Patents

Literature

50results about How to "Good thermal response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

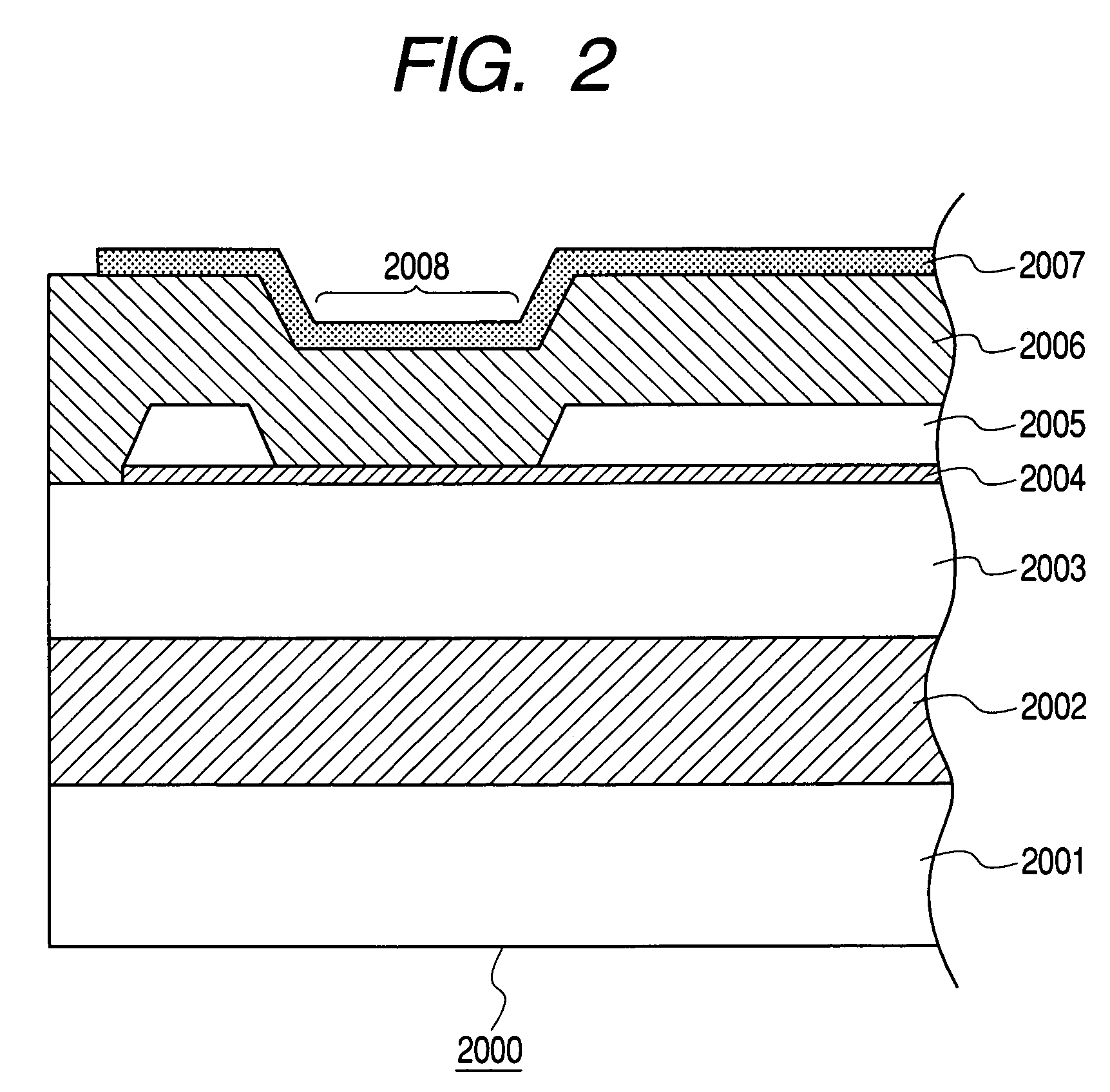

Biological sample temperature control system and method

InactiveUS20100087325A1Remove heatSlow responseHeating or cooling apparatusLibrary screeningTemperature controlTotal internal reflection

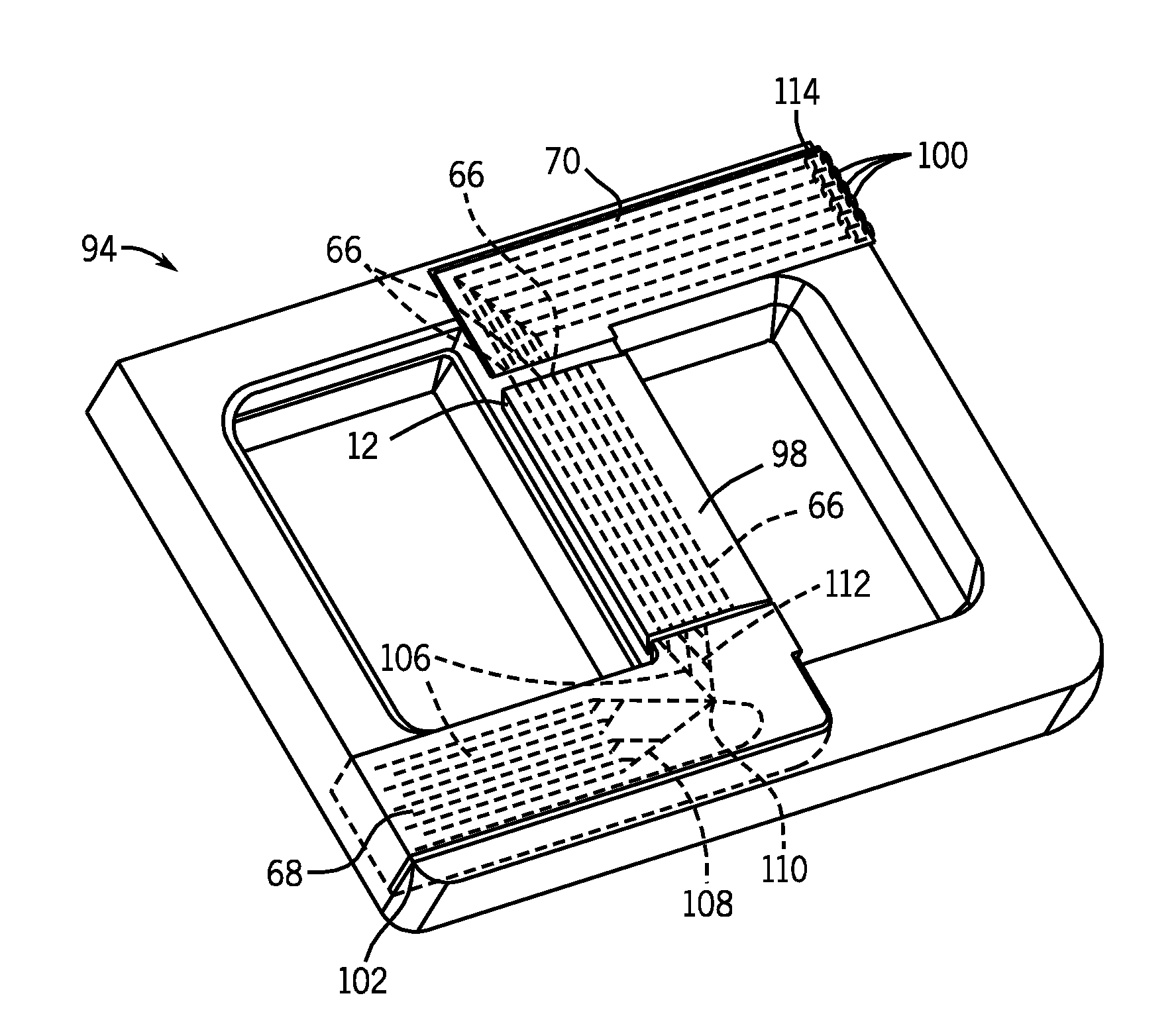

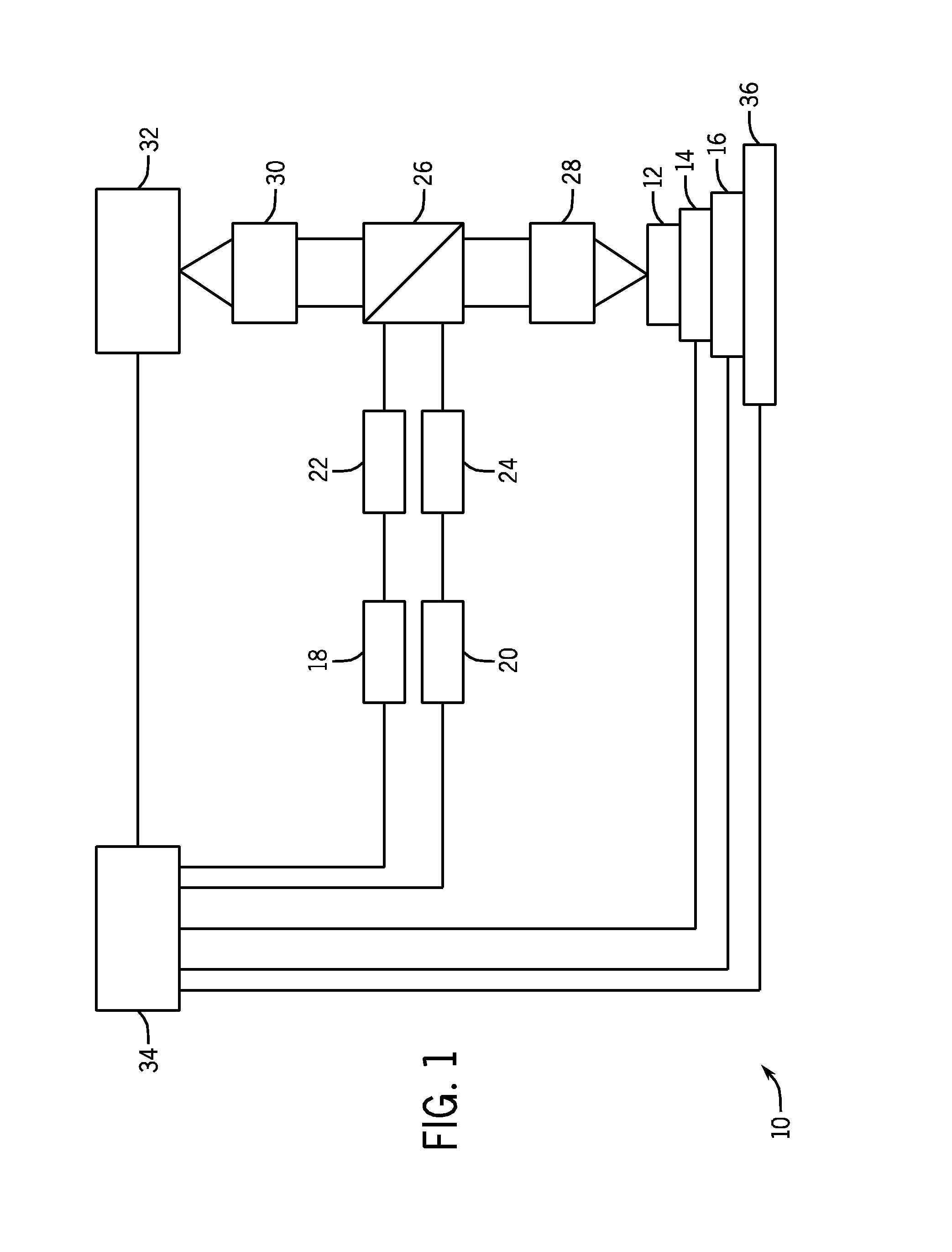

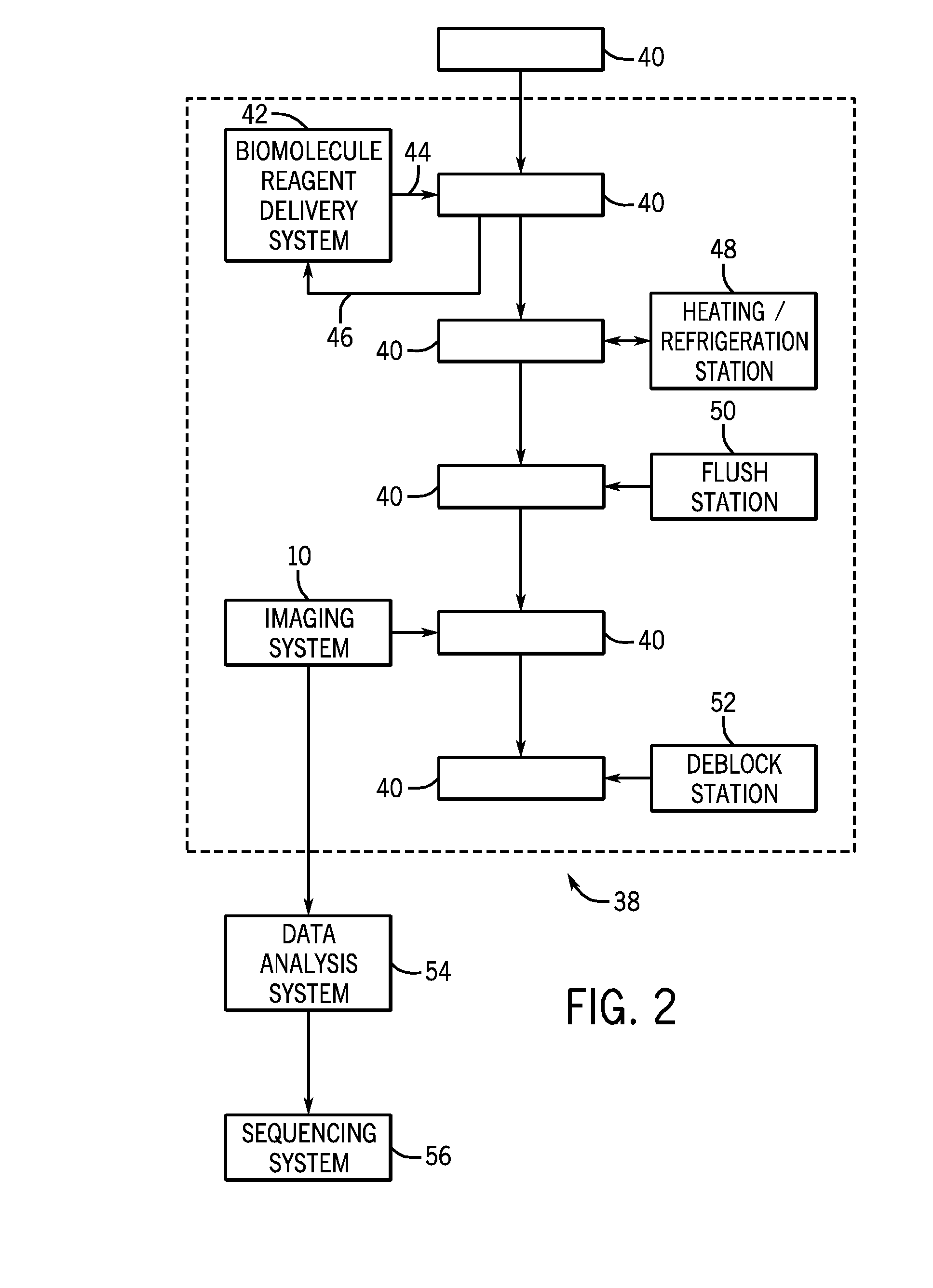

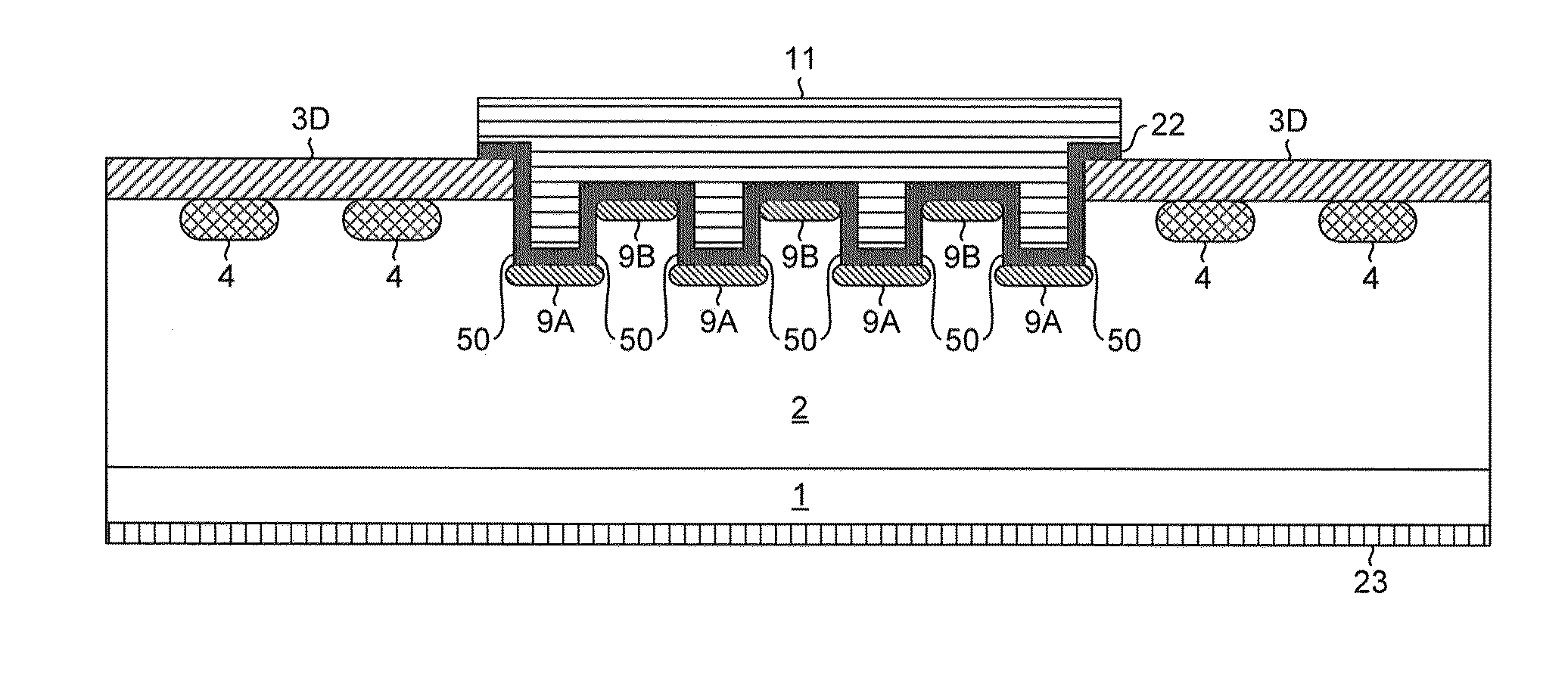

The present invention provides a novel approach for controlling the temperature of biological samples on a support structure. The support structure may, for instance, be a flow cell through which a reagent fluid is allowed to flow and interact with biological samples. A thermoelectric heat exchange device, such as a Peltier device, may be used to heat or cool the biological samples on the support structure. In addition, a fluid circulating heat exchange device, such as a water heating or cooling system, may be used to heat or cool the thermoelectric heat exchange device. In general, the support structure may be located on top of the thermoelectric heat exchange device which, in turn, may be located on top of the fluid circulating heat exchange device. The thermoelectric heat exchange device and fluid circulating heat exchange device may be integrated into a holder bench which may be part of a station within an imaging processing system. The holder bench may be configured to hold multiple support structures at a time. In addition, the support structures may be configured to be evaluated and imaged using both epifluorescent and total internal reflection (TIRF) excitation techniques.

Owner:ILLUMINA INC

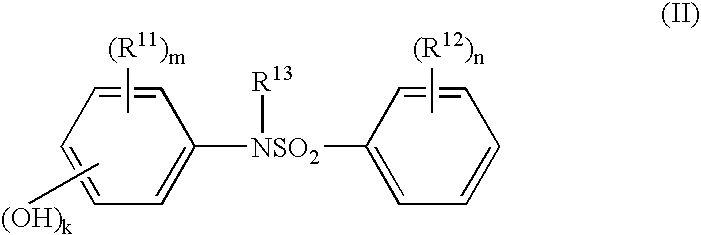

Electron-receiving compound and thermal recording material

InactiveUS6921740B1Good thermal responseEnhance the imageOrganic chemistryAblative recordingUv absorberRecording layer

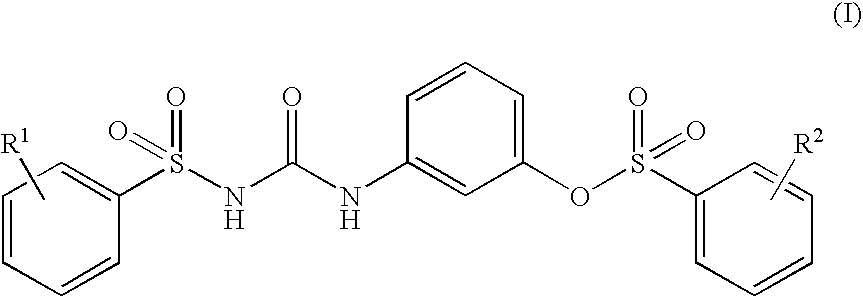

Disclosed are a novel electron-accepting compound which is a benzenesulfonamide derivative having a specific structure, a heat-sensitive recording material having a heat-sensitive recording layer containing the above electron-accepting compound, a heat-sensitive recording material having a heat-sensitive recording layer containing at least two specific benzenesulfonamide derivatives, a heat-sensitive recording material having a heat-sensitive recording layer containing a benzenesulfonamide derivative and a diphenylsulfone derivatives a heat-sensitive recording material having a heat-sensitive recording layer containing a specific benzenesulfonamide derivative and an ultraviolet absorbent or an aromatic isocyanate compound, and a heat-sensitive recording material having a substrate containing a recycled paper pulp or a non-wood pulp.These heat-sensitive recording materials are excellent in thermal response, retainability of ground / recorded image, saturation density and retainability of an image portion against light.

