Thermal protector

A thermal protector, bimetal technology, applied in the protection switch operation/release mechanism, thermal switch, thermal switch components, etc., to achieve the effect of simple structure, excellent current responsiveness or thermal responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

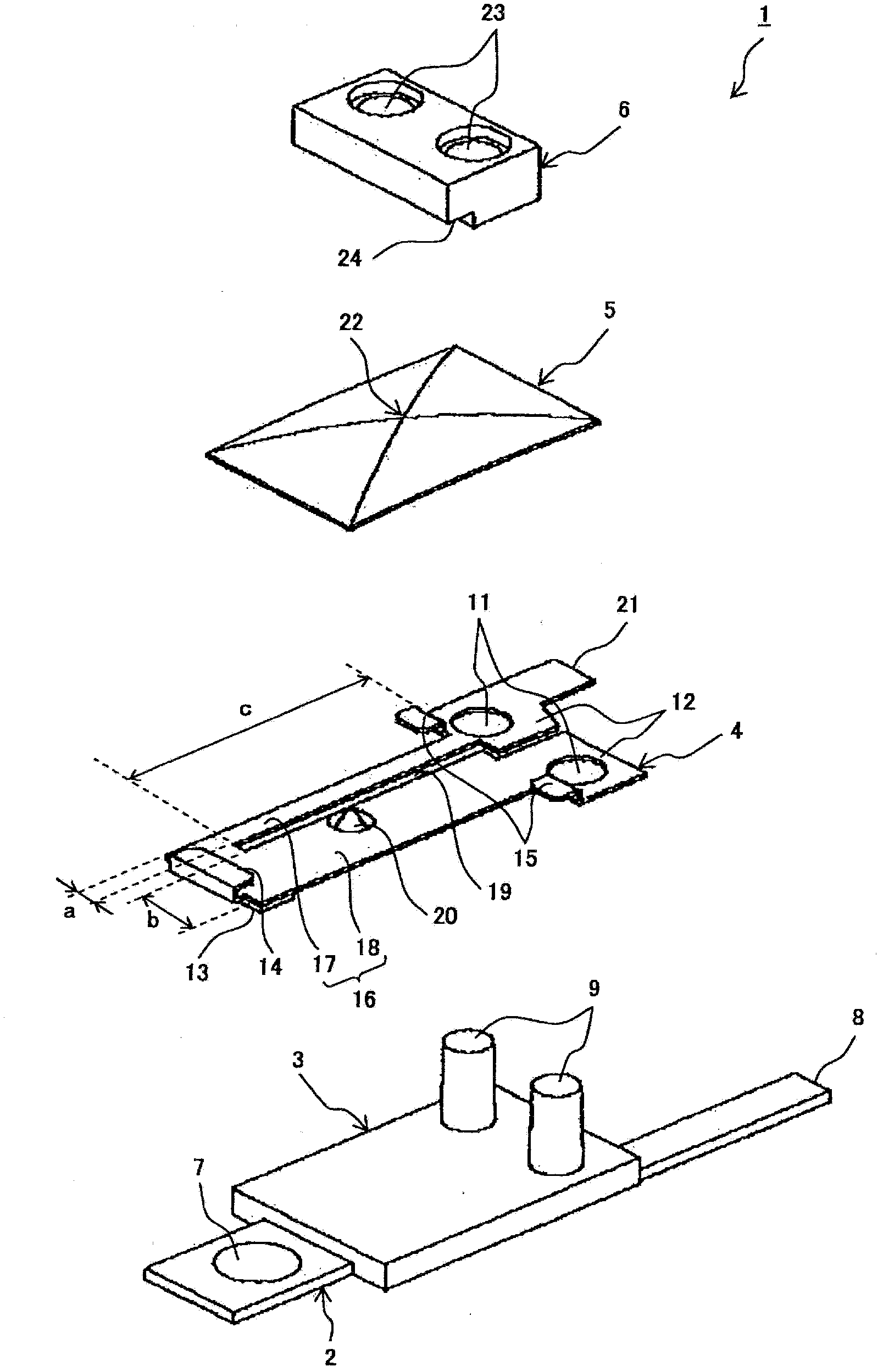

[0027] figure 1 It is an exploded perspective view showing the structure of the thermal protector of Example 1. Such as figure 1 As shown, the thermal protector 1 of this example is composed of a fixed conductor 2 , an insulator 3 , a movable plate 4 , a bimetal 5 and a resin block 6 .

[0028] The fixed conductor 2 has: a fixed contact 7 provided at one end; and a first terminal 8 for external connection connected to the end opposite to the end provided with the fixed contact 7 .

[0029] The insulator 3 is provided between the fixed contact 7 and the first terminal 8 of the fixed conductor 2 by resin molding. This insulator 3 has two pillars 9 integrally molded by resin molding.

