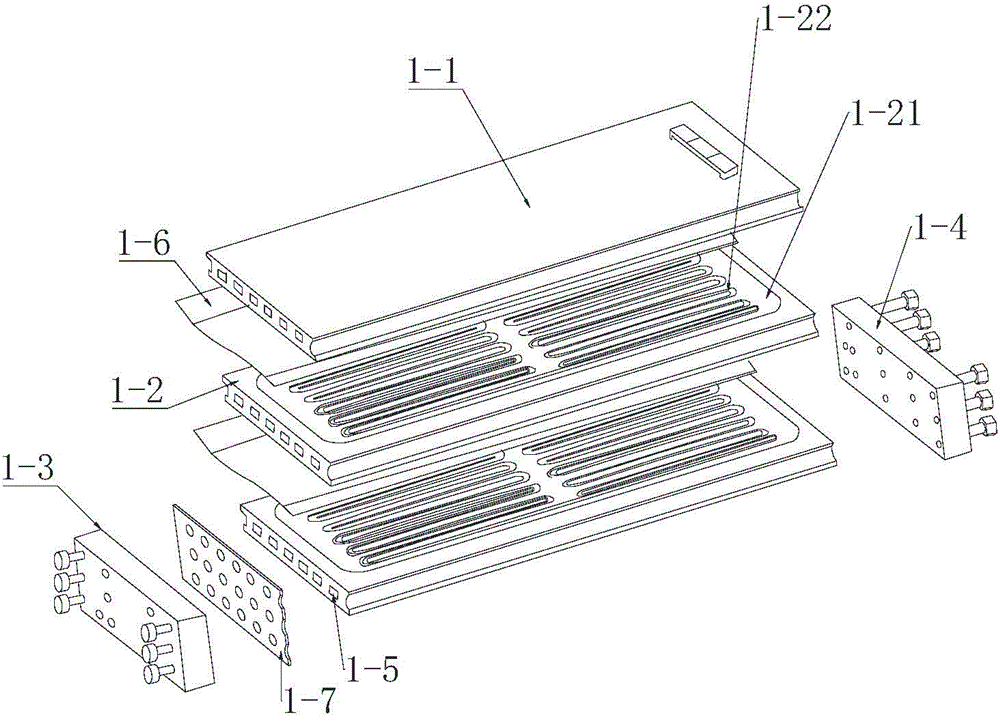

Modularized combined intelligent heat collector system

A combined heat collector technology, which is applied in the fields of agriculture, industry, and military water supply and heating systems, can solve the problems of large capacity, multi-function, all-weather, high cost of equipment structure, low temperature of heat source, etc., and achieve thermoelectric conversion High efficiency, low manufacturing cost, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