Owner:MITSUBISHI PAPER MILLS LTD

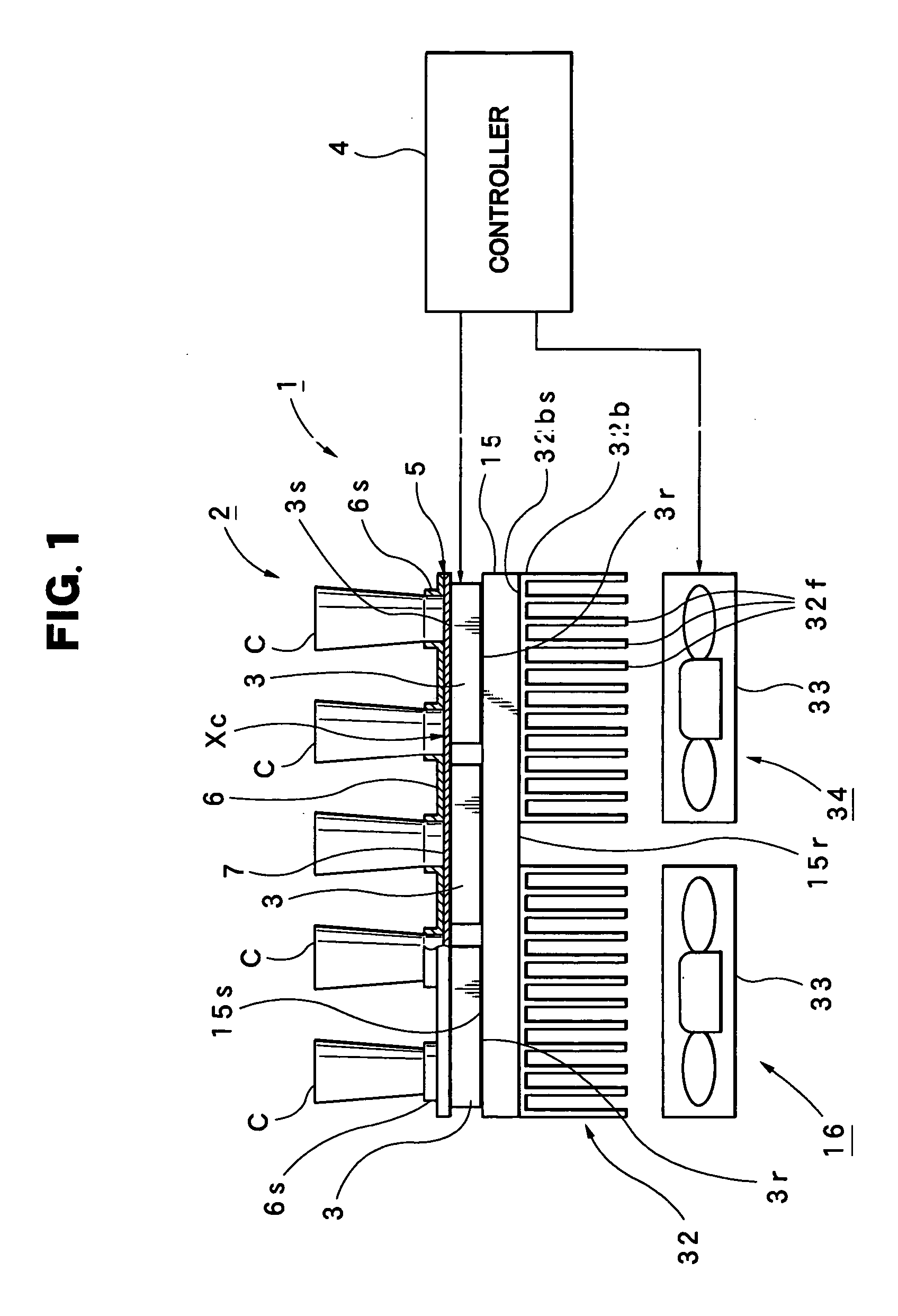

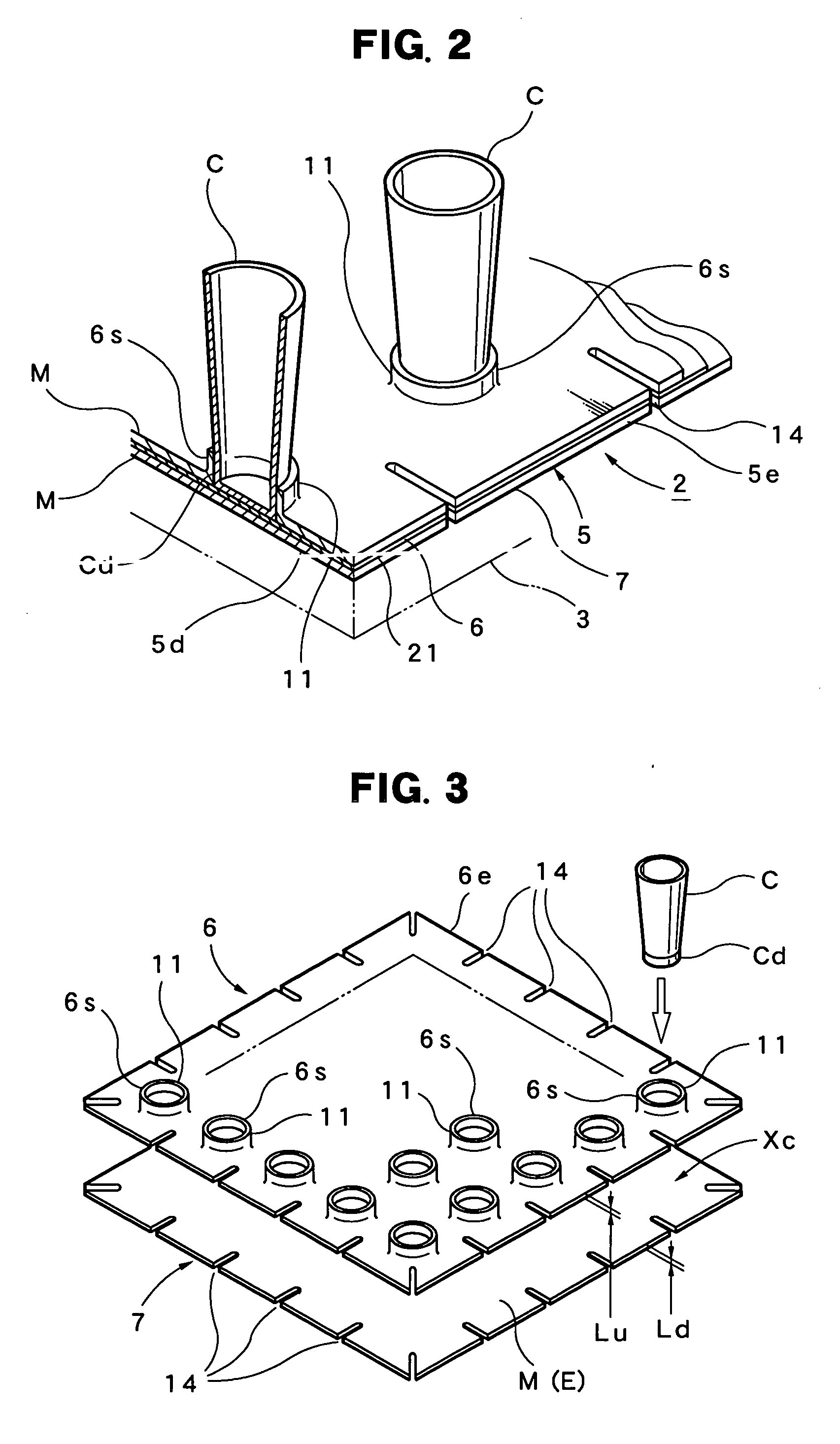

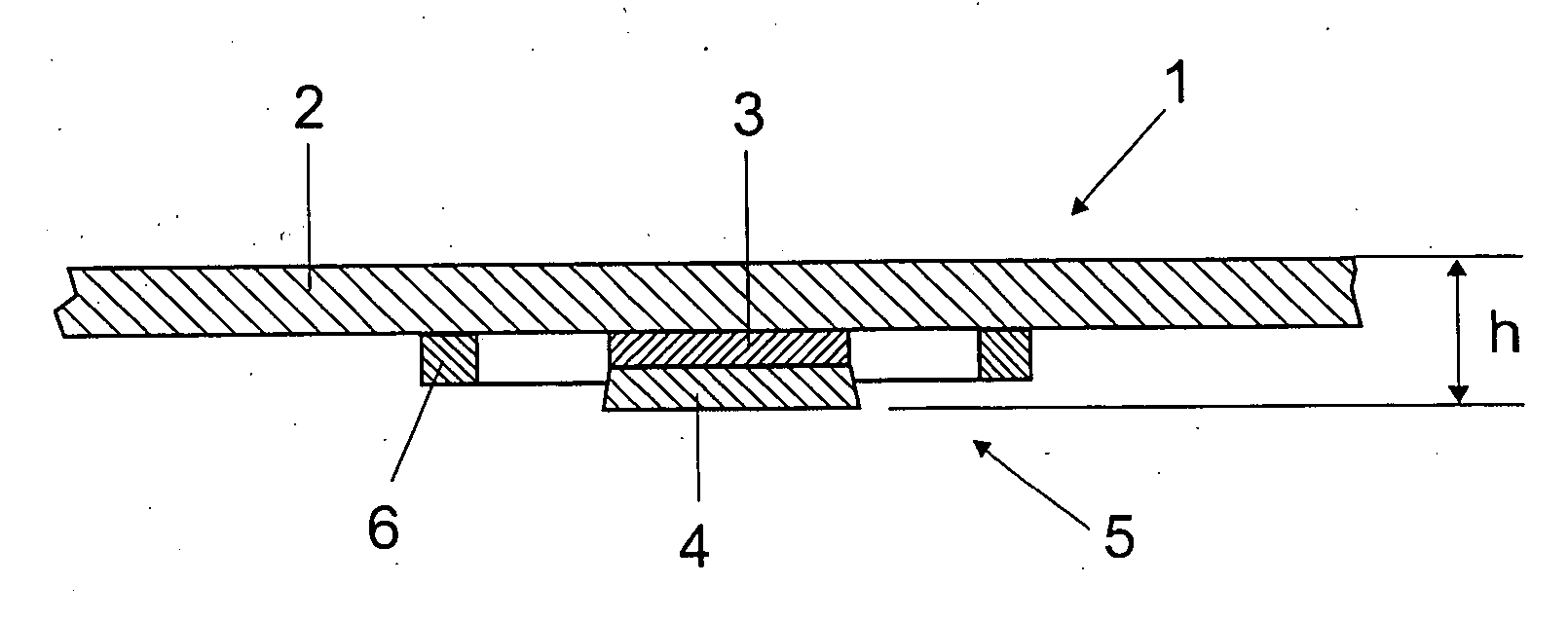

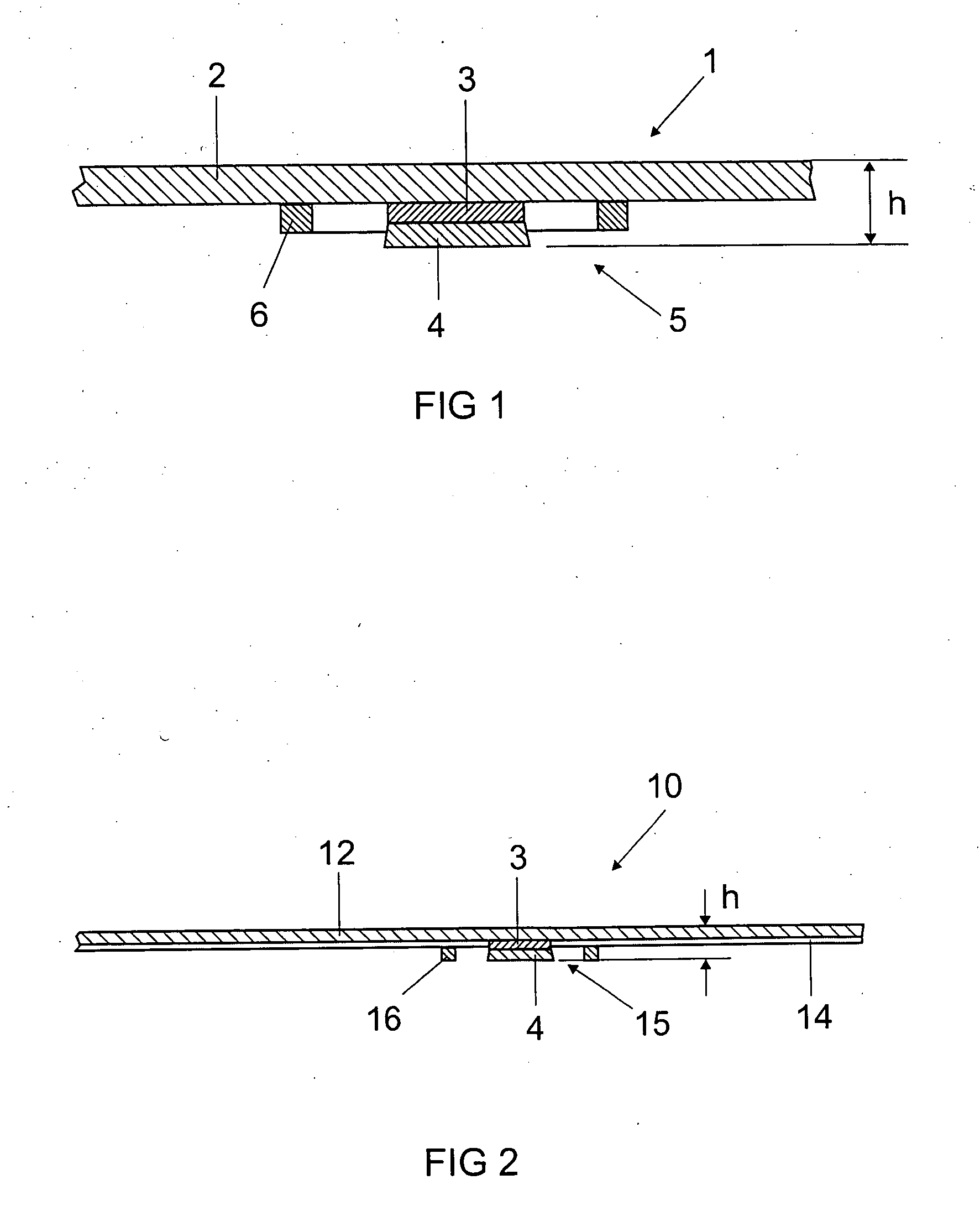

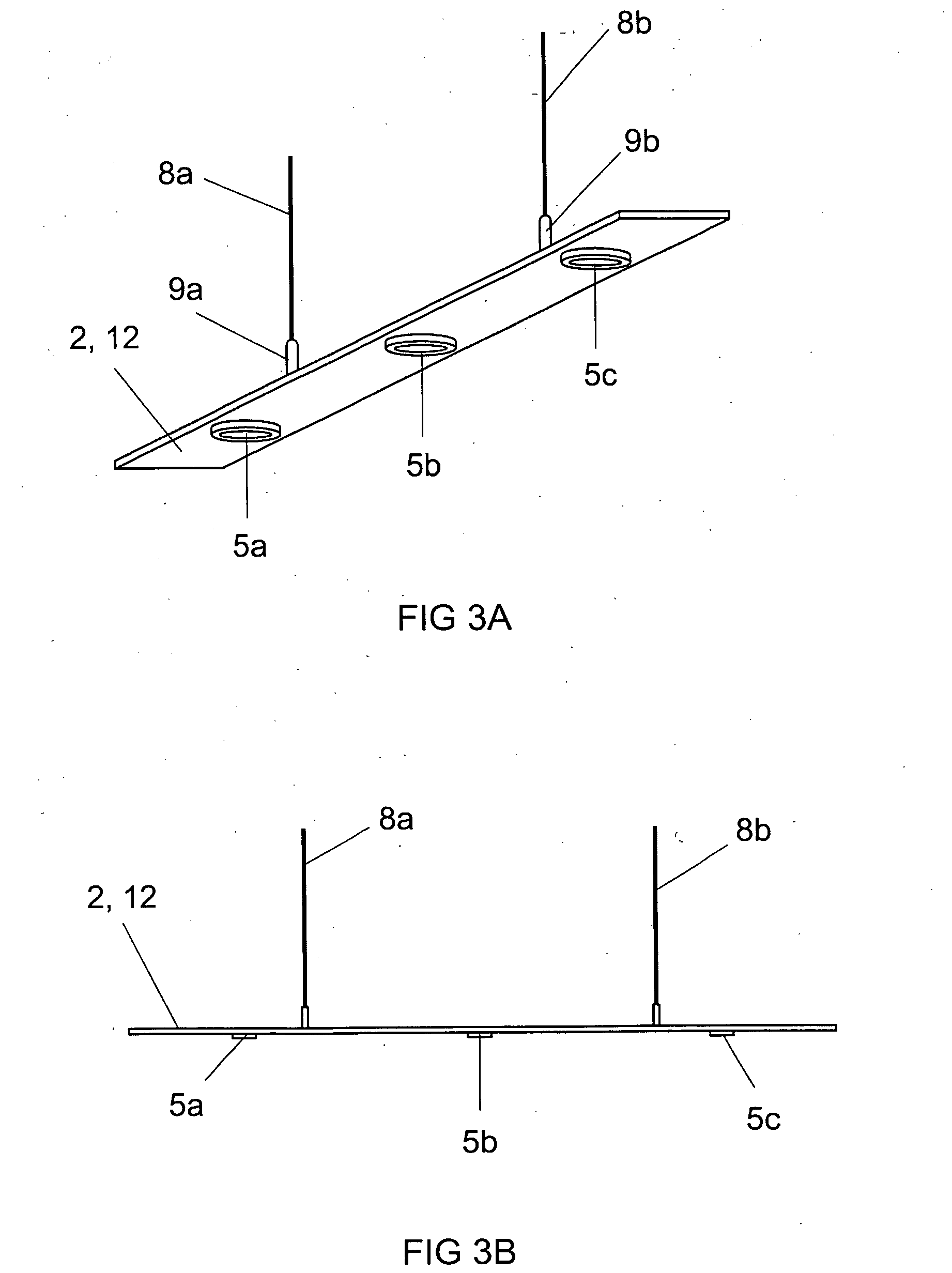

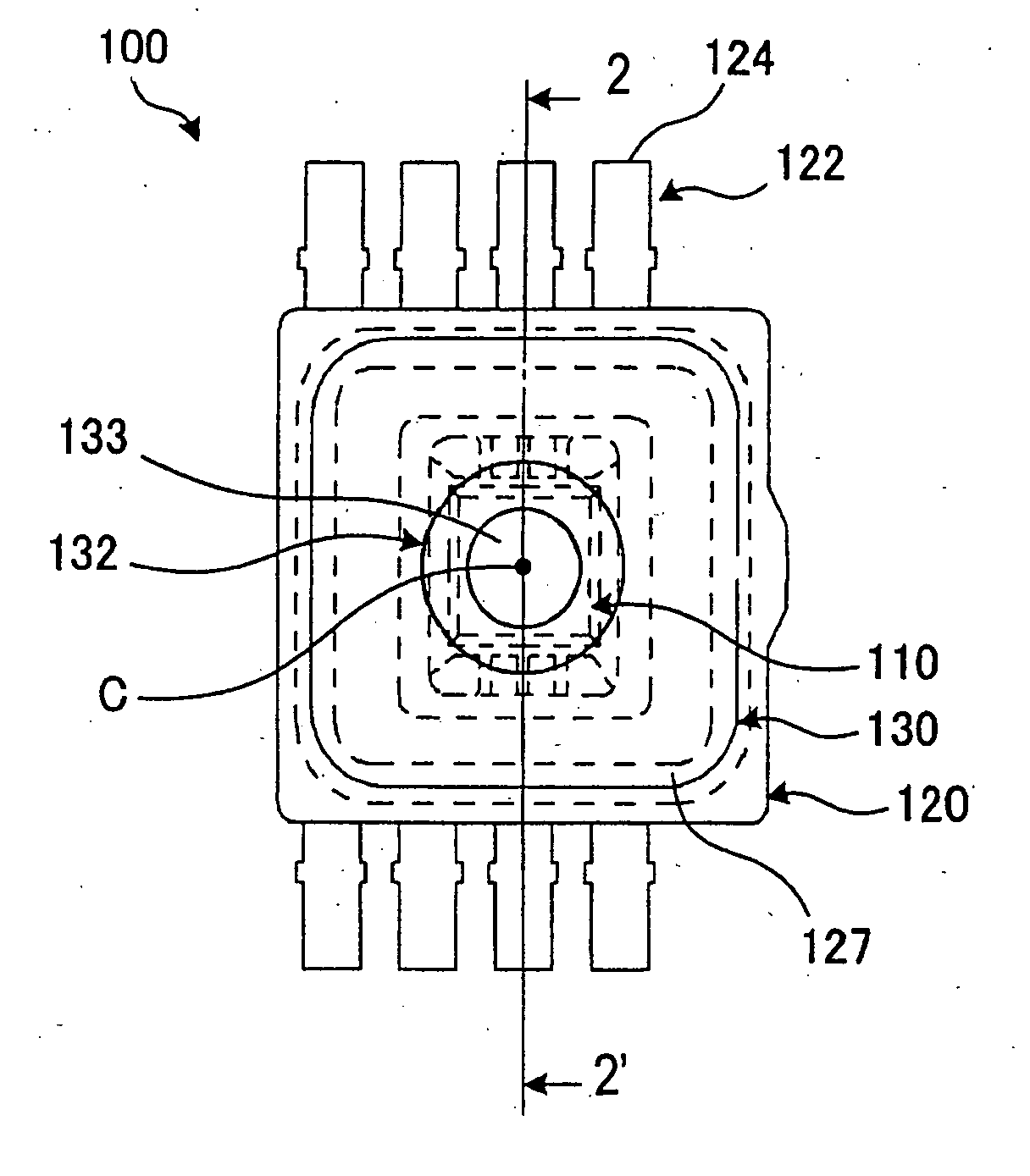

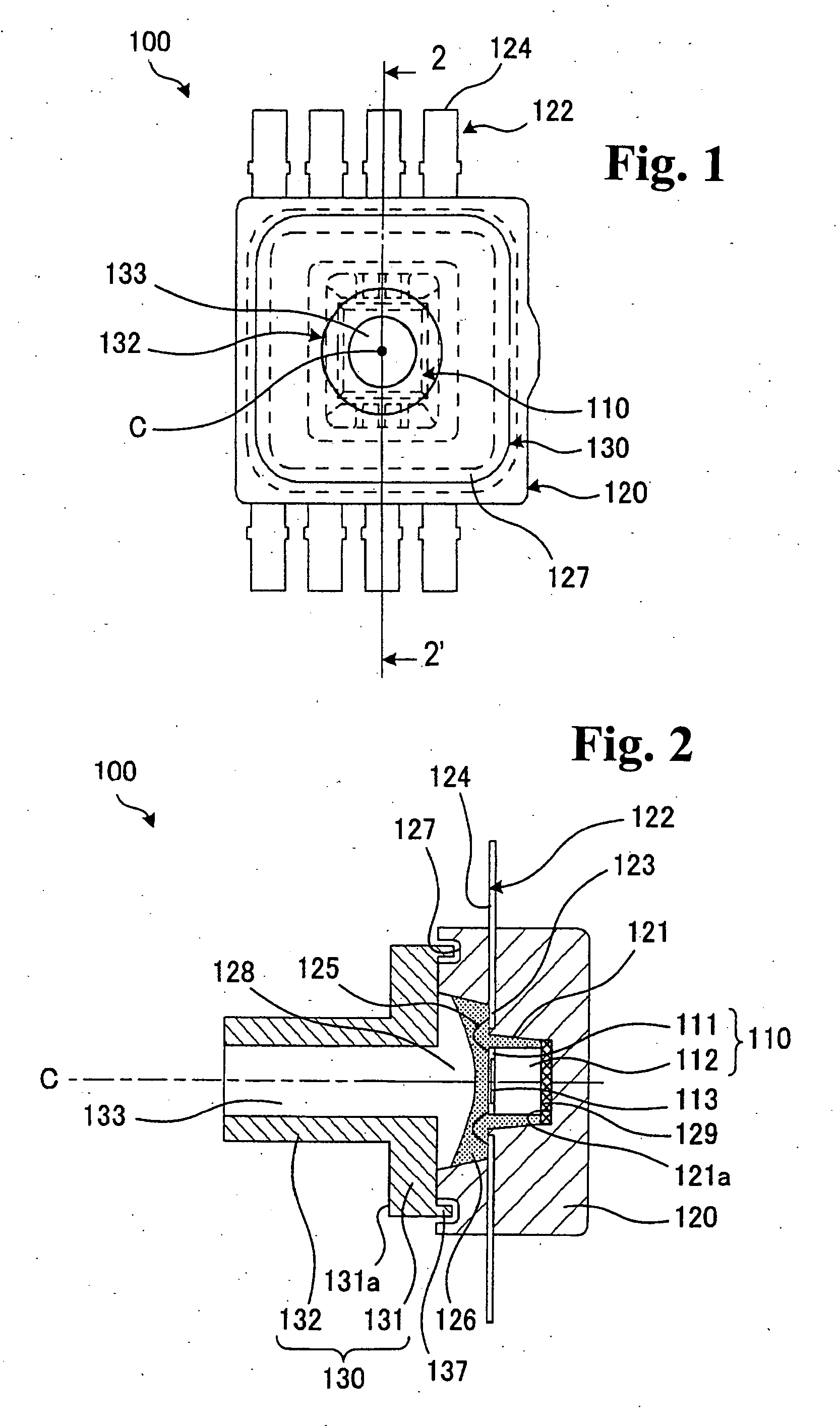

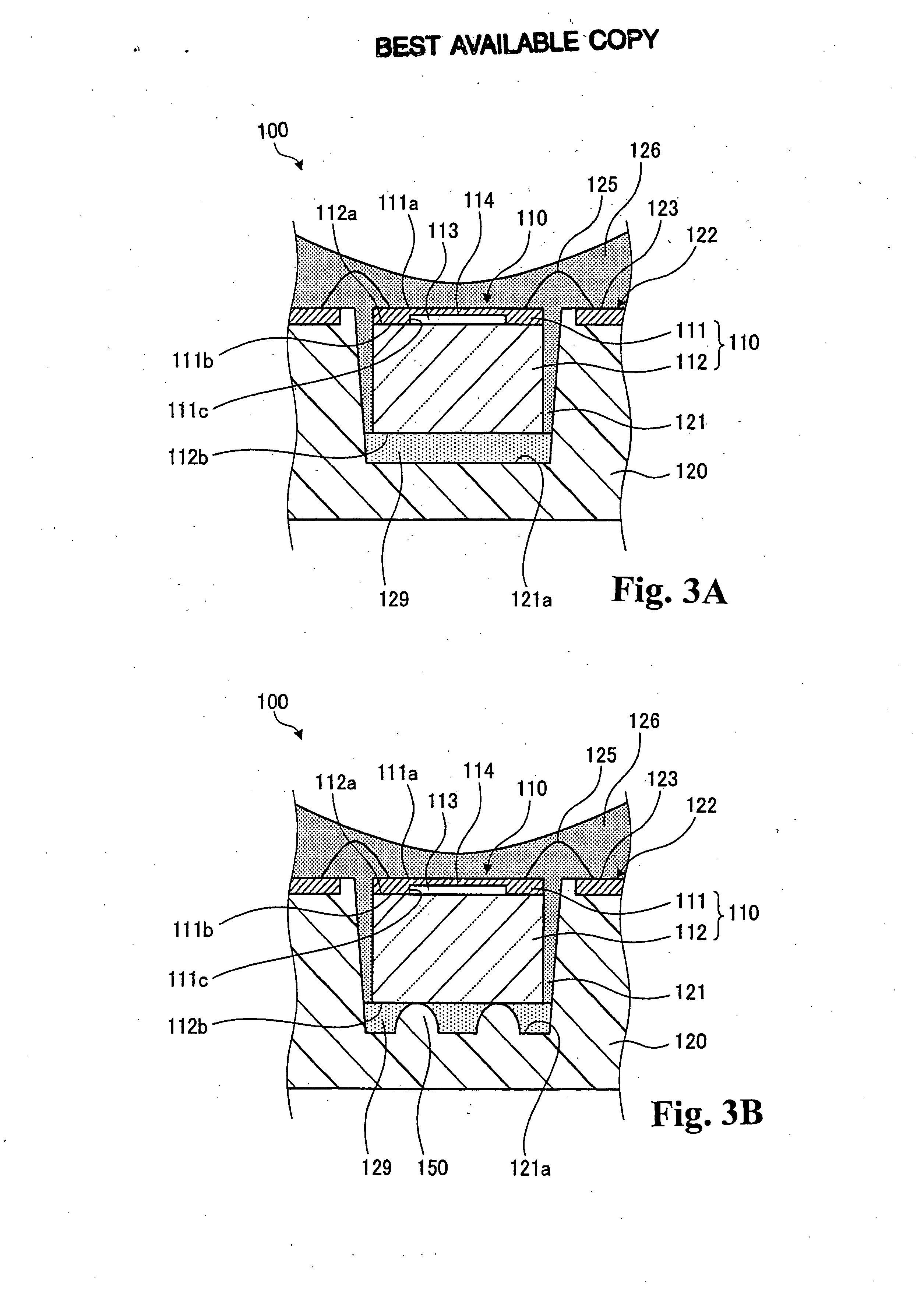

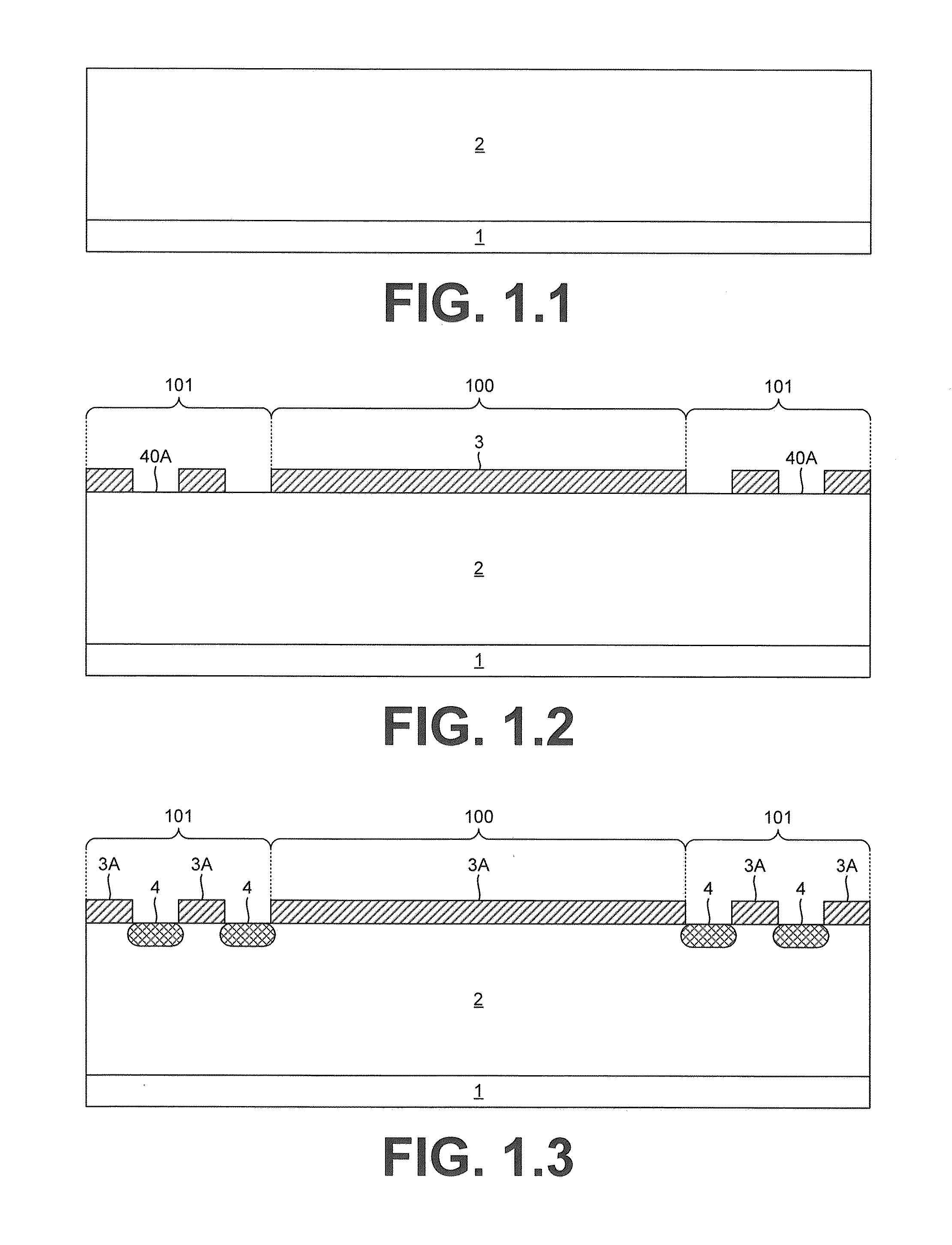

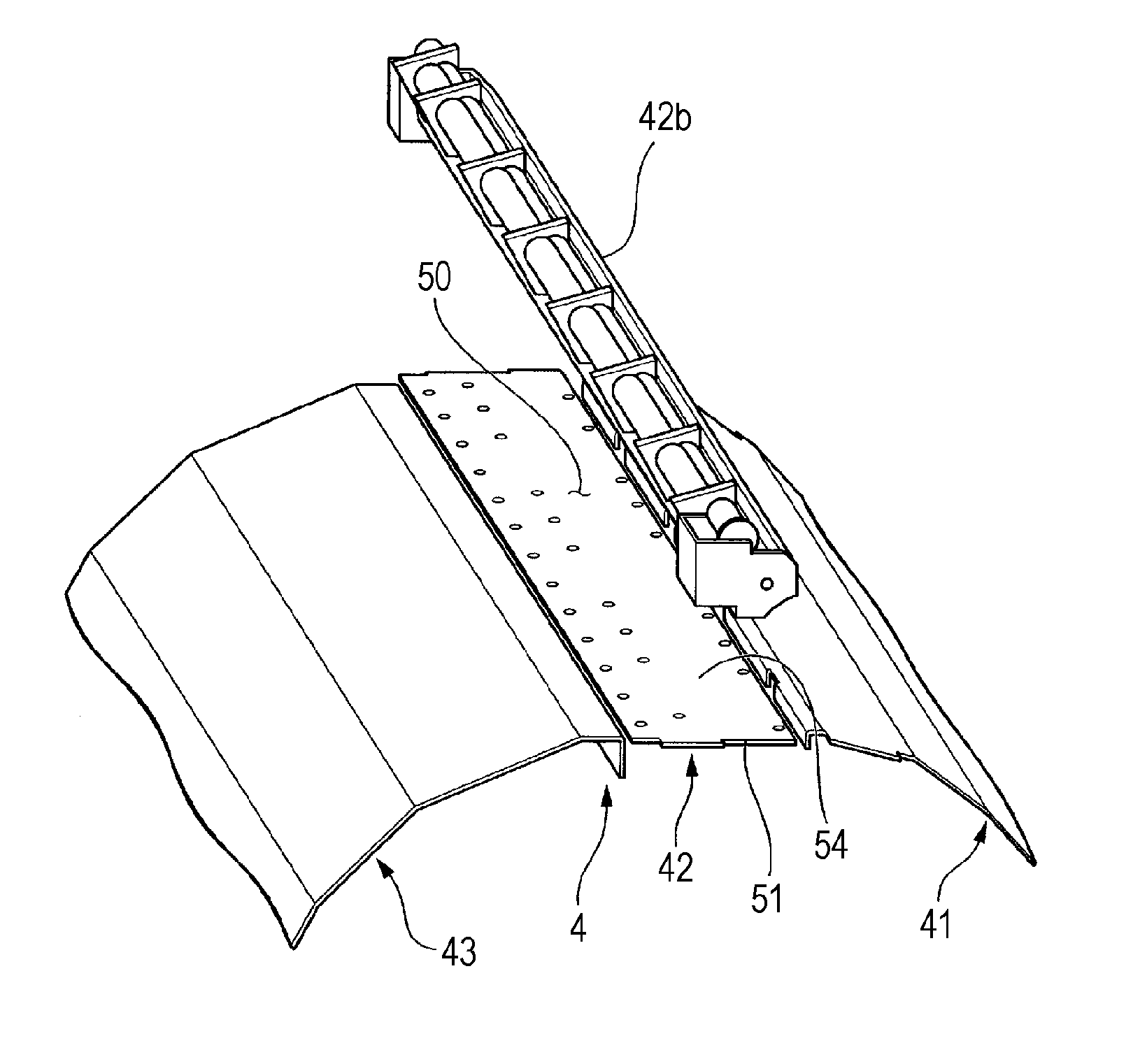

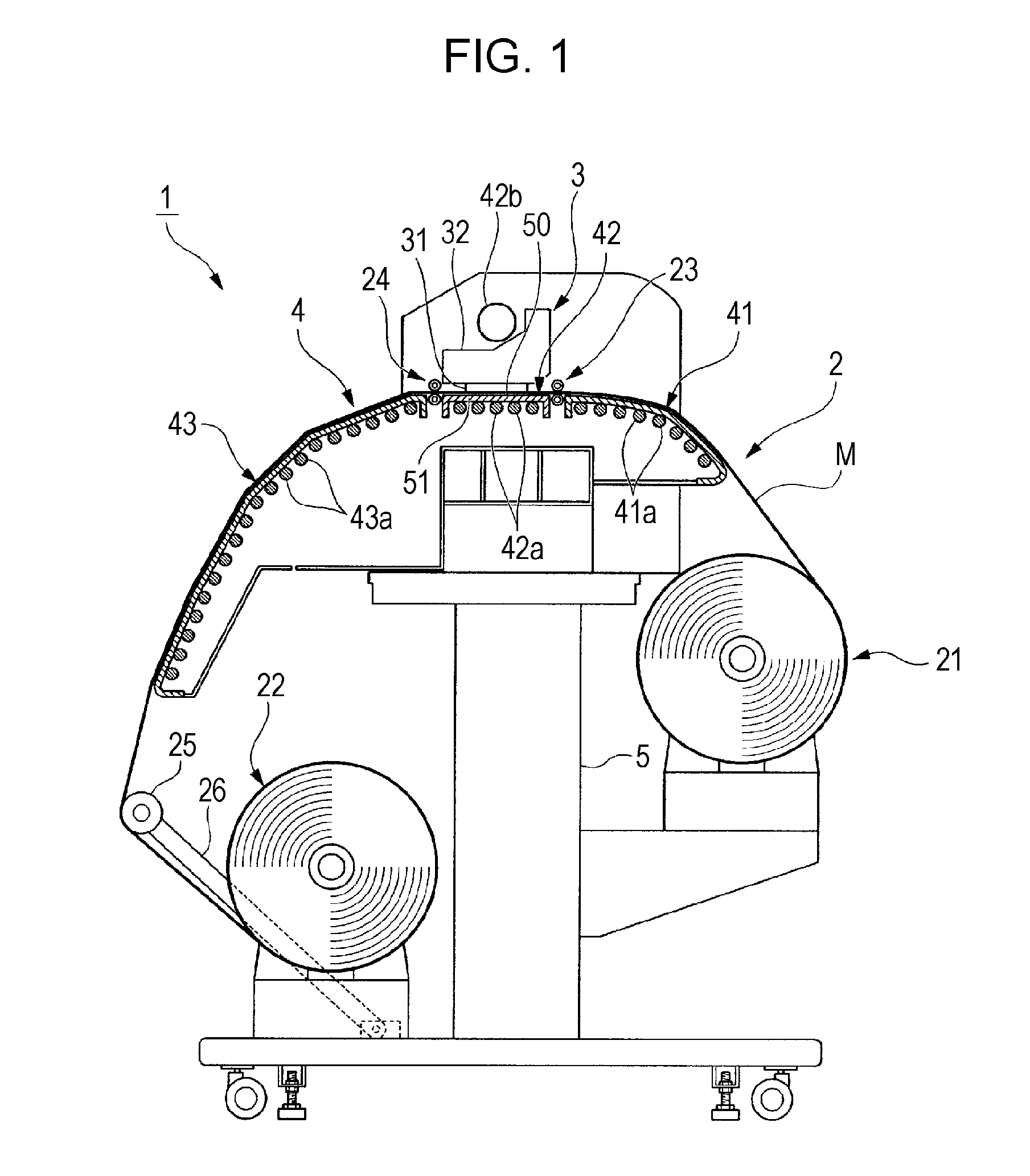

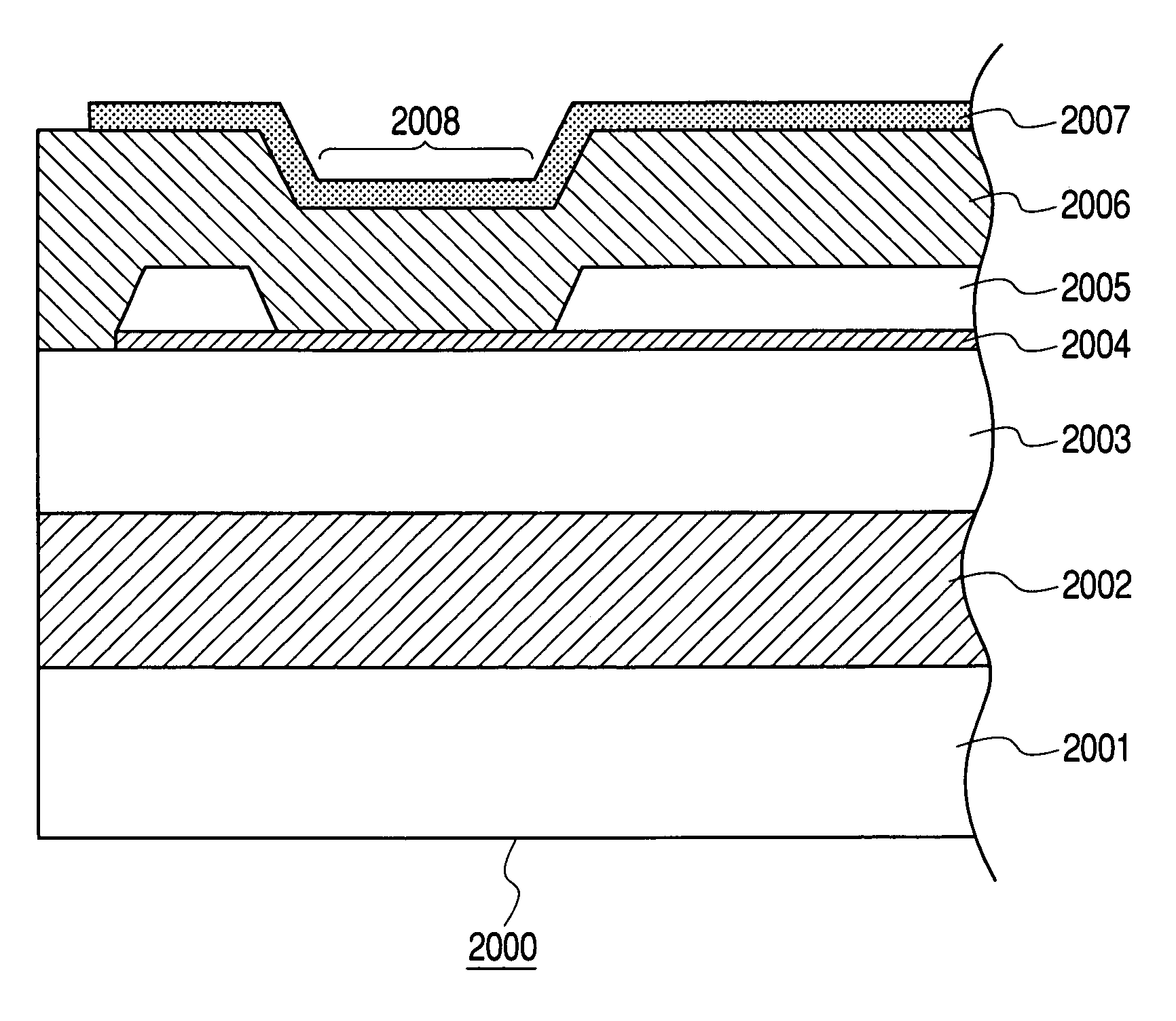

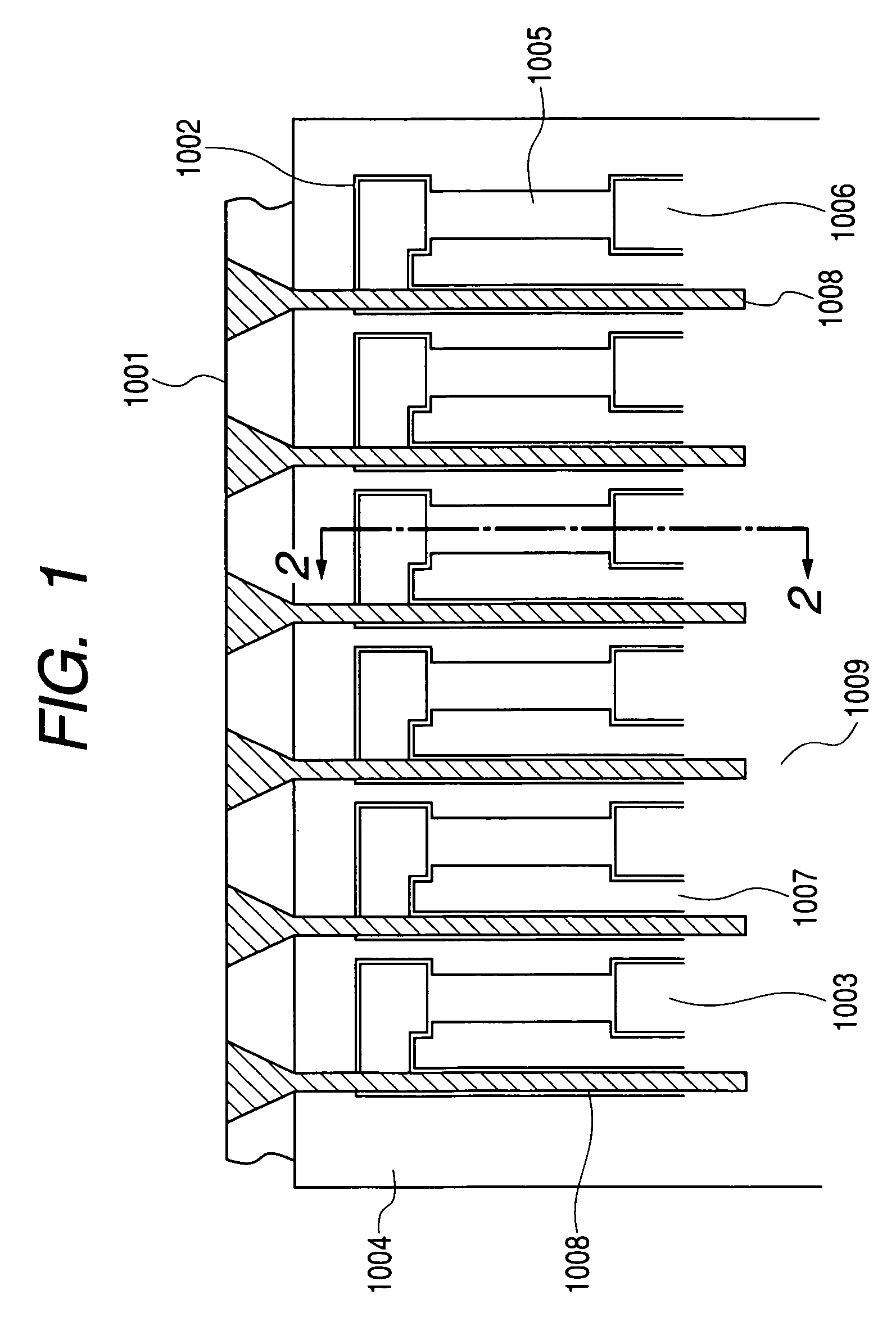

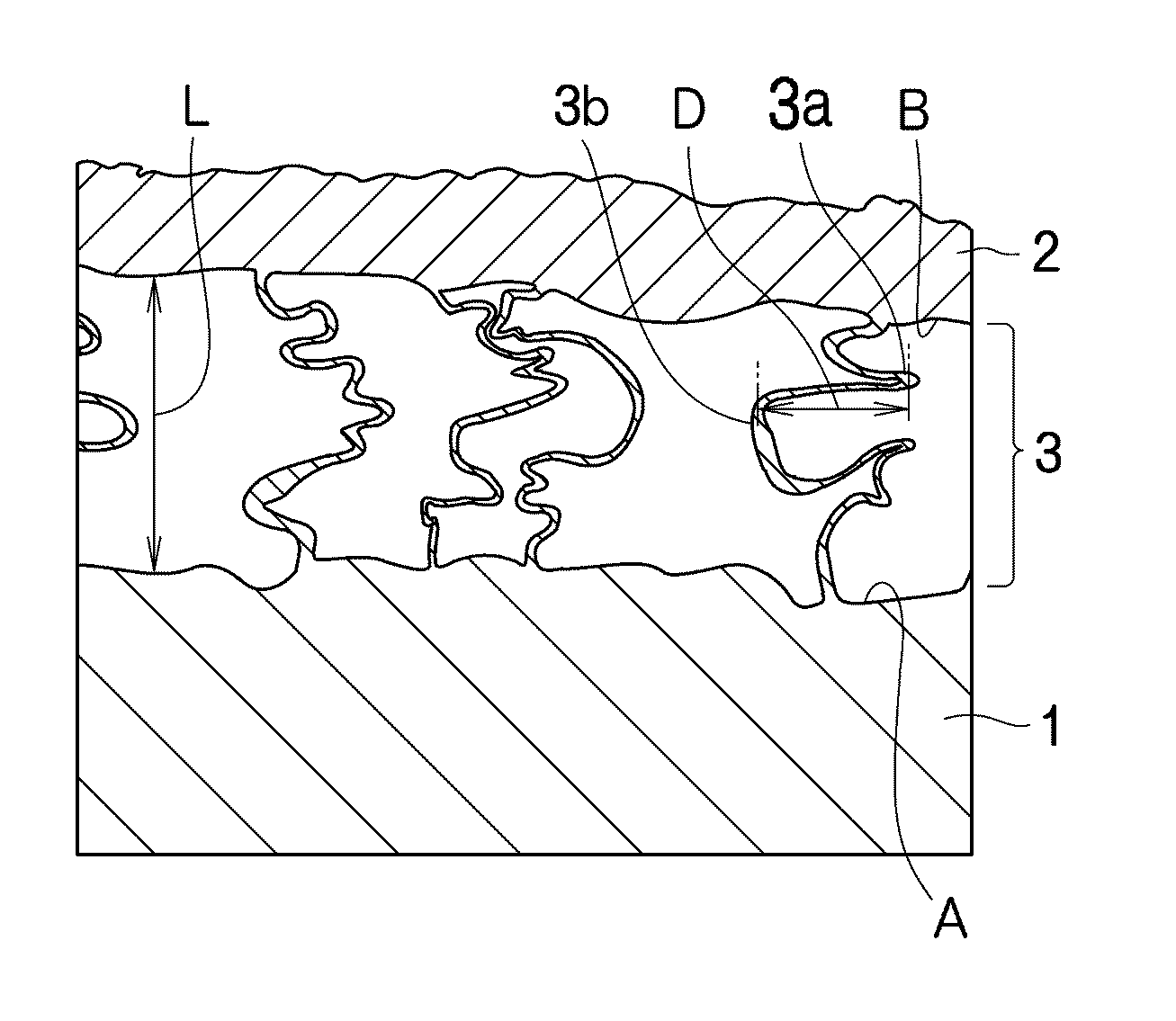

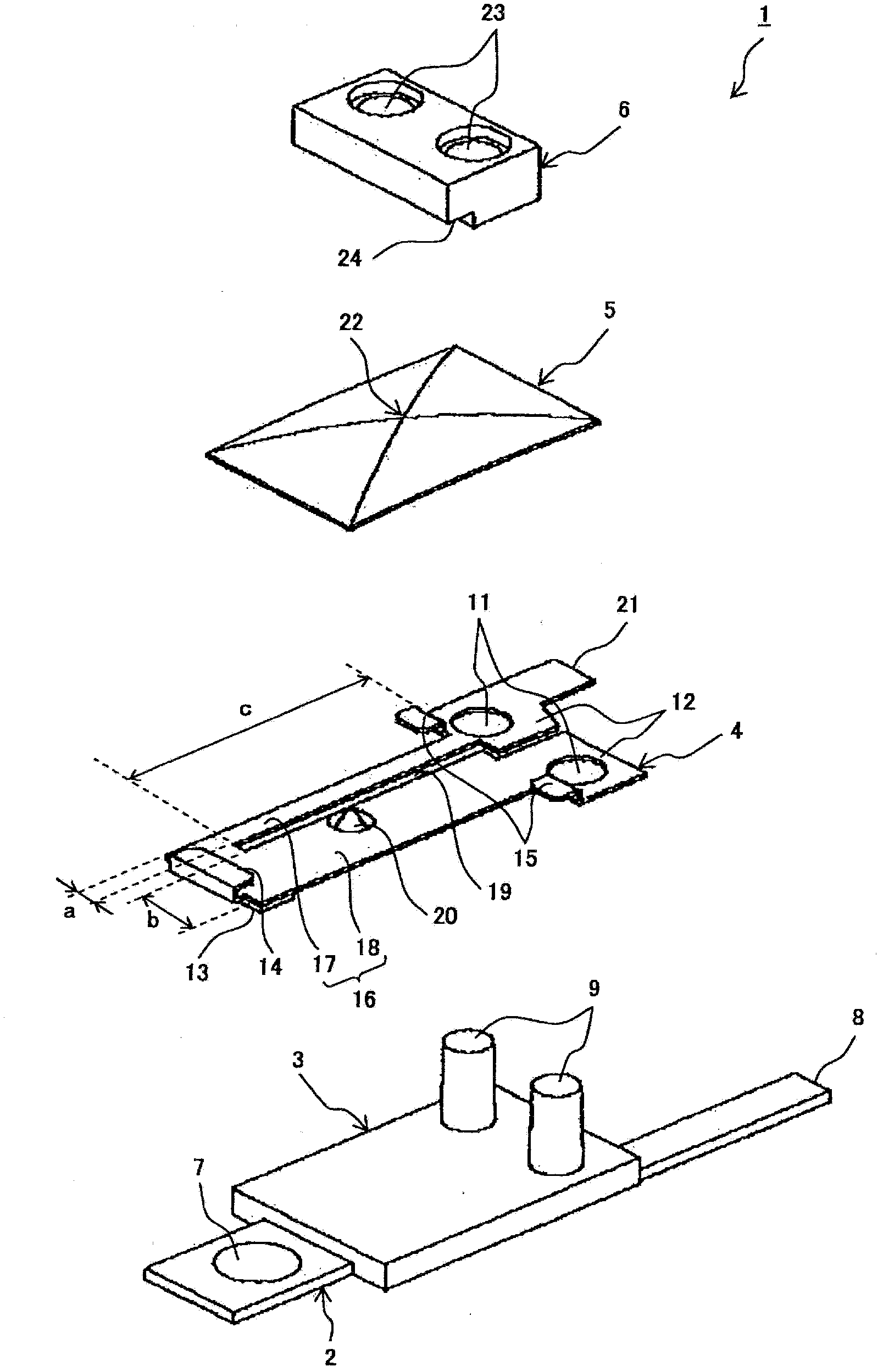

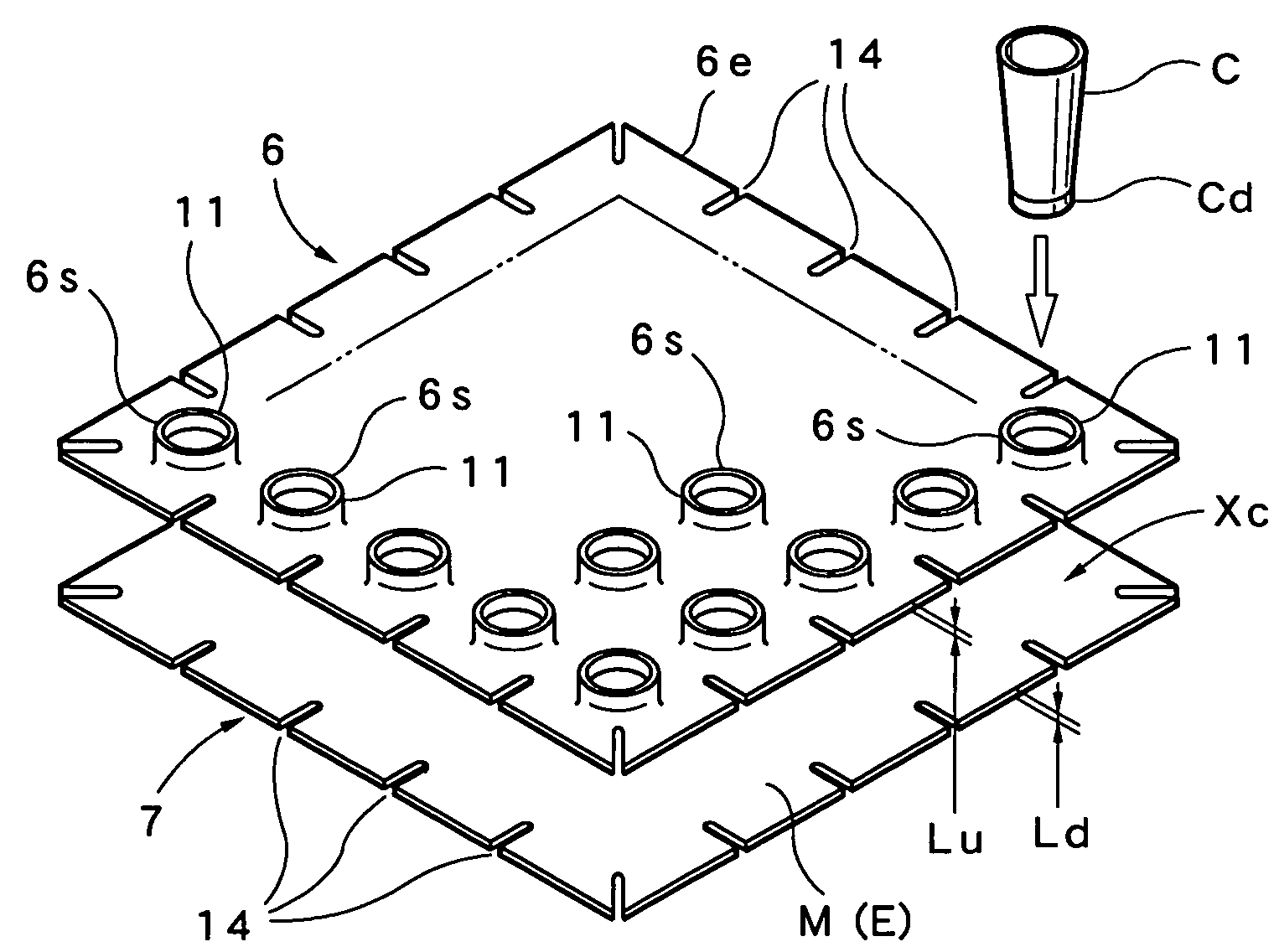

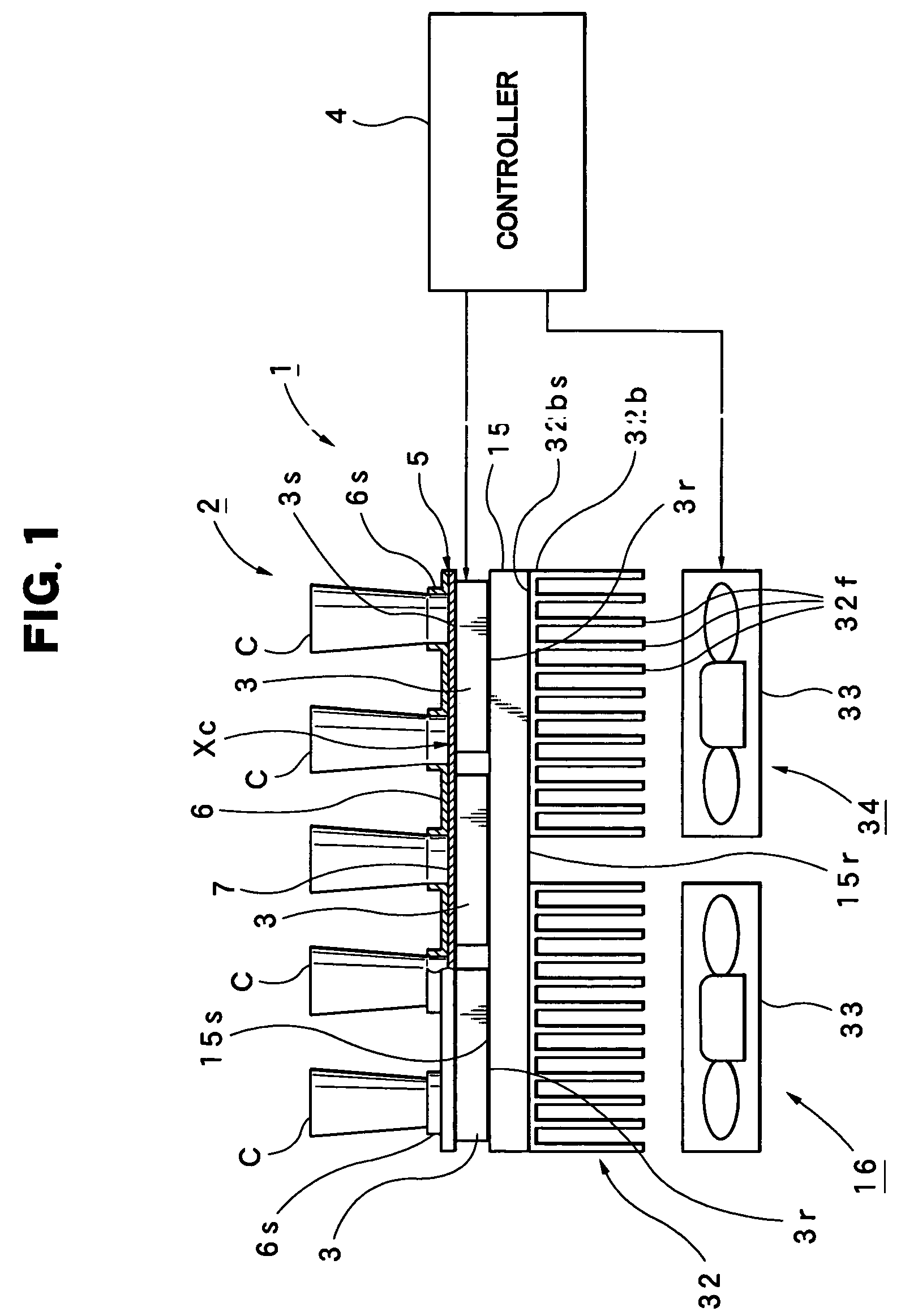

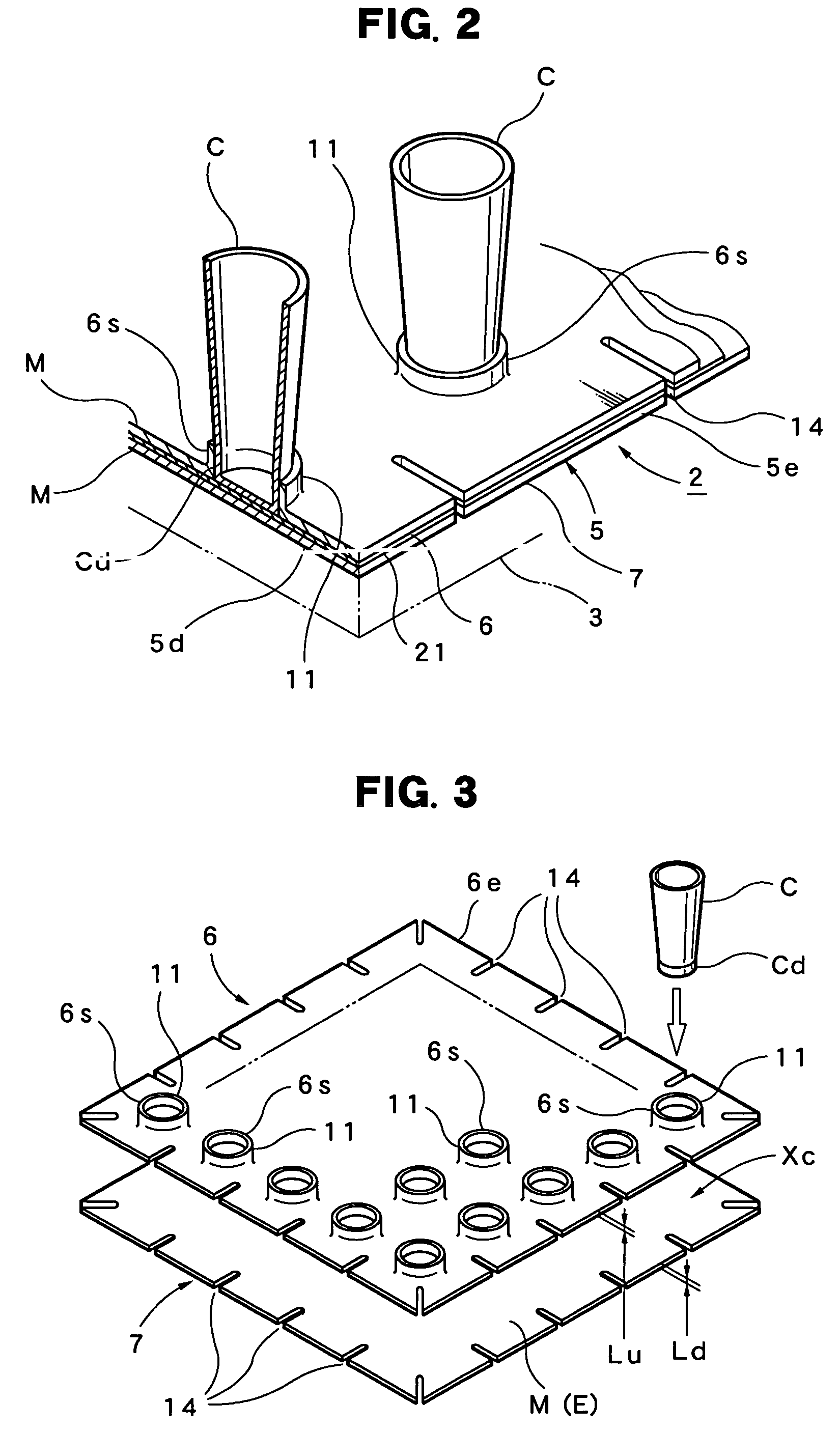

DNA amplification device

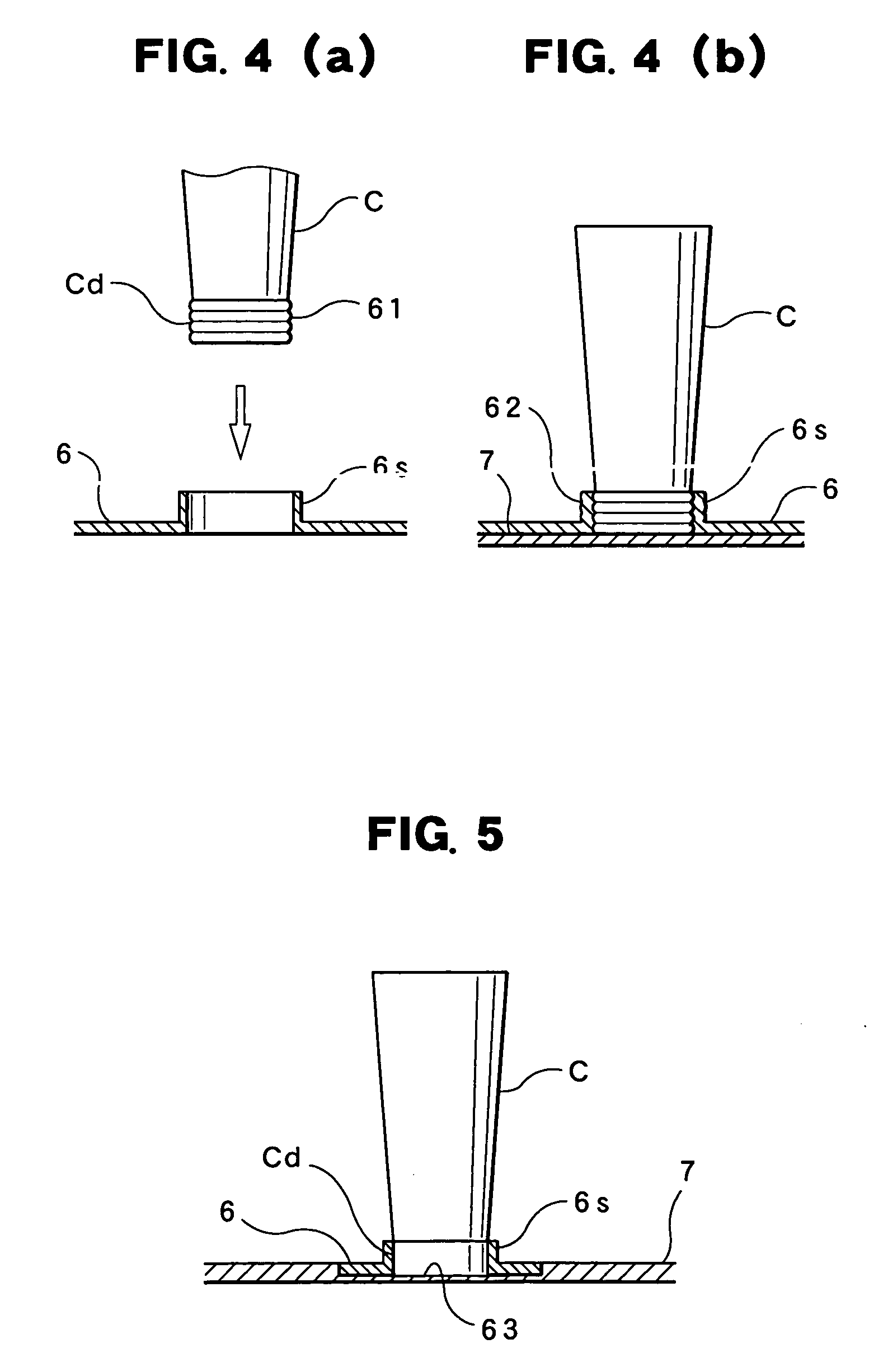

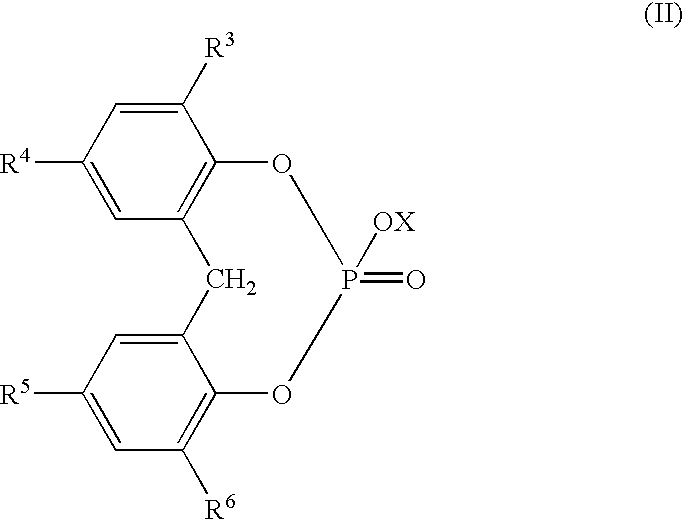

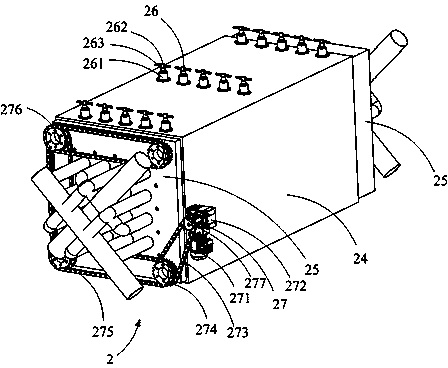

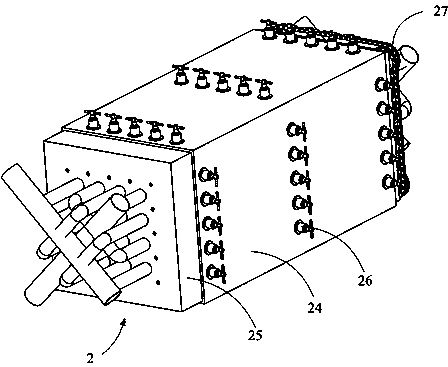