[0030] The movable plate 4 has: a fixed portion 12 having a hole 11 fitted to the post 9 on the insulator 3; The opposite position of the fixed contact 7; and a claw 14 and two claws 15, which are used to hold the bimetal 5 on the movable end side where the movable contact 13 is located and the...

Embodiment 2

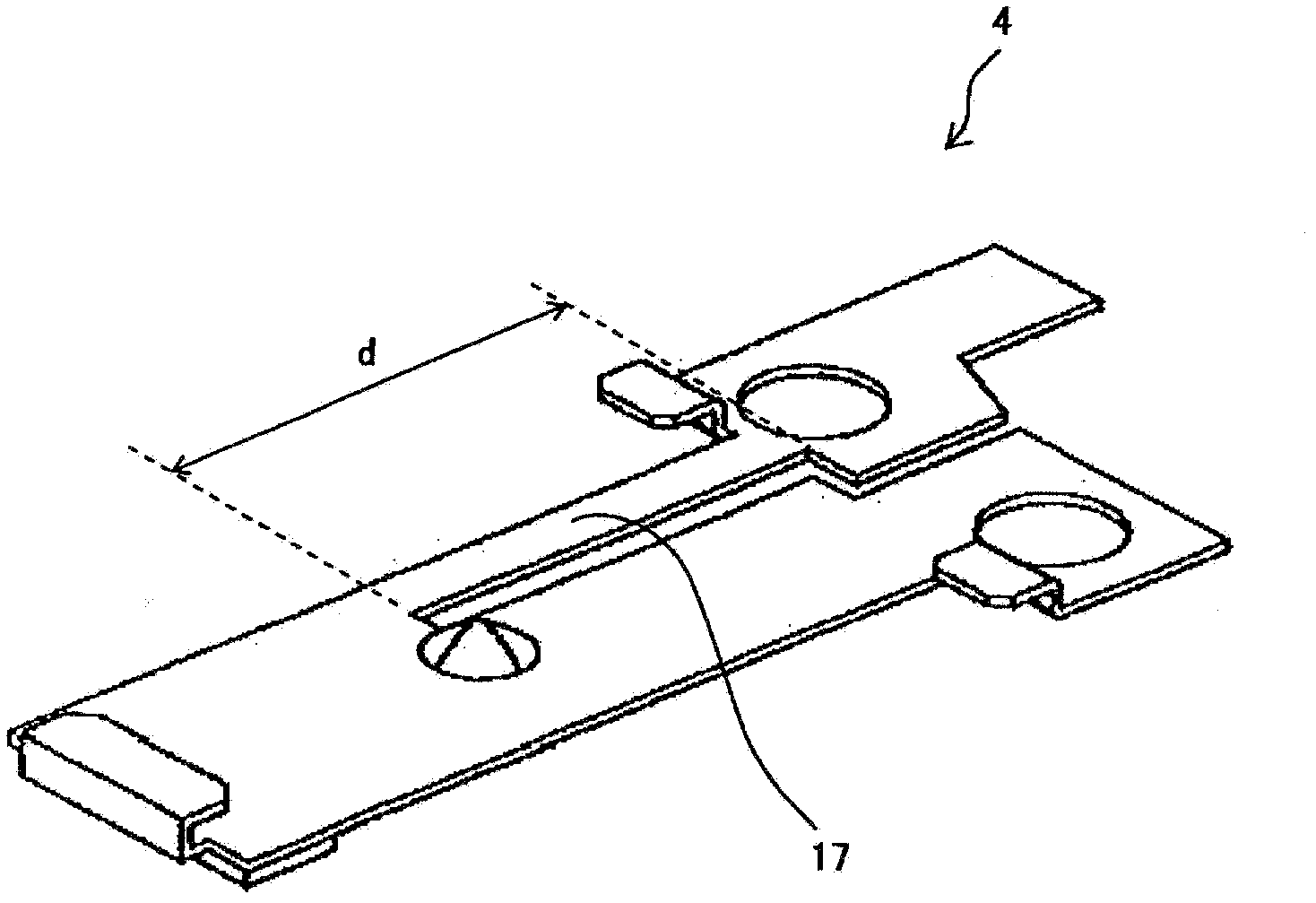

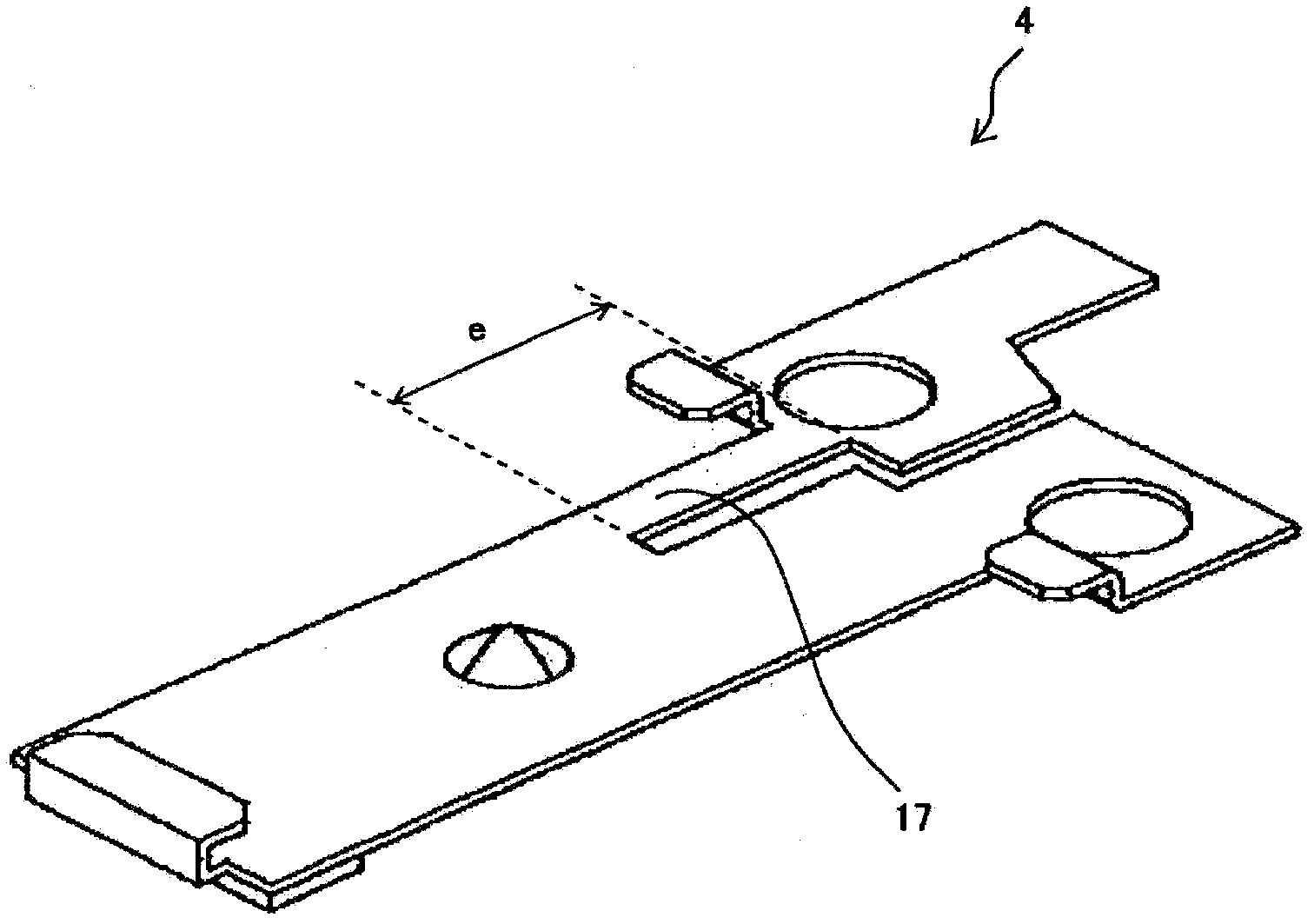

[0063] Image 6 It is a perspective view showing the structure of the movable plate of the thermal protector of Example 2 of this invention. in addition, Image 6 Above the movable plate 4 is also shown the bimetallic strip 5 that moves along with the structure of the movable plate 4 .

[0064] In the movable plate 4 in this example, a protruding portion 29 raised by one step is provided on a portion near the narrow portion 17 at the base of the wide portion 18 side. Like this, when the protruding portion 29 is close to the side of the narrow portion 17, when the fixed-side end of the bimetal 5 engages with the hook 15 on the fixed side of the movable plate 4, the fixed-side end of the bimetal 5 A point 31 of the narrow portion 17 at the center of the portion abuts against the protruding portion 29 .

[0065] As a result, the fixed-side end of the bimetal 5 is inclined toward the wide portion 18 in terms of balance as shown by arrows g and h, with the protruding portion 29 ...

Embodiment 3

[0074] Figure 8 It is an exploded perspective view illustrating the structure of a thermal protector according to Example 3 of the present invention. In addition, in Figure 8 in, with figure 1 The same structure part plus with figure 1 same label. Such as Figure 8 As shown, in the thermal protector 30 of this example, the structure of the fixed conductor 2, the insulator 3 and the resin block 6 is the same as figure 1 The situation is the same.

[0075] The heat protector 30 of this example is deleted figure 1 The movable plate 4, and the bimetallic strip 33 has three ways of the function of the movable plate, the function of the resistor, and the function of the bimetallic strip. That is, the thermal protector 30 of this example is an example of a structure in which a current directly flows through a bimetal strip.

[0076] The bimetallic strip 33 of this example has a fixing portion 35 having a hole 34 fitted to the post 9 in the insulator 3 . In addition, this b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com