Patents

Literature

113results about How to "Avoid physical contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

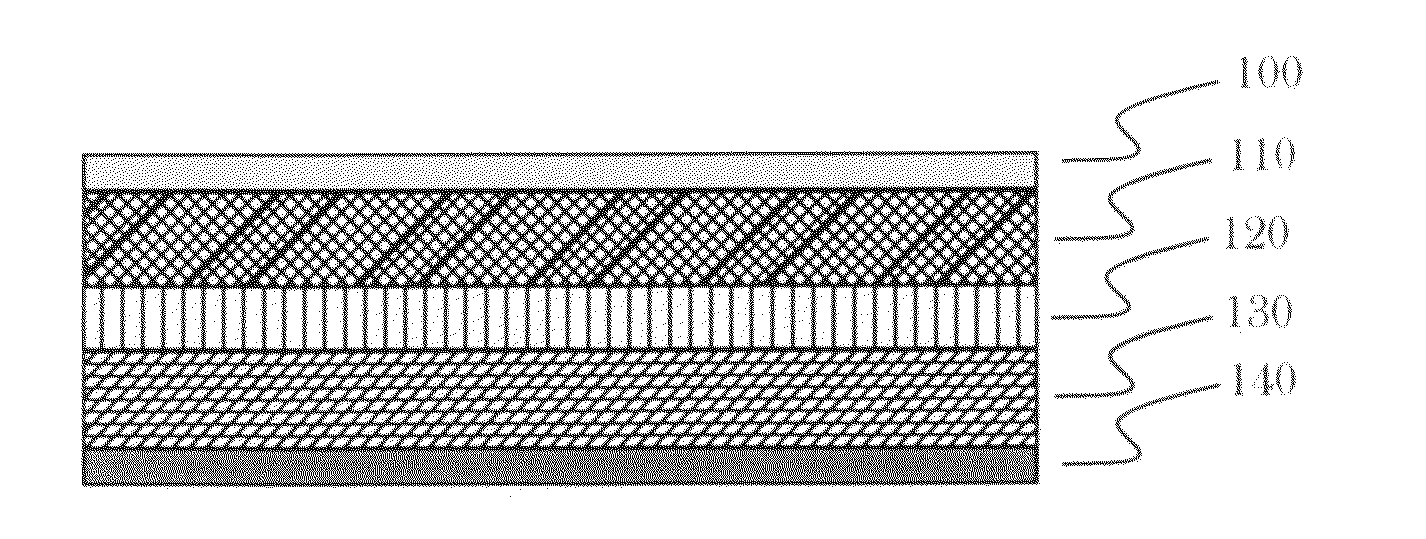

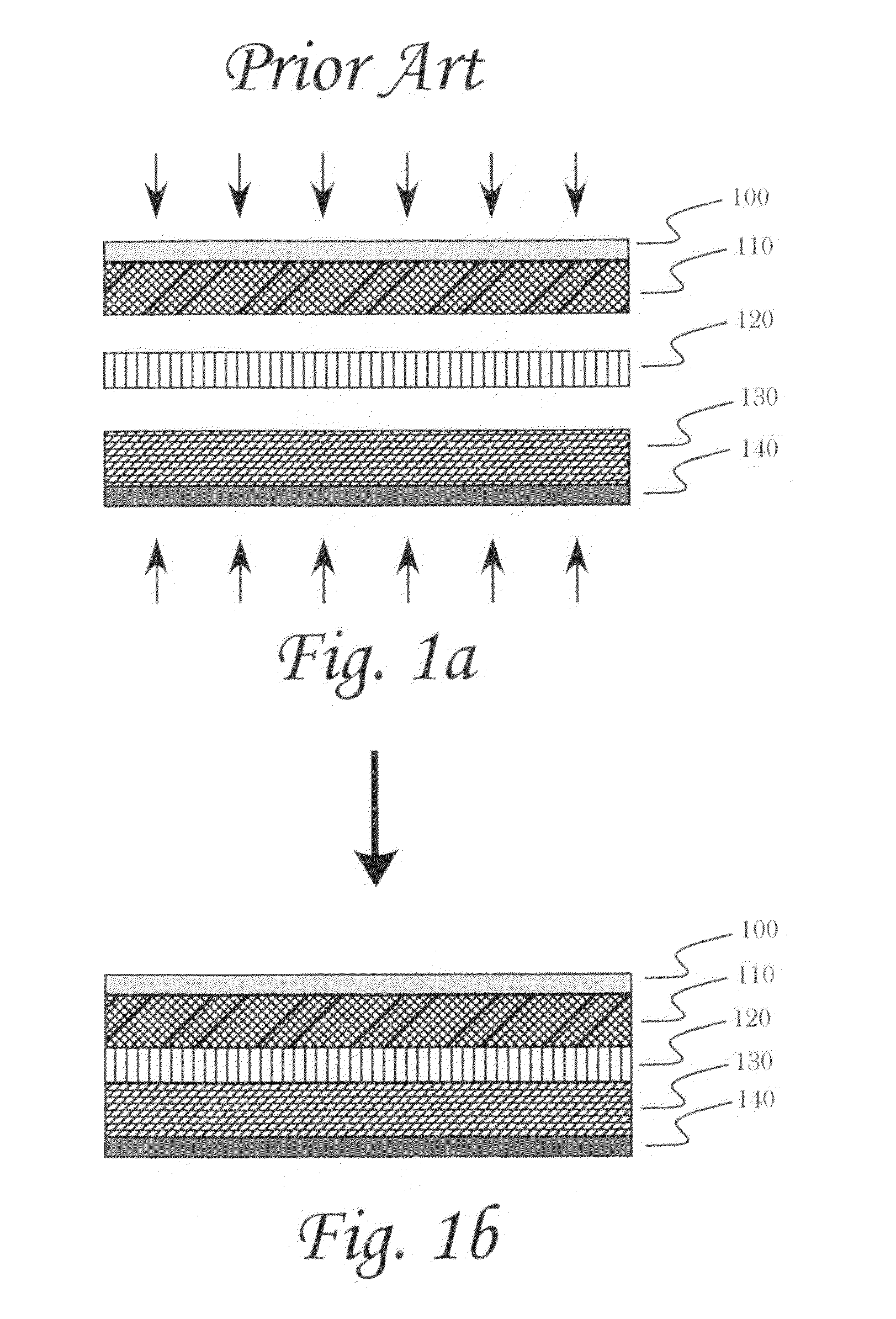

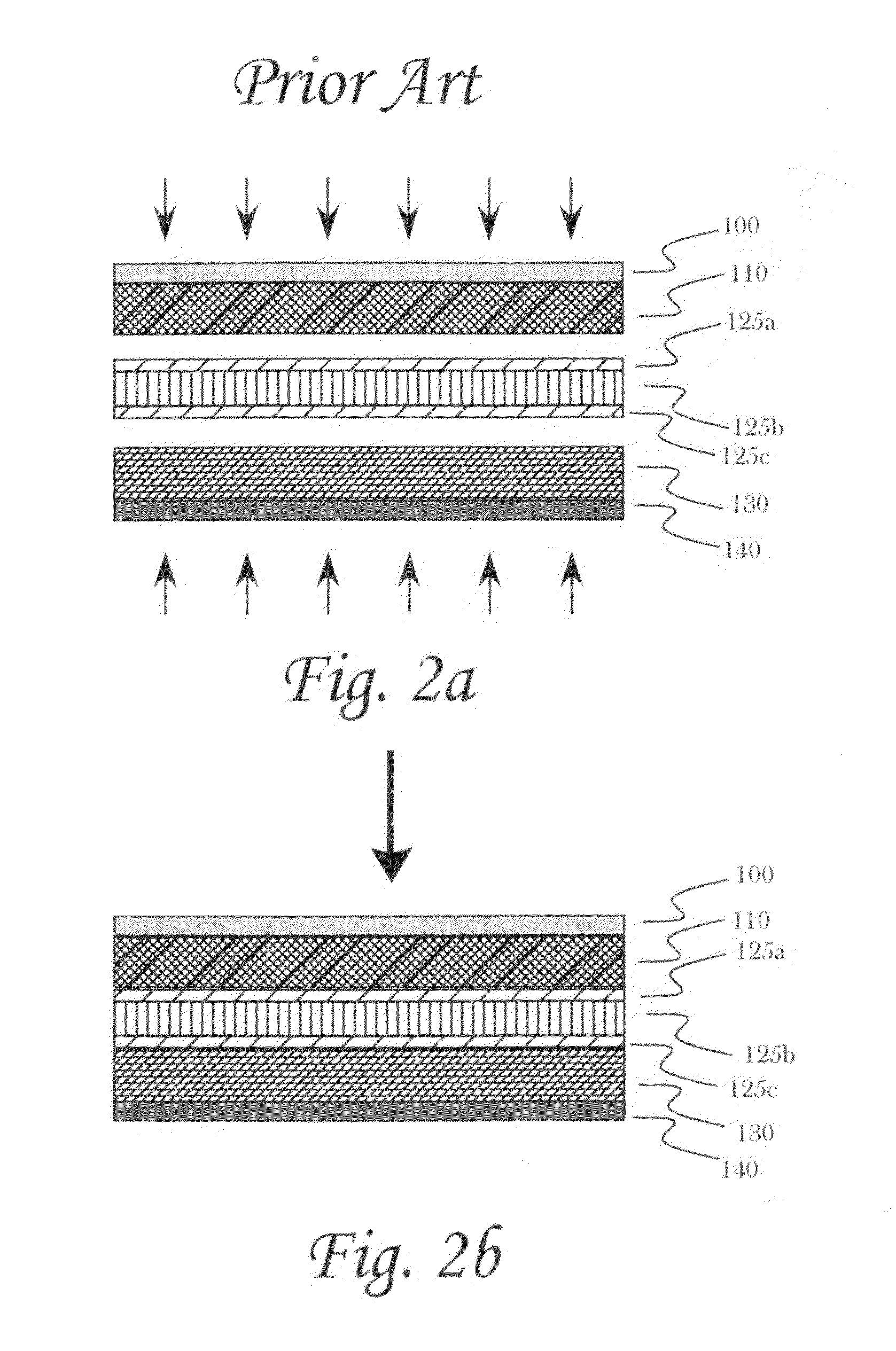

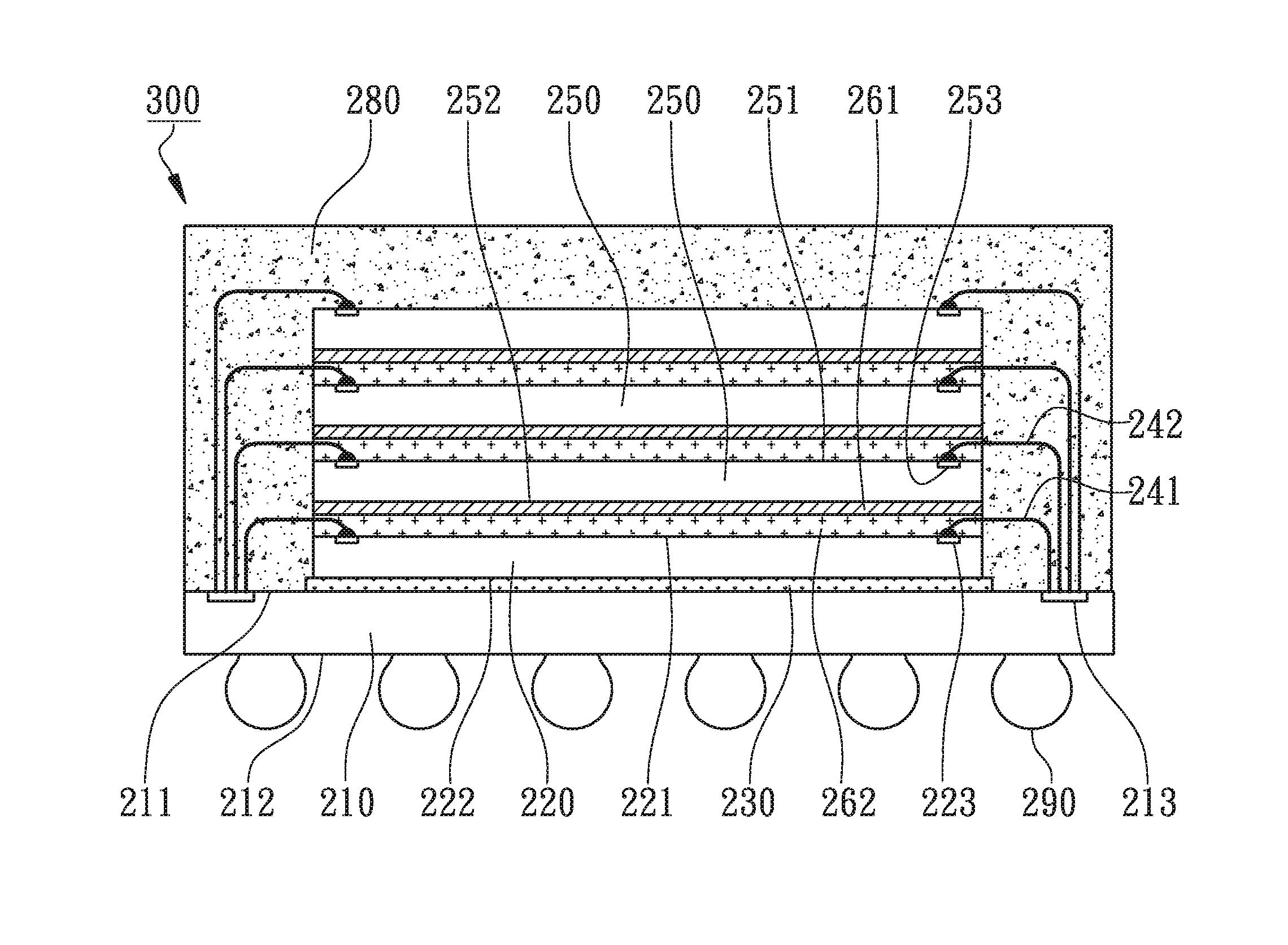

Polymer supported electrodes

InactiveUS20110183203A1Prevent thermal runawayInhibit growthMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSpray coatingPolymer supported

Methods and devices arising from the practice thereof for making and using battery electrodes formed onto ion permeable, electrically non-conductive substrates, preferably battery separators are disclosed herein. Electrodes are formed onto substrates using a variety of methods including, but not limited to, spray coating and electrophoretic deposition. Electrically conductive layers may be applied to the electrode coating layer side opposite or adjacent to the substrate to act as current collectors for the battery. Multilayer devices having alternating layers of conductive layers, electrode layers and substrates, wherein the conductive layers may be in electrical communication with other conductive layers to form a battery.