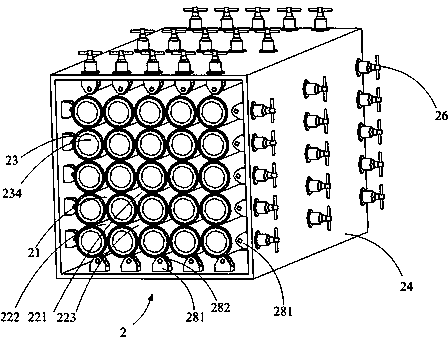

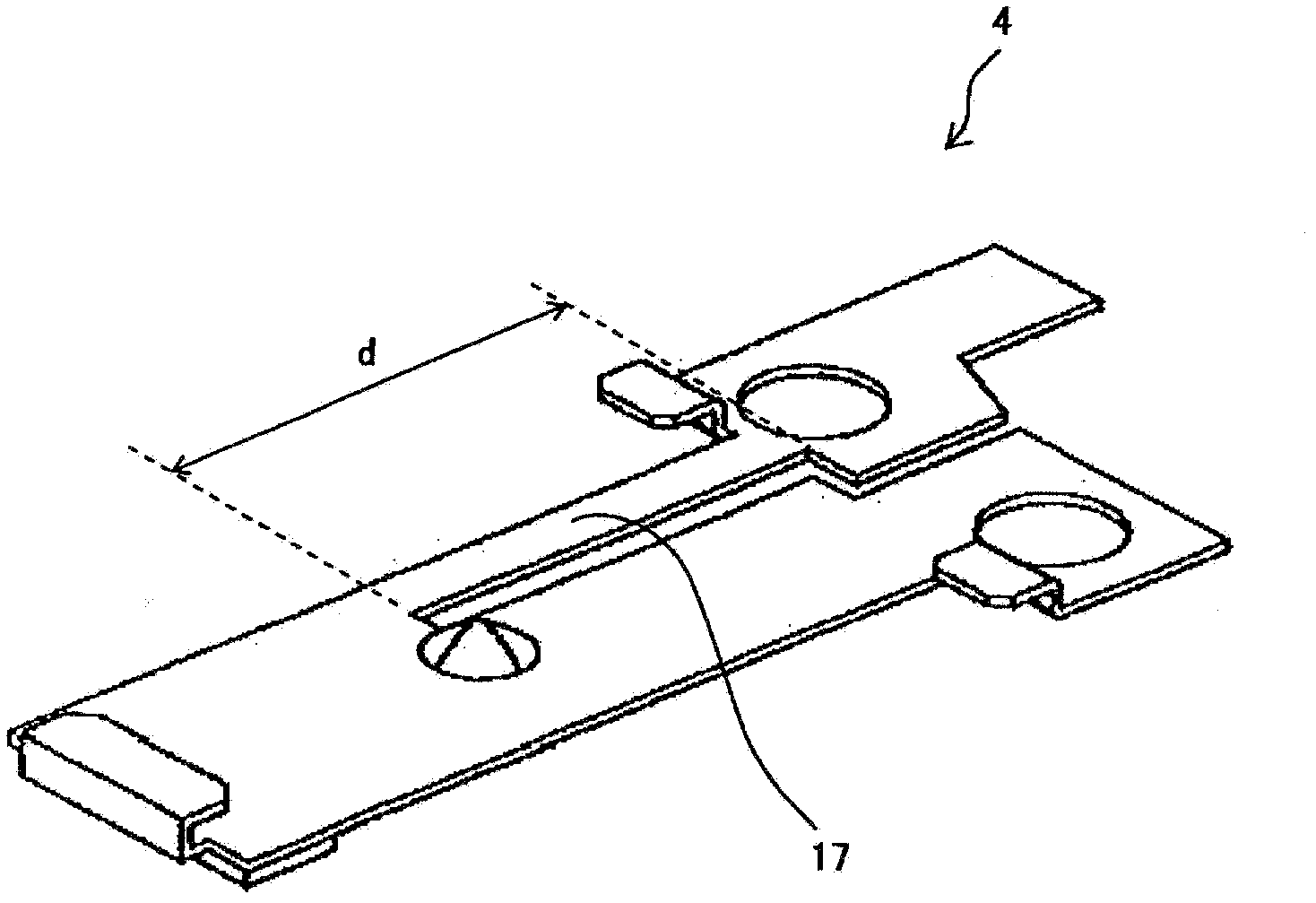

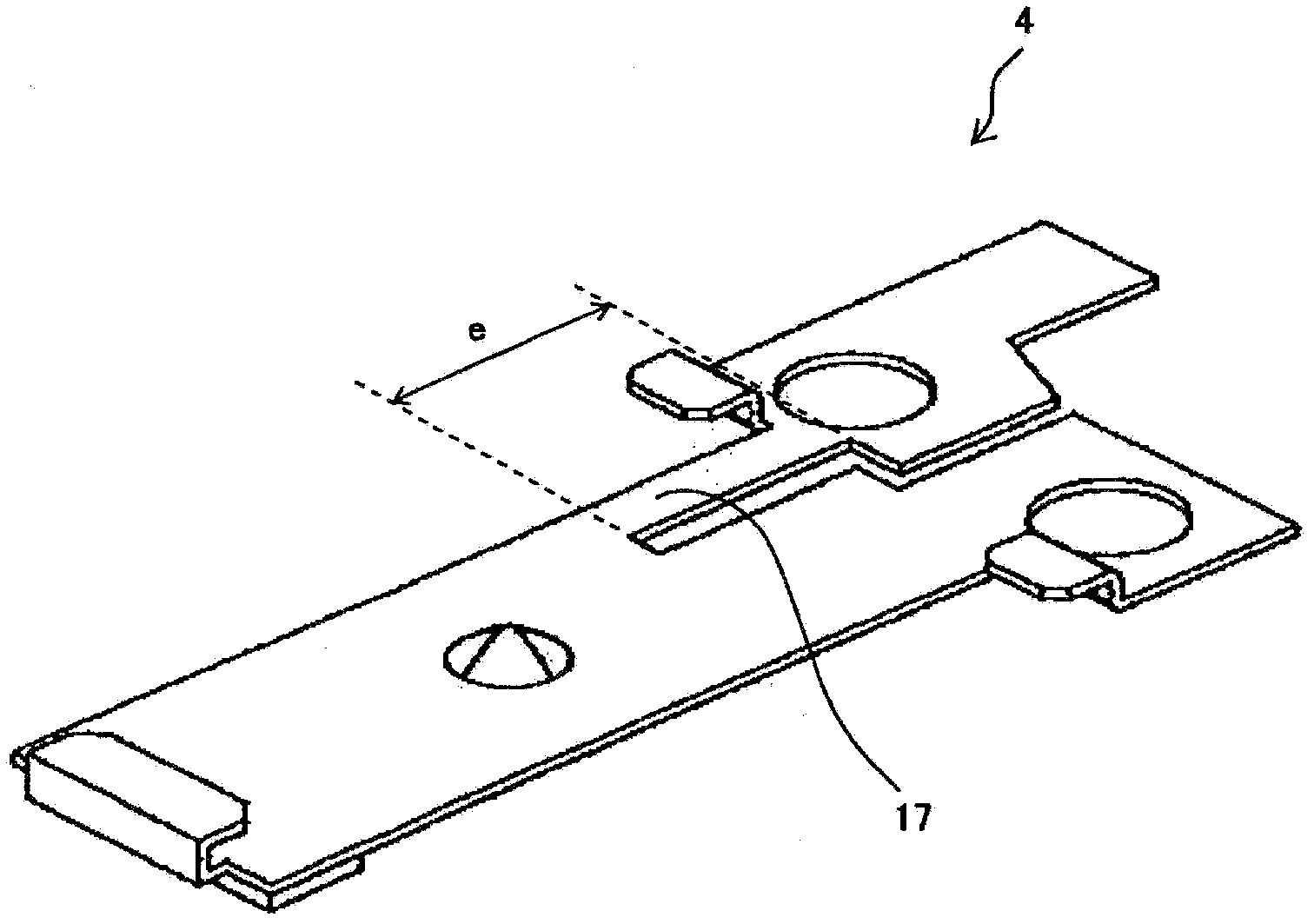

InactiveUS20060166226A1Shorten the construction periodSimple processBioreactor/fermenter combinationsHeating or cooling apparatusMetallurgyDna amplification

A processing block 2 is composed of a base 5, where an upper substrate 6 formed with a metal material M and a lower substrate 7 formed with the metal material M or a ceramic material E are adhered, and cells C . . . supported by this base 5; and the cells C . . . are secured to the upper substrate 6 and / or the lower substrate 7 at least via cell positioners 6s . . . established in the upper substrate 6 for positioning the cells C . . . , respectively. At the same time, at least the thickness Ld of regions Xc . . . situated under the cells C . . . in the lower substrate 7 is selected to be 1.0 [mm] or thinner, and, a thermo-module(s) comes into contact with the lower surface of the base 5.

