High-strength starch/clay composite material and preparation method thereof

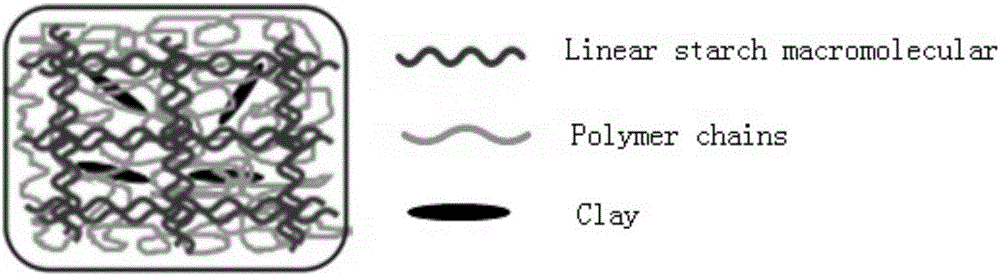

A composite material and high-strength technology, applied in the field of high-strength starch/clay composite materials and their preparation, can solve the problem of high preparation cost, and achieve the effects of low cost, simple preparation and huge application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0048] Specific embodiment one: its preparation method adopts following method step:

[0049] Step 1: Mix starch and deionized water at a mass ratio of 0.05:10, heat to 60°C, and stir until completely dissolved;

[0050] Step 2: Add isopropylacrylamide and XLG to the mixture in step 1. The mass ratio of isopropylacrylamide, XLG and deionized water is 0.5:0.4:10 for mixing, and stir evenly under the mixer .

[0051] Step 3: Add 2,2-diethoxyacetophenone to the mixed solution in step 2, wherein the added mass is 0.08% of the mixed solution, and stir evenly; pour the mixed solution into a mold, The composite was irradiated for 2 hours under a special ultraviolet lamp, and the composite was peeled off from the template, and washed in clear water to obtain a starch / clay composite material, which was composited by polyacrylamide and XLG.

