Electronic paste, preparation method thereof, thick-film circuit chip hot source and preparation method of thick-film circuit chip hot source

A technology of electronic paste and thick film circuit, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems that the application requirements of special electronic paste are difficult to meet, and achieve the effect of high production efficiency and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

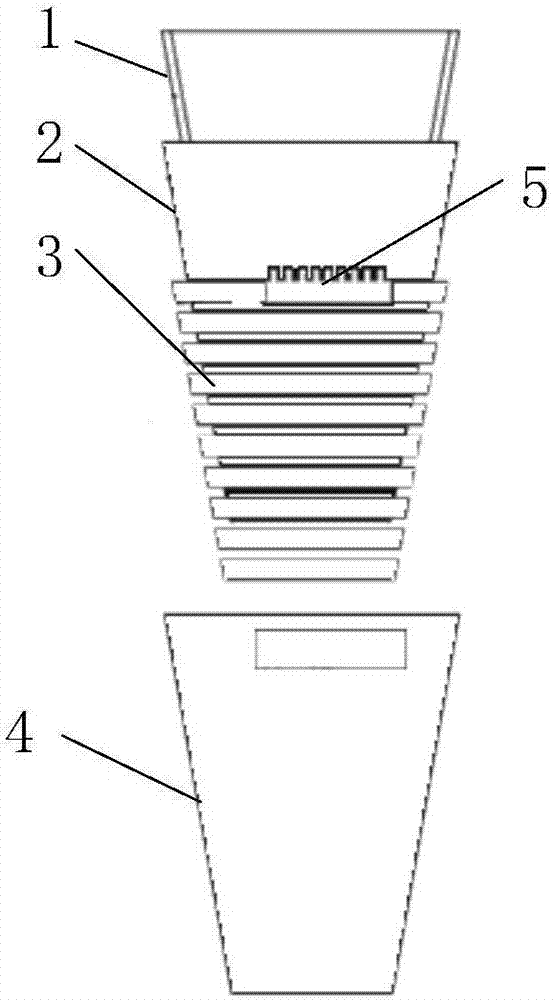

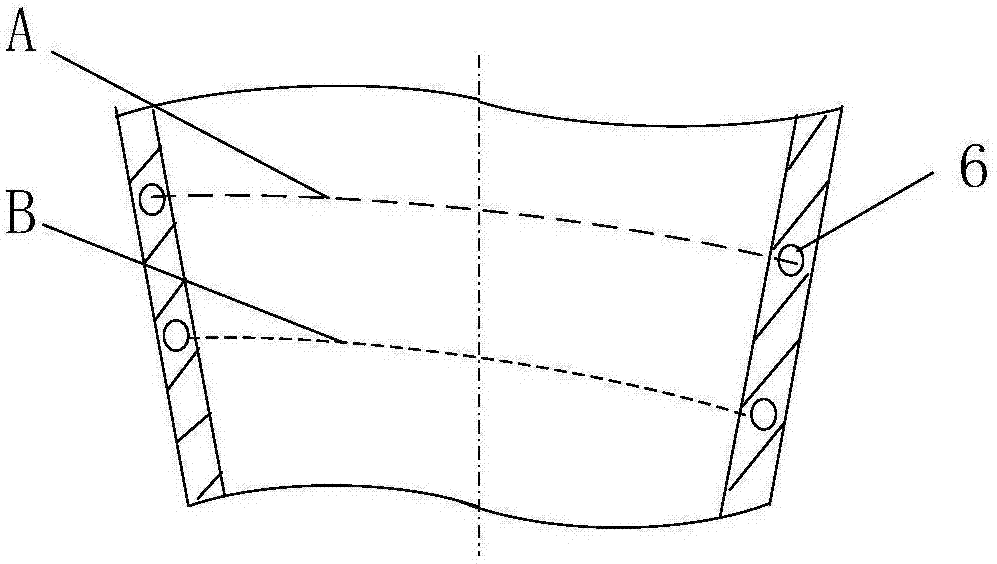

[0080] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

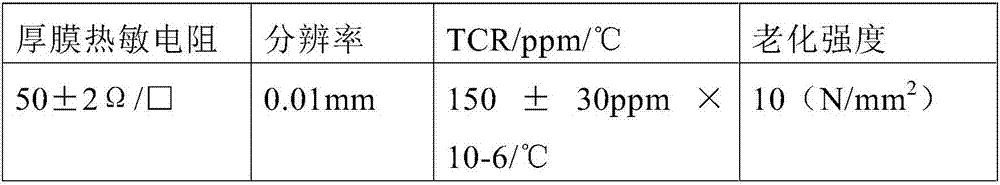

[0081] The electronic paste for preparing thick film circuits according to the embodiment of the present invention includes a solid phase component and an organic solvent carrier; wherein, the weight ratio of the solid phase component to the organic solvent carrier is 65-90:35-10, and the solid phase The components comprise graphene or graphene oxide and at least one rare earth oxide.

[0082] The electronic paste for preparing thick-film circuits in the embodiment of the present invention disperses a small amount of graphene or graphene-like particles into the thick-film circuit layer and the thick-film dielectric layer, and the carbon formed in the thick-film circuit layer and the thick-film dielectric layer The fine mesh of micro-nano materials improves the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com