Owner:THERMOGEN

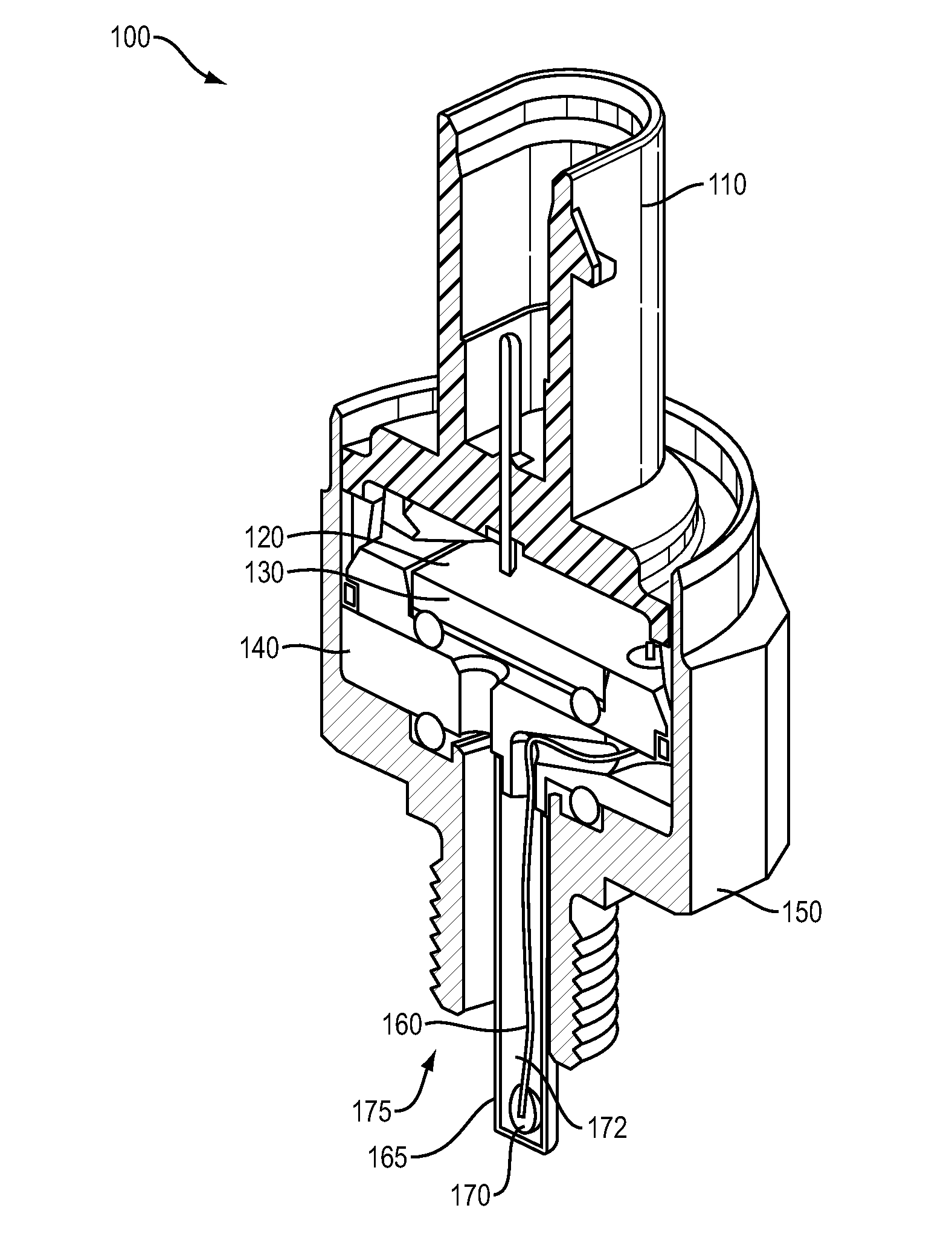

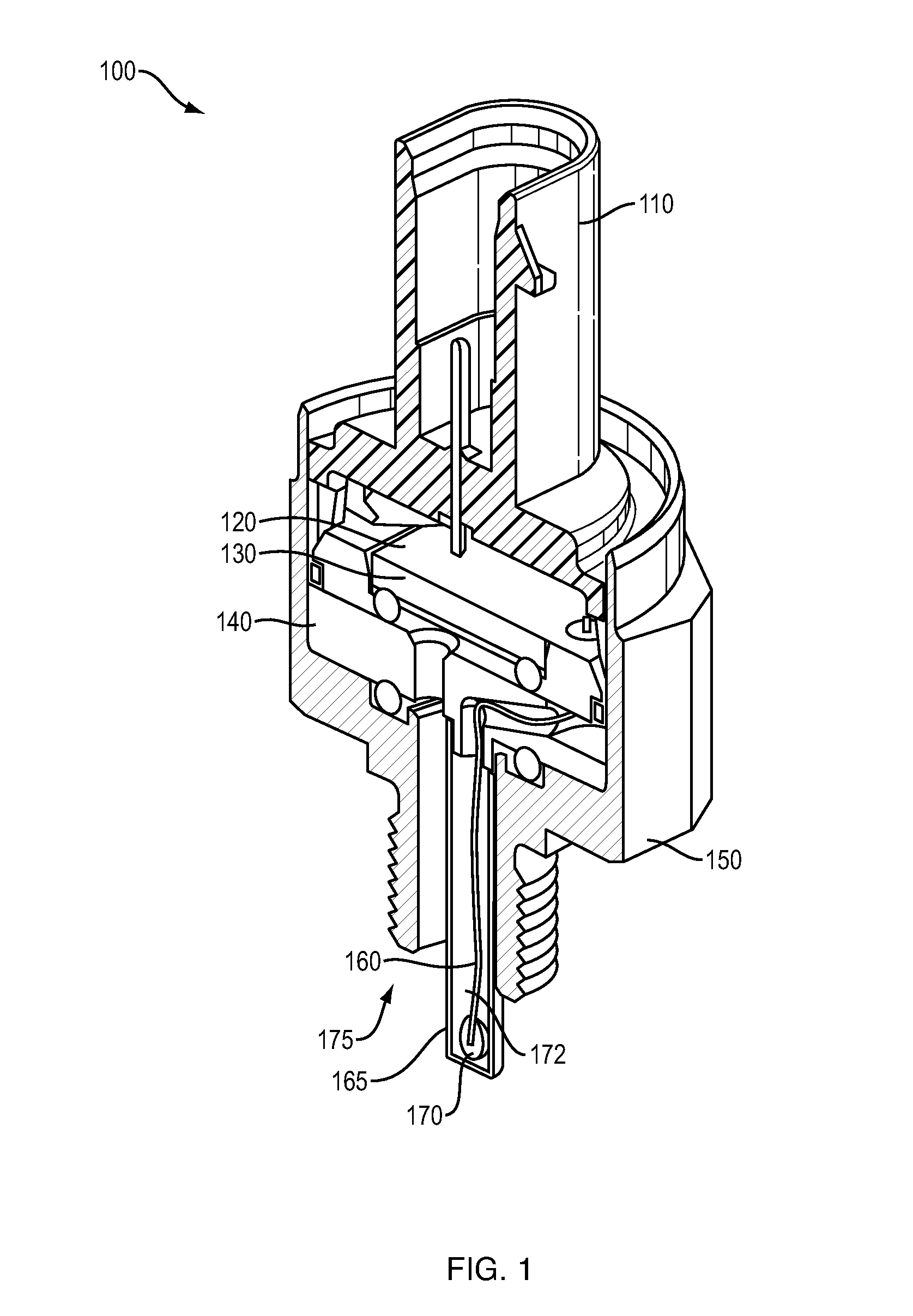

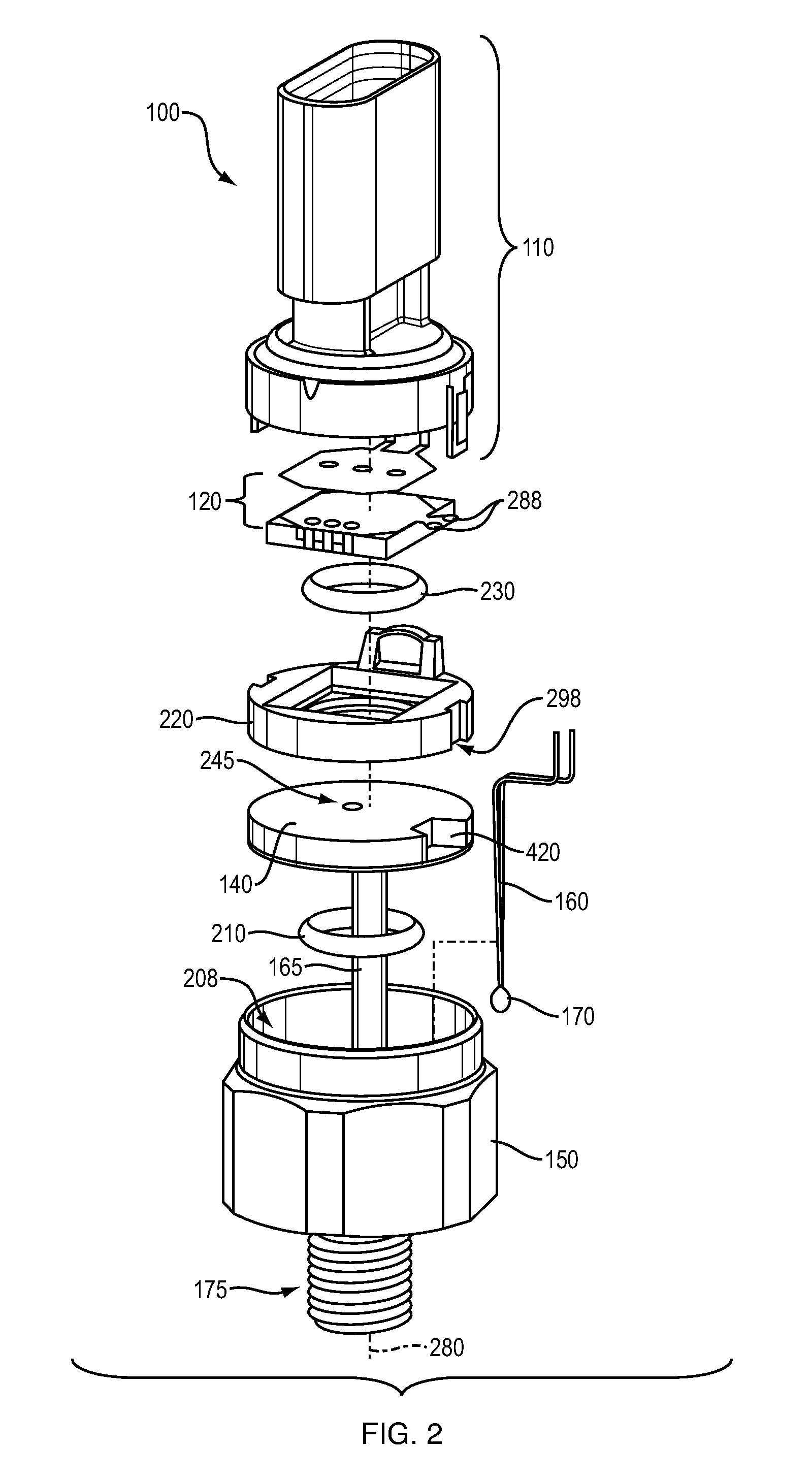

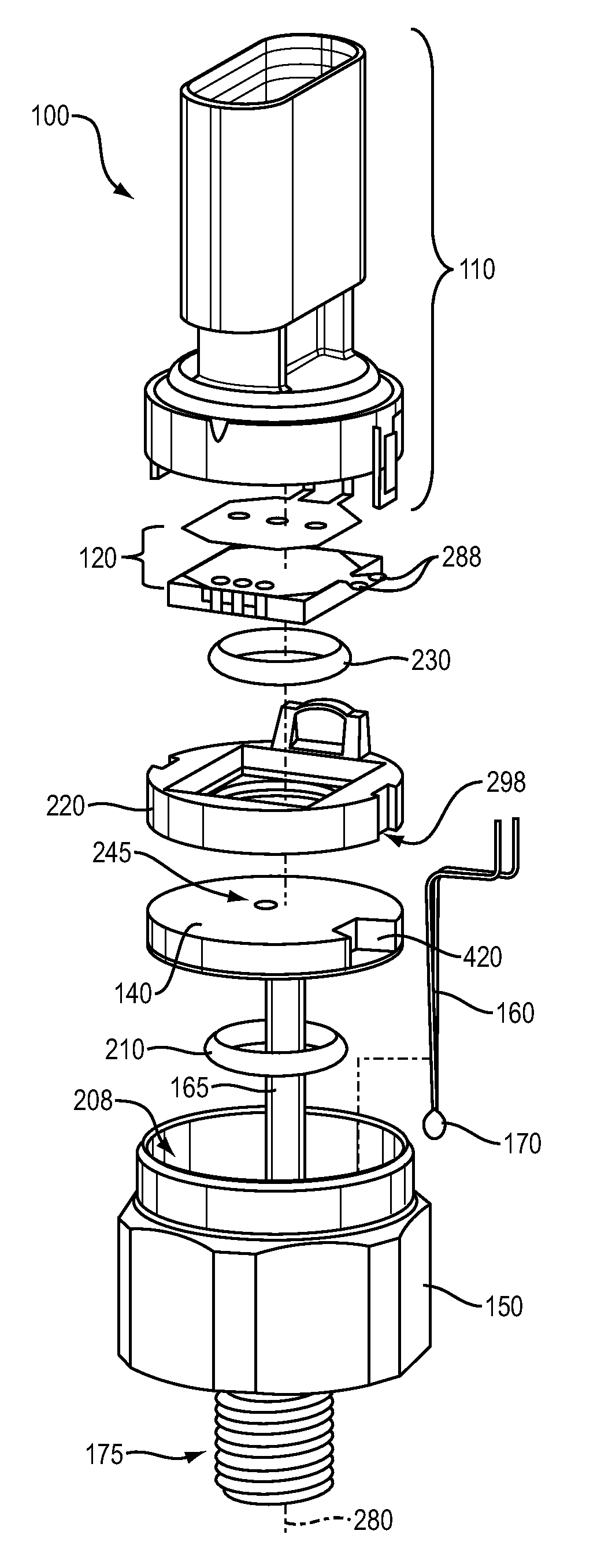

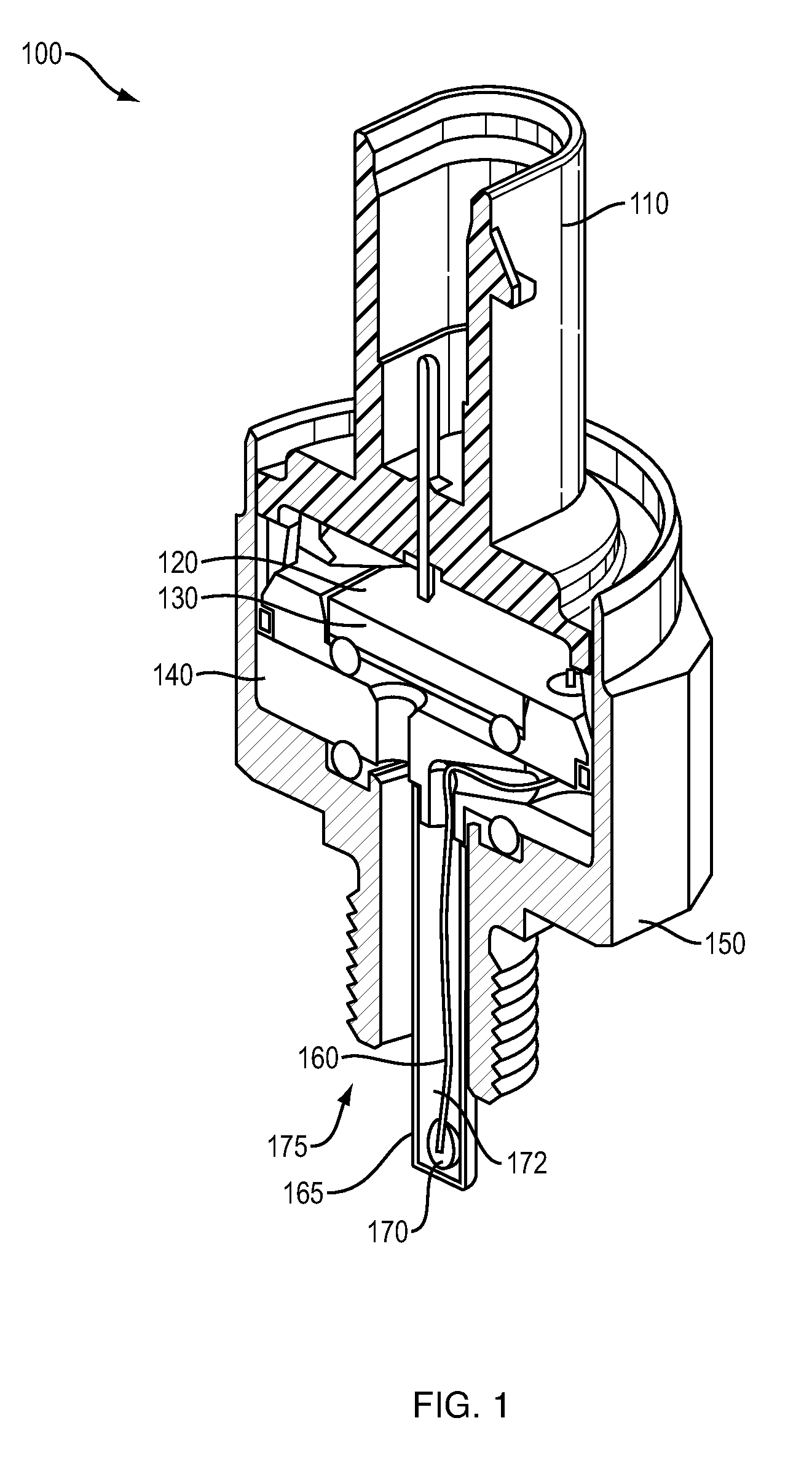

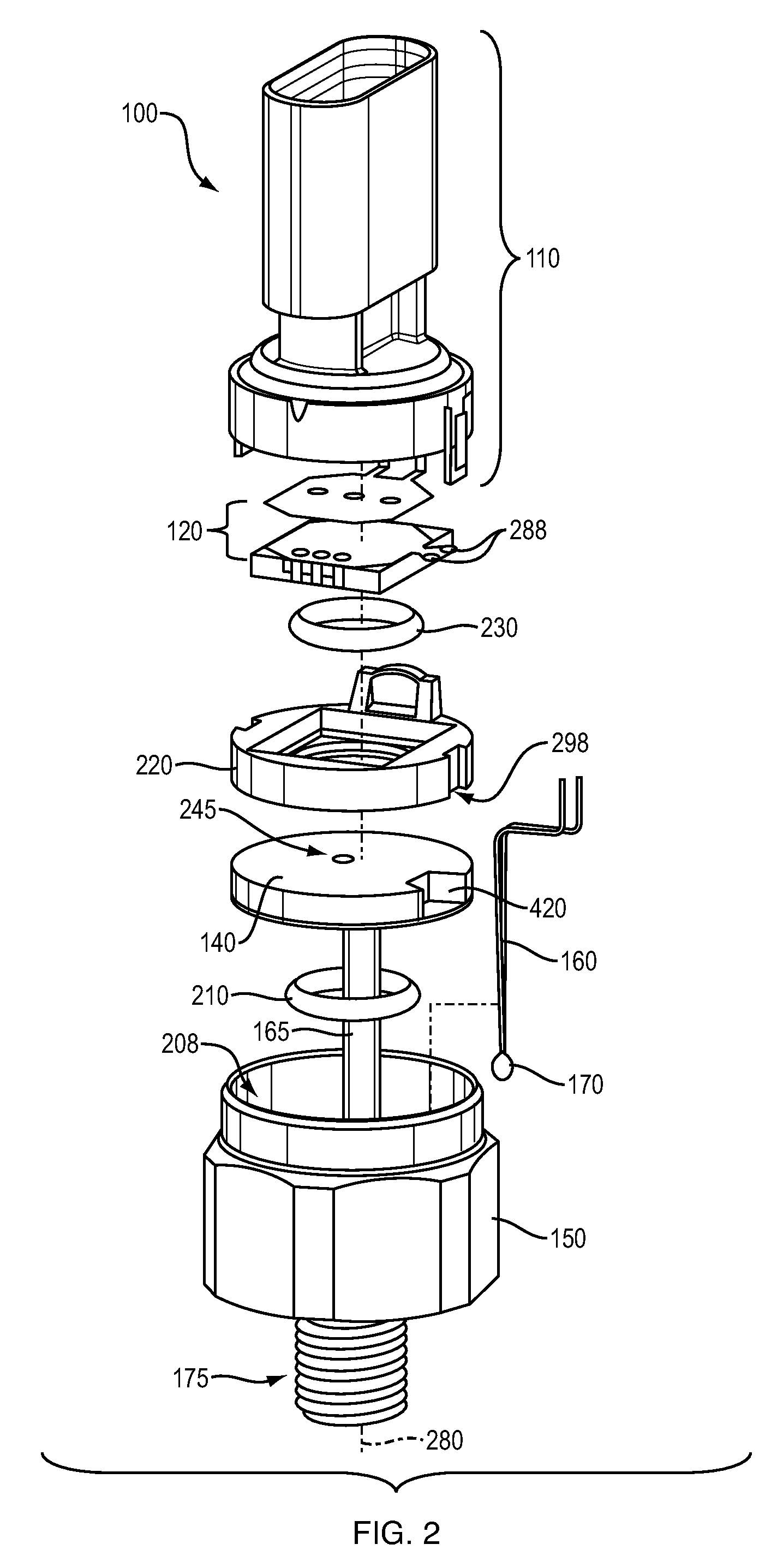

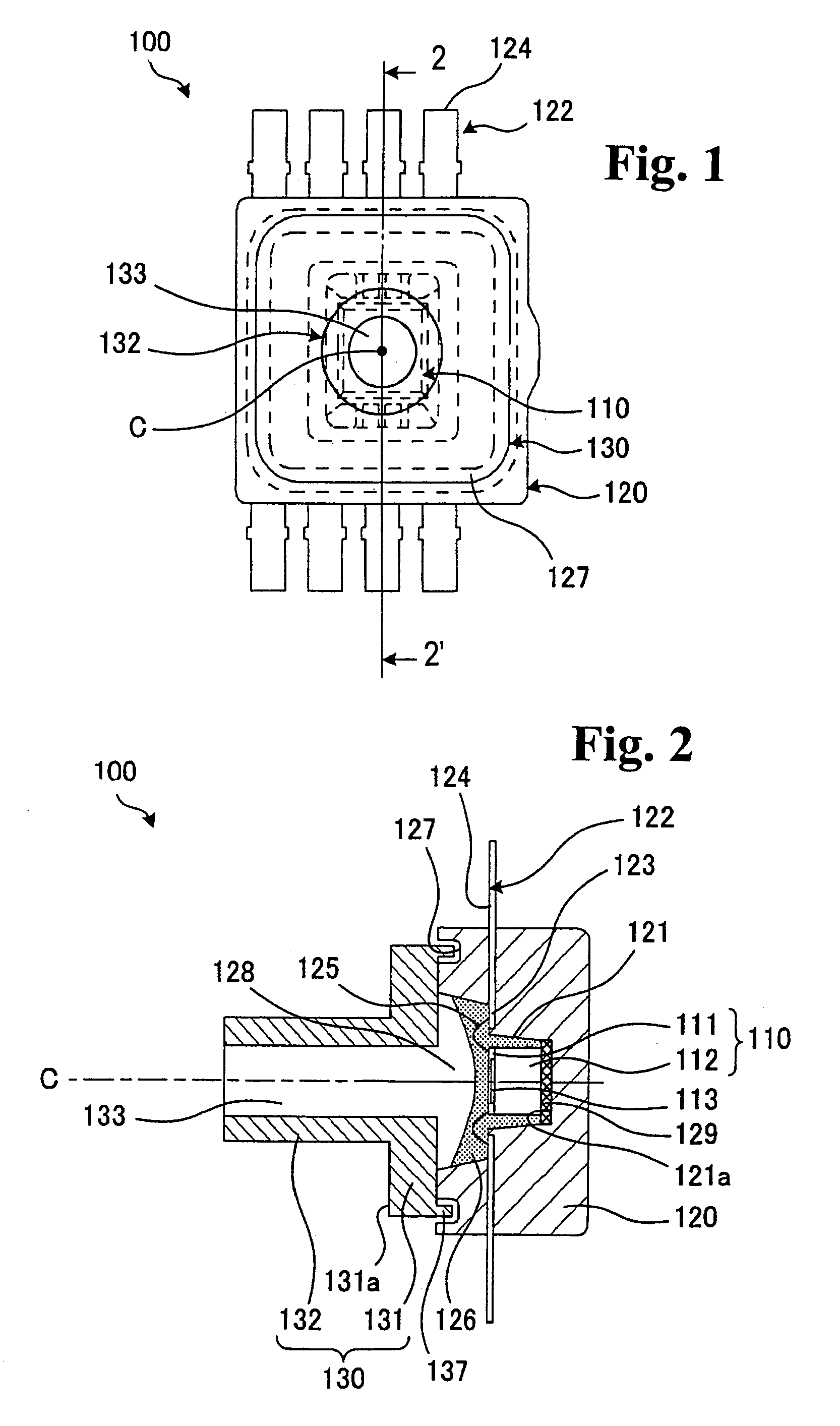

Combination pressure/temperature in a compact sensor assembly

ActiveUS20130047736A1Avoid physical contactGood thermal responseThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsElectricityForce sensor

A sensor assembly includes a rectangular-shaped pressure sensor element and an electronic circuitry coupled to receive a signal from the pressure sensor element. An open-ended fluid-tight passageway of the sensor assembly conveys fluid from a portal opening of the sensor assembly to a surface of the rectangular-shaped pressure sensor element. The sensor assembly further includes a closed-ended fluid-tight passageway, at least a portion of which is fabricated from metal. The closed-ended fluid tight passageway extends from at least from the portal opening of the sensor assembly to the electronic circuitry on at least a portion of a path adjacent to the rectangular-shaped ceramic pressure sensor element. The sensor assembly includes a temperature sensor element disposed in an end of the closed-ended fluid-tight passageway. Conductive links disposed in the closed-ended fluid tight passageway electrically couple the temperature sensor element to the electronic circuitry.