Owner:MOLECULAR NANOSYST

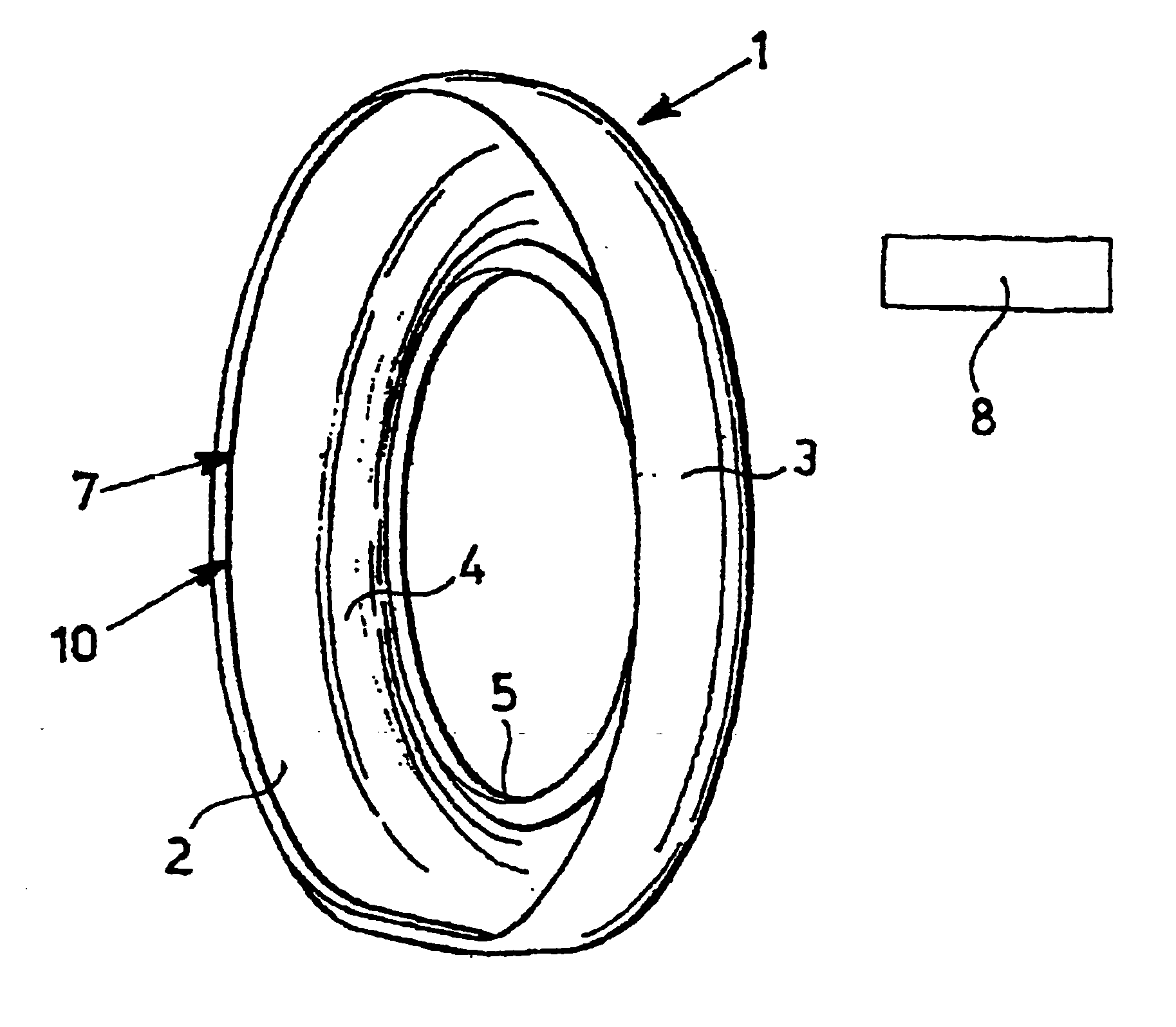

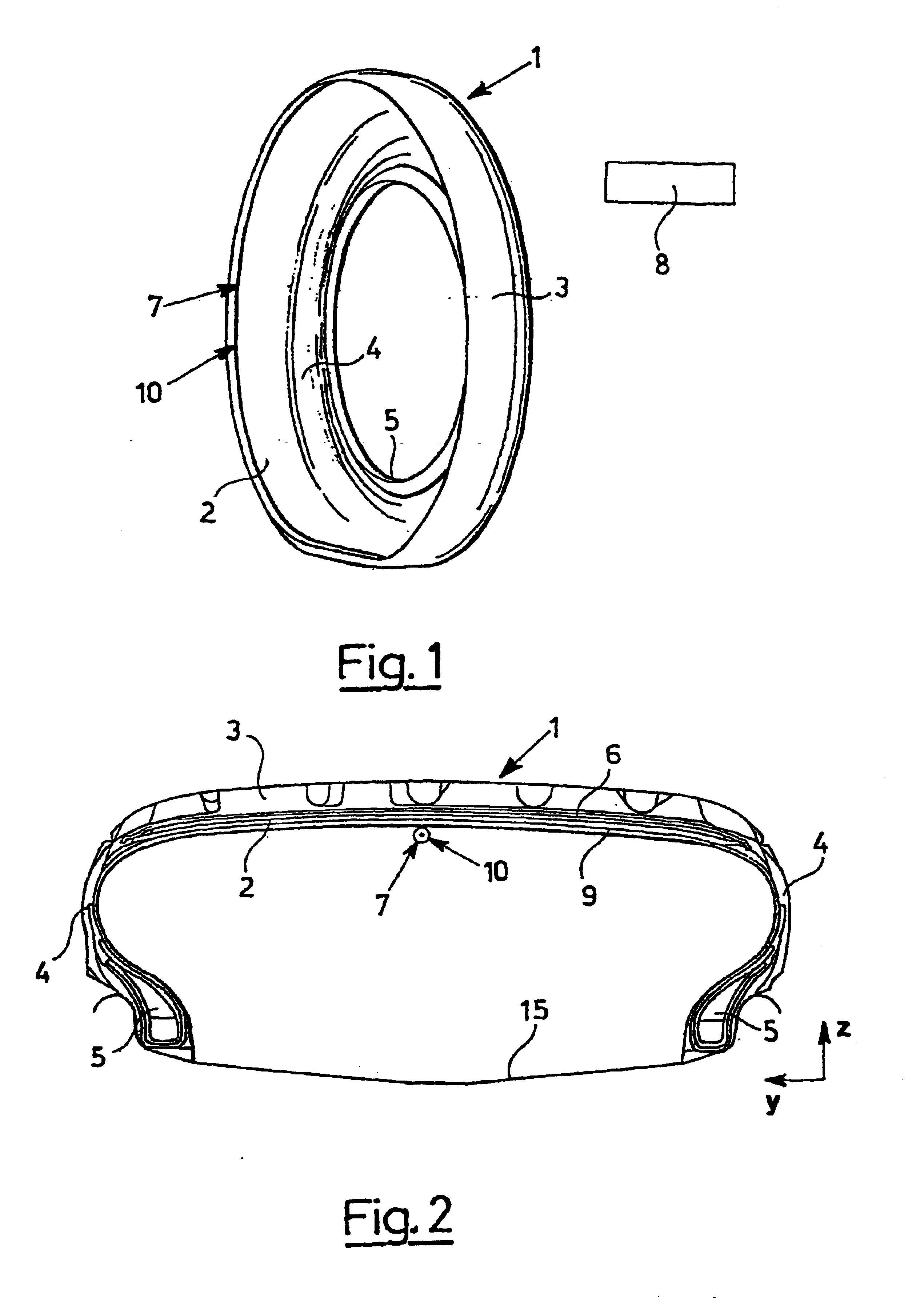

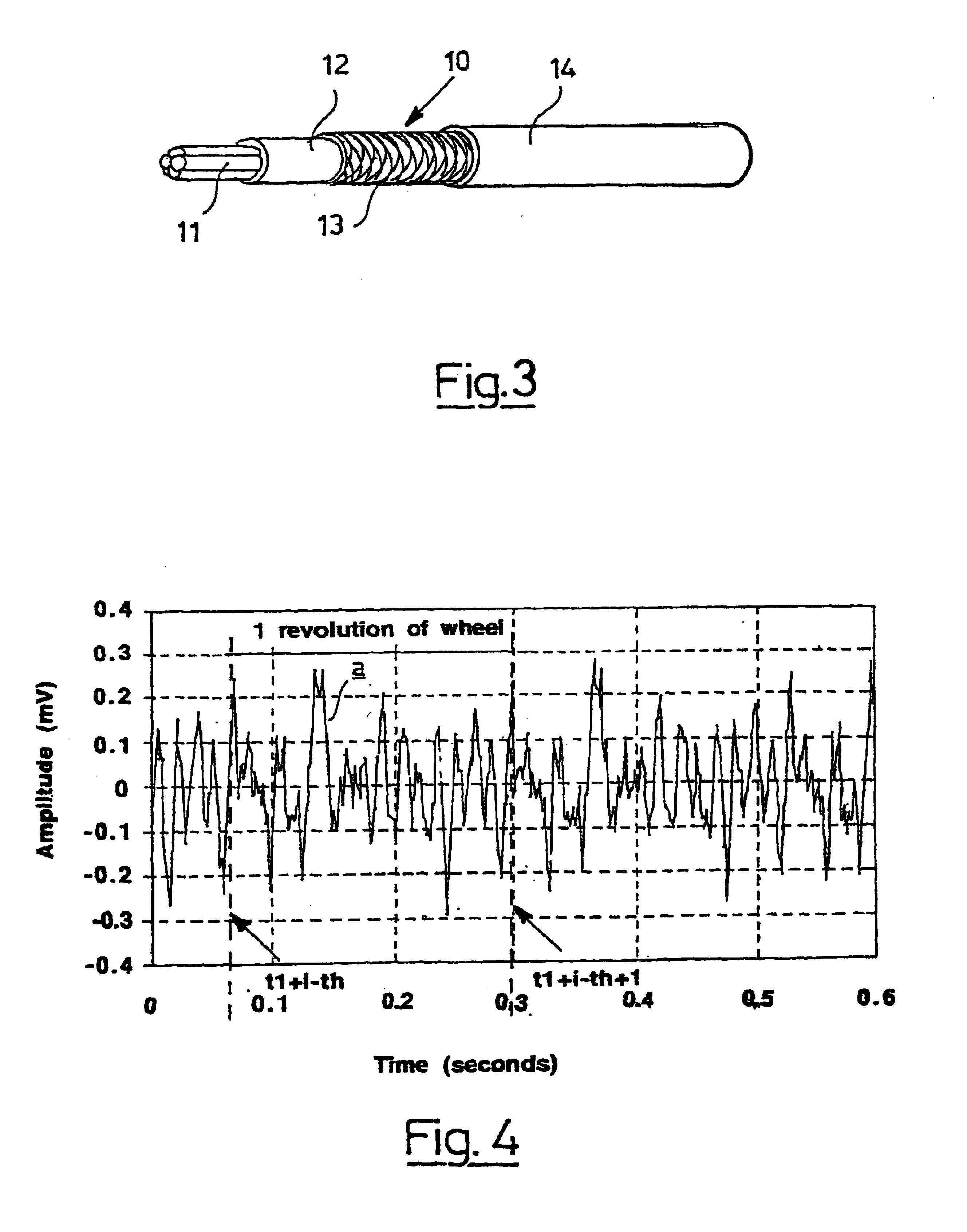

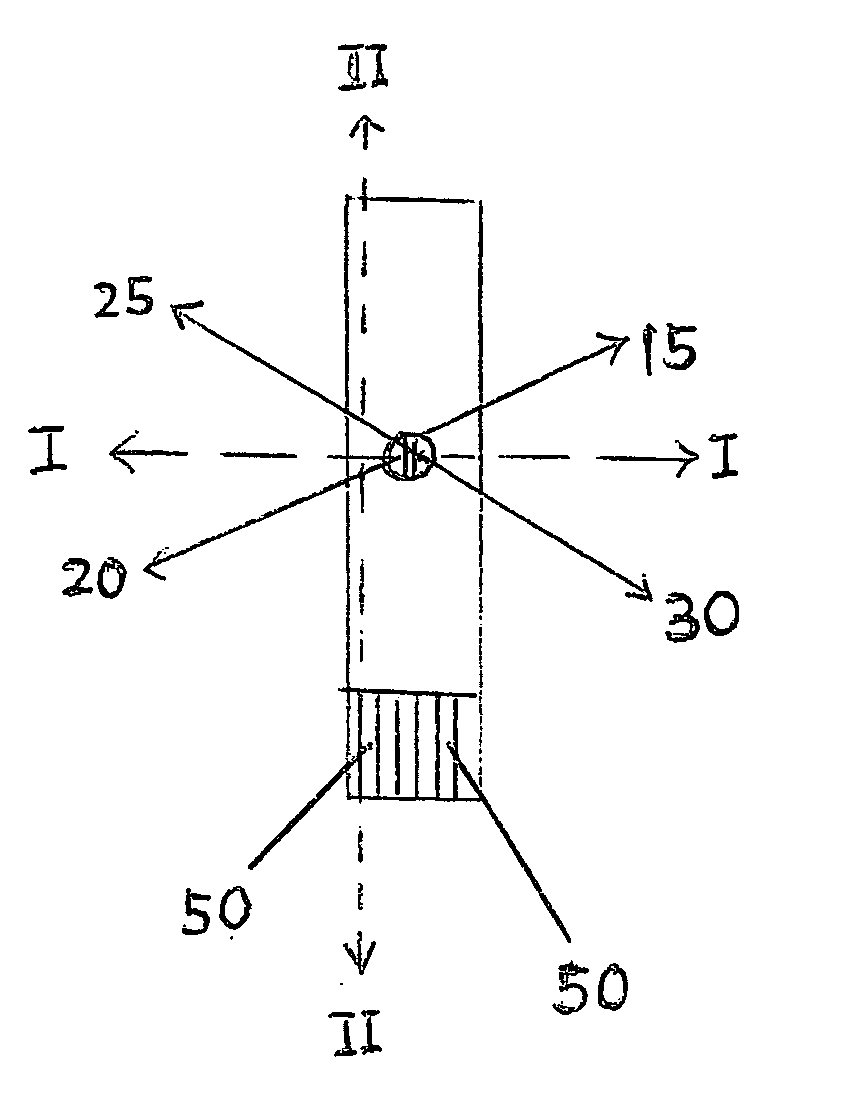

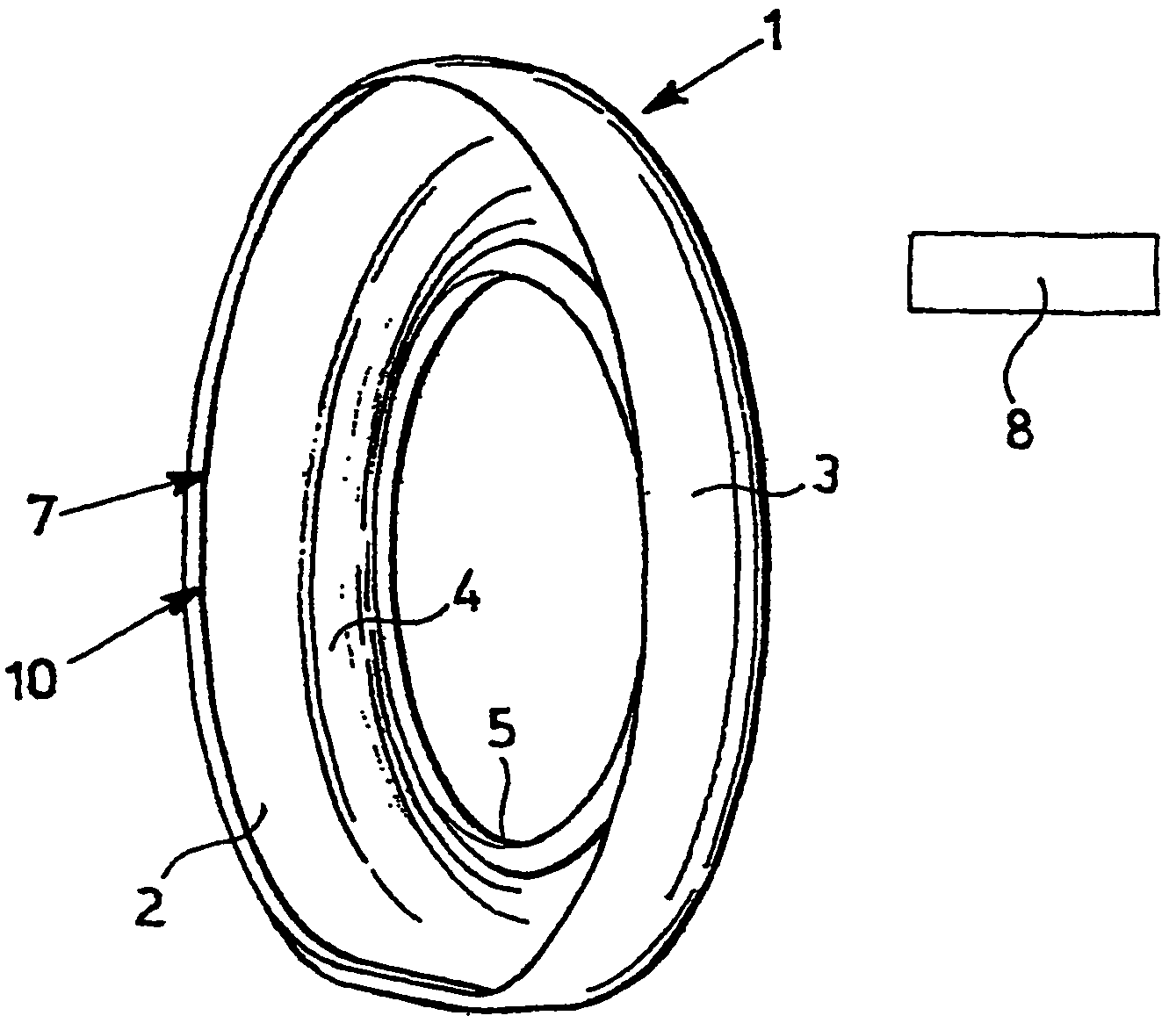

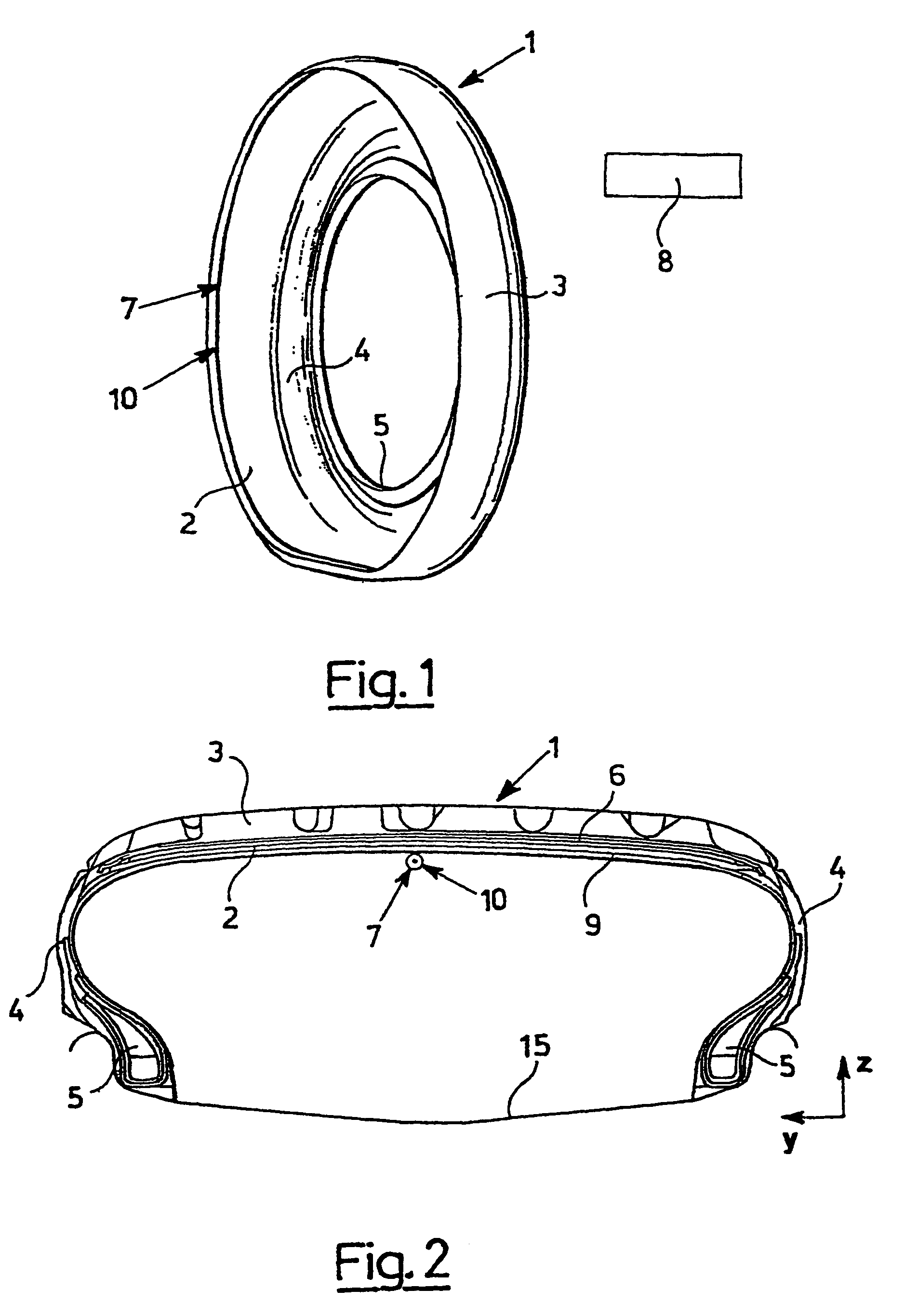

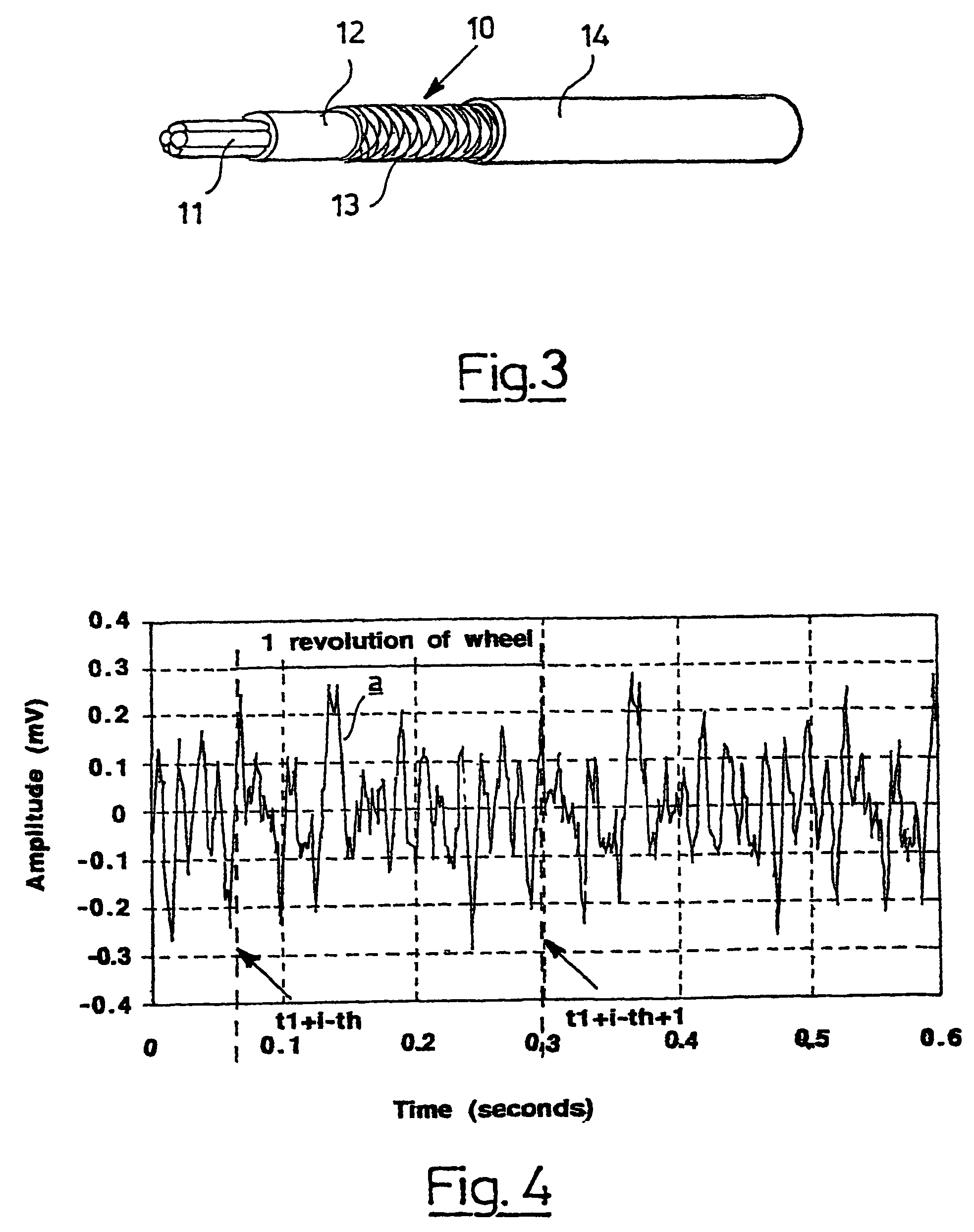

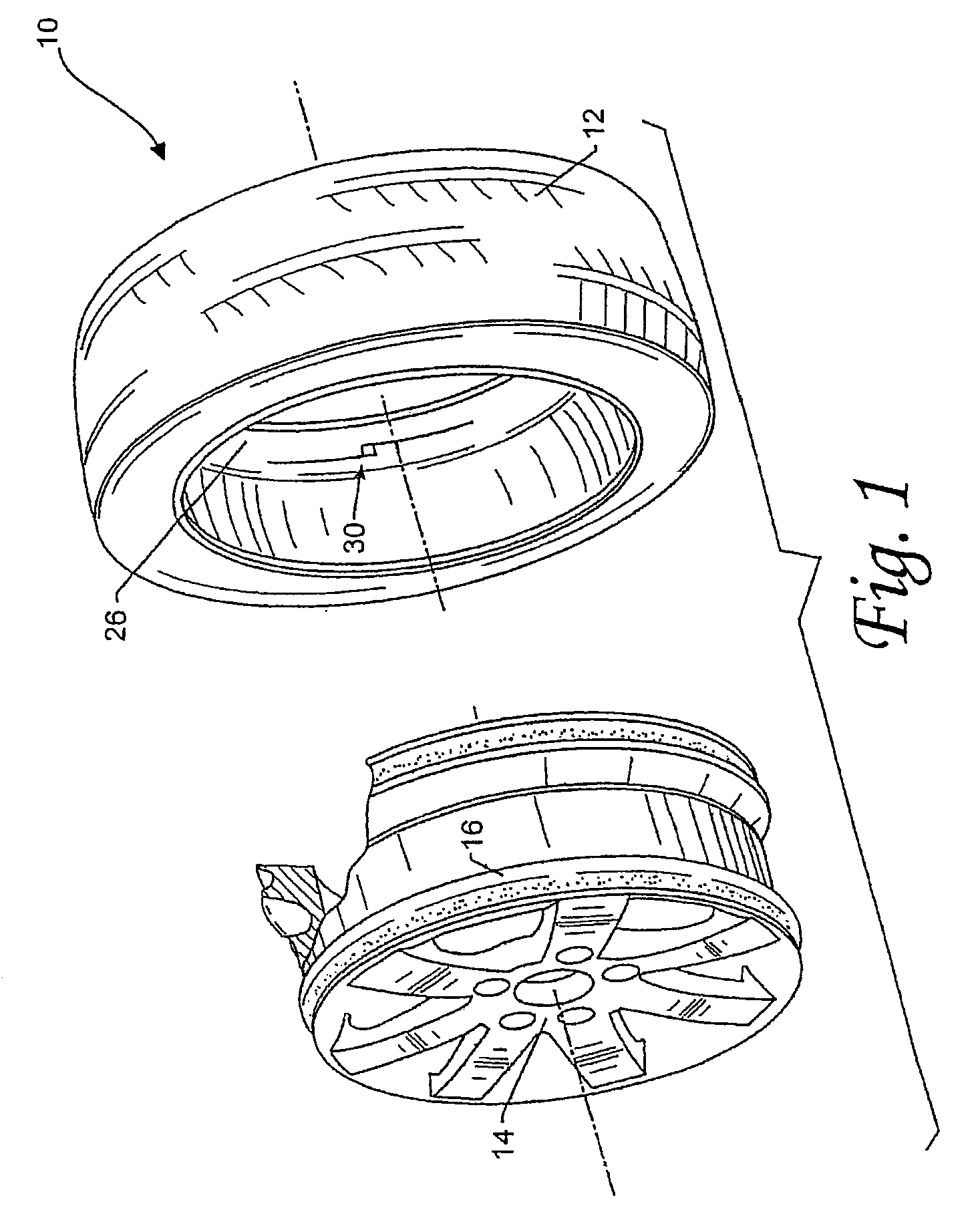

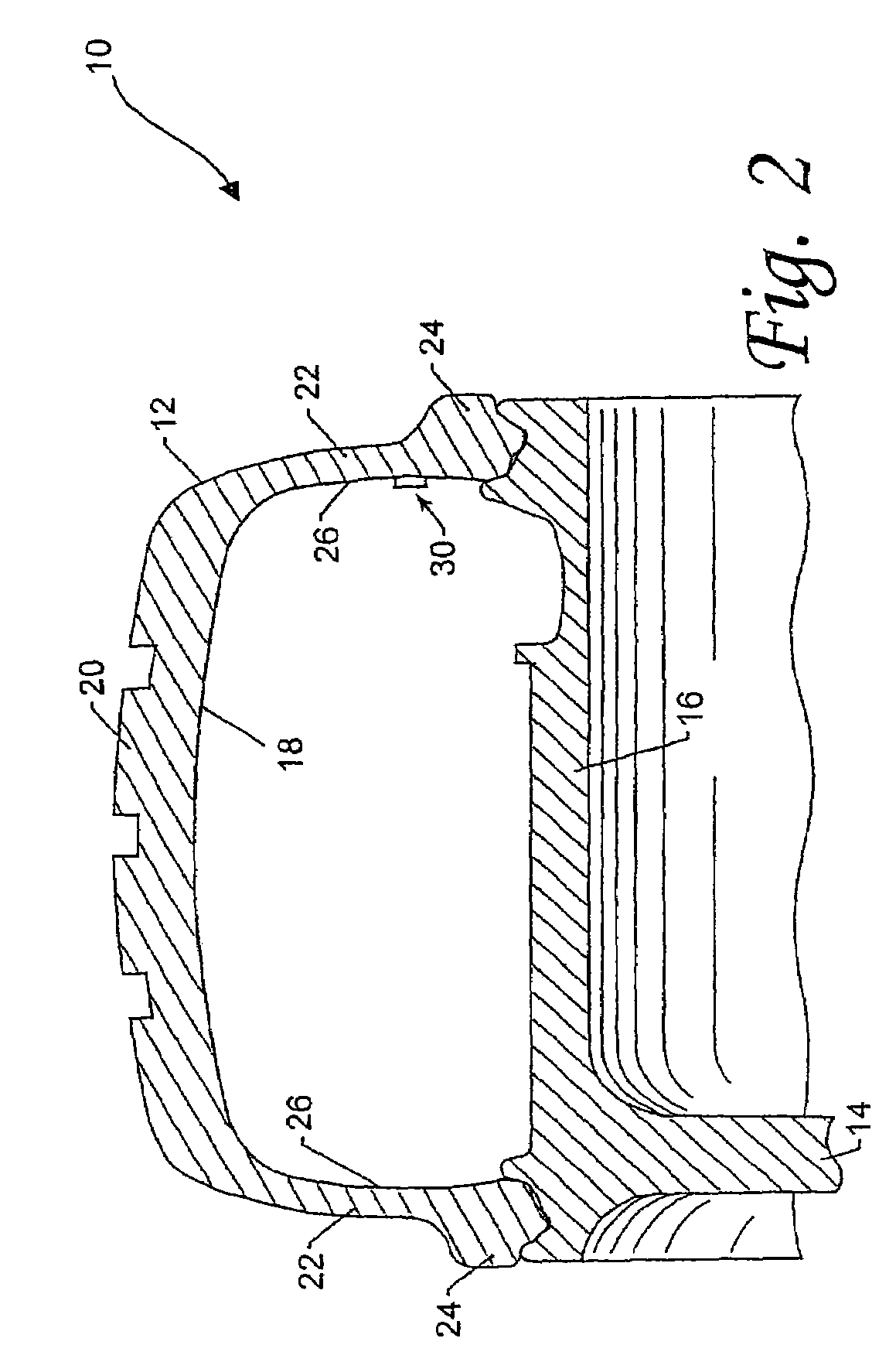

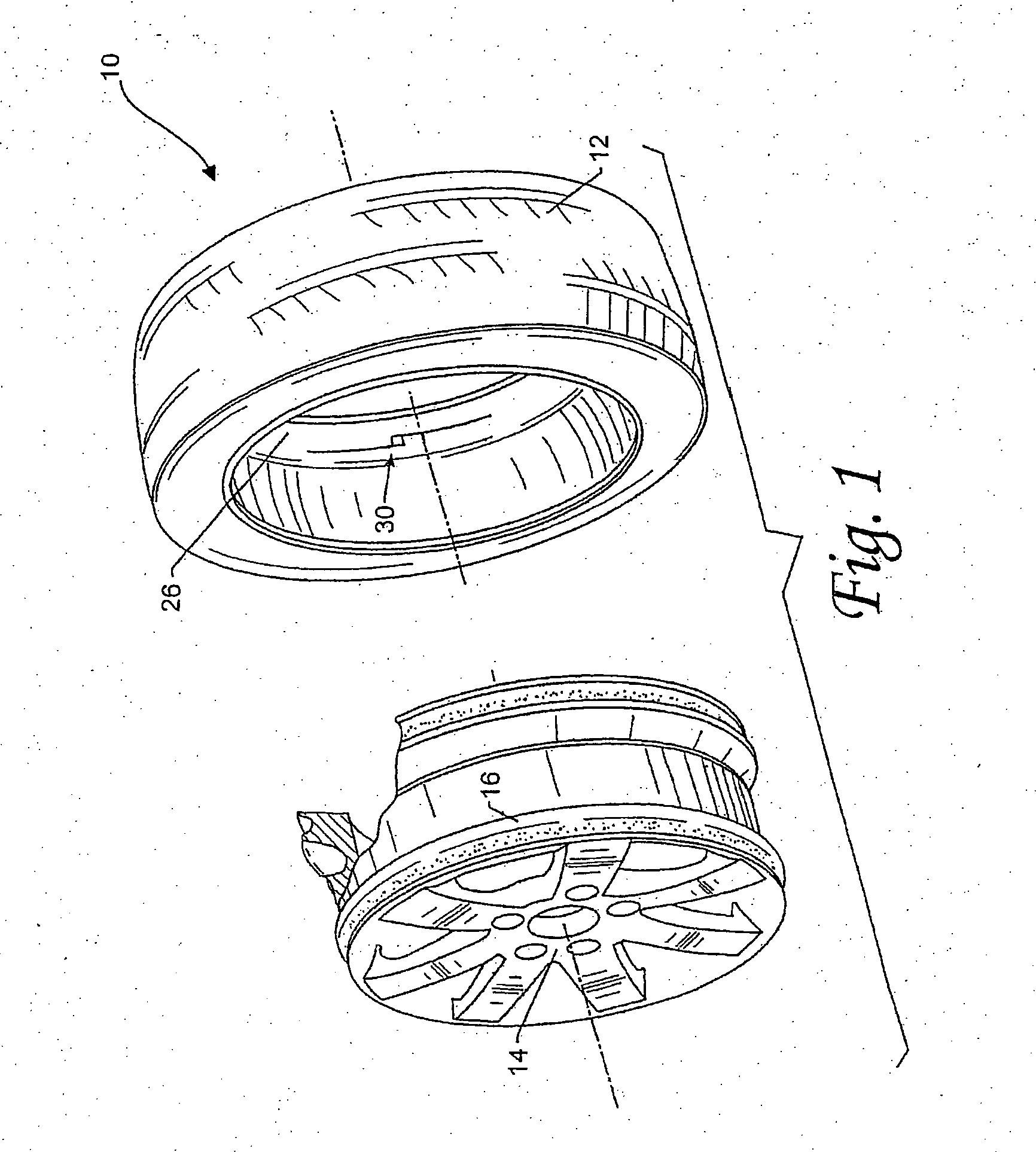

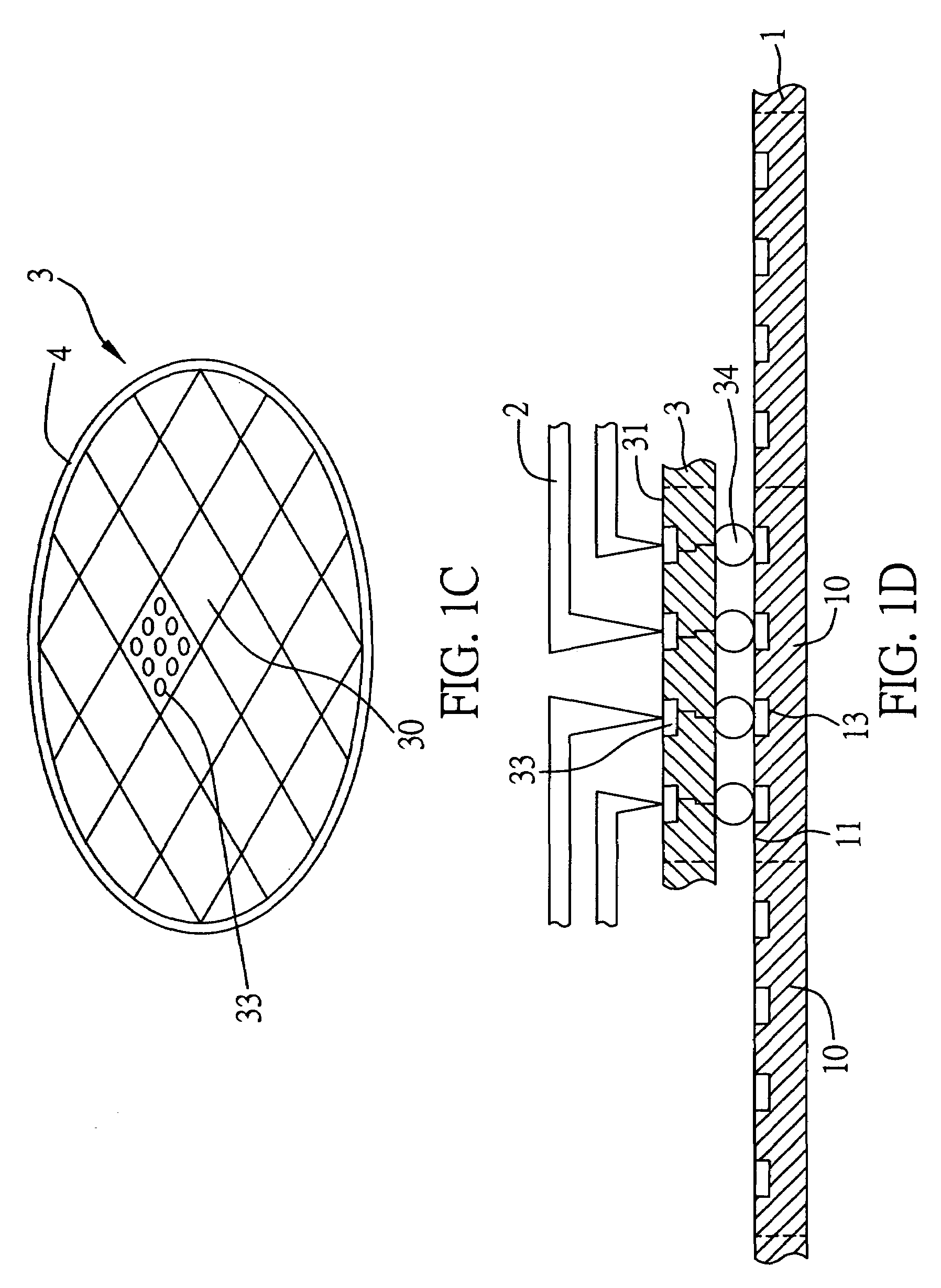

System, tire, wheel, vehicle, and method for determining the behavior of a tire in motion

InactiveUS6959593B2Uniform structureAvoid physical contactSuspensionsSubsonic/sonic/ultrasonic wave measurementElectricityMobile vehicle

A system for determining interaction between a tire and a contact surface during movement of a motor vehicle includes at least one first sensor and processing means. The at least one first sensor includes one or more first elongated piezoelectric elements which extend along at least a first portion of the tire. The at least one first sensor supplies a first signal to the processing means. The first signal is generated by rotation of the tire and is generated cyclically with each revolution of the tire. The processing means detects variations in time intervals between distinctive elements of the first signal. A tire including the system, a kit for detecting behavior of a tire moving with respect to a contact surface, a method for monitoring events correlated with interactions between tires of a moving vehicle and a contact surface, and related systems, tires, methods, and vehicles are also disclosed.