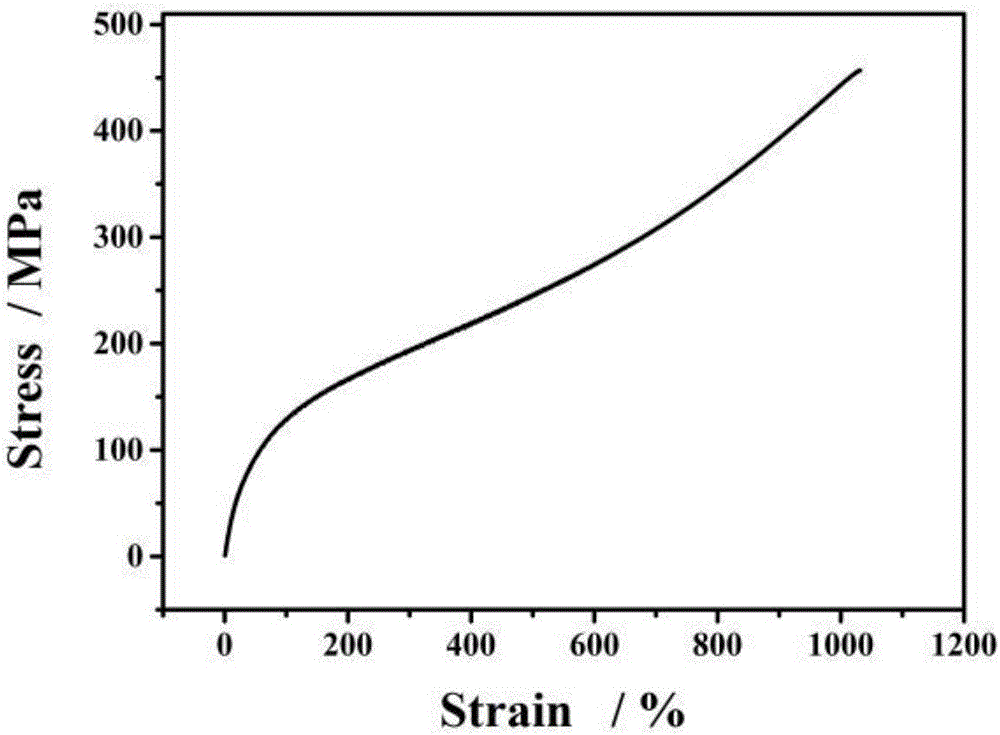

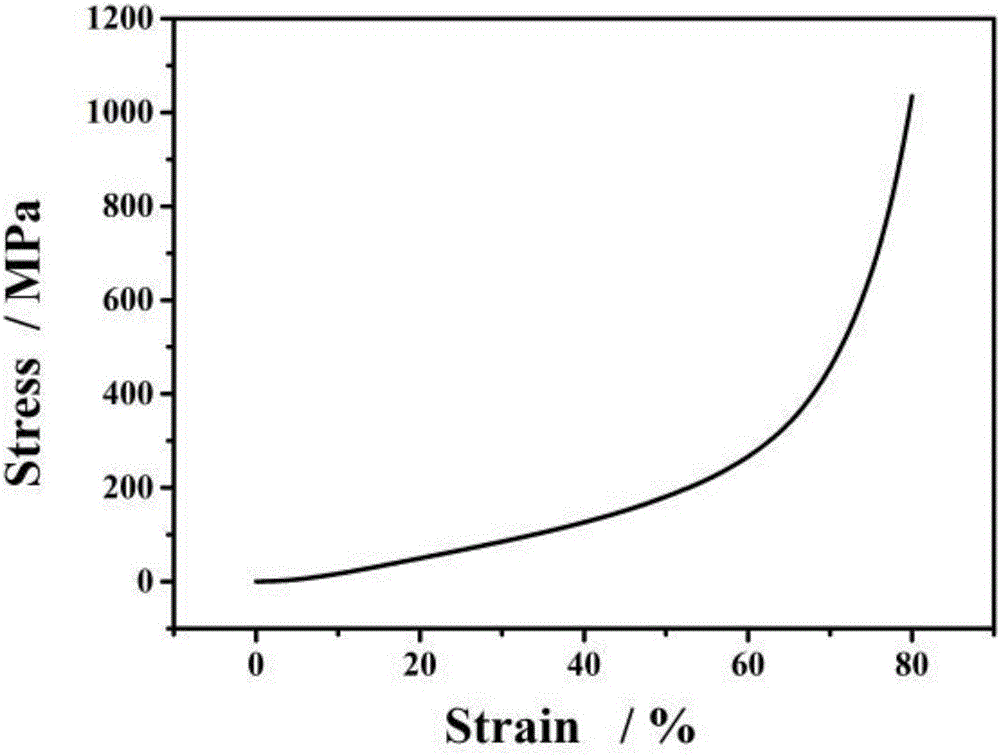

[0052] Step 4: If figure 1 and figure 2 As shown, the prepared hydrogel was tested for tensile and compressive strength, and the instrument u...

specific Embodiment 2

[0053] Specific embodiment two: its preparation method adopts following method steps:

[0054] Step 1: Mix starch and deionized water at a mass ratio of 0.1:10, and dissolve in an environment of 60°C;

[0055] Step 2: Add isopropylacrylamide and S482 to the mixed liquid in step 1, and mix with isopropylacrylamide, S482, and deionized water at a mass ratio of 1:2.5:10, and stir evenly under the mixer .

[0056] Step 3: Add 2,2-diethoxyacetophenone to the mixed solution in Step 2, wherein the added mass is 0.12% of the mixed solution, and stir evenly. Pour the mixture into the mold, irradiate for 2 hours under a 365nm ultraviolet lamp, peel off the composite from the template, and wash it in clean water to obtain a starch / clay composite material, which is composed of polyacrylamide and S482 .

[0057] Step 4: Test the tensile and compressive strength of the prepared hydrogel. The instrument used in the experiment is an electronic universal testing machine (RGM-2010). The ten...

specific Embodiment 3

[0058] Specific embodiment three: its preparation method adopts following method steps:

[0059] Step 1: Mix starch and deionized water in a mass ratio of 0.1:10, and dissolve in an environment of 100°C;

[0060] Step 2: Add isopropylacrylamide and S482 to the mixed liquid in step 1, wherein the mass ratio of isopropylacrylamide, S482, and deionized water is 0.75:1.5:10 for mixing, and stir evenly under the mixer .

[0061] Step 3: Add 2,2-diethoxyacetophenone to the mixed solution in step 2, wherein the added mass is 0.1% of the mixed solution mass, stir evenly, add tetramethylethylenediamine, the mass is mixed 0.12% of liquid. Pour the mixed solution into the mold, thermally polymerize at a constant temperature of 30°C for 25 hours, peel off the composite from the template, and wash it in clean water to obtain a starch / clay composite material, which is composed of polyacrylamide and S482.

[0062] Step 4: Test the tensile and compressive strength of the prepared hydrogel....

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com