Owner:SENSATA TECHNOLOGIES INC

LED luminaire and arrangement comprising a luminaire body and an LED operating device

InactiveUS20060274531A1Reduce heat outputLower installation heightPoint-like light sourceElectric circuit arrangementsEngineeringHeat sink

The invention discloses an LED luminaire, in the case of which an LED module is applied to the luminaire body such that the height of the luminaire body and the LED module is ≦8 mm and the luminaire body at least partially forms the heat sink for the LED module. In this case, LED modules having power ratings of ≧3 watts are used. LED operating devices can be used for voltage supply purposes which form an outer face section of an arrangement comprising a luminaire body and an LED operating device, the total height of the luminaire body and LED operating device being ≦10 mm, and the LED operating device preferably being cooled via the luminaire body.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

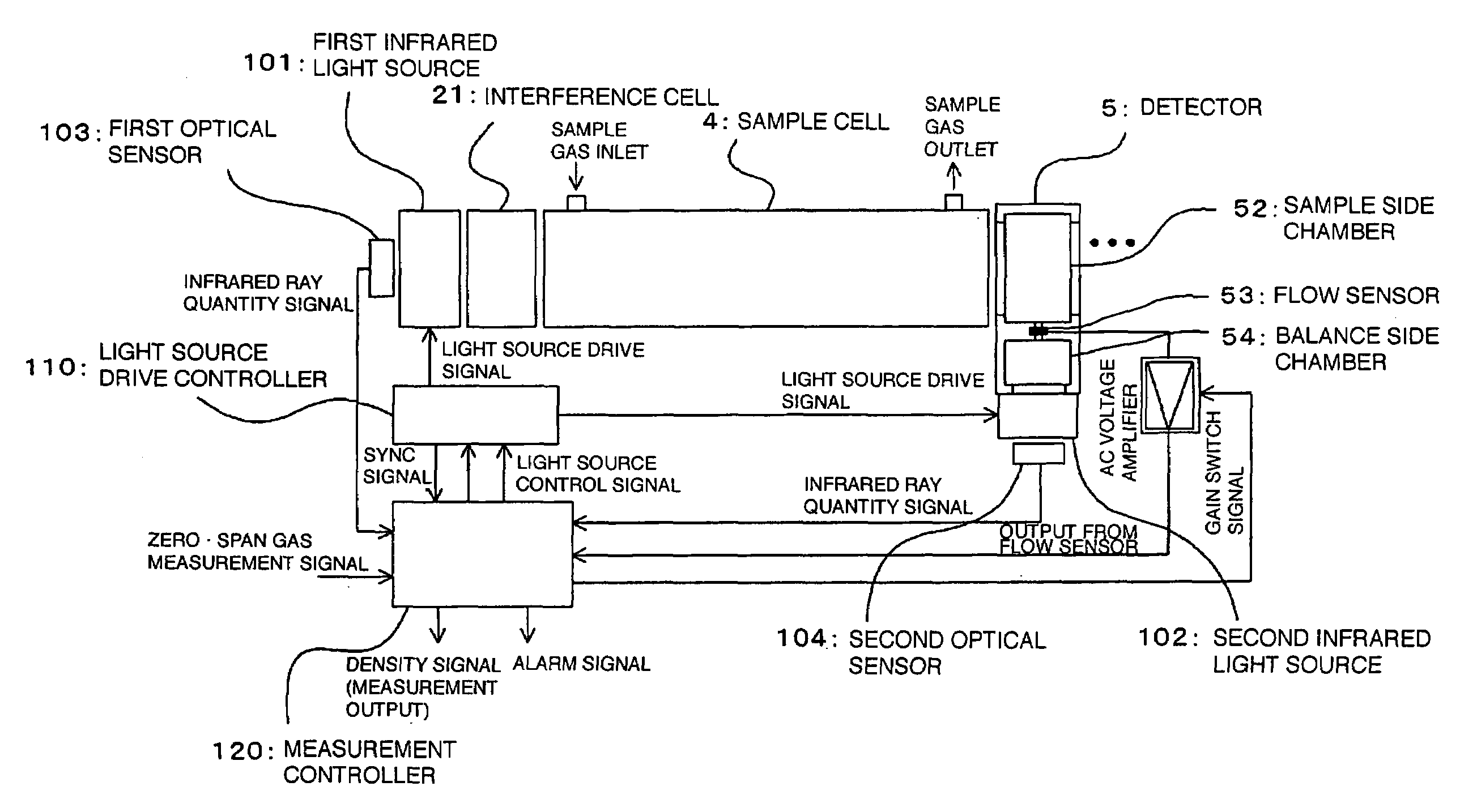

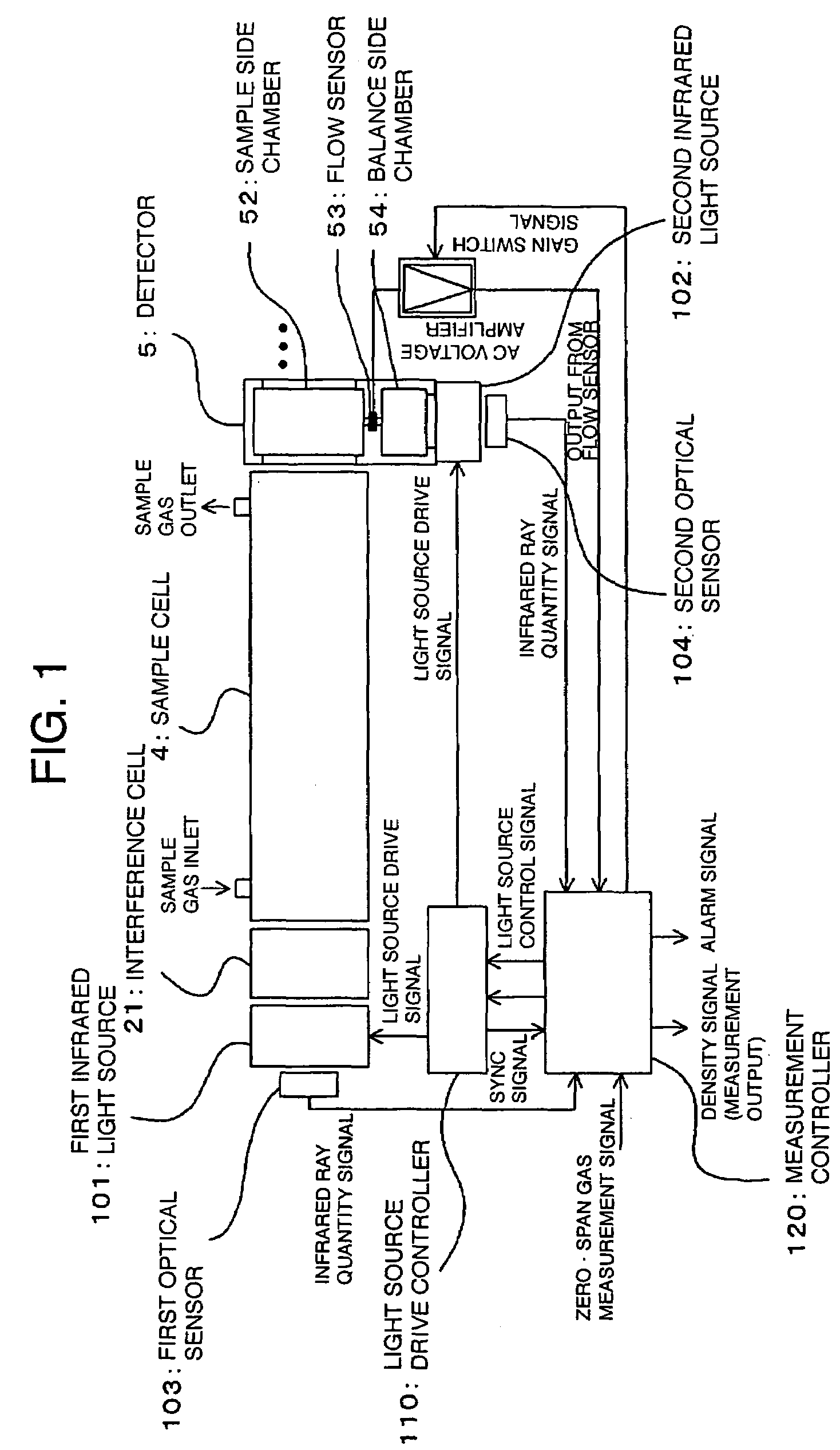

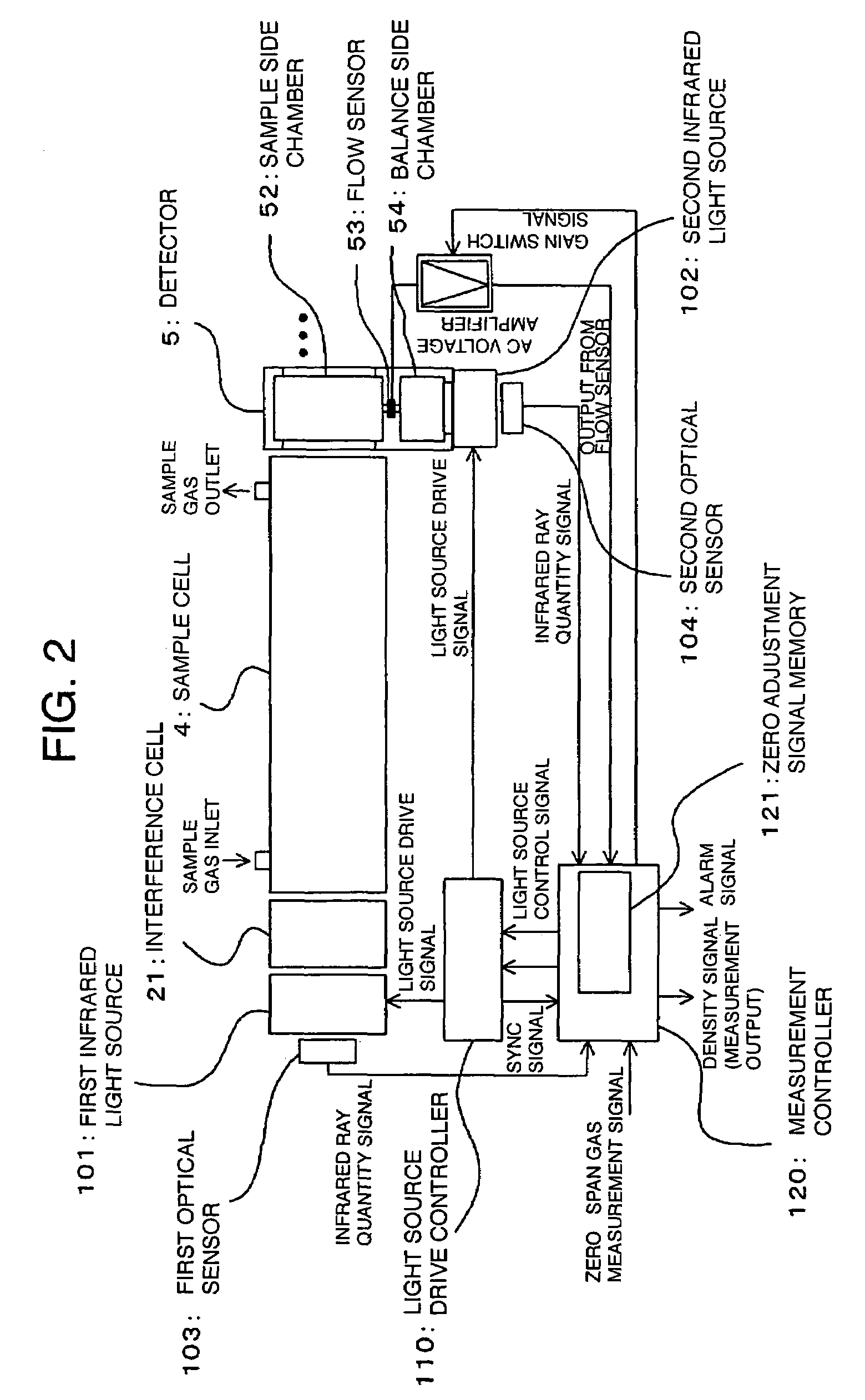

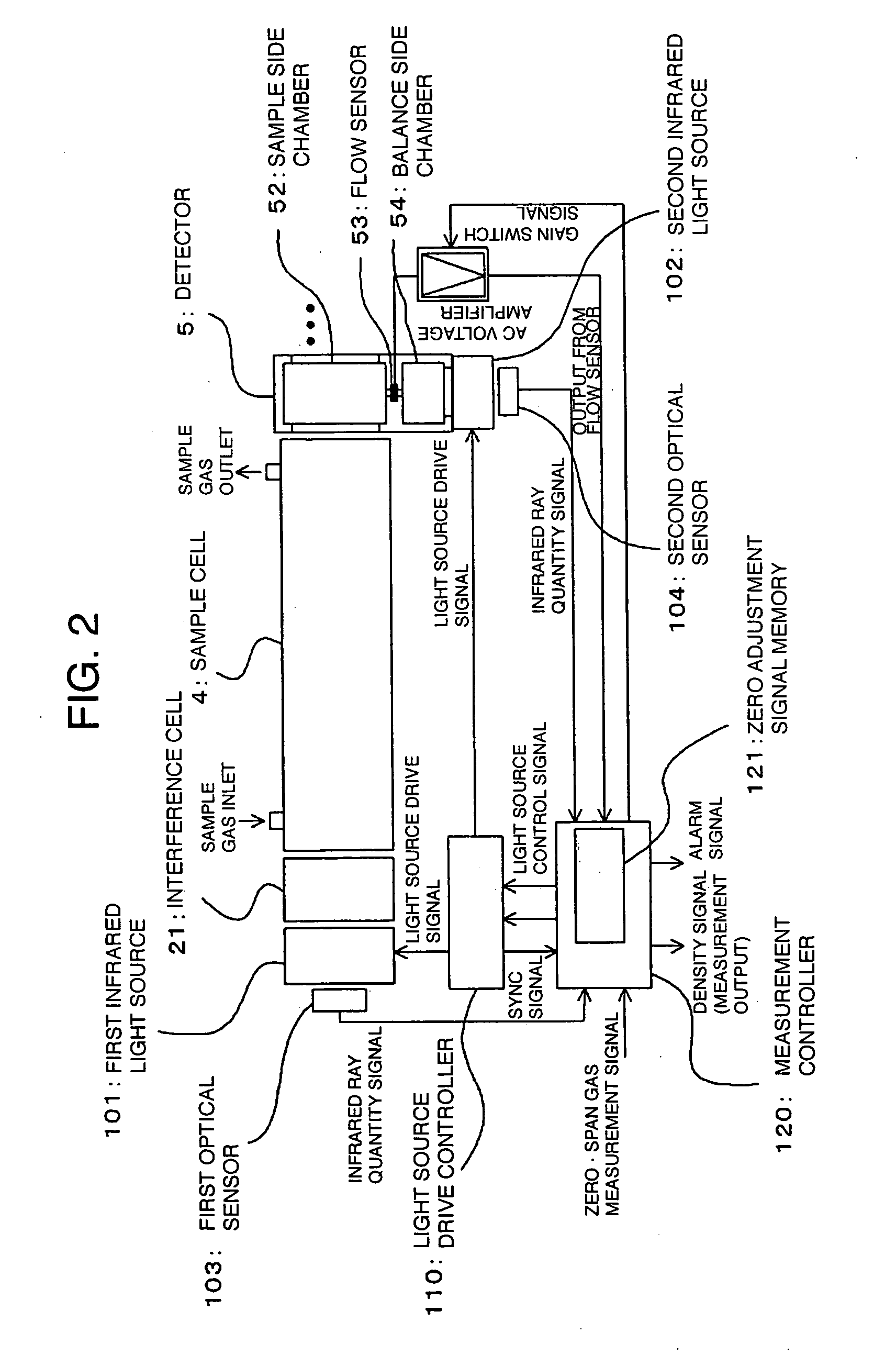

Infrared gas analyzer and infrared gas analysis method

InactiveUS7323687B2Simple configurationGood thermal responseRadiation pyrometryTransmissivity measurementsGas analysisAnalysis method

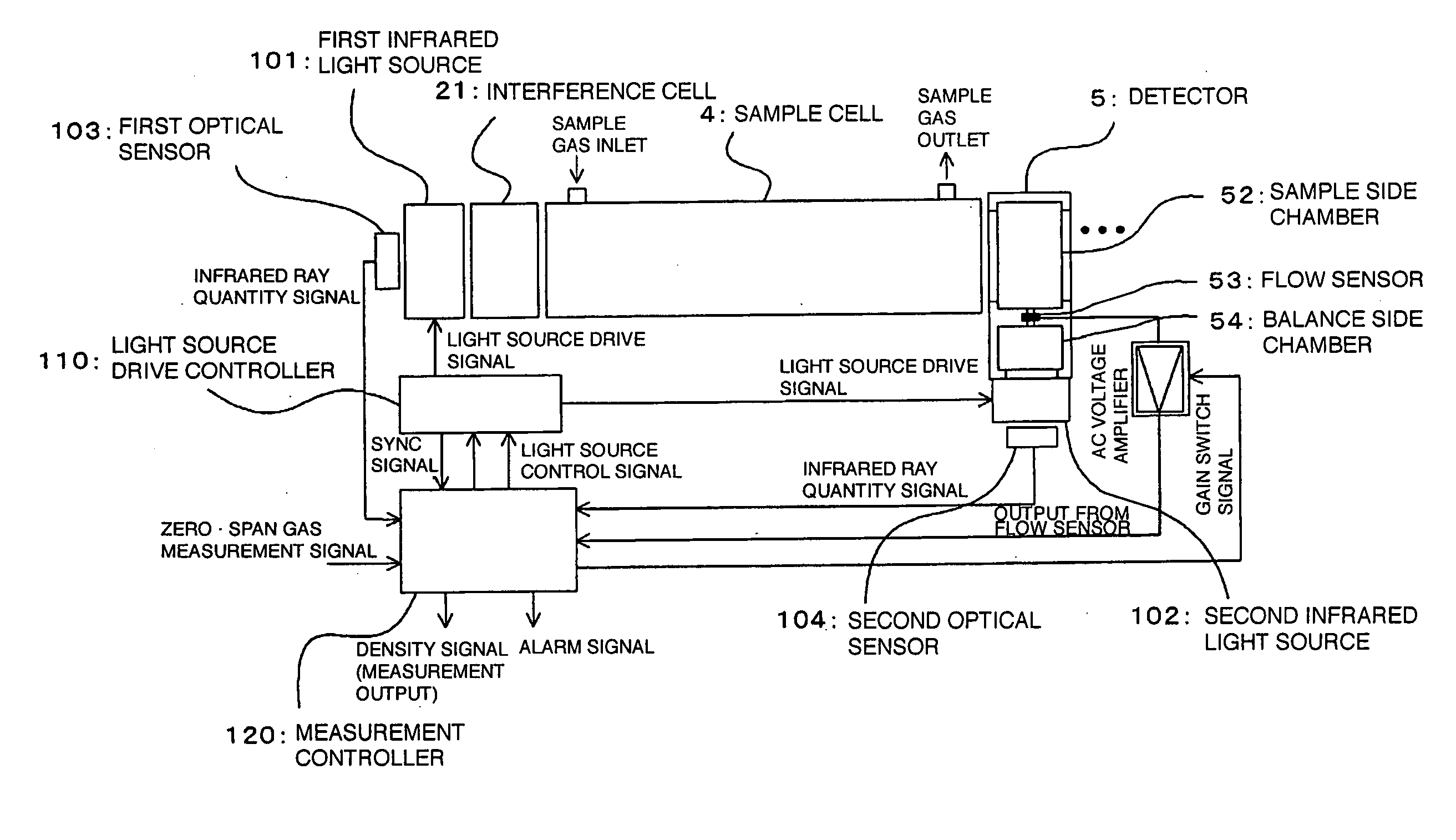

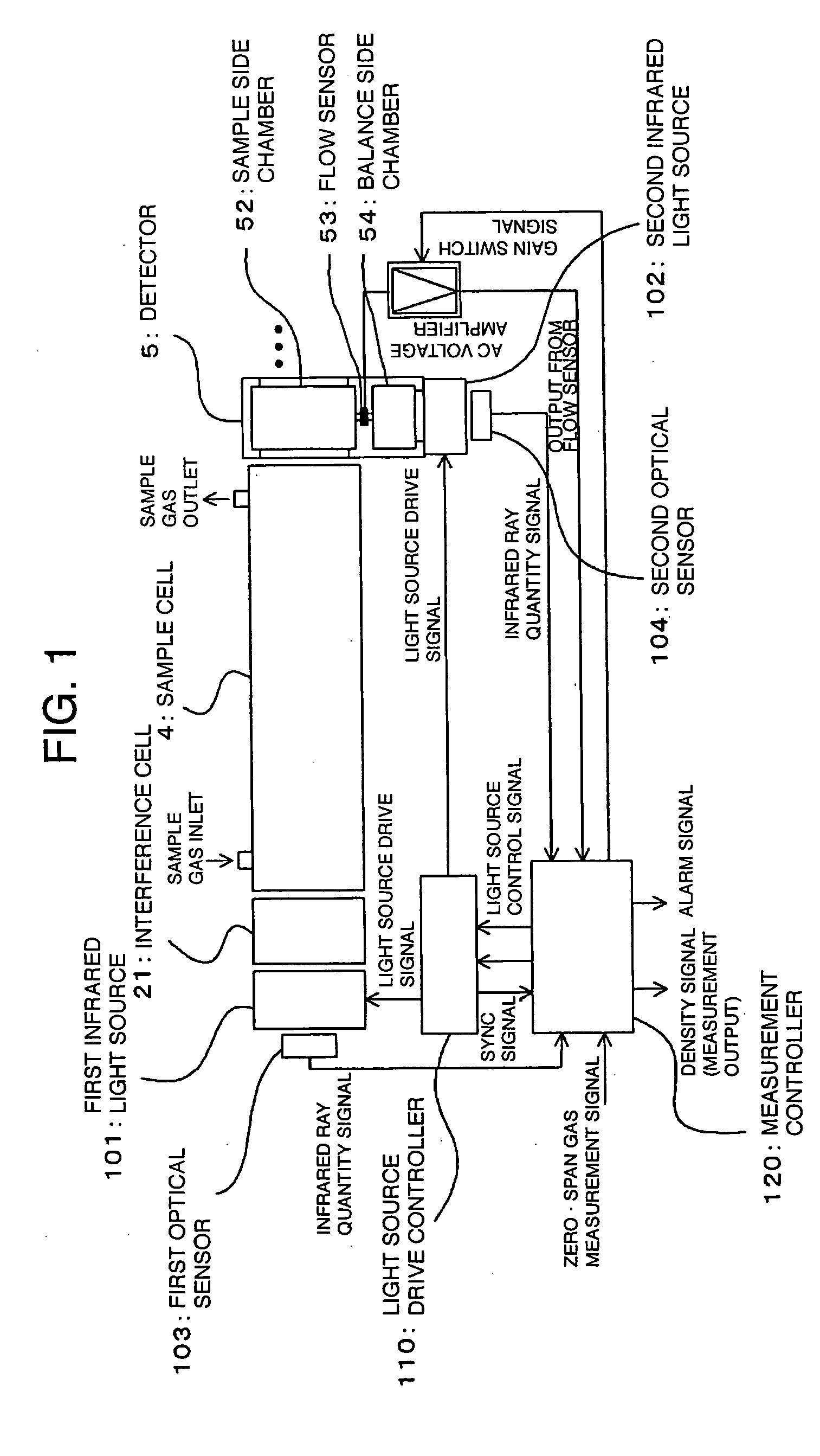

There are provided an infrared gas analyzer of a simple configuration, capable of taking measurements with high precision when using an infrared light source excellent in thermal responsiveness, and capable of ON / OFF operations at high speed, and an infrared gas analysis method using the same. The infrared gas analyzer having a sample cell into which a sample gas is distributed, for detecting concentration of a measuring target component of the sample gas by taking advantage of variation in absorption amount of infrared rays having passed through the sample cell, comprising a first infrared light source for irradiating the sample cell with first infrared rays, a second infrared light source having a response characteristic equal to that of the first infrared light source, a detector for detecting a difference between the first infrared rays emitted from the first infrared light source, and having passed through the sample cell, and second infrared rays emitted from the second infrared light source, a light source drive controller for synchronously driving the first and second infrared light sources, respectively, and a measurement controller for providing the light source drive controller with instructions for respective drive amounts of the first and second infrared light sources while receiving an output signal from the detector, thereby generating a measurement output corresponding to the concentration of the measuring target component of the sample gas.

Owner:YOKOGAWA ELECTRIC CORP

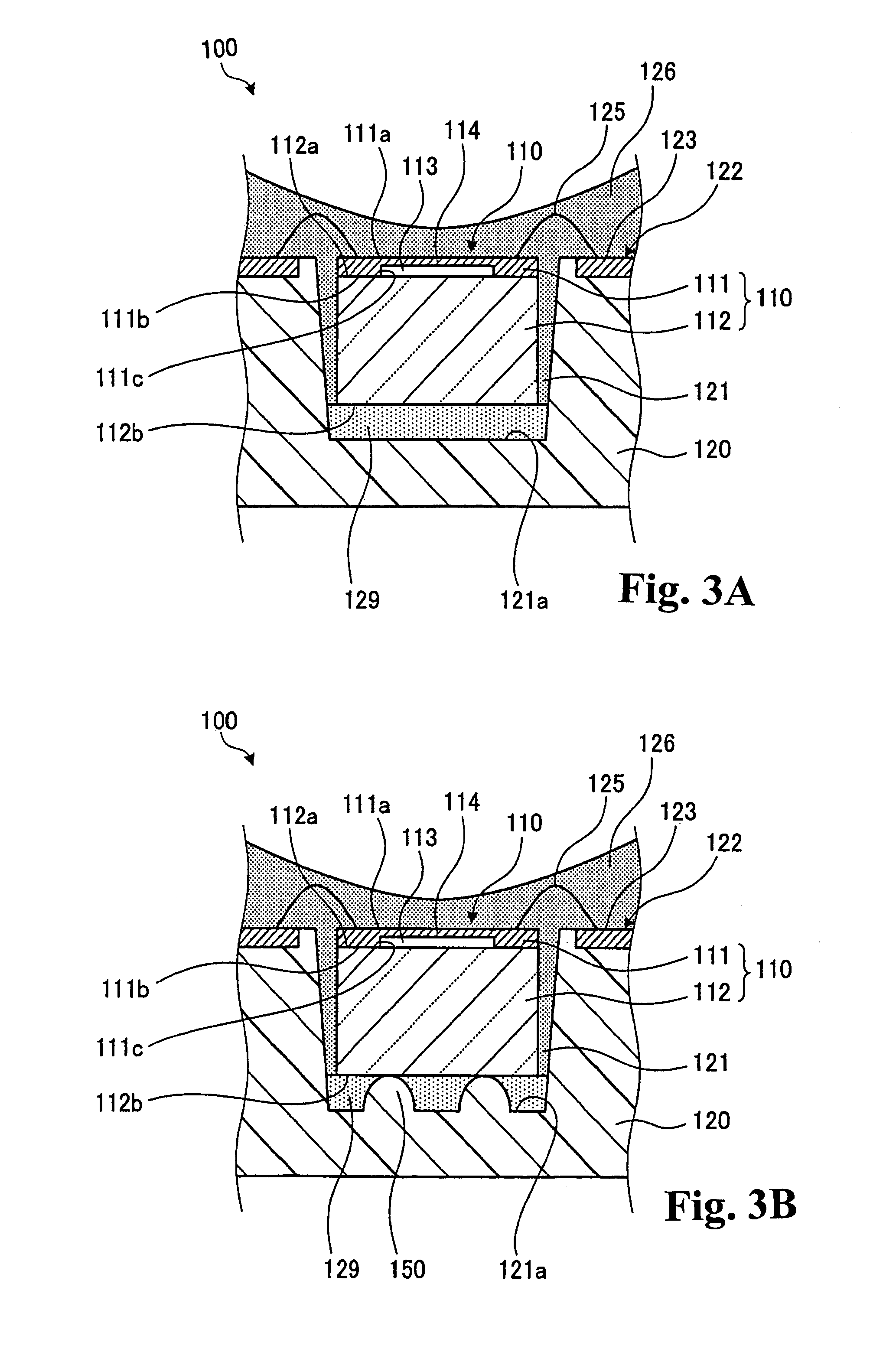

Pressure detecting apparatus

ActiveUS20060243054A1Promote absorptionImprove featuresFluid pressure measurement by electric/magnetic elementsSolid-state devicesEngineeringElectric signal

A pressure detecting apparatus has a pressure detecting device that converts a strain caused by a stress exerted thereto to an electrical signal, and outputs the converted electrical signal. The apparatus has a housing base including a housing recess that houses the pressure detecting device therein, and a connecting material interposed between the pressure detecting device and the housing recess. The connecting material connects the pressure detecting device and the housing recess with a tensile elongation percentage of about 400% or higher. The pressure detecting apparatus facilitates preventing thermal stress from adversely affecting the detection performance thereof, and produces excellent thermal response.

Owner:FUJI ELECTRIC CO LTD

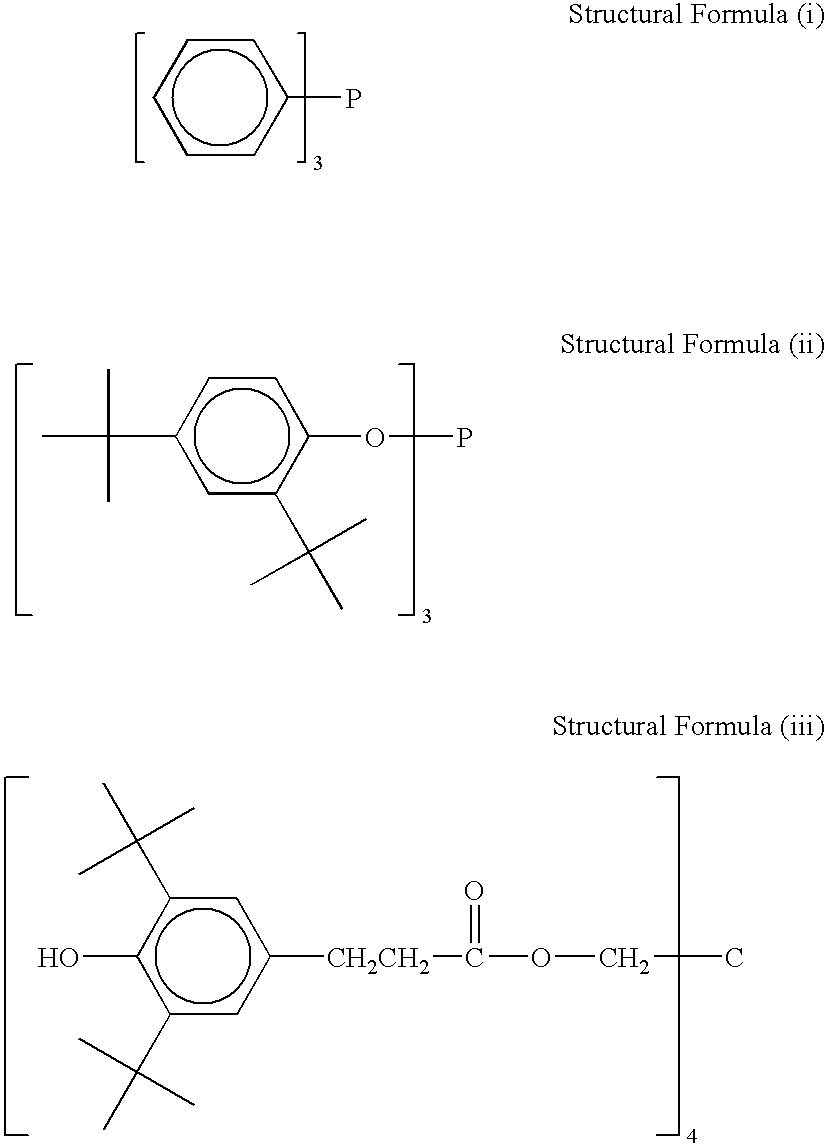

Heat-sensitive pressure-sensitive adhesive and heat-sensitive adhesive material

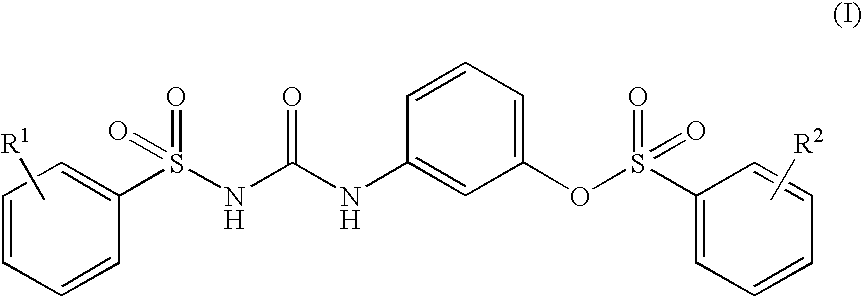

InactiveUS7993732B2High bonding strengthLess reduction in adhesive strengthFilm/foil adhesivesSynthetic resin layered productsVitrificationPropionate

A heat-sensitive pressure-sensitive adhesive which contains at least a thermoplastic resin and a thermofusible material, wherein the thermoplastic resin has a glass transition temperature of −70° C. to −30° C., and the thermofusible material comprises triphenylphosphine, and at least any one of tris(2,4-di-t-butylphenyl)phosphite and tetrakis[3-(3,5-di-t-butyl-4-hydroxyphenyl)propionate]methane, or a heat-sensitive pressure-sensitive adhesive which contains at least a thermoplastic resin, a thermofusible material and a non-thermofusible material, wherein the thermofusible material contains triphenylphosphine.

Owner:RICOH KK

Sic transient voltage suppressor

ActiveUS20160126306A1Higher reverse biasesGood thermal responseThyristorSolid-state devicesEngineeringTransient voltage suppressor

A high power, high current Unidirectional Transient Voltage Suppressor, formed on SiC starting material is disclosed. The device is structured to avalanche uniformly across the entire central part (active area) such that very high currents can flow while the device is reversely biased. Forcing the device to avalanche uniformly across designated areas is achieved in different ways but consistently in concept, by creating high electric fields where the device is supposed to avalanche (namely the to active area) and by relaxing the electric field across the edge of the structure (namely in the termination), which in all embodiments meets the conditions for an increased reliability under harsh environments.

Owner:MICROSEMI

Combination pressure/temperature in a compact sensor assembly

ActiveUS8935961B2Avoid physical contactGood thermal responseThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsElectricityEngineering

Owner:SENSATA TECHNOLOGIES INC

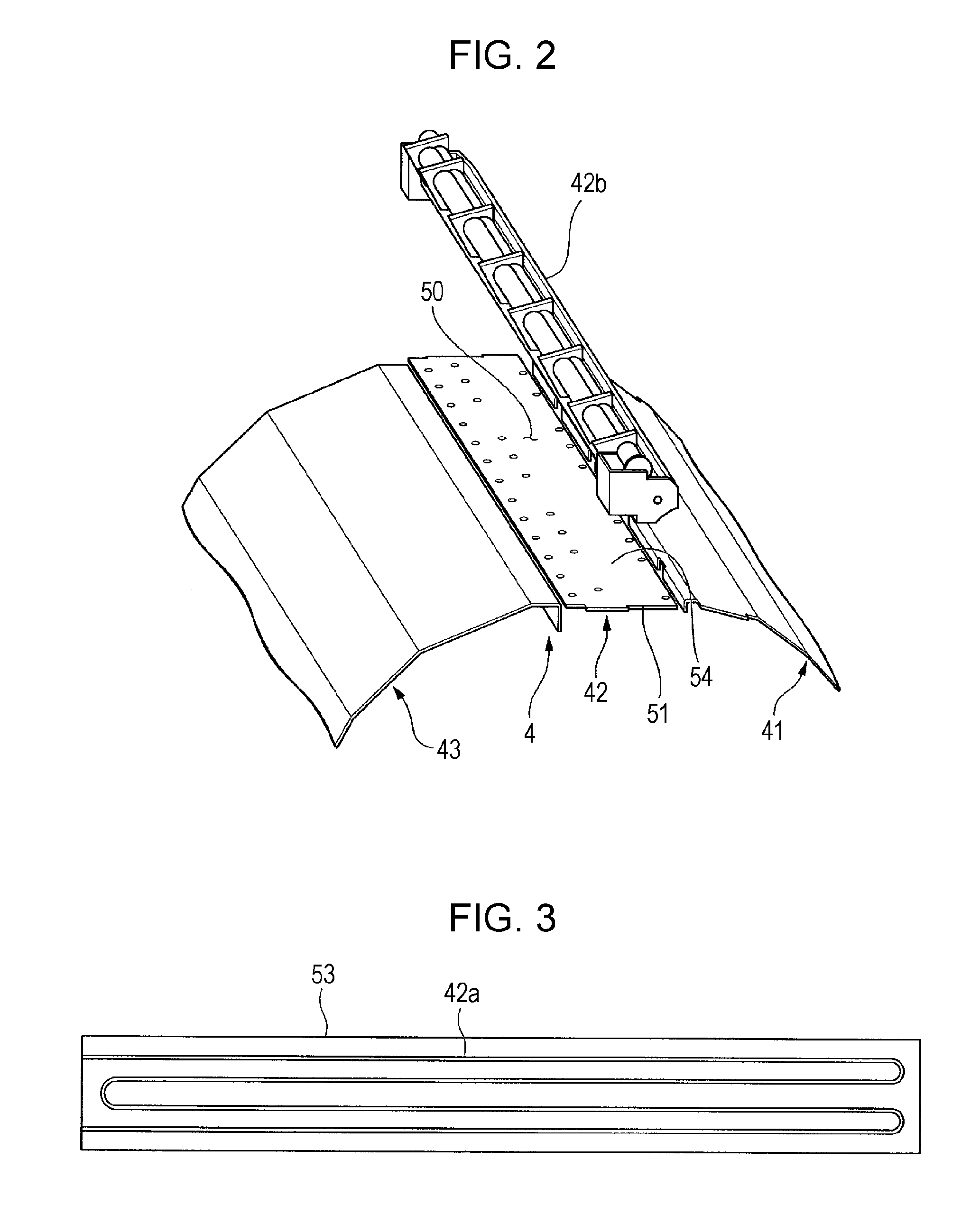

Recording apparatus

ActiveUS20120162335A1Prevent heatGood thermal responseOther printing apparatusRecording headRadiation

A recording apparatus includes: a recording head that ejects fluid onto a recording medium; a supporting member that supports the recording medium; and a heating device that heats the supporting member, in which a supporting surface that supports the recording medium in the supporting member has a surface treatment layer having a radiation factor of 0.85 or more.