Owner:PIRELLI TYRE SPA

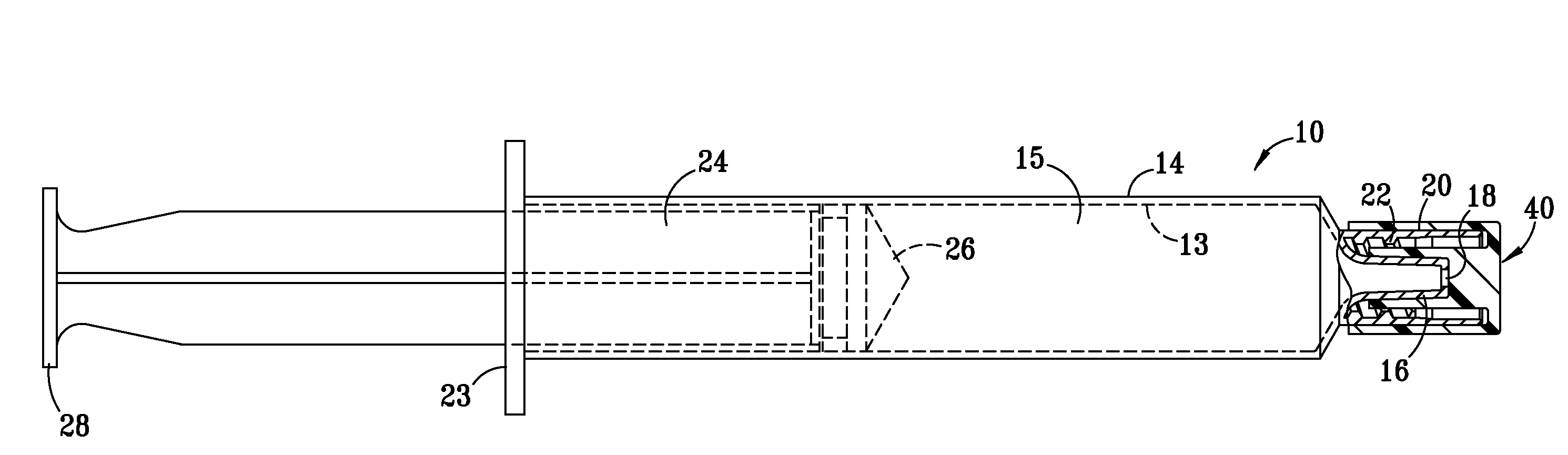

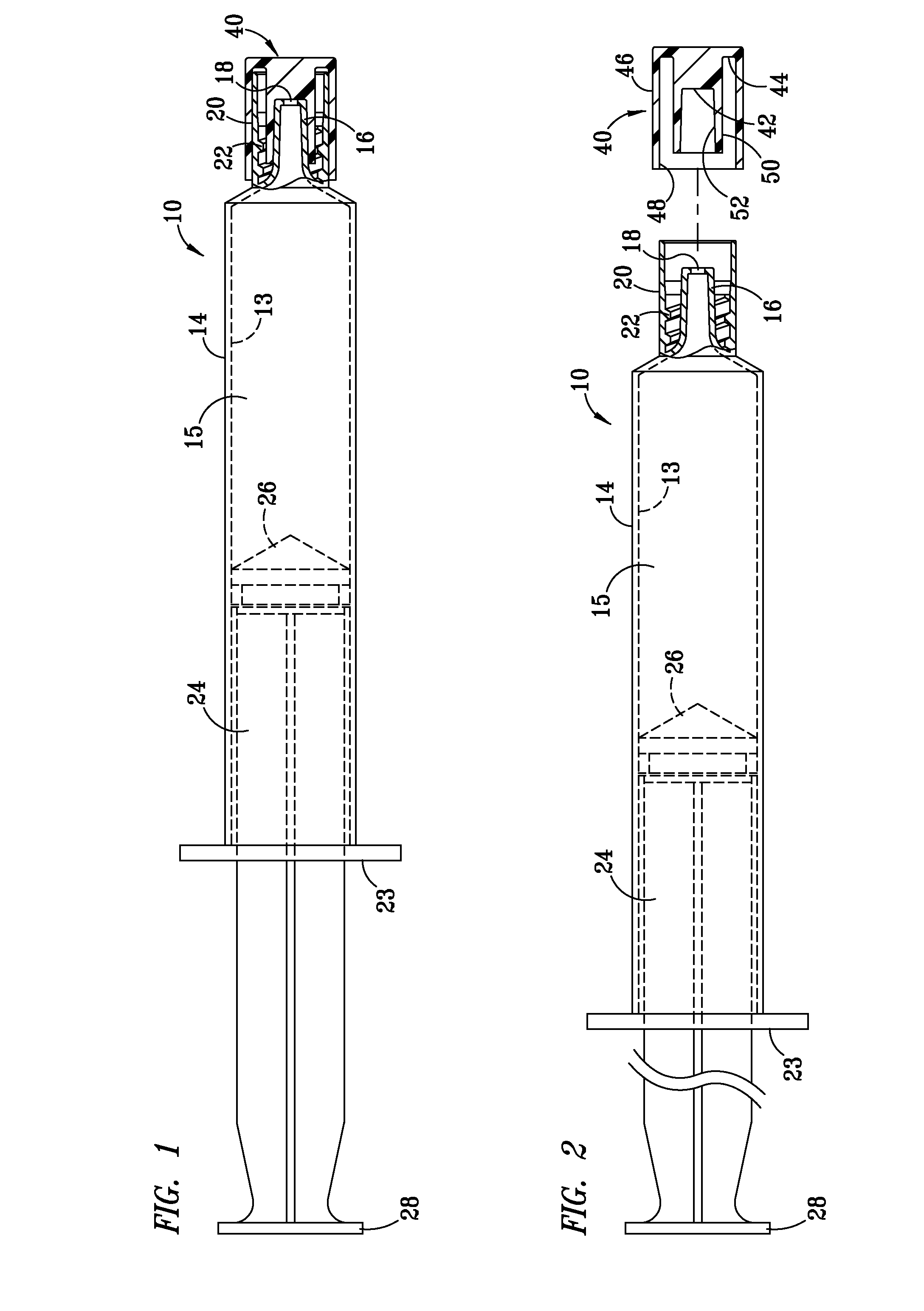

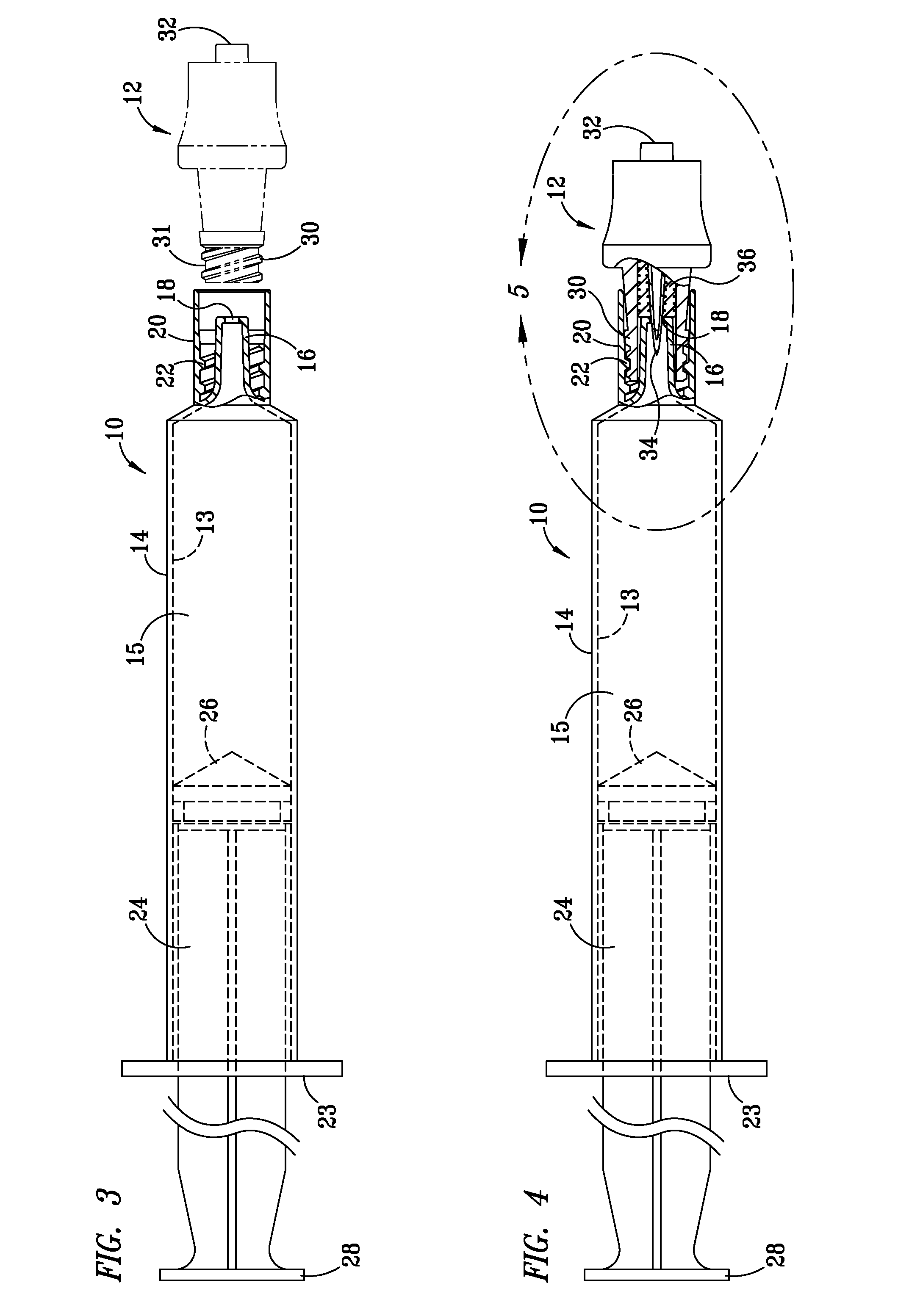

Syringe with Recessed Nose for Use with Frontal Attachments

InactiveUS20070260189A1Avoid pollutionAvoid spreadingInfusion syringesIntravenous devicesNoseEngineering

A syringe for use with frontal attachments with a forwardly extending projecting structure, which recesses the nose of the syringe and keeps the recessed nose from becoming contaminated by physical contact. In one preferred embodiment, the projecting structure is tubular and internally threaded such that a standard CLAVE® connector can be attached to a pre-filled syringe at such time as the syringe is to be used. In another preferred embodiment, the projecting structure is tubular and internally threaded such that a luer lock needle attachment can be attached to a luer lock syringe at such time as the syringe is to be used.

