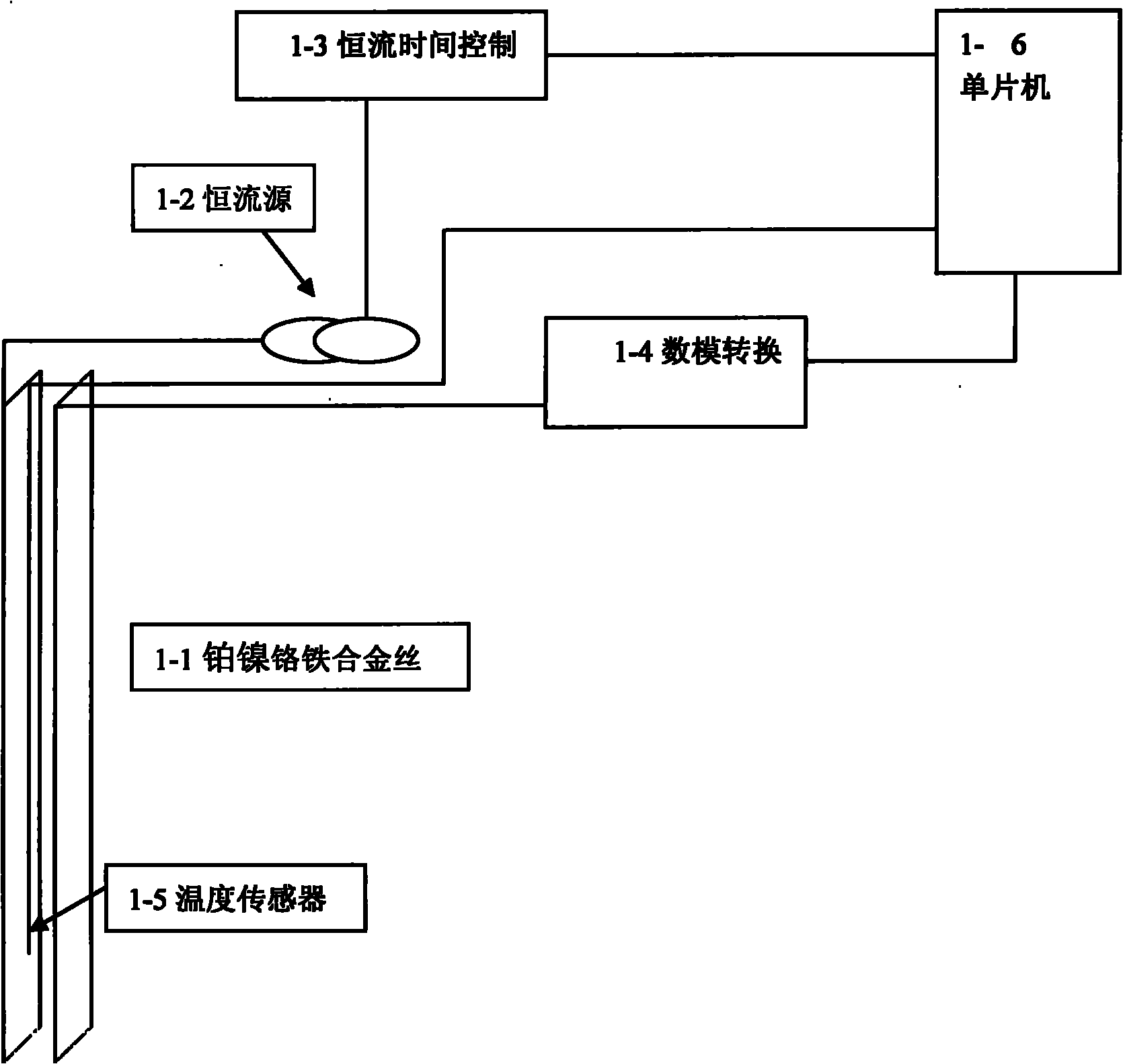

Online deep dynamic level-temperature measuring system for geothermal well

InactiveCN102003990AHas a positive temperature coefficientFast thermal responseThermometers using electric/magnetic elementsUsing electrical meansLeast squaresTemperature measurement

The invention relates to an online deep dynamic level-temperature measuring system for a geothermal well, a temperature sensor arranged in the geothermal well is connected as a singlechip. One end of a platinum nickel chrome ferroalloy wire arranged in the geothermal well is connected with a constant flow source while the other end thereof is connected with a digital to analog converter. The constant flow source is connected with a constant flow source switch time controller and the digital to analog converter and the constant flow source switch time controller are connected with the singlechip. The platinum nickel chrome ferroalloy wire has positive temperature coefficient and great thermal response speed. A constant flow is introduced to the platinum nickel chrome ferroalloy wire under control of the constant flow source switch time controller so that temperature change, resistance change and voltage variation in the upper and lower parts of the platinum nickel chrome ferroalloy wire are different because the thermal resistance of air is far greater than that of liquid. Therefore, level variation can be measured through the digital to analog converter, the temperature sensor and the singlechip and actual liquid and temperature of liquid can be measured through calibration and least square regression.

Owner:TIANJIN GEOTHERMAL EXPLORATION & DEV DESIGNING INST

Preparation method of intelligent energy-saving composite film

ActiveCN108504271AComfort temperature rangeImprove heat sensitivityPolyurea/polyurethane coatingsRadiation-absorbing paintsWeather resistanceComposite film

The invention discloses a preparation method of an intelligent energy-saving composite film. The preparation method comprises the steps: mixing thermochromic slurry and tungsten bronze heat absorbingslurry to prepare composite slurry; then, adding a polymer film forming agent; and coating a substrate to prepare the intelligent energy-saving composite film. By utilizing the infrared absorption characteristic of tungsten bronze, the heat sensitivity of a thermochromic material is improved, the thermal response speed is increased, and the phase-change response time is shortened; meanwhile, due to the combination of the ultraviolet barrier property of the thermochromic material, the weather resistance of tungsten bronze is improved, the intelligent energy-saving composite film with high efficiency and high stability is obtained, and the intelligent energy-saving composite film can be widely applied to building glass, automotive glass and the like, can make the temperature inside a room ora vehicle reach a comfortable temperature range all the year round and has a good application prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com