Owner:SEIKO EPSON CORP

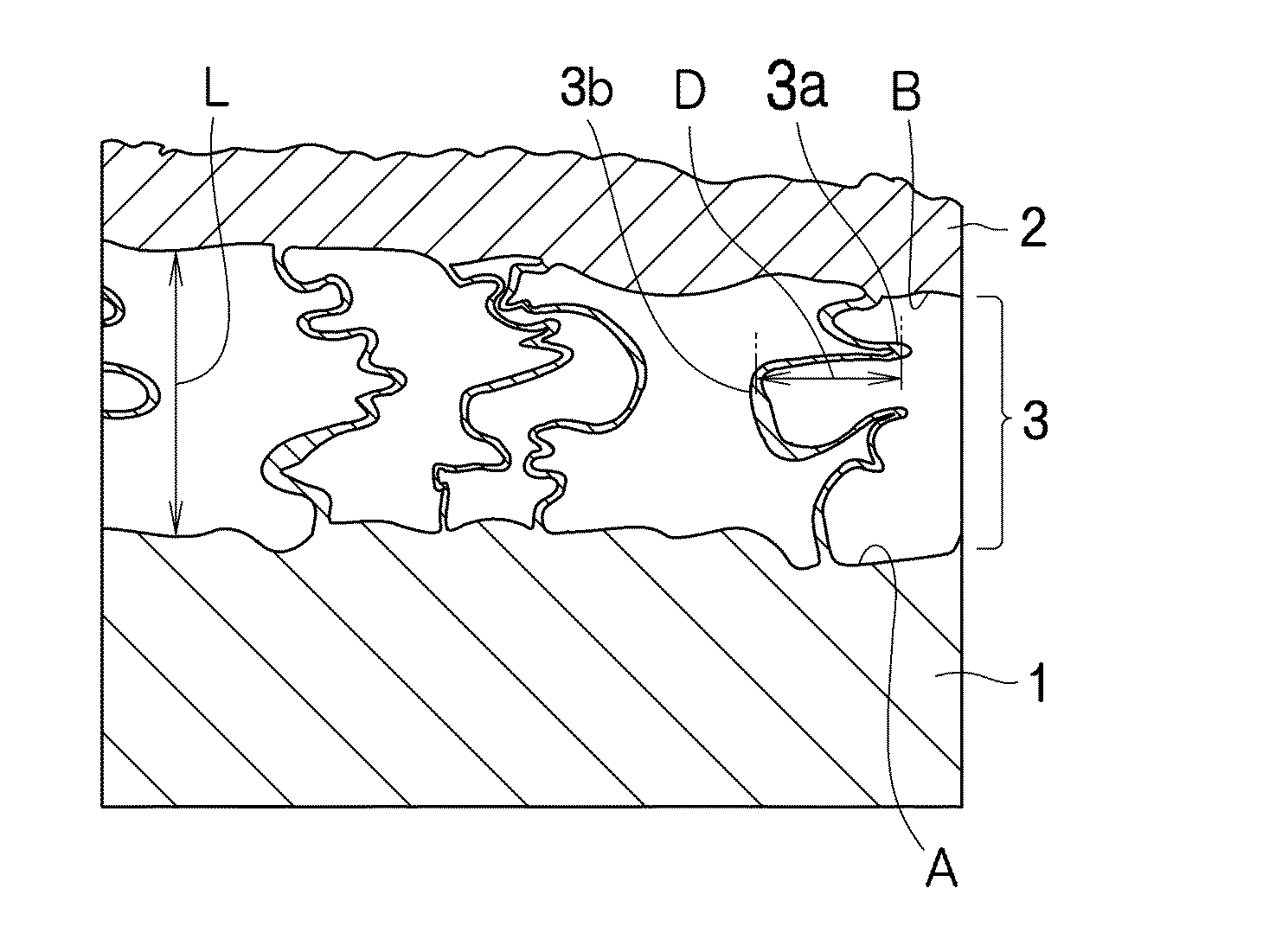

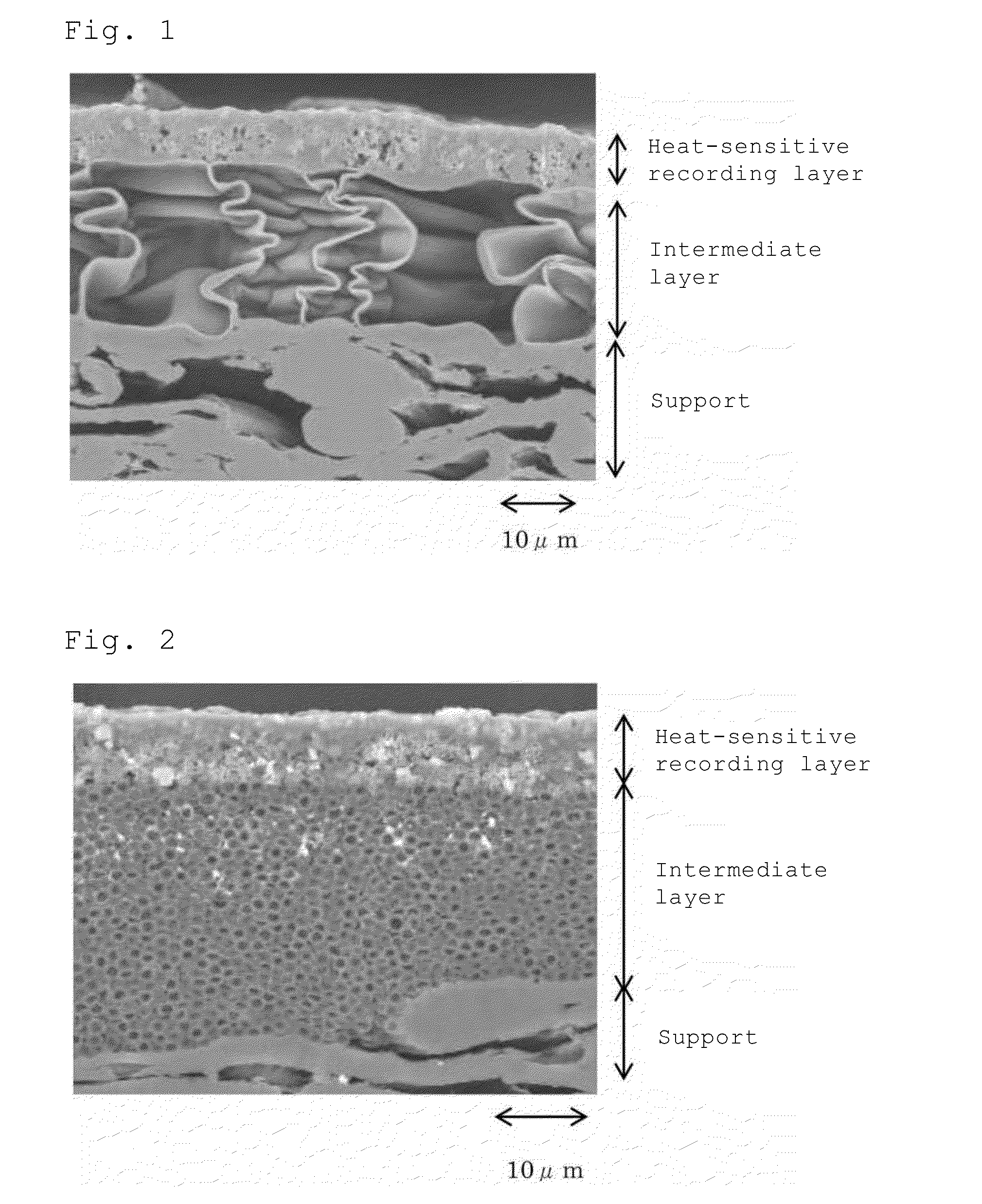

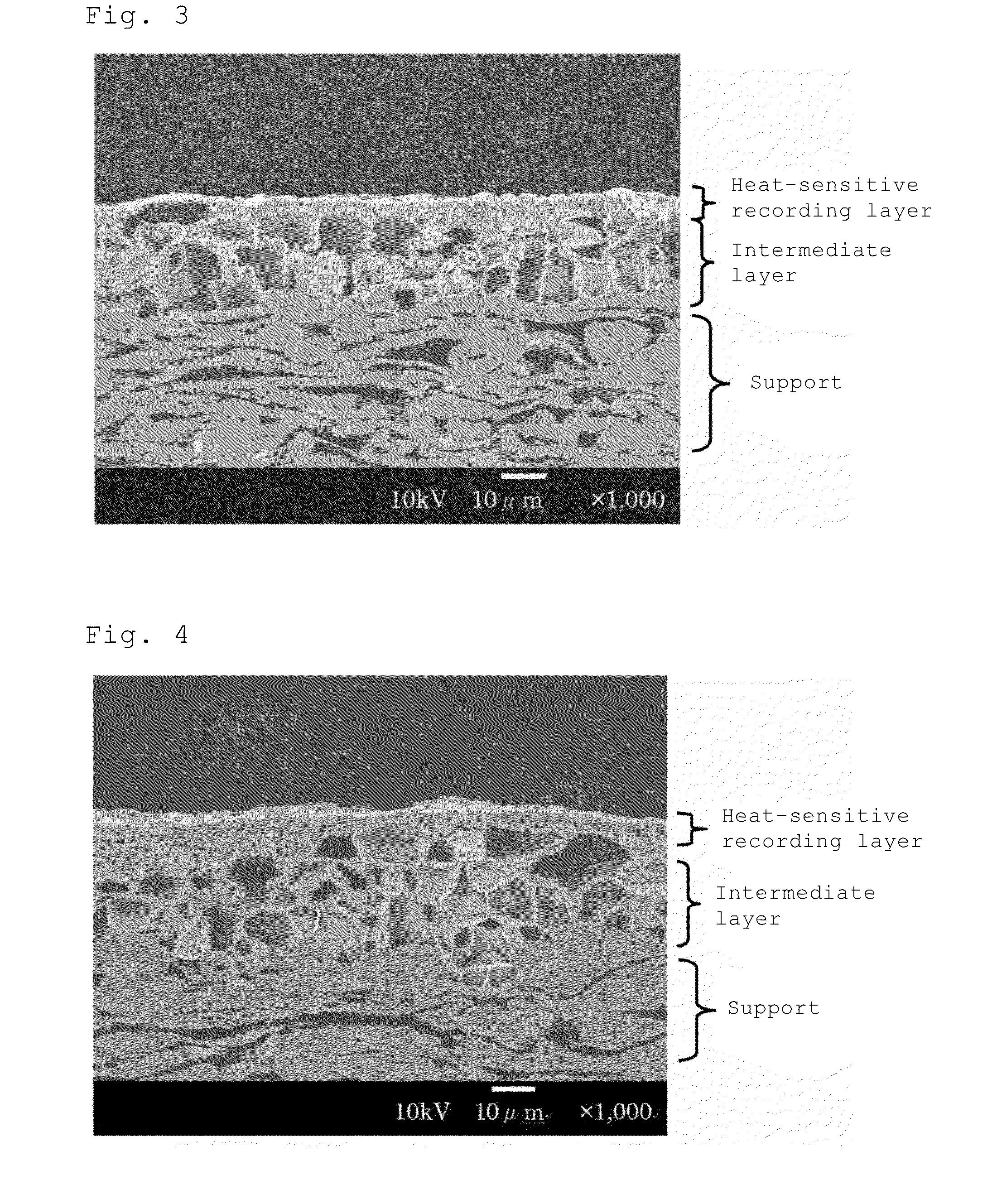

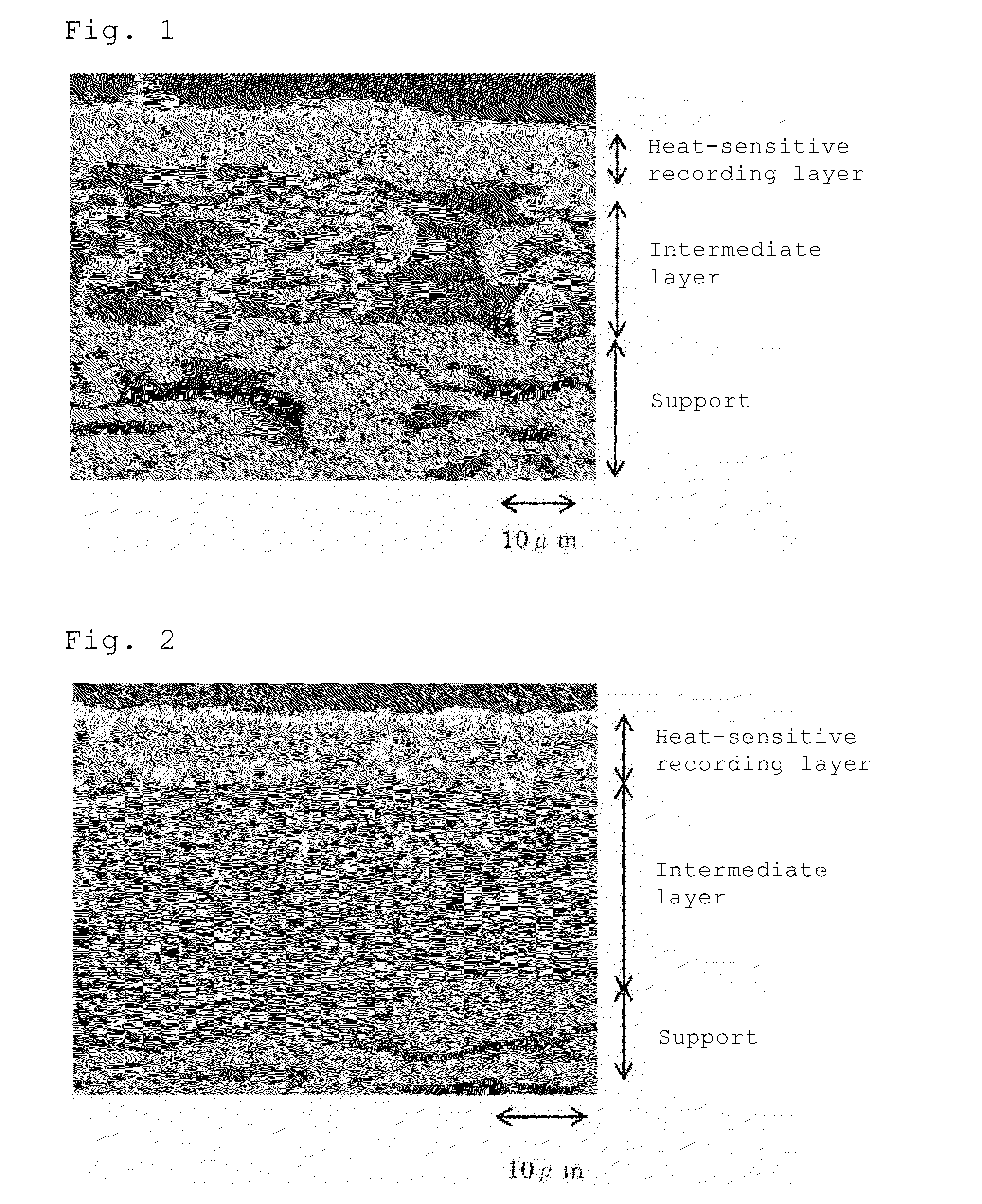

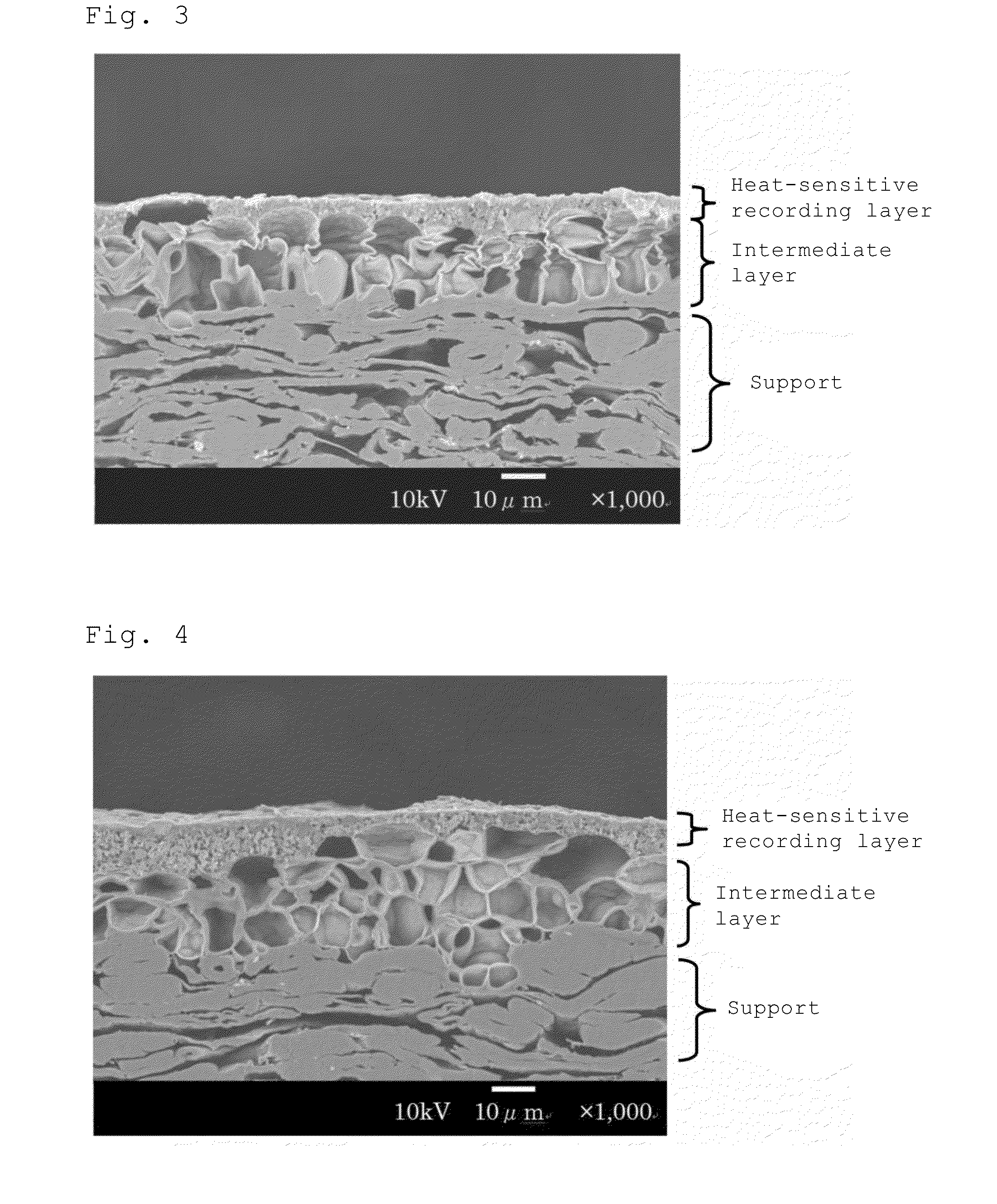

Thermal recording material and method for producing the same

ActiveUS20130053240A1Quality improvementExcellent in thermal responsivenessLamination ancillary operationsLaminationHeat sensitiveRecording layer

Provided is a thermal recording material comprising an intermediate layer and a heat-sensitive recording layer for color formation by heat stacked in this order onto a support, the thermal recording material being characterized in that the intermediate layer contains a bellows-shaped hollow resin and that the roughness of the surface on the color forming side is 1.0 μm or less as measured by Parker Print Surf. The method for producing such a thermal recording material comprises the steps of:applying a coating liquid containing heat-expandable resin particles to a support,drying the coated support at a temperature lower than the expansion starting temperature of the heat-expandable resin particle, andsubjecting the coated support to thermoforming for formation of an intermediate layer; andapplying, to the intermediate layer, heat-sensitive recording-related components which contribute to color formation by heat, for formation of a heat-sensitive recording layer.

Owner:MITSUBISHI PAPER MILLS LTD

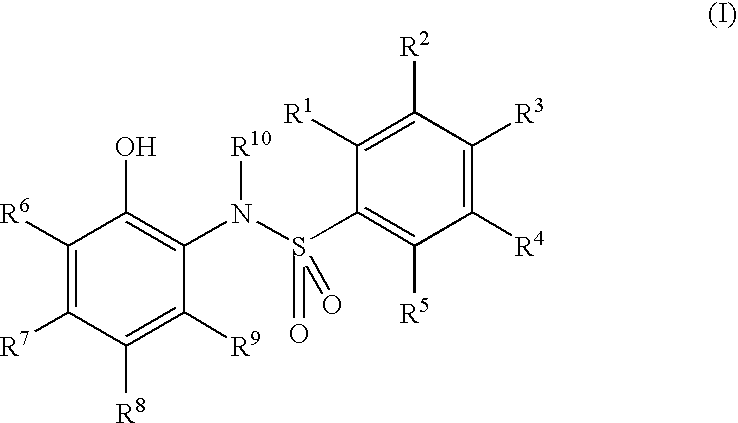

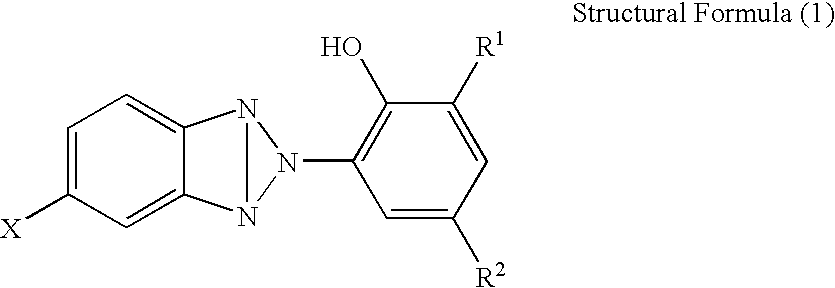

Thermal recording materials

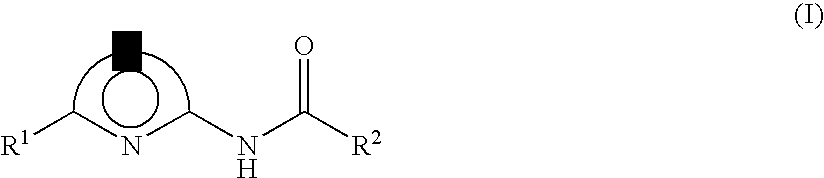

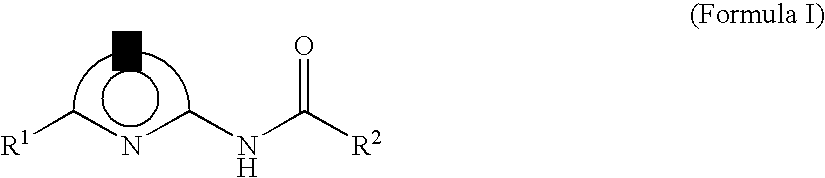

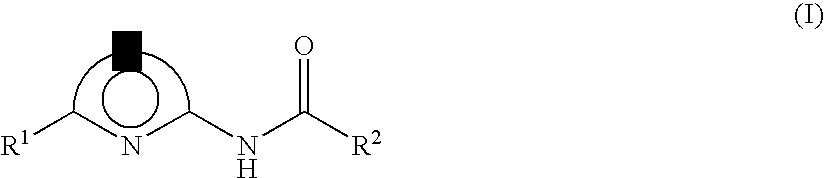

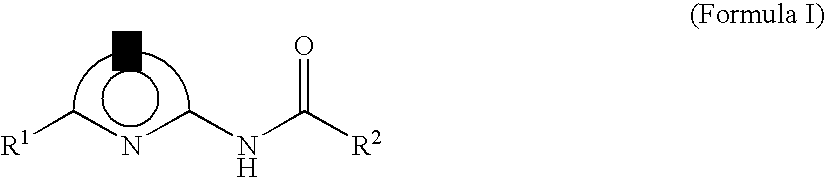

InactiveUS6890881B2Good thermal responseHigh whitenessAblative recordingPhotosensitive material auxillary/base layersHydrogen atomHeat resistance

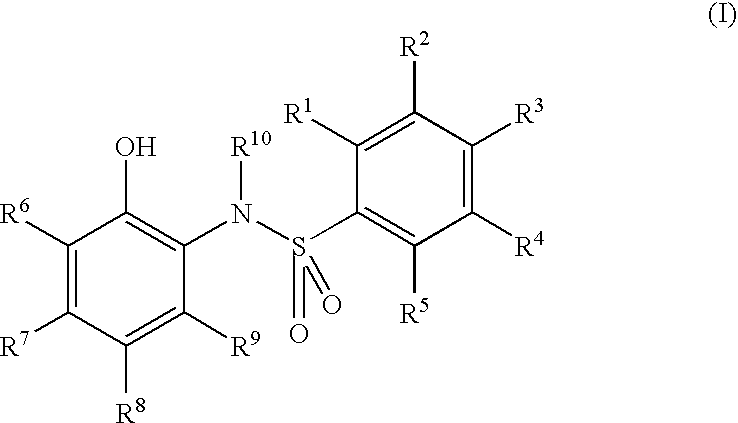

Disclosed are a thermal recording material having a thermal recording layer containing an electron-donating dye precursor and an electron-accepting compound, wherein the thermal recording layer comprises an electron-accepting compound of the general formula (I), (each of R1 and R2 is a hydrogen atom or an alkyl group), and a specific aromatic phosphorus compound, and a thermal recording material wherein said thermal recording layer comprises the electron-accepting compound of the above general formula (I) and an undercoat layer formed on a substrate comprises an organic pigment having a specific morphological structure.The former thermal recording material is excellent particularly in thermal response as well as heat resistance and light resistance of a ground and images in storage, and the latter thermal recording material is excellent particularly in whiteness.

Owner:MITSUBISHI PAPER MILLS LTD

Pressure detecting apparatus

ActiveUS7234358B2Promote absorptionImprove featuresFluid pressure measurement by electric/magnetic elementsSolid-state devicesEngineeringElectric signal

A pressure detecting apparatus has a pressure detecting device that converts a strain caused by a stress exerted thereto to an electrical signal, and outputs the converted electrical signal. The apparatus has a housing base including a housing recess that houses the pressure detecting device therein, and a connecting material interposed between the pressure detecting device and the housing recess. The connecting material connects the pressure detecting device and the housing recess with a tensile elongation percentage of about 400% or higher. The pressure detecting apparatus facilitates preventing thermal stress from adversely affecting the detection performance thereof, and produces excellent thermal response.