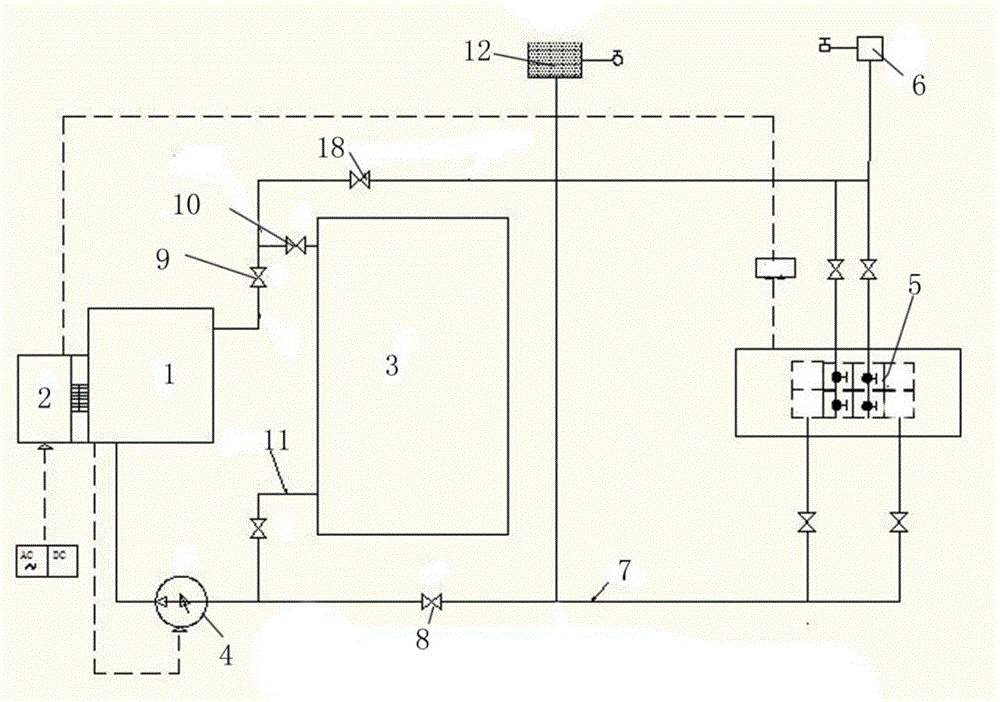

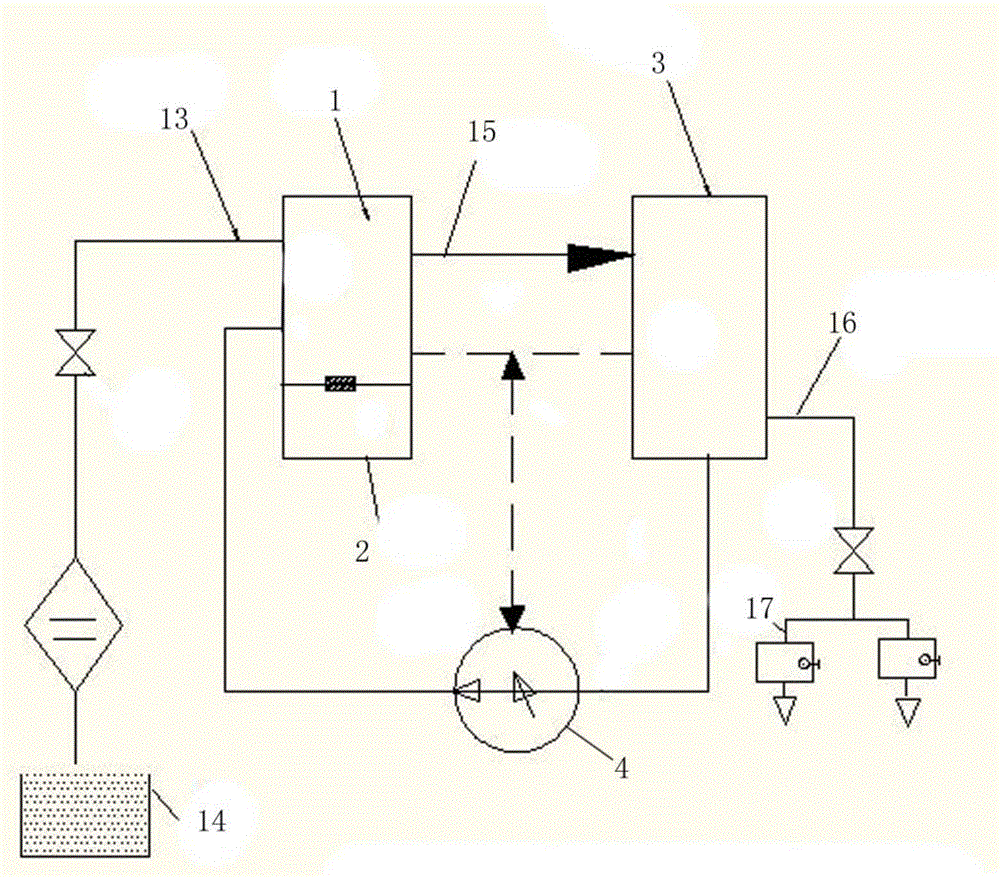

[0044] According to the above-mentioned structural circulation system, design and install 20kw small-scale commercial residential water supply and heating equipment, a set of PTCR-xthm electric heating chip modular combined intelligent heat collector system, 12 indoor heat exchangers, circulating water through the PTCR-xthm electric heating chip heat source module , into the room heat exchanger, the heat medium is heated up by 30°C, and the flow rate is 550 liters / h. According to regional heating standards, the average indoor temperature is 18°C, the lowest outdoor temperature is -18°C, and the heating area is 380 square meters.

[0045] Example notes:

[0046] The multi-hole terminal of this embodiment has more ports after modularization. It is advisable to choose a plug-in terminal for aviation electrical appliances or design a special plug-in terminal, which is safe and reliable. PTCR-xthm electric heating chip modular combined intelligent collector system, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com