Owner:RETRACTABLE TECH INC

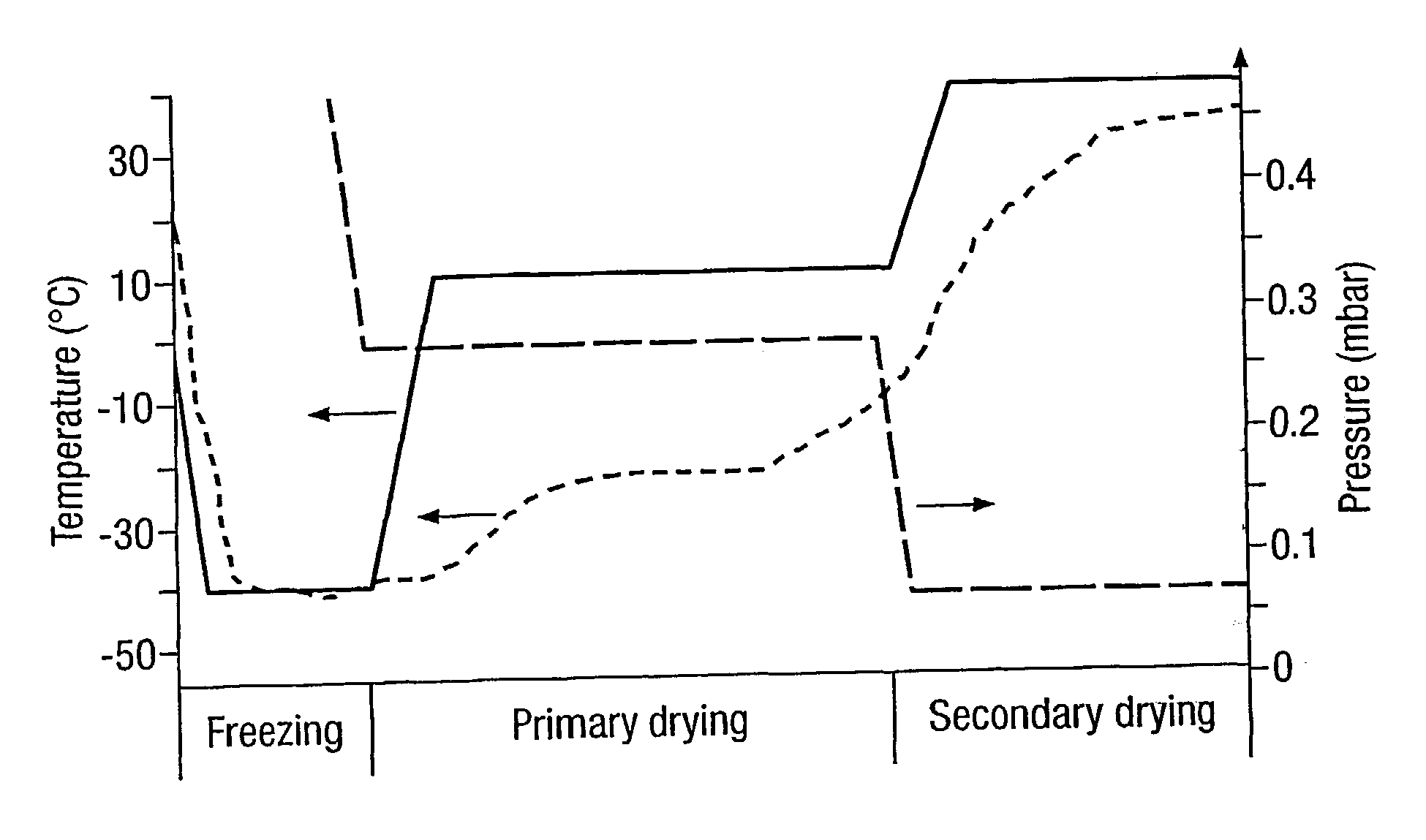

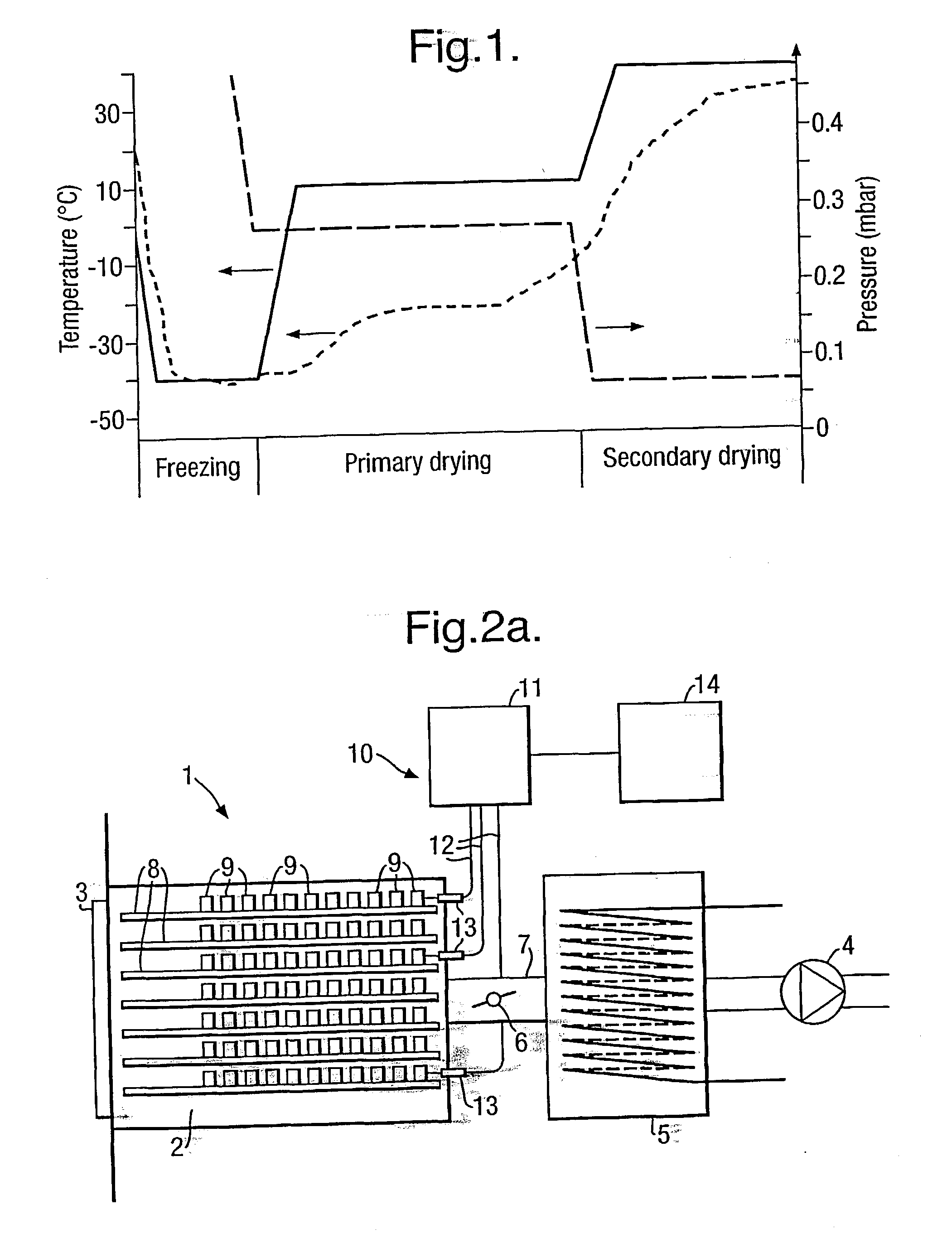

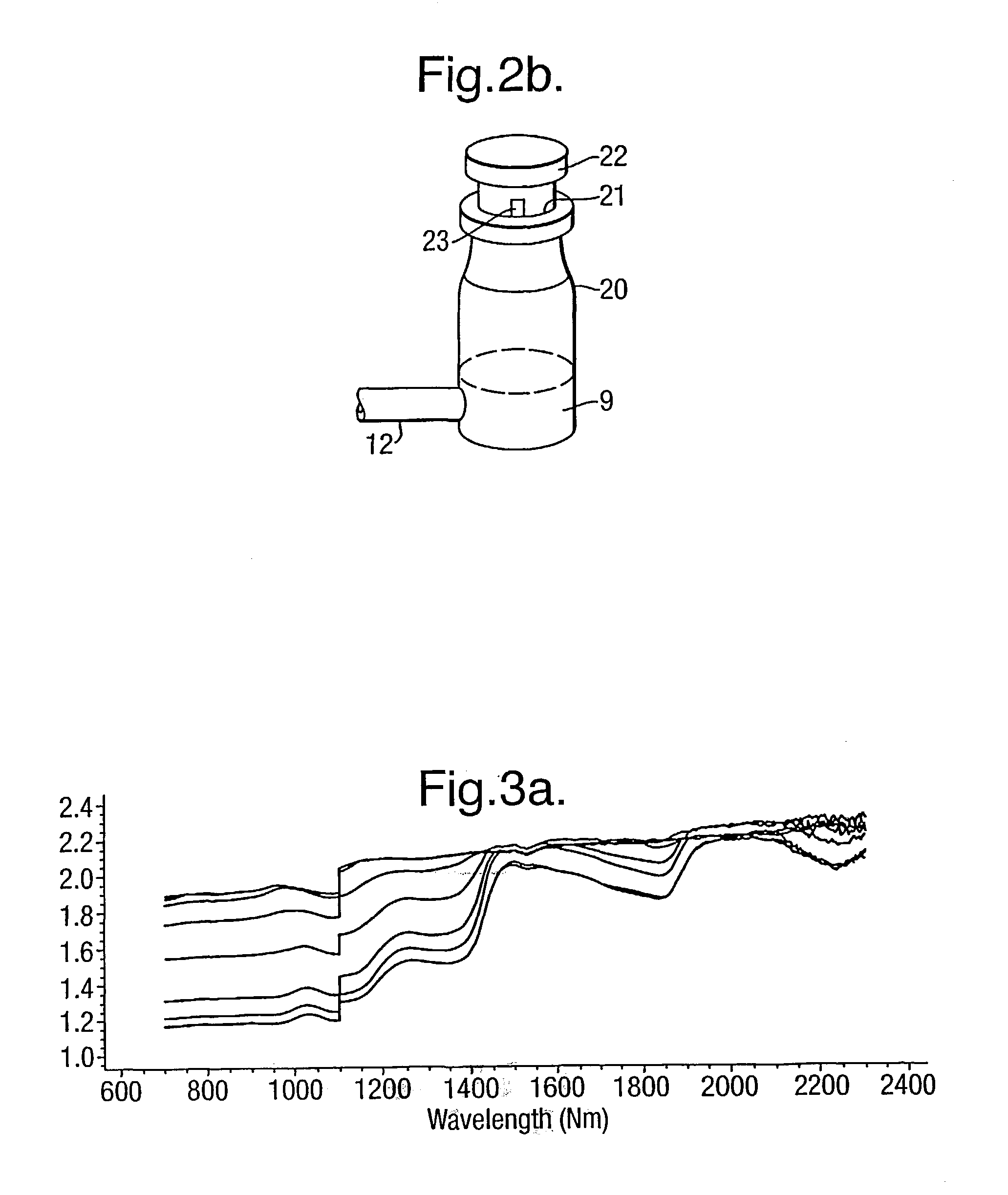

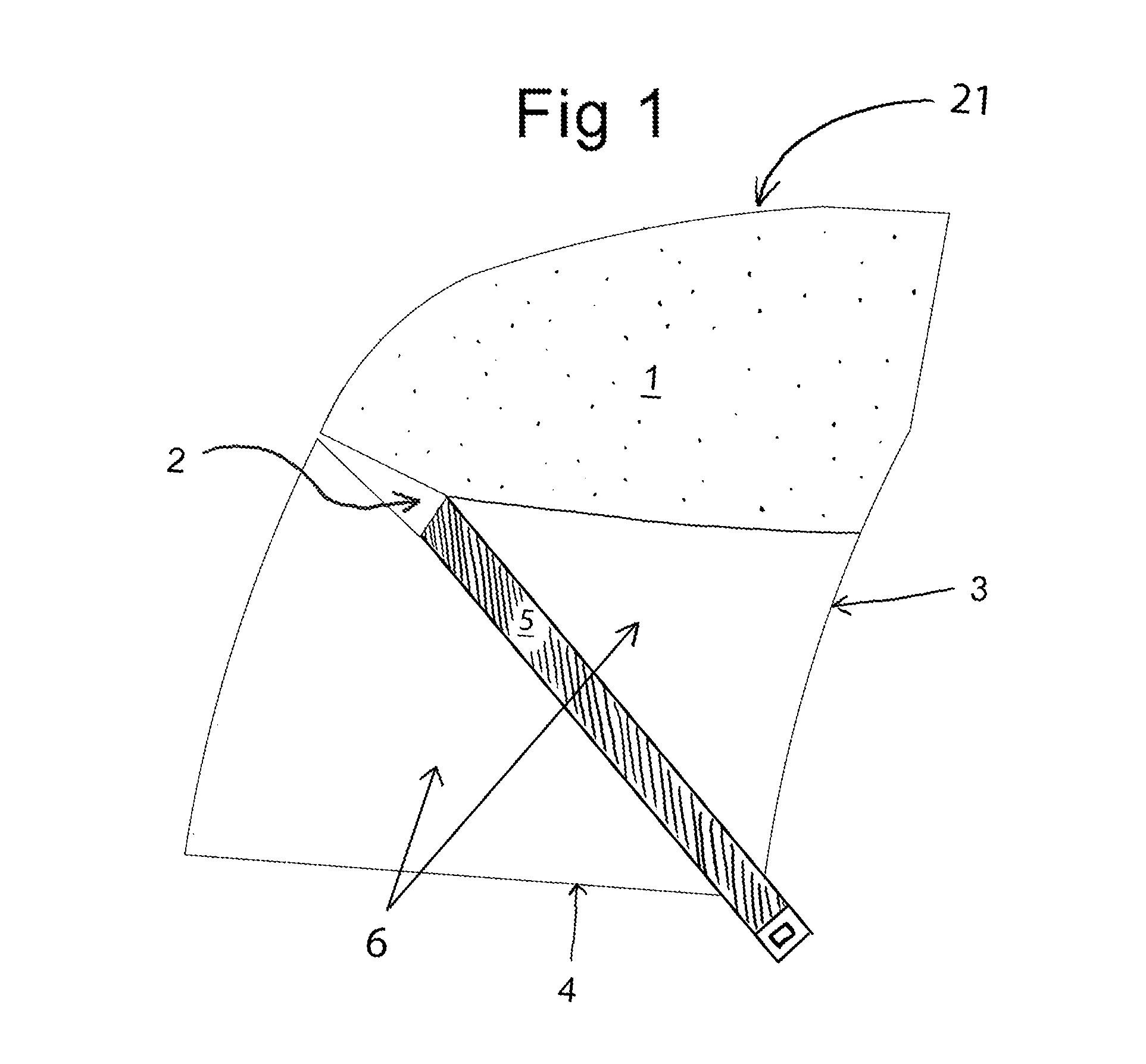

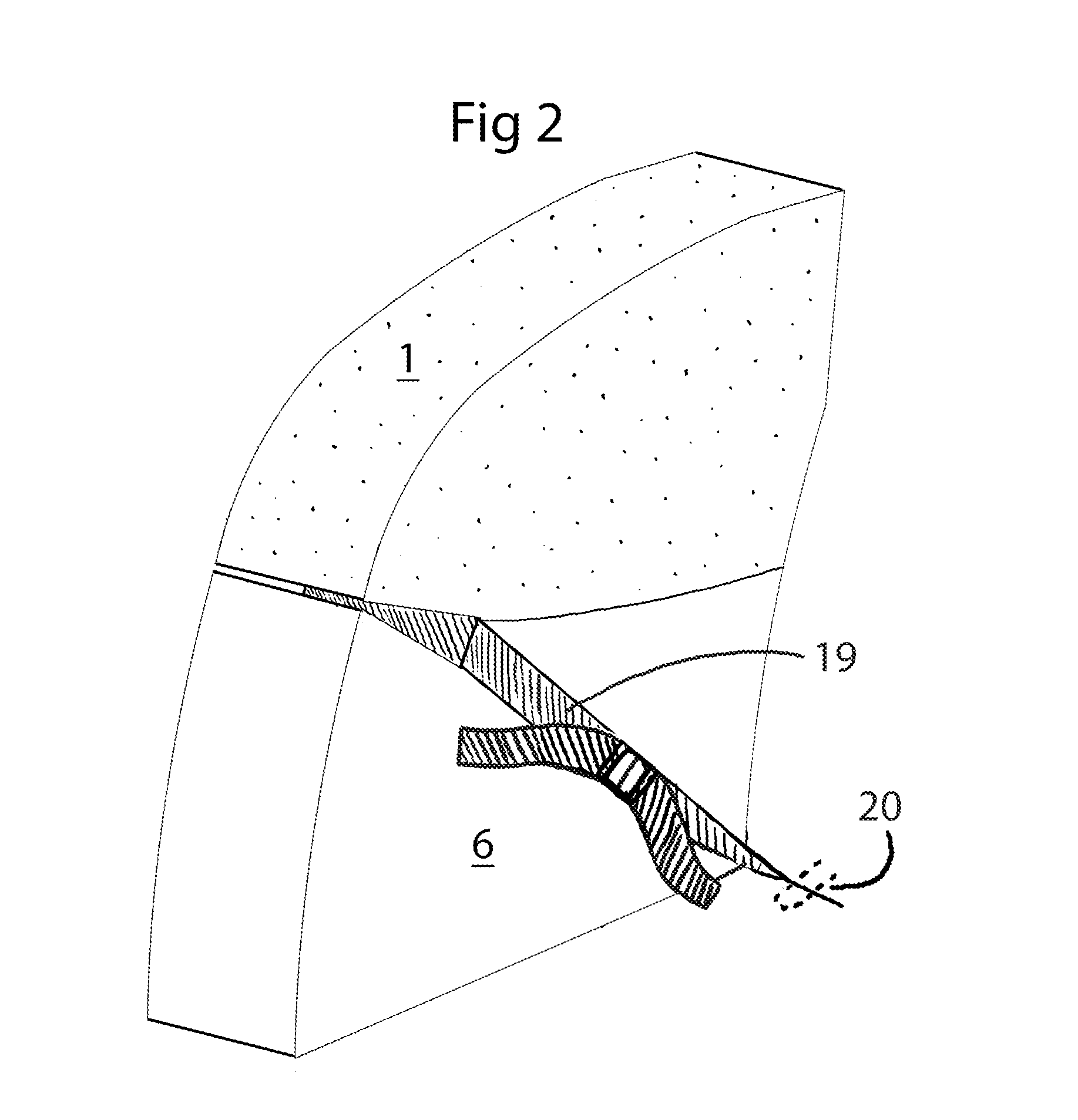

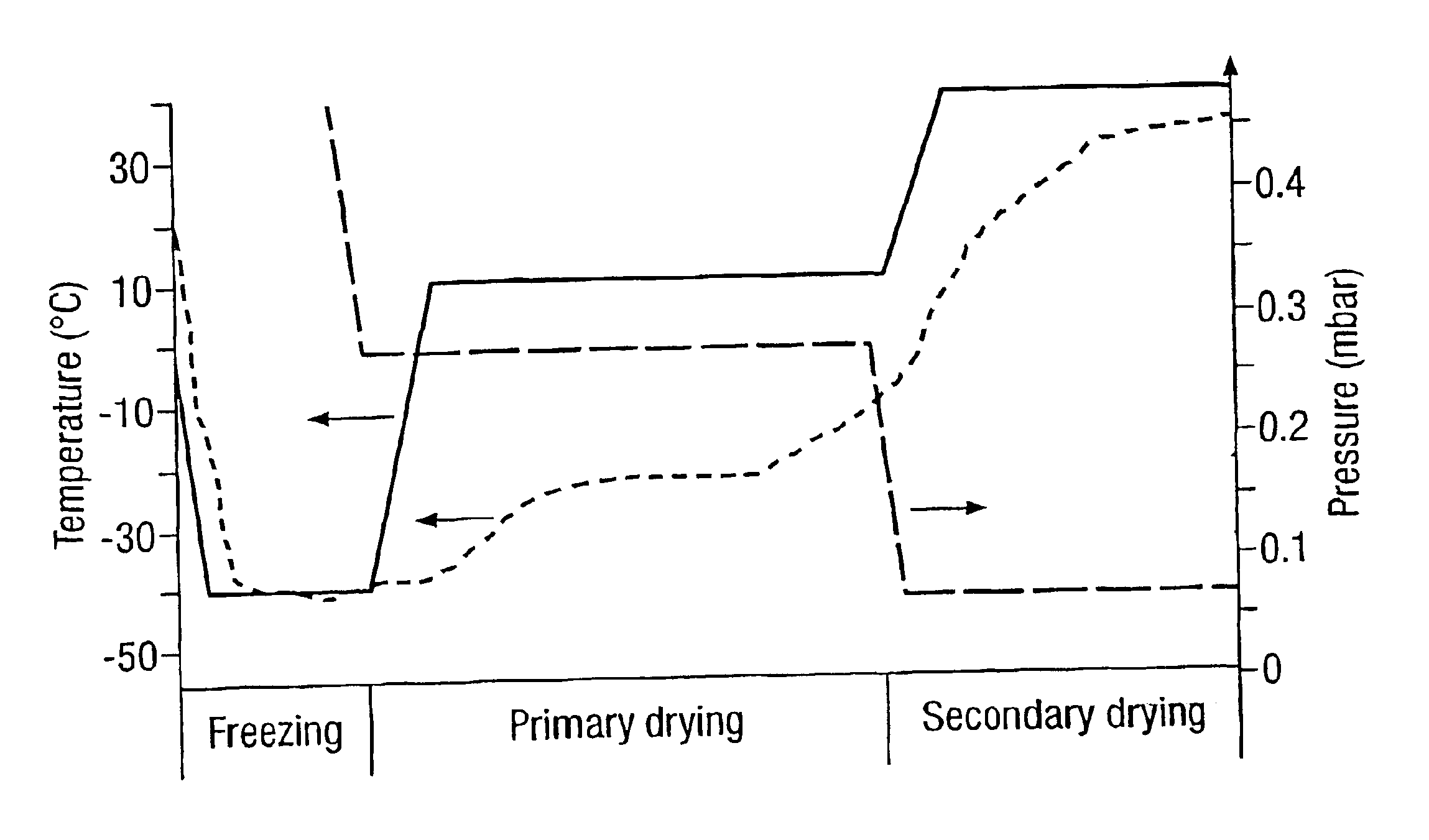

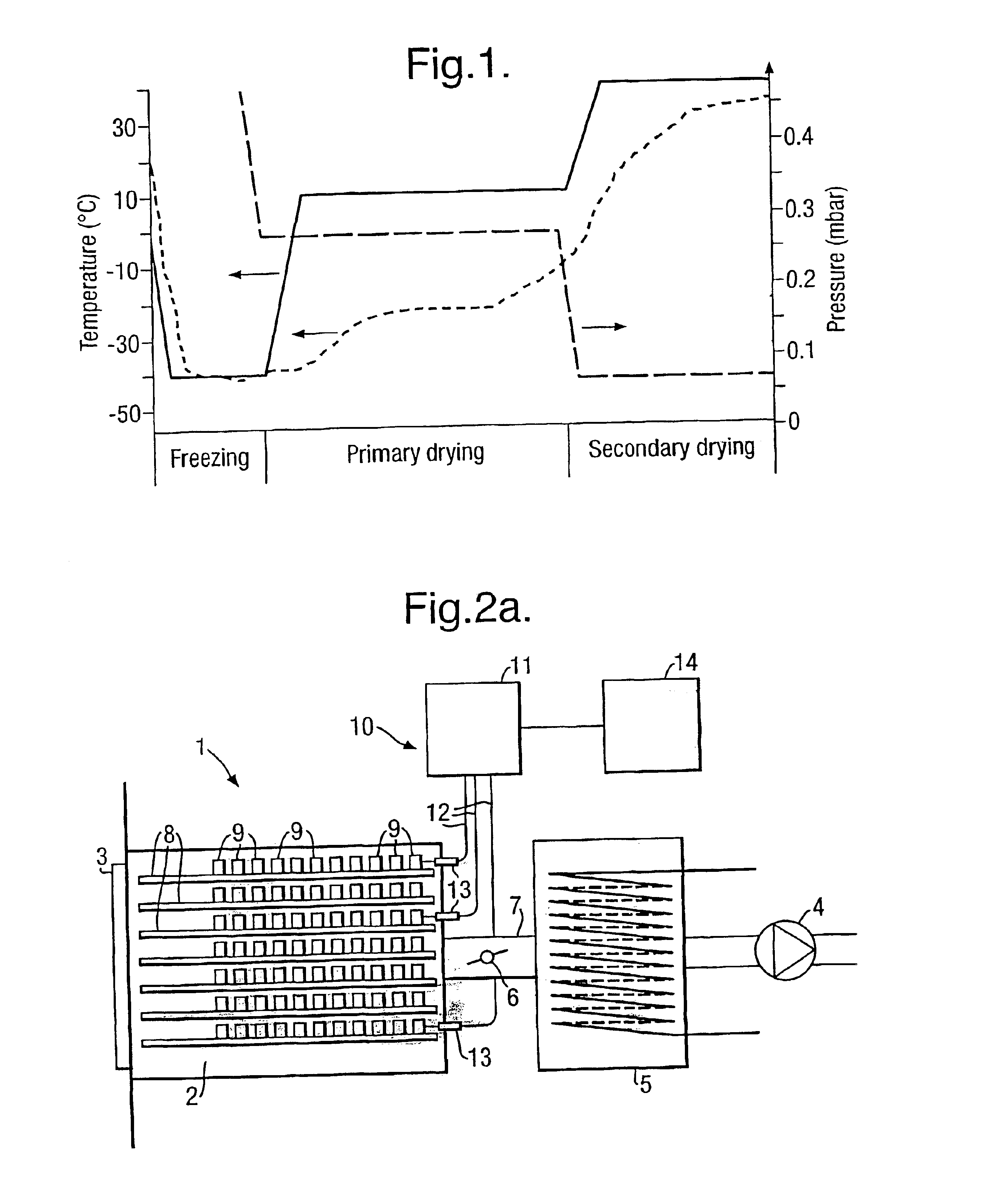

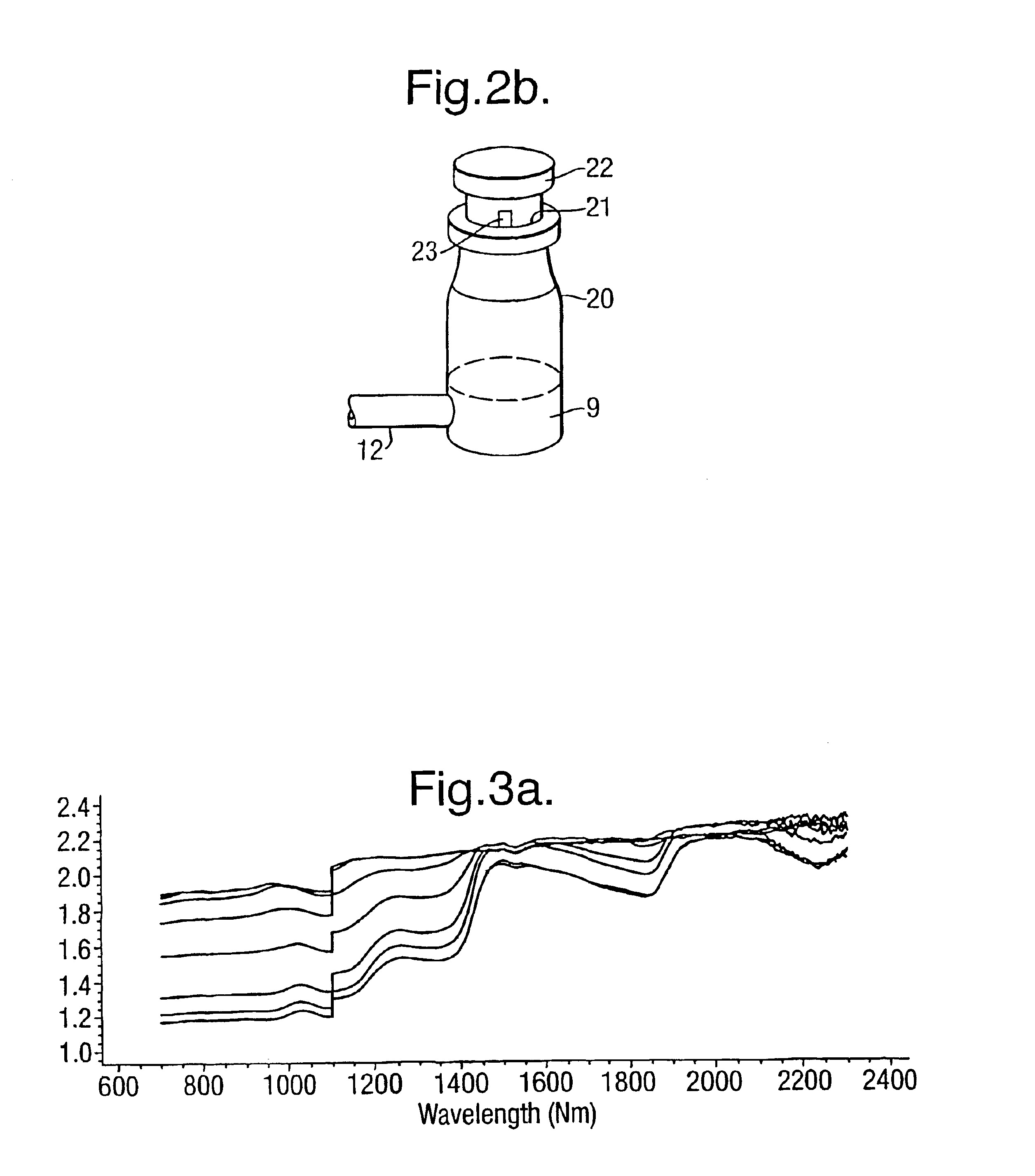

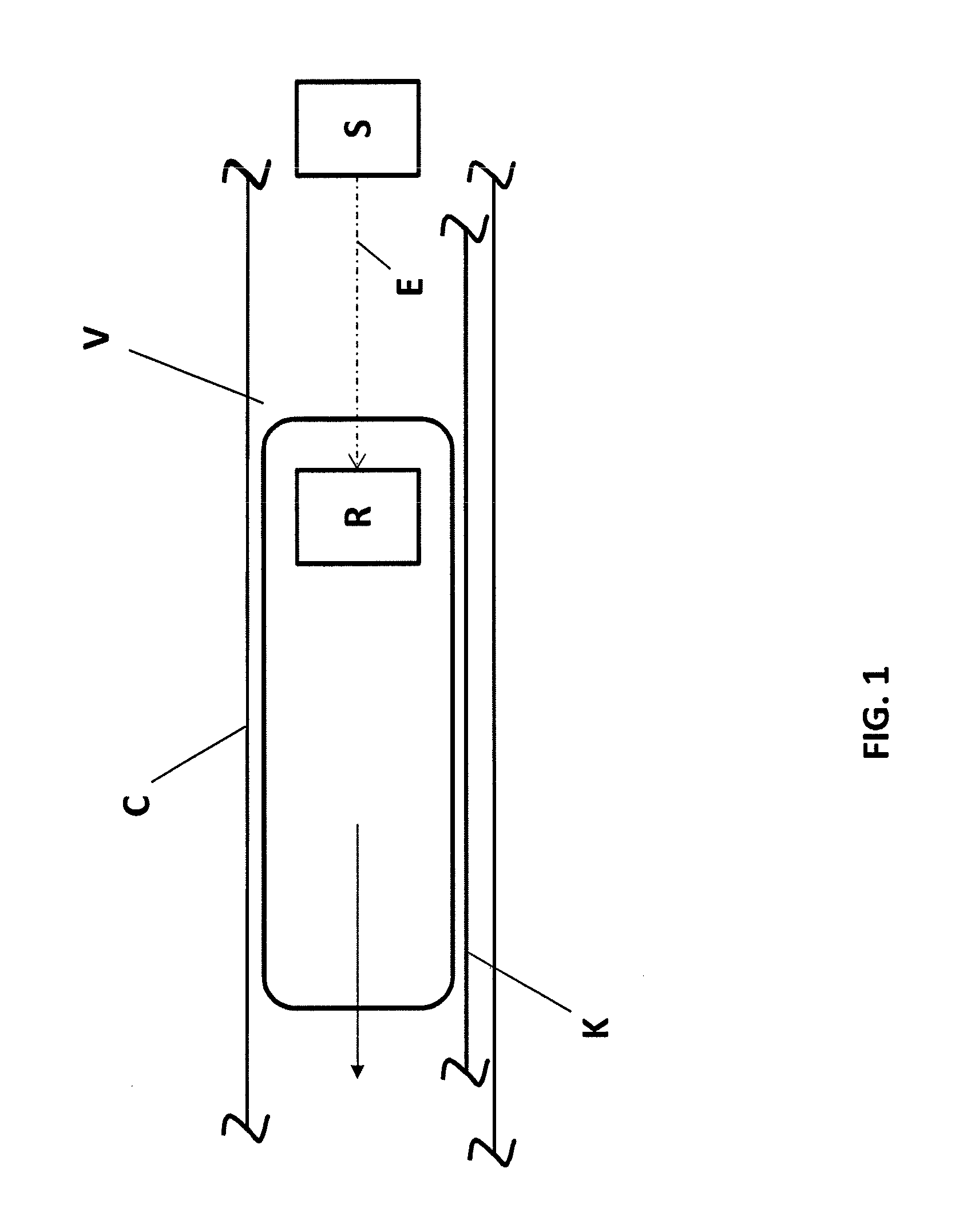

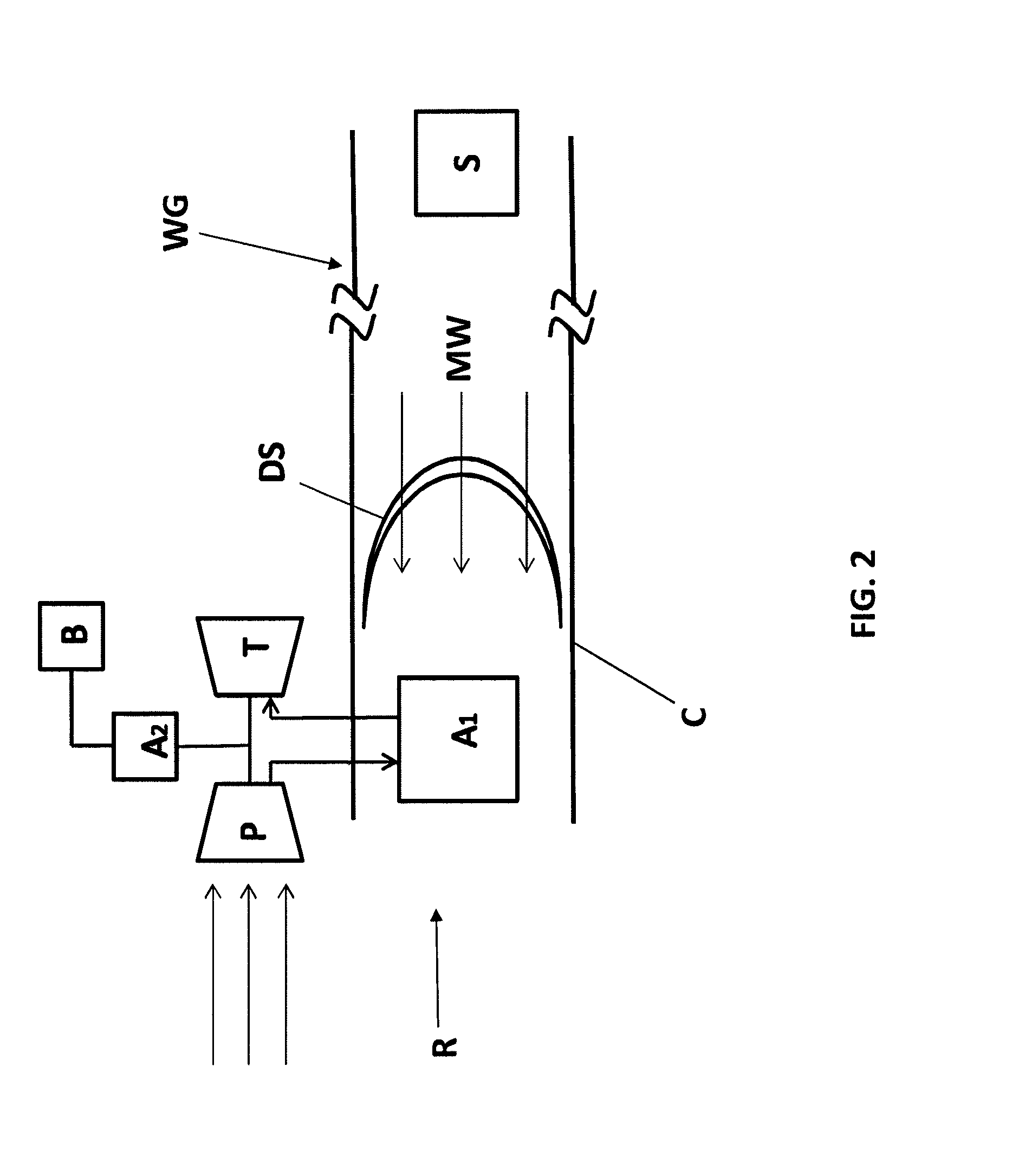

Method of monitoring a freeze drying process