Owner:FUJI ELECTRIC CO LTD

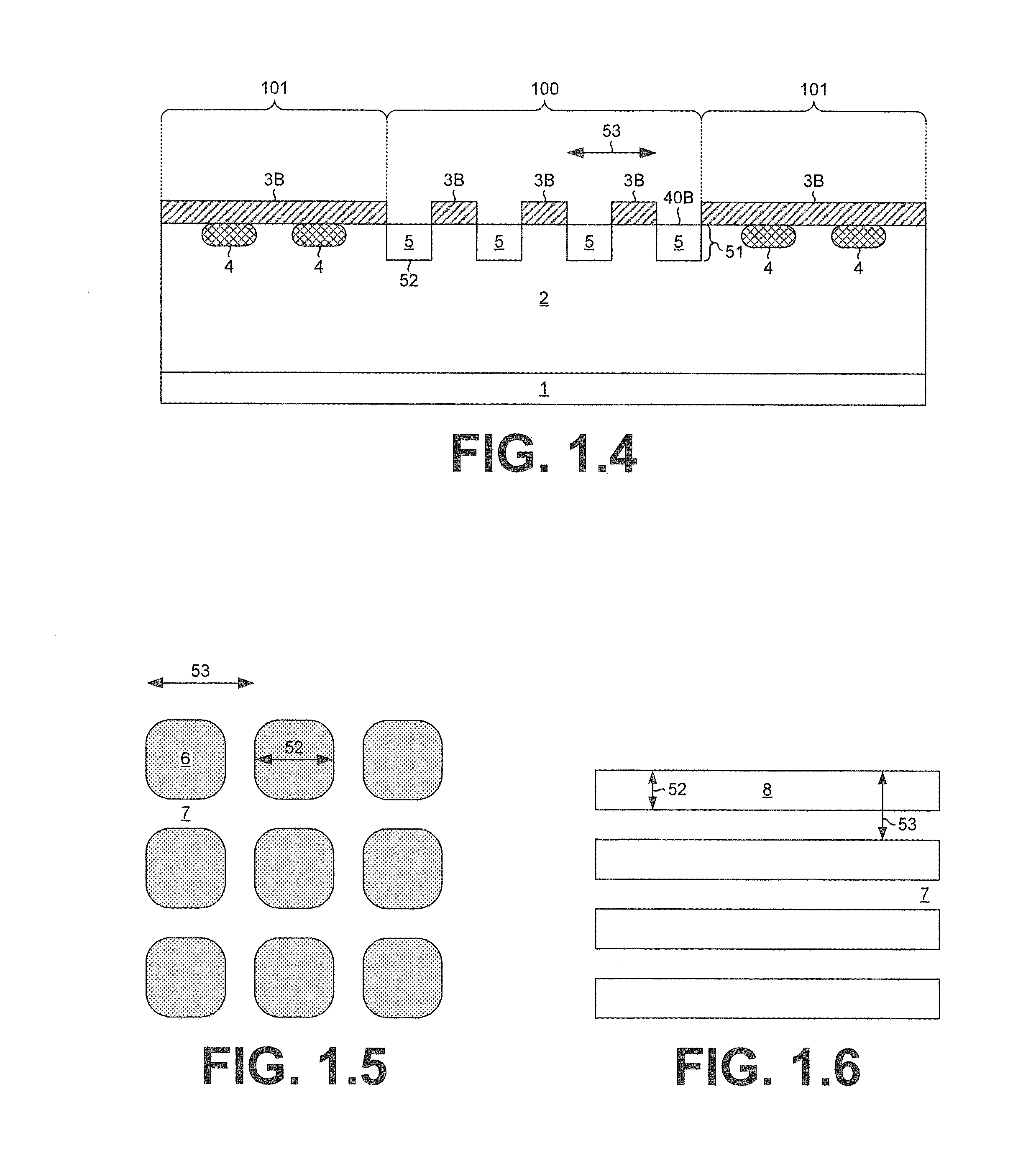

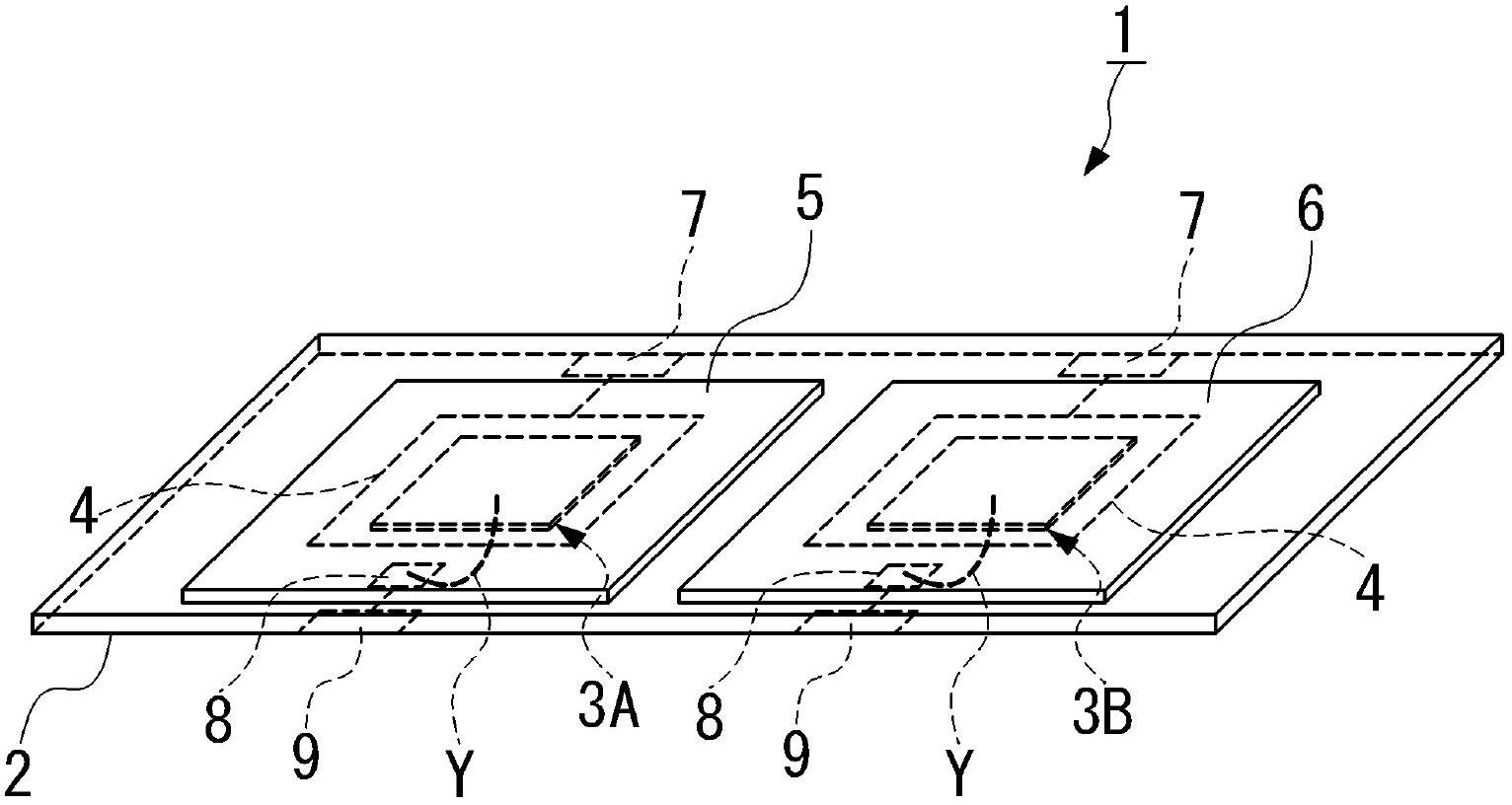

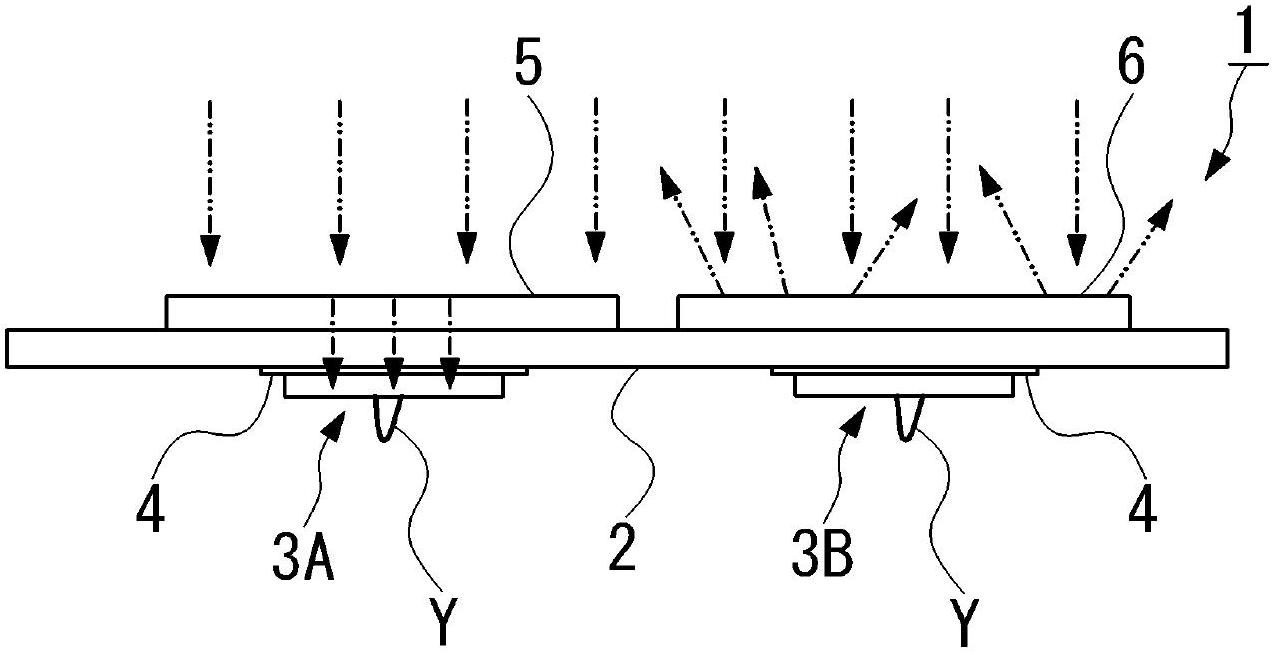

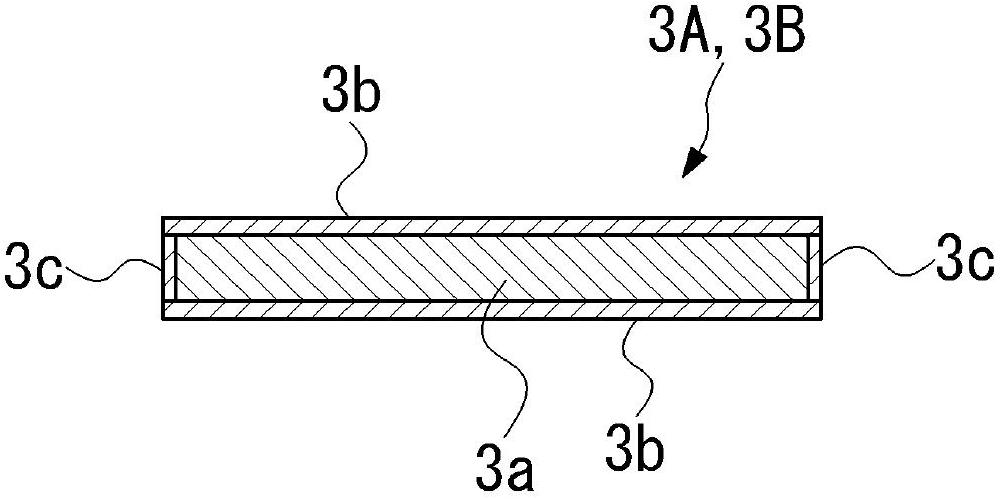

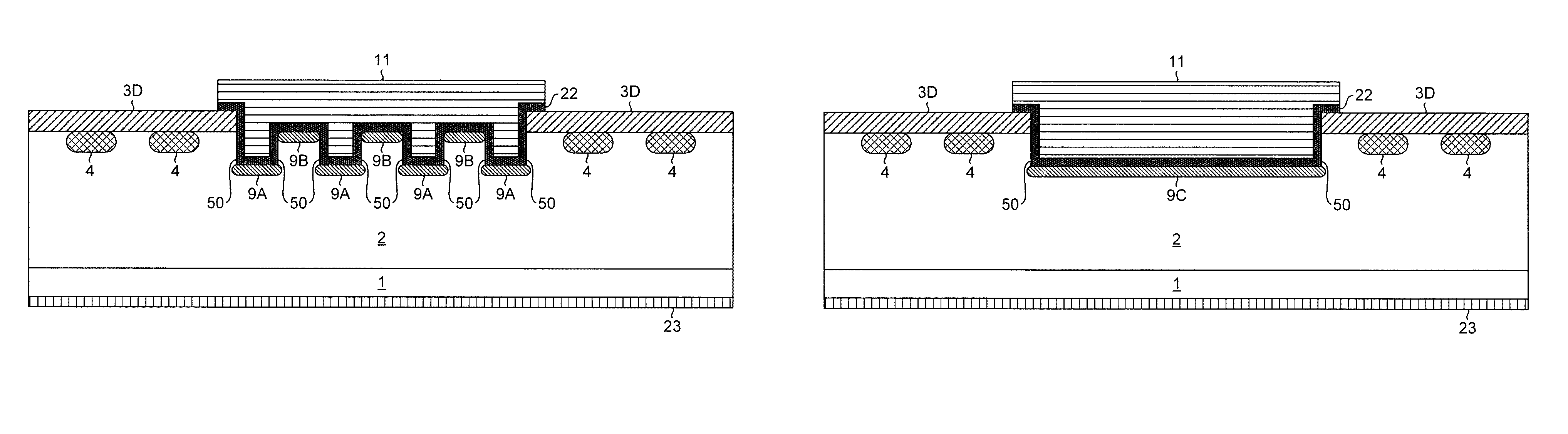

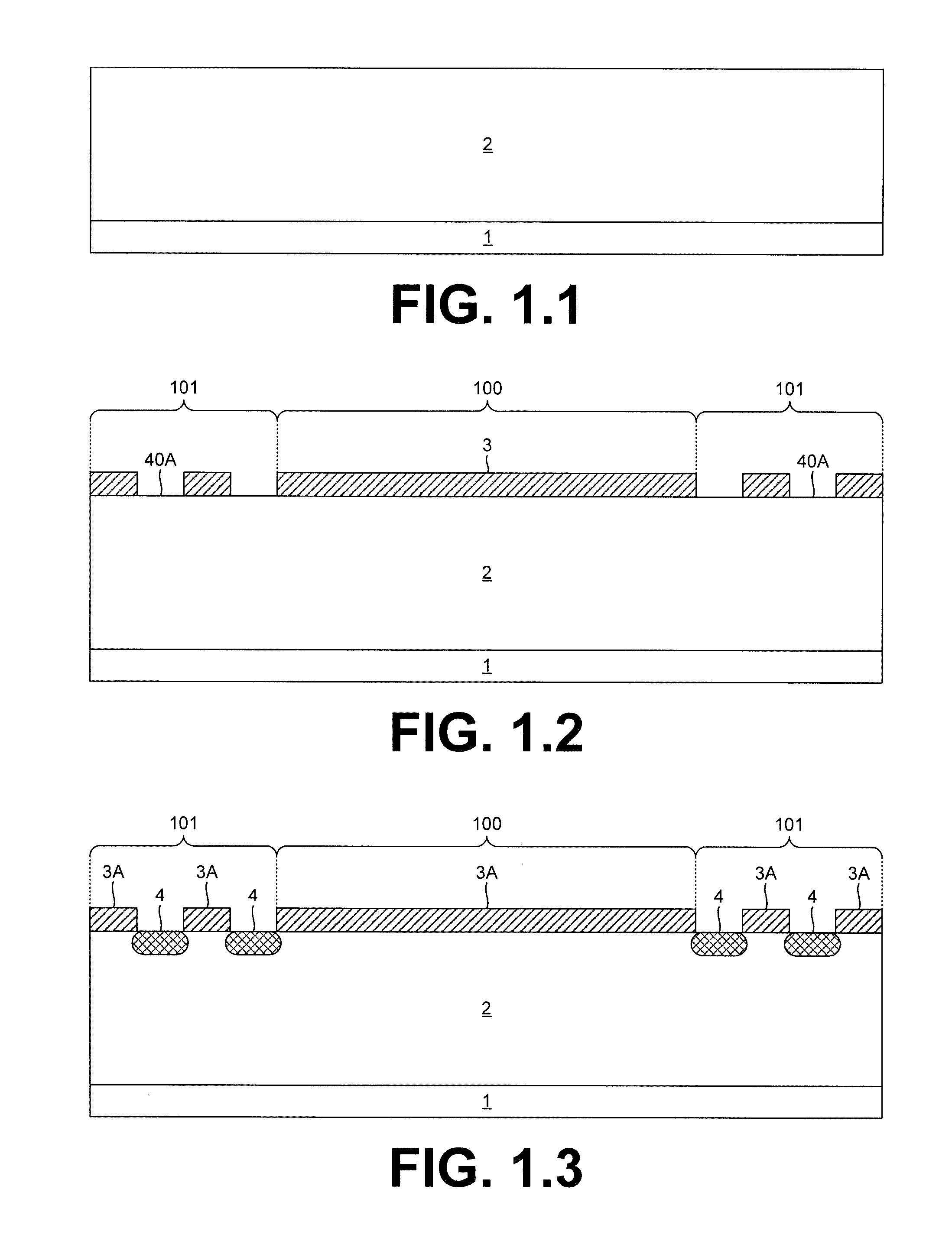

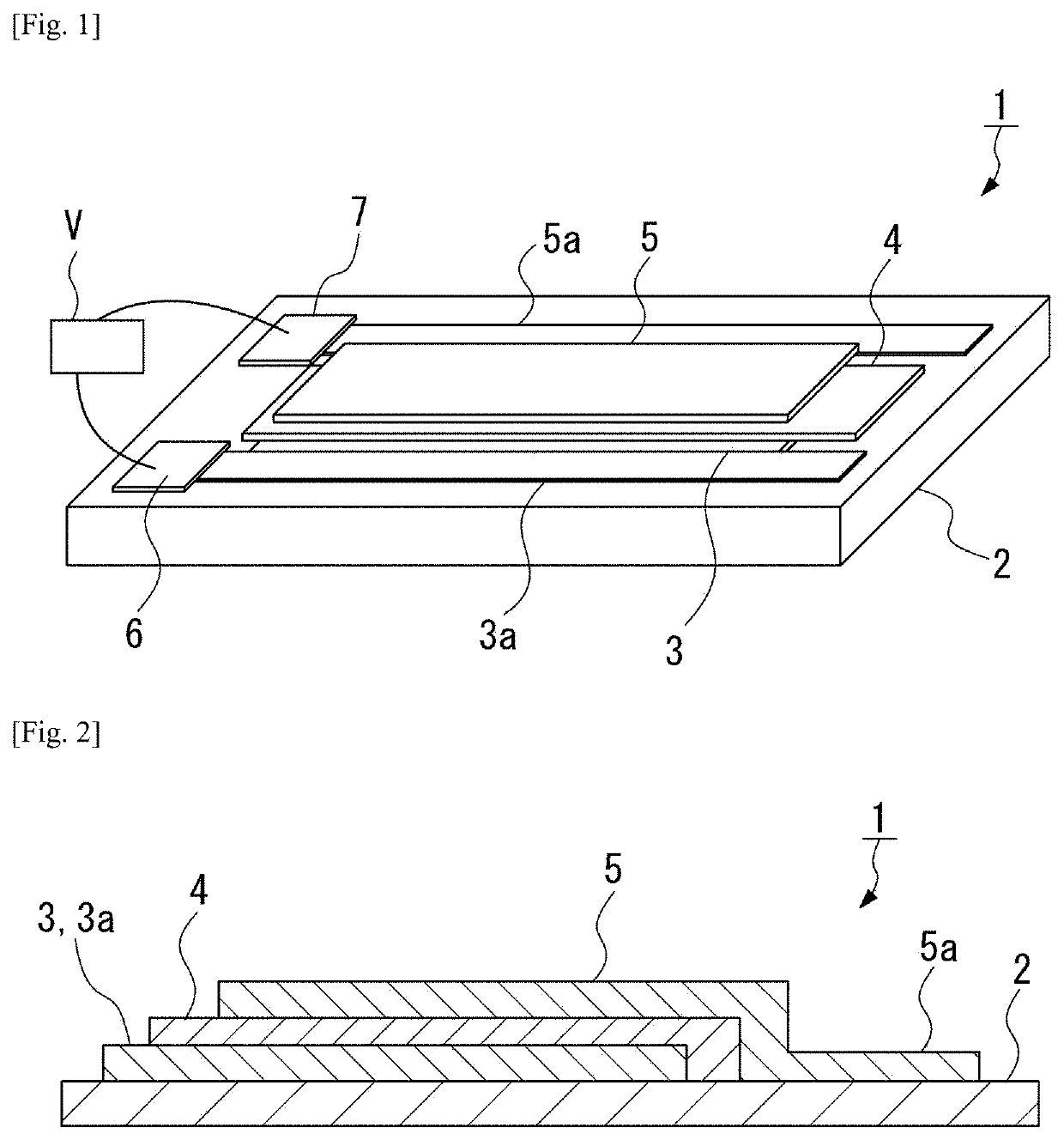

Infrared sensor

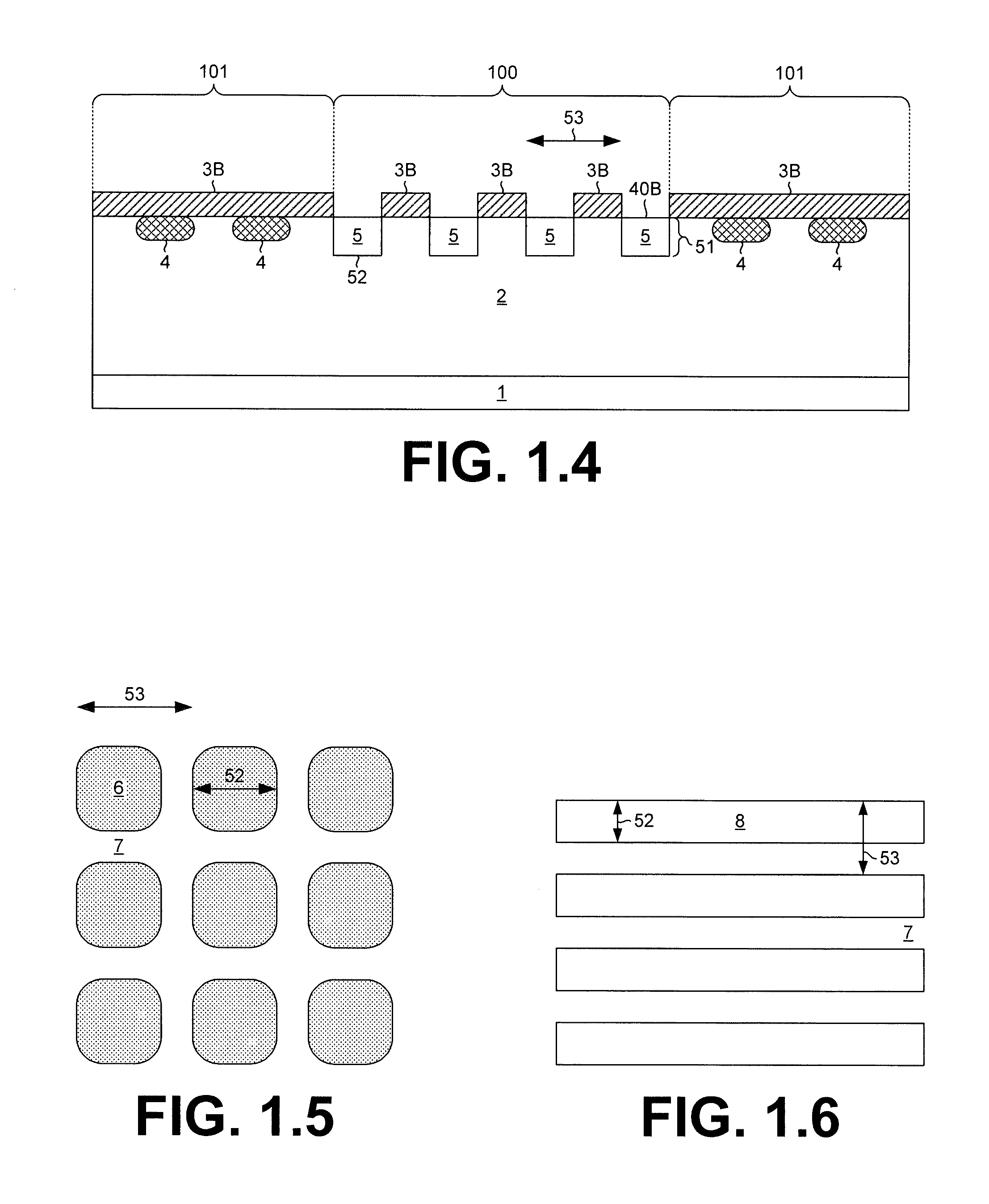

ActiveCN102667431AGood temperature differentialSmall and cheap to makePhotometryPyrometry using electric radation detectorsInfraredHeat sensitive

Disclosed is an infrared sensor which is able to obtain a large temperature difference between a heat sensitive element for infrared ray detection and a heat sensitive element for temperature compensation, as well as has an inexpensive structure which is conducive to a compact assembly. The infrared sensor comprises an insulating film (2); a first heat sensitive element (3A) and a second heat sensitive element (3B) spaced apart from each other on one face of the insulating film (2); a pair of adhesive electrodes (4), formed on one face of the insulating film (2), to which the first heat sensitive element (3A) and the second heat sensitive element (3B) adhere respectively; an infrared absorbing film (5) arranged on the other face of the insulating film (2) opposite the first heat sensitive element (3A); and an infrared reflecting film (6) arranged on the other face of the insulating film (2) opposite the second heat sensitive element (3B). The first heat sensitive element (3A) and the second heat sensitive element (3B) have a tabular thermistor body (3a) and a pair of electrode layers formed respectively on front and back surfaces of the thermistor body (3a), with one of the electrode layers adhering to the adhesive electrode (4).

Owner:MITSUBISHI MATERIALS CORP

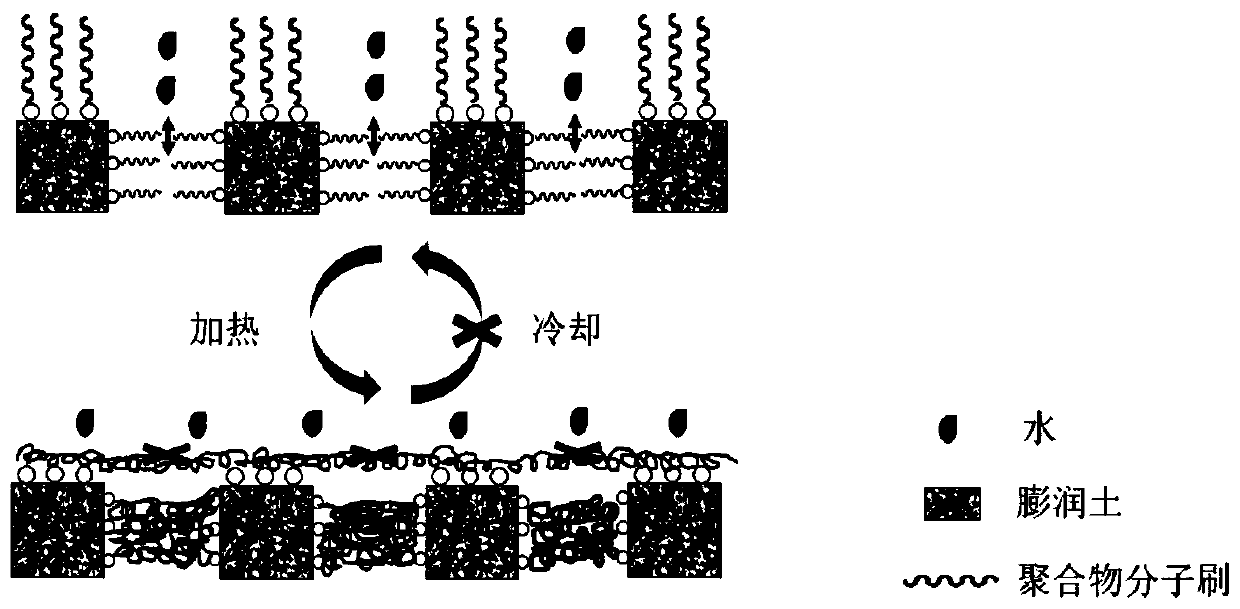

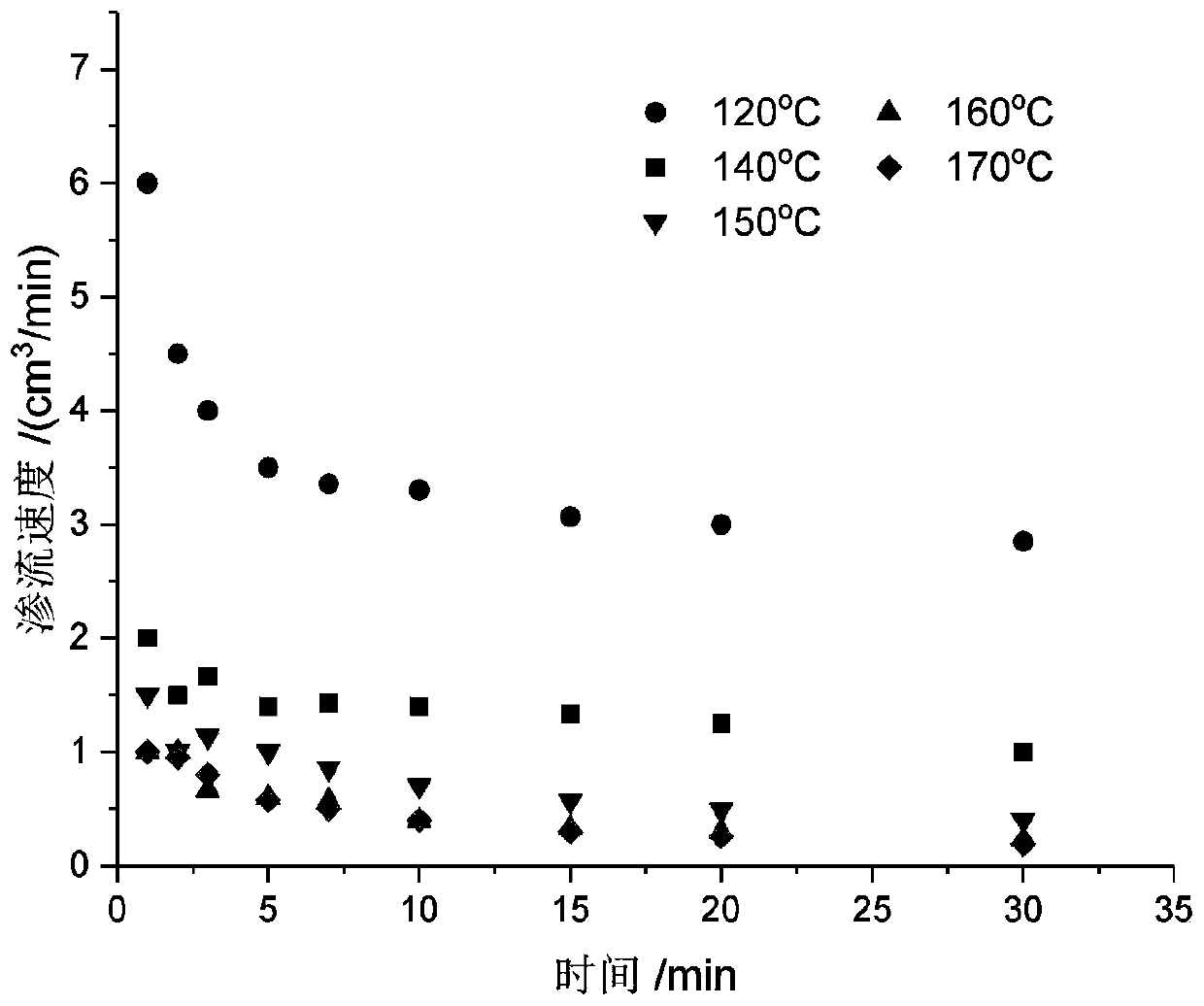

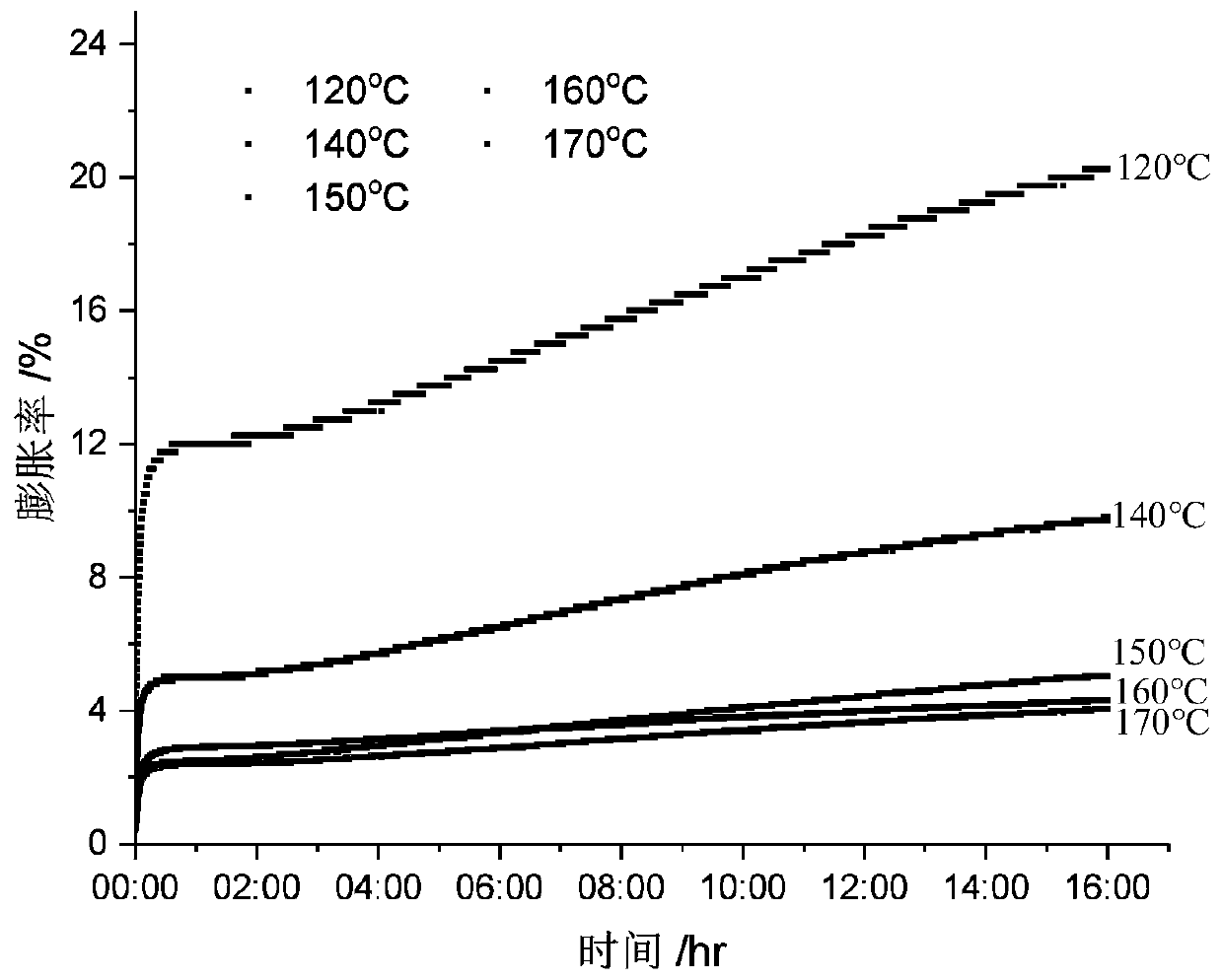

High-temperature heat-response bentonite and high-temperature heat-response bentonite drilling fluid

ActiveCN109837075AGood temperature sensitivityStrong and stable plugging performanceDrilling compositionSilicon compoundsSodium BentoniteNitrogen gas

The invention provides high-temperature heat-response bentonite and a preparation method thereof, and a high-temperature heat-response bentonite drilling fluid. A high-temperature heat-response bentonite core is a rigid bentonite particle, and the exterior of the high-temperature heat response bentonite core is a flexible high-temperature heat-response molecular brush. The preparation method comprises the following steps: activating bentonite with an acid, drying, carrying out ATRP modification, rinsing and drying to obtain the high-temperature heat-response bentonite. The modification methodcomprises the following steps: mixing activated bentonite and a (3-aminopropyl) trimethoxysilane (ATMS) and methanol solution, carrying out magnetic stirring to provide a modified activation site, adding dichloromethane (containing (v / v) piperidine) and 2-bromoisobutyryl bromide to carry out ATRP modification, and meanwhile, adding phenyl methacrylate and p-xylene (copper bromide and N, N, N', N '', N '''-pentamethyldivinyl triamine), and stirring under nitrogen protection. The high-temperature heat-response bentonite is high in temperature sensitivity, the high-temperature self-healing capability is achieved, and the high-temperature plugging property of a mud cake is enhanced. The drilling fluid has the advantages of good self-repairing performance, stable rheological property, excellentheat responsiveness and excellent plugging property.

Owner:SOUTHWEST PETROLEUM UNIV

Lithographic printing plate precursor

ActiveUS8192918B2Improve the immunityGood thermal responsePhotosensitive materialsPlate printingPlanographic printingPhotochemistry

A lithographic printing plate precursor is disclosed which comprises a support having a hydrophilic surface or which is provided with a hydrophilic layer, and a coating thereon, said coating comprising an IR absorbing agent and a contrast enhancing compound, characterized in that said contrast enhancing compound has the structure of formula (I). The printing plate comprising the contrast enhancing compound improves the thermoresponsivity of the coating and is capable of improving the resistance of the coating in the non-exposed areas against the alkaline developer.

Owner:AGFA OFFSET BV

Heat generating resistant element film, substrate for ink jet head utilizing the same, ink jet head and ink jet apparatus

The invention provides a heat generating resistant element having a high durability and a high resistance suitable for constituting an electrothermal converting member in an ink jet head or an ink jet apparatus. There is employed, as the heat generating resistant element, a film constituted of Cr, Si and N, having a composition of Cr: 15 to 20 at. %, Si: 40 to 60 at. % and N: 20 to 45 at. %, which constitute 100 at. % or substantially 100 at. %.

Owner:CANON KK

SiC transient voltage suppressor

ActiveUS9478606B2Higher reverse biasesGood thermal responseThyristorSolid-state devicesEngineeringTransient voltage suppressor

A high power, high current Unidirectional Transient Voltage Suppressor, formed on SiC starting material is disclosed. The device is structured to avalanche uniformly across the entire central part (active area) such that very high currents can flow while the device is reversely biased. Forcing the device to avalanche uniformly across designated areas is achieved in different ways but consistently in concept, by creating high electric fields where the device is supposed to avalanche (namely the active area) and by relaxing the electric field across the edge of the structure (namely in the termination), which in all embodiments meets the conditions for an increased reliability under harsh environments.

Owner:MICROSEMI CORP

Stirling engine and heat exchange method thereof

ActiveCN110821706AGood thermal responseShort heat exchange timeHot gas positive displacement engine plantsCrankHot work

The invention provides a Stirling engine and a heat exchange method thereof. The Stirling engine comprises a crank shaft, expansion cylinders, compression cylinders, a heat exchanger and an air cooler. The heat exchanger comprises a heat cavity, multiple work medium cavities and multiple rotation columns. Cold and hot work mediums are in mutual countercurrent flow, and the heat cavity and the workmedium cavities at least share the outer side wall of the same rotation column as the respective inner wall. The air cooler comprises a first cooling channel. The expansion first cylinder and the first compression cylinder can be alternately compressed when the crank shaft rotates. Working work mediums perform surface heat exchange in the work medium cavities and do not need to be filled with heat retainer materials, and a heat storage and release function of a heat regenerator can be achieved. The situation is avoided that due to too small gaps of heat retainers, the flow resistance of the work mediums is large, and multiple problems are caused. High-temperature hot air energy is sufficiently used through countercurrent flow heat exchange. The heat exchange method of the Stirling engineis suitable for heat exchange of the Stirling engine under a high-temperature environment and achieves high comprehensive heat efficiency.

Owner:BEIJING FUDIAN ENG TECH CO LTD

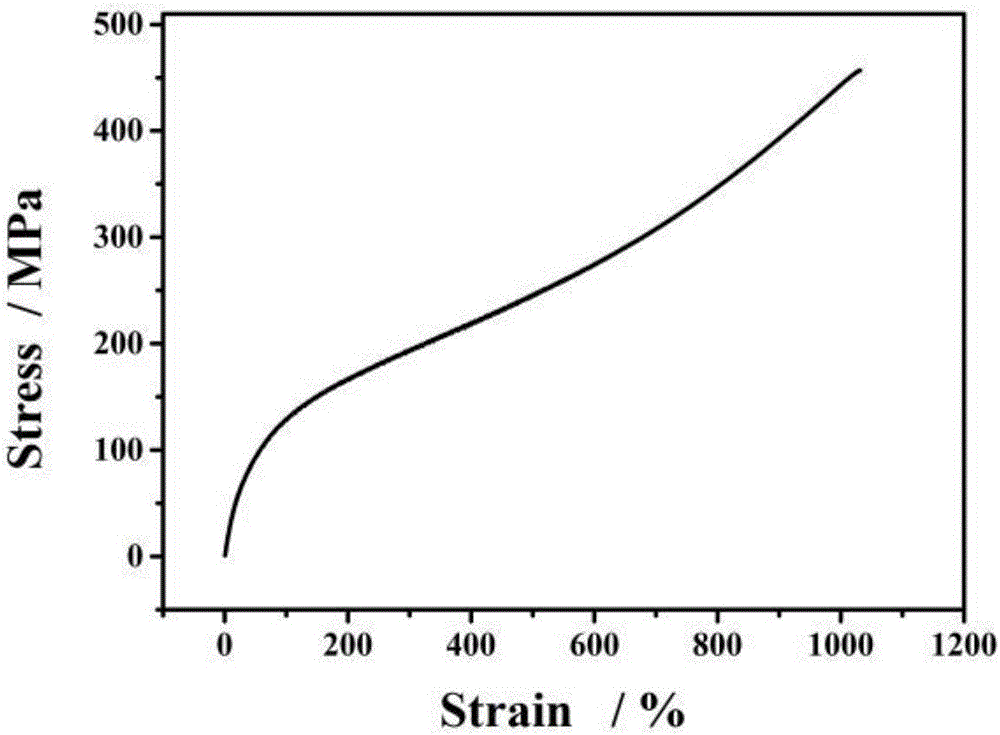

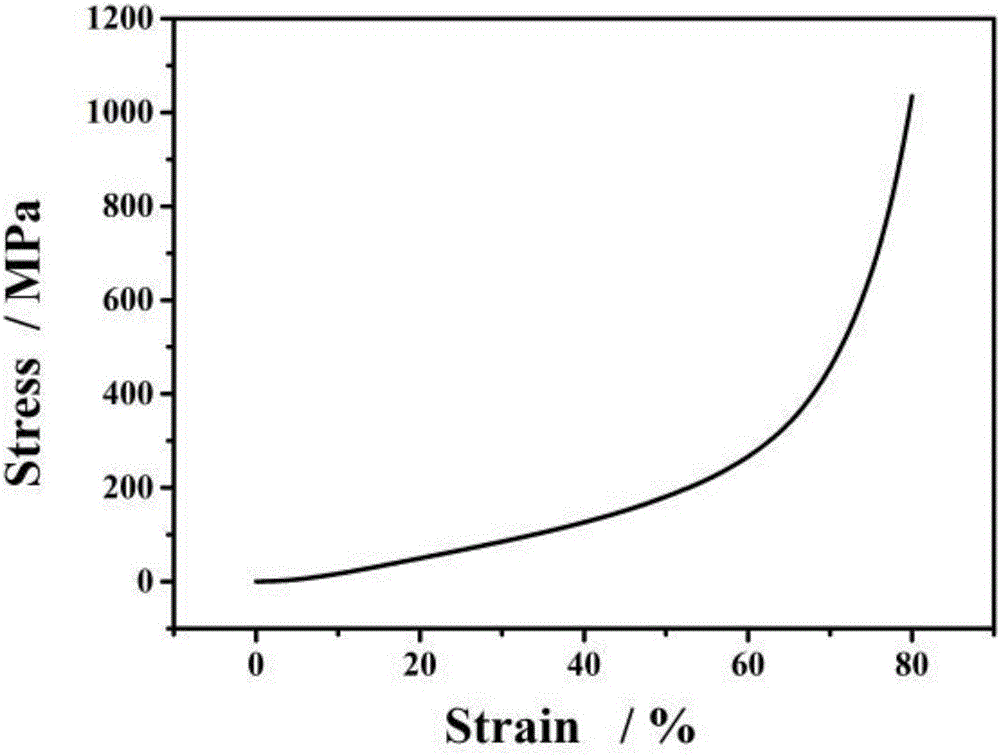

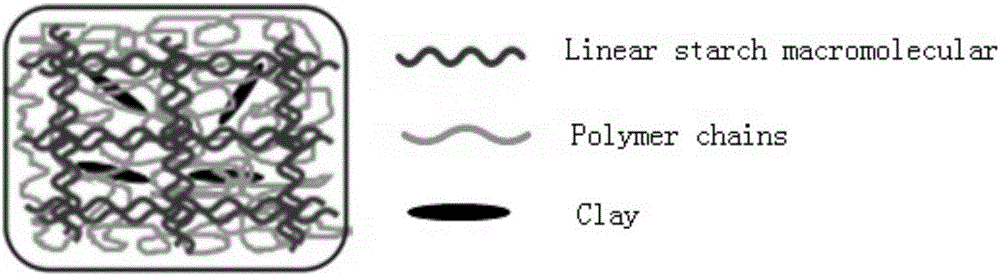

High-strength starch/clay composite material and preparation method thereof

ActiveCN106751318AImprove hydrophilicityGood thermal responseControlled releaseMaterials preparation

The invention relates to the technical field of composite material preparation, in particular to a high-strength starch / clay composite material and a preparation method thereof. According to the following technical scheme, the composite material is prepared by the following steps: mixing starch and deionized water; heating to dissolve completely; adding monomers and clay, and stirring uniformly to form a pre-polymerized liquid, wherein the monomers, the clay and the deionized water are in the mass ratio of (0.5-1):(0.5-3.5):10; then, adding a photoinitiator, and irradiating for 2 hours by an ultraviolet lamp under the wavelength of 365 nm; or adding a thermal initiator and a catalyst into the pre-polymerized liquid, and polymerizing for 20 to 40 hours at 20 to 40 DEG C to obtain the starch / clay composite material. The composite material has a ternary interpenetrating network structure which consists of the starch, a polymer and the clay; the tensile strength can reach 500 KPa and the compressive strength can reach 1 Mpa; the composite material has hydrophilcity and thermal response, has a great application prospect in the field of medical materials, such as medicament controlled-release carriers, and also has the advantages of simple preparation, low cost, environmental friendliness, and the like.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Thermal recording material and method for producing the same

ActiveUS8623785B2Good thermal responseQuality of recordedPretreated surfacesPattern printingHeat sensitiveRecording layer

Provided is a thermal recording material comprising an intermediate layer and a heat-sensitive recording layer for color formation by heat stacked in this order onto a support, the thermal recording material being characterized in that the intermediate layer contains a bellows-shaped hollow resin and that the roughness of the surface on the color forming side is 1.0 μm or less as measured by Parker Print Surf. The method for producing such a thermal recording material comprises the steps of:applying a coating liquid containing heat-expandable resin particles to a support,drying the coated support at a temperature lower than the expansion starting temperature of the heat-expandable resin particle, andsubjecting the coated support to thermoforming for formation of an intermediate layer; andapplying, to the intermediate layer, heat-sensitive recording-related components which contribute to color formation by heat, for formation of a heat-sensitive recording layer.

Owner:MITSUBISHI PAPER MILLS LTD

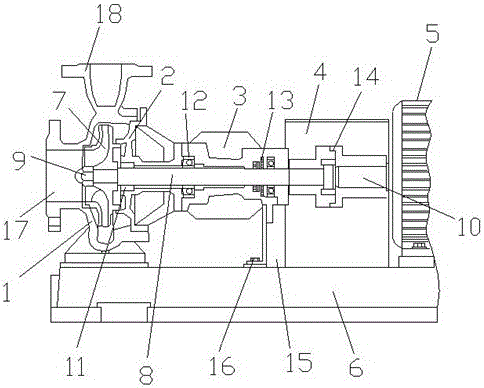

Hot oil pump

InactiveCN105041669AImproves sealing reliabilityStable structurePump componentsPump installationsImpellerCoupling

The invention discloses a hot oil pump. The hot oil pump comprises a pump body, a pump cover, a bearing pedestal, a coupling, a motor and a base. The pump body, the pump cover, the bearing pedestal and the coupling are fixedly connected in sequence. The pump body and the motor are fixedly connected with the base. An impeller and a pump shaft are arranged in the pump body. An acorn nut is arranged at the front end of the impeller. The impeller is fixedly connected with the pump shaft through the acorn nut. A motor shaft is arranged at on end of the motor. The motor shaft is in transmission connection with the motor. The pump shaft is in transmission connection with the motor shaft through the coupling. A filler pressing ring is arranged in the pump cover. The hot oil pump is simple in structure, small in size, good in performance and reliable in use, and operation cost is saved.

Owner:WUHU HUANQIU AUTO PARTS

Thermal protector

ActiveCN102341879ASimple structureGood thermal responseThermal switch detailsProtective switch operating/release mechanismsElectrical conductorResponsivity

Disclosed is a simply-structured thermal protector having an excellent current responsivity or thermal responsivity, wherein another process is not necessary to incorporate a resistor. In a press working process wherein a movable plate (4) is cut out from an original material, a movable plate body portion (16) of the movable plate (4) is separated into a small width portion (17) and a large width portion (18) by an elongated hole (19). The movable plate (4) is attached to a stationary conductor (2) via columns (9) of an insulator (3). A bimetal (5) is attached to the movable plate (4), and the assembled components are entirely pressed by a resin block (6). The tips of the columns (9) are melted to secure the securing portions of the assembled components. The large width portion (18) functions as an usual movable plate. The small width portion (17) functions as a conductor in a normal state, and functions as a resistor for excess current.

Owner:UCHIYA THERMOSTAT

Infrared gas analyzer and infrared gas analysis method

InactiveUS20060118724A1Detectable concentrationSimple configurationRadiation pyrometryMaterial analysis by optical meansGas analysisResponse characteristics

There are provided an infrared gas analyzer of a simple configuration, capable of taking measurements with high precision when using an infrared light source excellent in thermal responsiveness, and capable of ON / OFF operations at high speed, and an infrared gas analysis method using the same. The infrared gas analyzer having a sample cell into which a sample gas is distributed, for detecting concentration of a measuring target component of the sample gas by taking advantage of variation in absorption amount of infrared rays having passed through the sample cell, comprising a first infrared light source for irradiating the sample cell with first infrared rays, a second infrared light source having a response characteristic equal to that of the first infrared light source, a detector for detecting a difference between the first infrared rays emitted from the first infrared light source, and having passed through the sample cell, and second infrared rays emitted from the second infrared light source, a light source drive controller for synchronously driving the first and second infrared light sources, respectively, and a measurement controller for providing the light source drive controller with instructions for respective drive amounts of the first and second infrared light sources while receiving an output signal from the detector, thereby generating a measurement output corresponding to the concentration of the measuring target component of the sample gas.

Owner:YOKOGAWA ELECTRIC CORP

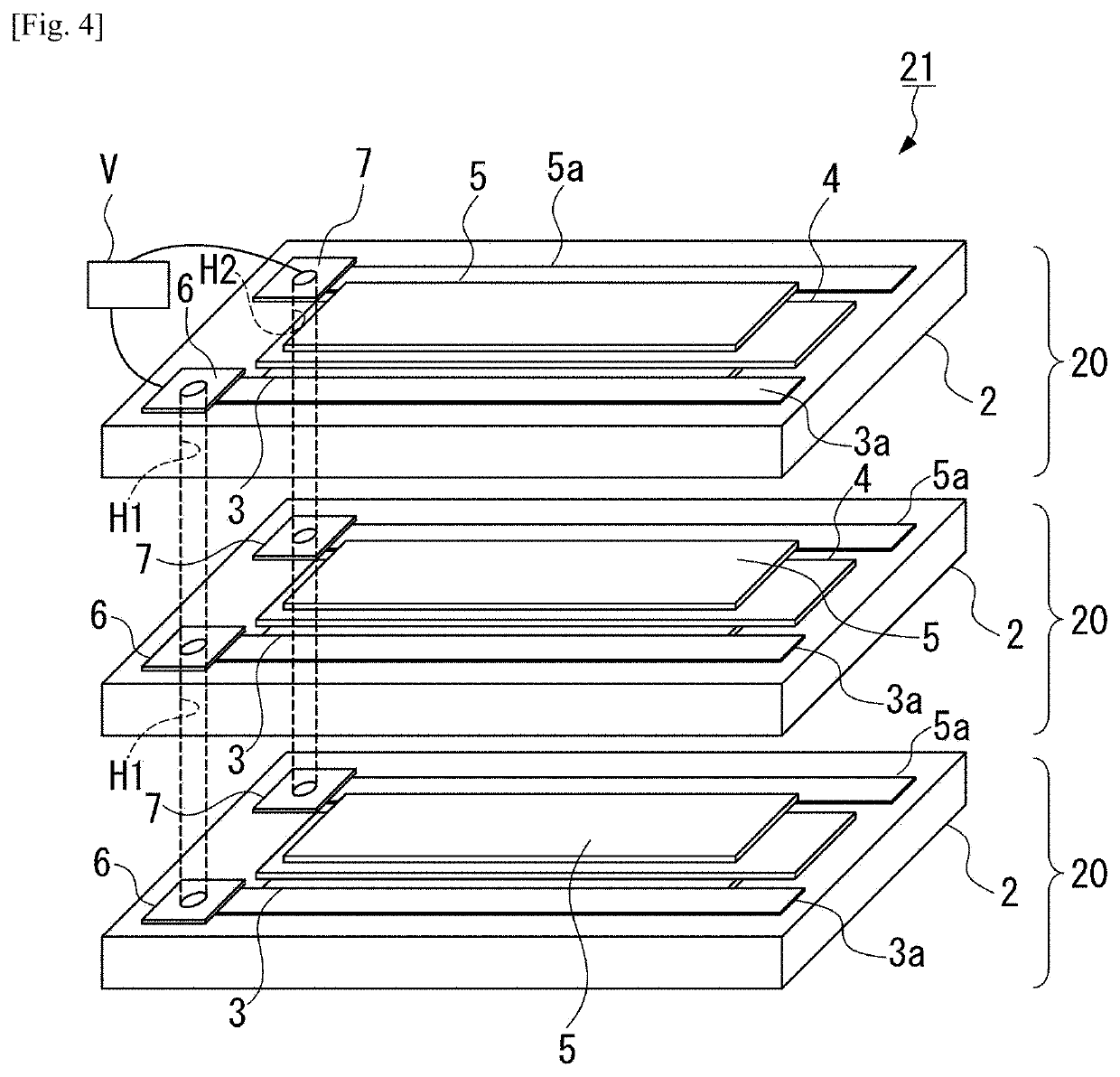

DNA amplification device

InactiveUS7659110B2Shorten the construction periodSimple processBioreactor/fermenter combinationsHeating or cooling apparatusDna amplificationMetal

A processing block 2 is composed of a base 5, where an upper substrate 6 formed with a metal material M and a lower substrate 7 formed with the metal material M or a ceramic material E are adhered, and cells C . . . supported by this base 5; and the cells C . . . are secured to the upper substrate 6 and / or the lower substrate 7 at least via cell positioners 6s . . . established in the upper substrate 6 for positioning the cells C . . . , respectively.At the same time, at least the thickness Ld of regions Xc . . . situated under the cells C . . . in the lower substrate 7 is selected to be 1.0 [mm] or thinner, and, a thermo-module(s) comes into contact with the lower surface of the base 5.

Owner:THERMOGEN

A lithographic printing plate precursor

ActiveUS20100112476A1Improve the immunityGood thermal responsePhotosensitive materialsPlate printingCompound (substance)Contrast enhancement

A lithographic printing plate precursor is disclosed which comprises a support having a hydrophilic surface or which is provided with a hydrophilic layer, and a coating thereon, said coating comprising an IR absorbing agent and a contrast enhancing compound, characterized in that said contrast enhancing compound has the structure of formula (I). The printing plate comprising the contrast enhancing compound improves the thermoresponsivity of the coating and is capable of improving the resistance of the coating in the non-exposed areas against the alkaline developer.

Owner:AGFA OFFSET BV

Heat flow switching element

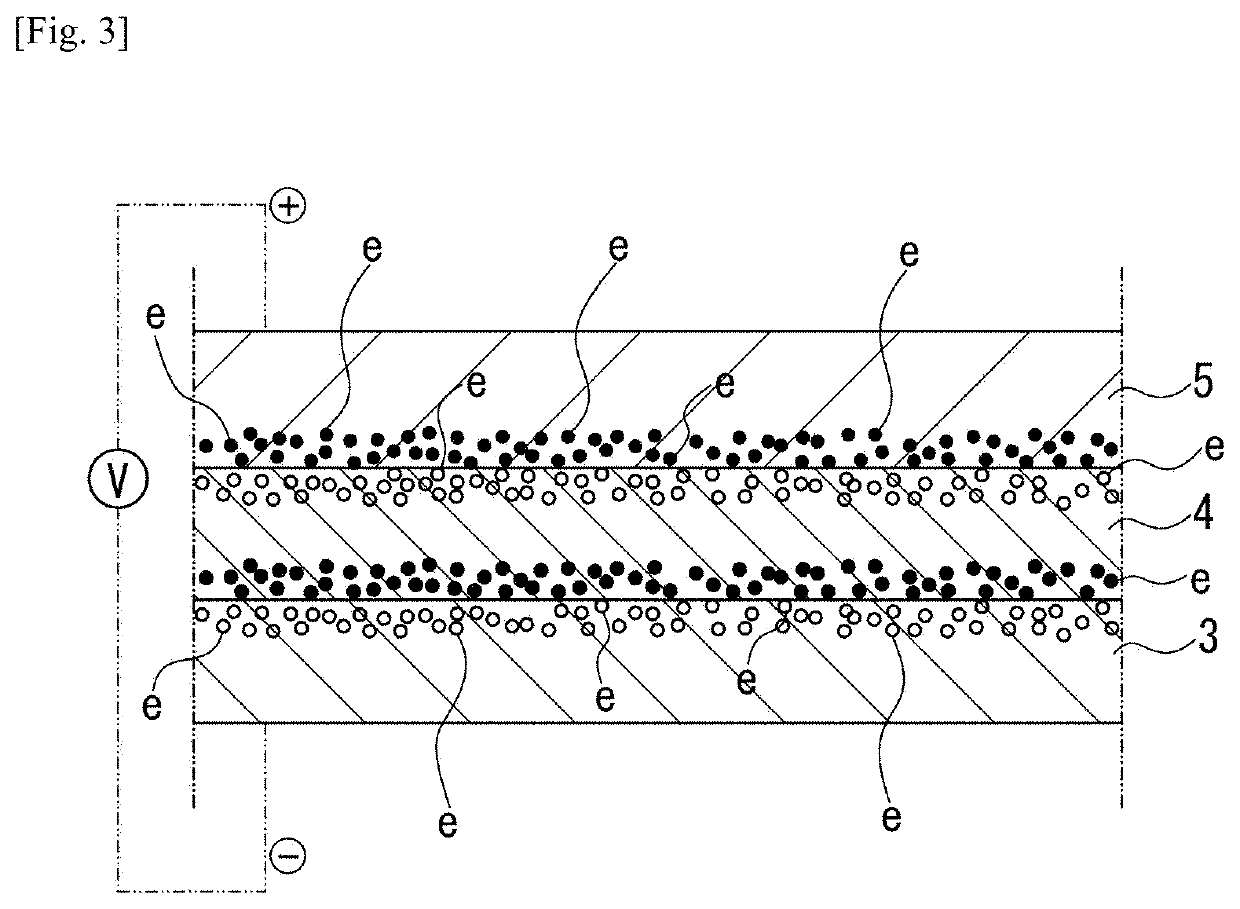

PendingUS20210249577A1Large variation in thermal conductivityImprove thermal responsivenessThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHeat flowEngineering physics

A substrate of which at least an upper surface is formed of an insulating material, an N-type semiconductor layer, a P-type semiconductor layer, and an insulator layer are provided, one semiconductor layer of the N-type semiconductor layer and the P-type semiconductor layer is formed on the substrate, the insulator layer is formed on the one semiconductor layer, and the other semiconductor layer of the N-type semiconductor layer and the P-type semiconductor layer is formed on the insulator layer. In this way, since electric charges induced by an external voltage are generated both at and near an interface between the N-type semiconductor layer and the insulator layer and at and near an interface between the P-type semiconductor layer and the insulator layer, an amount of the generated charge increases, and thus a larger variation in thermal conductivity and high thermal responsiveness can be obtained.

Owner:MITSUBISHI MATERIALS CORP +1

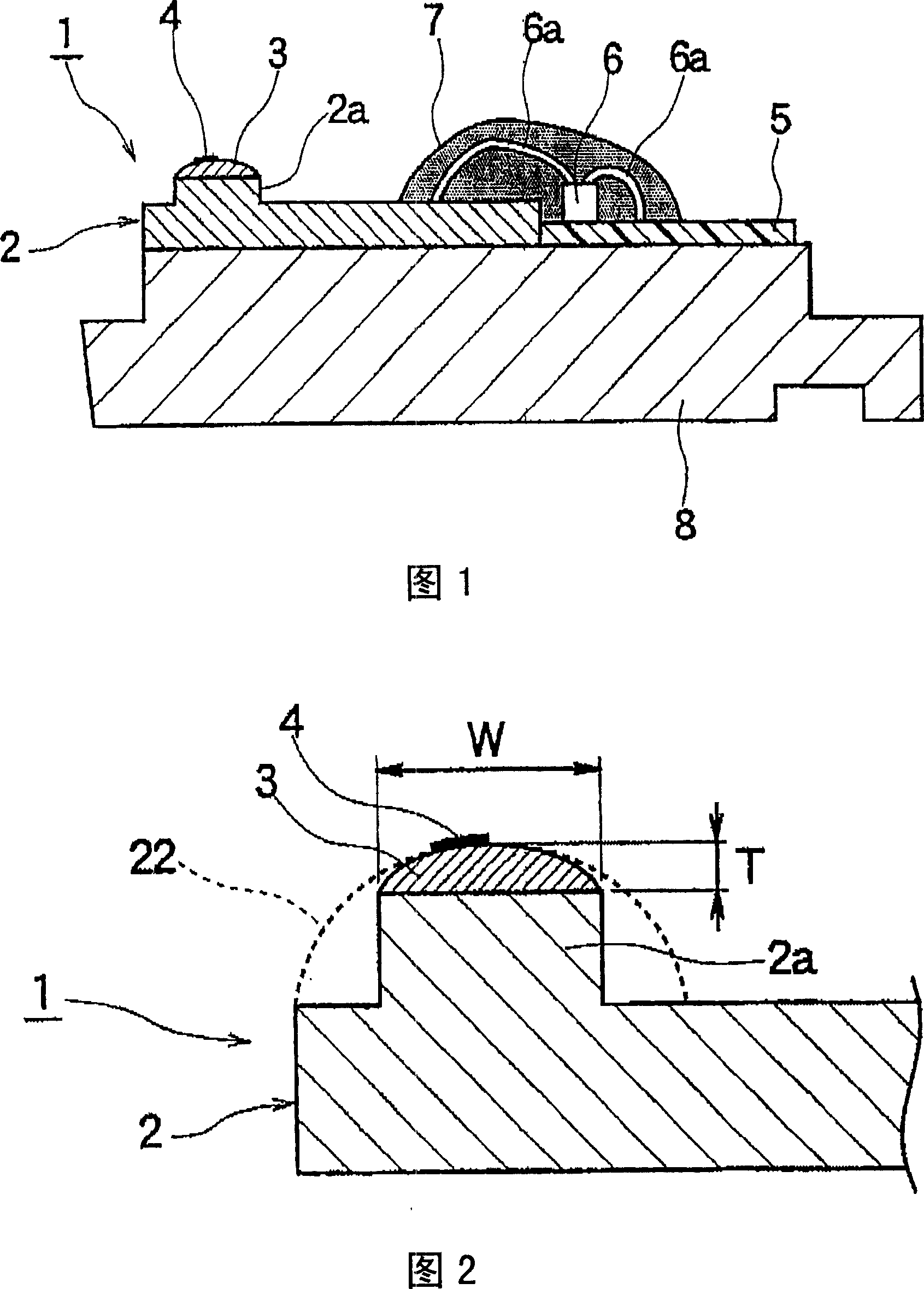

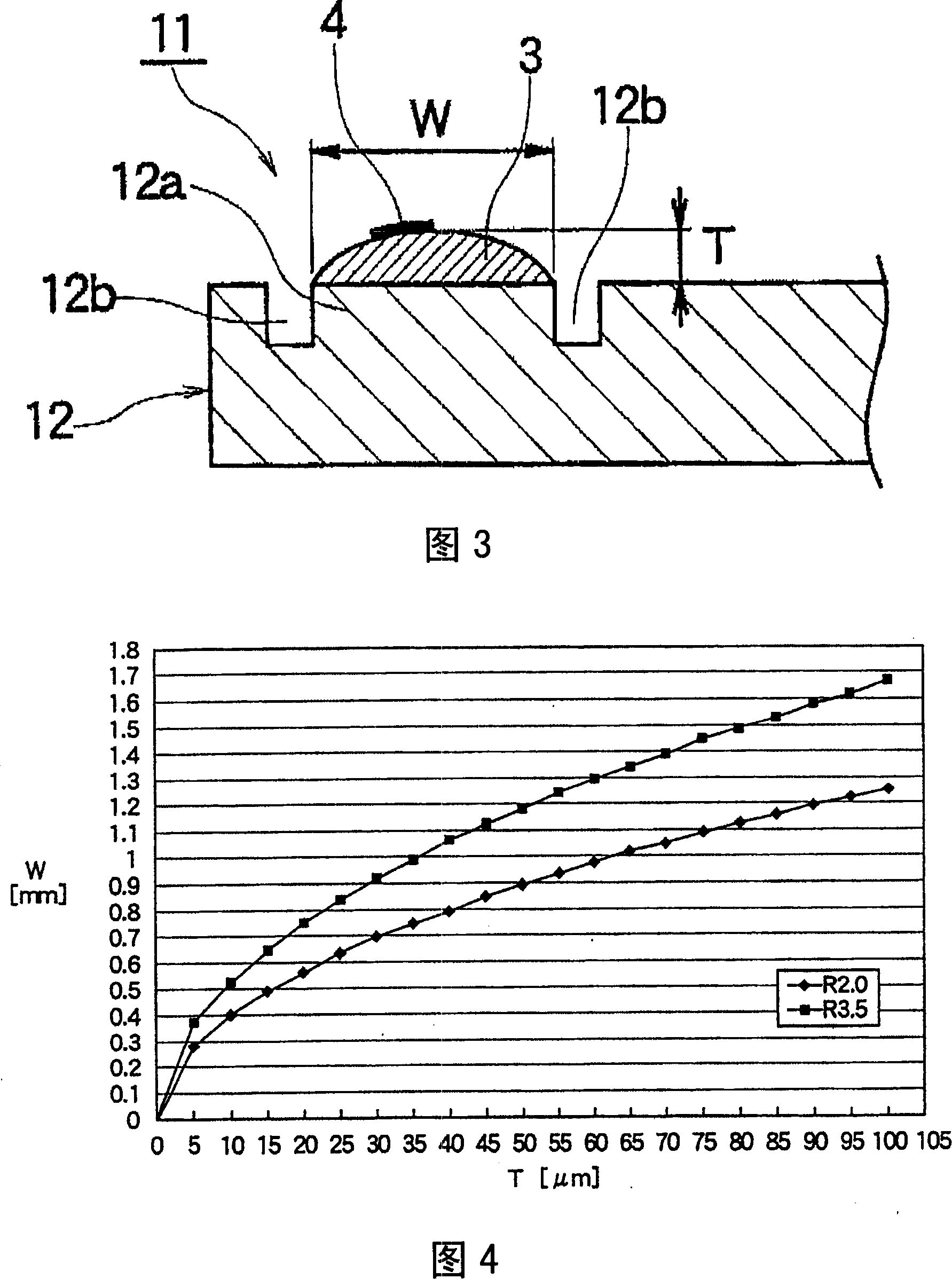

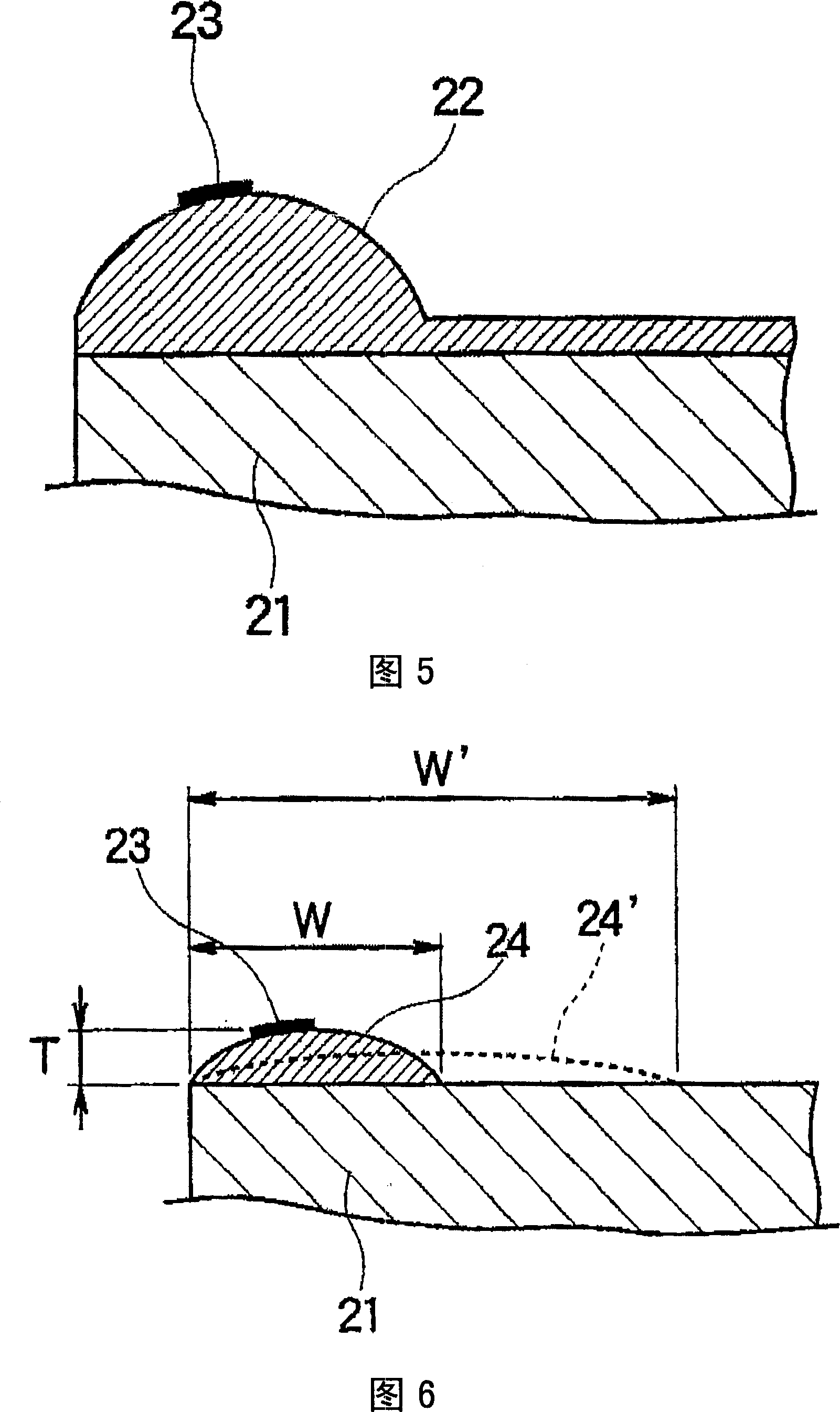

Thermal head and manufacturing method thereof

A thermal head and a manufacturing method capable of forming a heat insulating layer having excellent thermal responsiveness, and setting the curvature radius of the heat insulating layer in the vicinity of heat radiating parts to a dimension which does not affect printing quality are provided. The thermal head includes an insulating head substrate, a heat insulating layer formed in the shape of a circular arc with a desired height and base dimension on a surface of the head substrate, heat radiating parts composed of resistive elements formed at an apex of the heat insulating layer. The surface of the head substrate is formed with a heat insulating layer forming part whose width is equal to the base dimension of the heat insulating layer. The heat insulating layer is formed with a predetermined height T on the heat insulating layer forming part. The curvature radius of the circular arc-shaped heat insulating layer in the vicinity of the heat radiating parts is set to a desired dimension.

Owner:ALPS ALPINE CO LTD

Zinc stearate aqueous emulsified dispersed liquid and producing method thereof

InactiveCN100497817CRealize pulverization and micronizationSimple methodDefoamers additionPaper/cardboardEmulsionZinc

The present invention provides a zinc stearate water emulsified dispersion liquor and its preparation method. Its composition includes the following components: (by wt%) 1-4% of wetting dispersing agent, 4-10% of emulsifying agent, 15-35% of zinc stearate, 0.1-0.2% of defoaming agent and 50.8-79.9% deionized water. Its preparation method includes the following steps: firstly, adding the deionized water into a pre-dispersion kettle, then adding wetting dispersing agent emulsifying agent and stirring them, then adding zinc stearate and stirring them for 20-50 min, and adding defoaming agent, grinding and making emulsion so as to obtain the invented product.

Owner:苏州三威纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com