InactiveUS20030116027A1Avoid physical contactMinimal redesignDrying solid materials without heatBeverage vesselsFreeze-dryingPhysical chemistry

A method of monitoring a freeze-drying process in an apparatus (1) holding one or more samples (9) of a material to be freeze dried, comprises the steps of directing input radiation onto the sample (9), the input radiation forming output radiation by interaction with the sample (9); collecting at least part of the output radiation and leading the thus collected radiation to a radiation analyzer (11); and analyzing the collected radiation spectroscopically in the radiation analyzer (11) to obtain a measurement value of one or more freeze-drying parameters of the sample (9), such as the temperature of the sample (9) and / or the content of a solvent in the sample (9) and / or the structure of the sample (9).

Owner:ASTRAZENECA AB

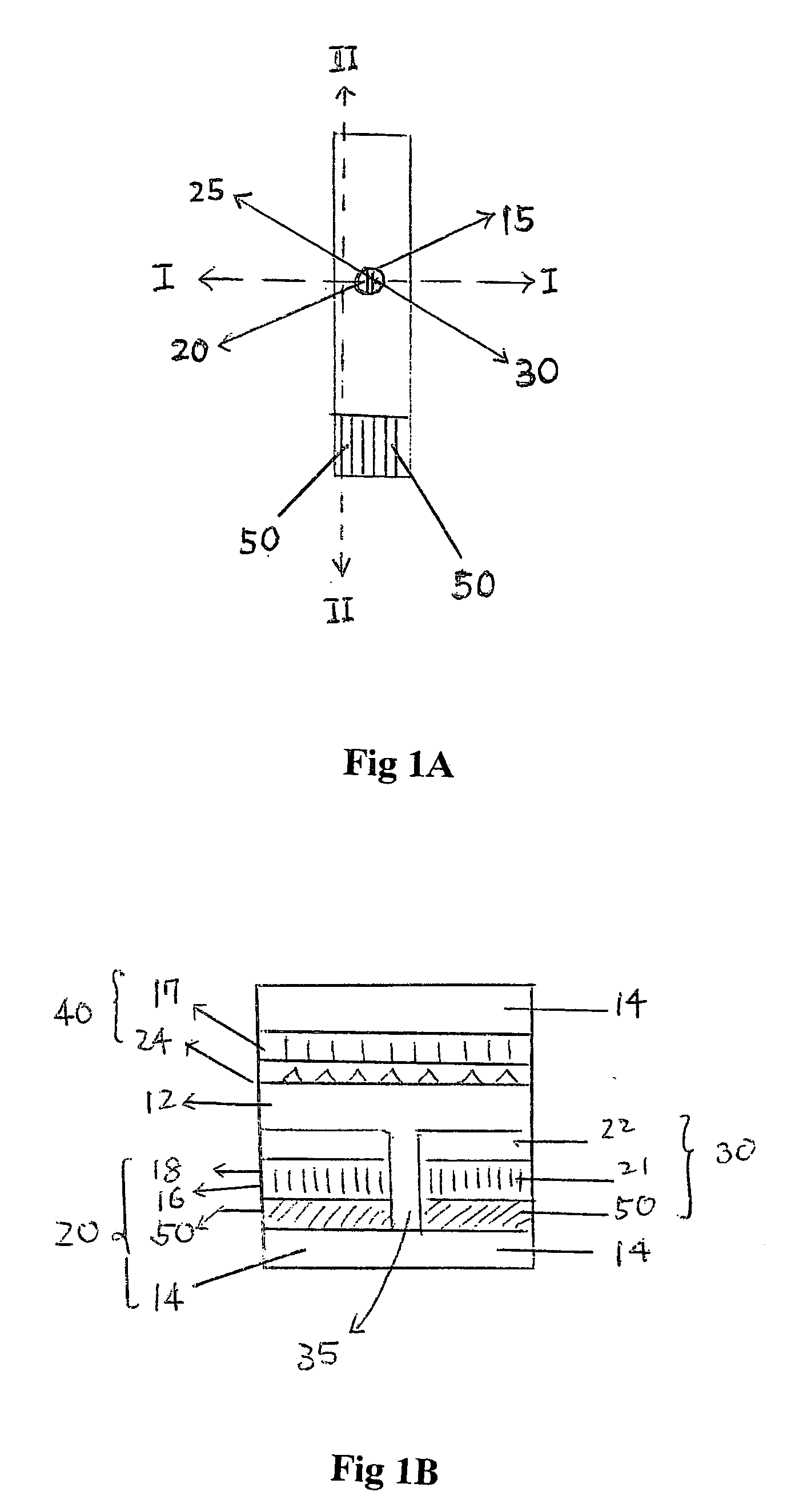

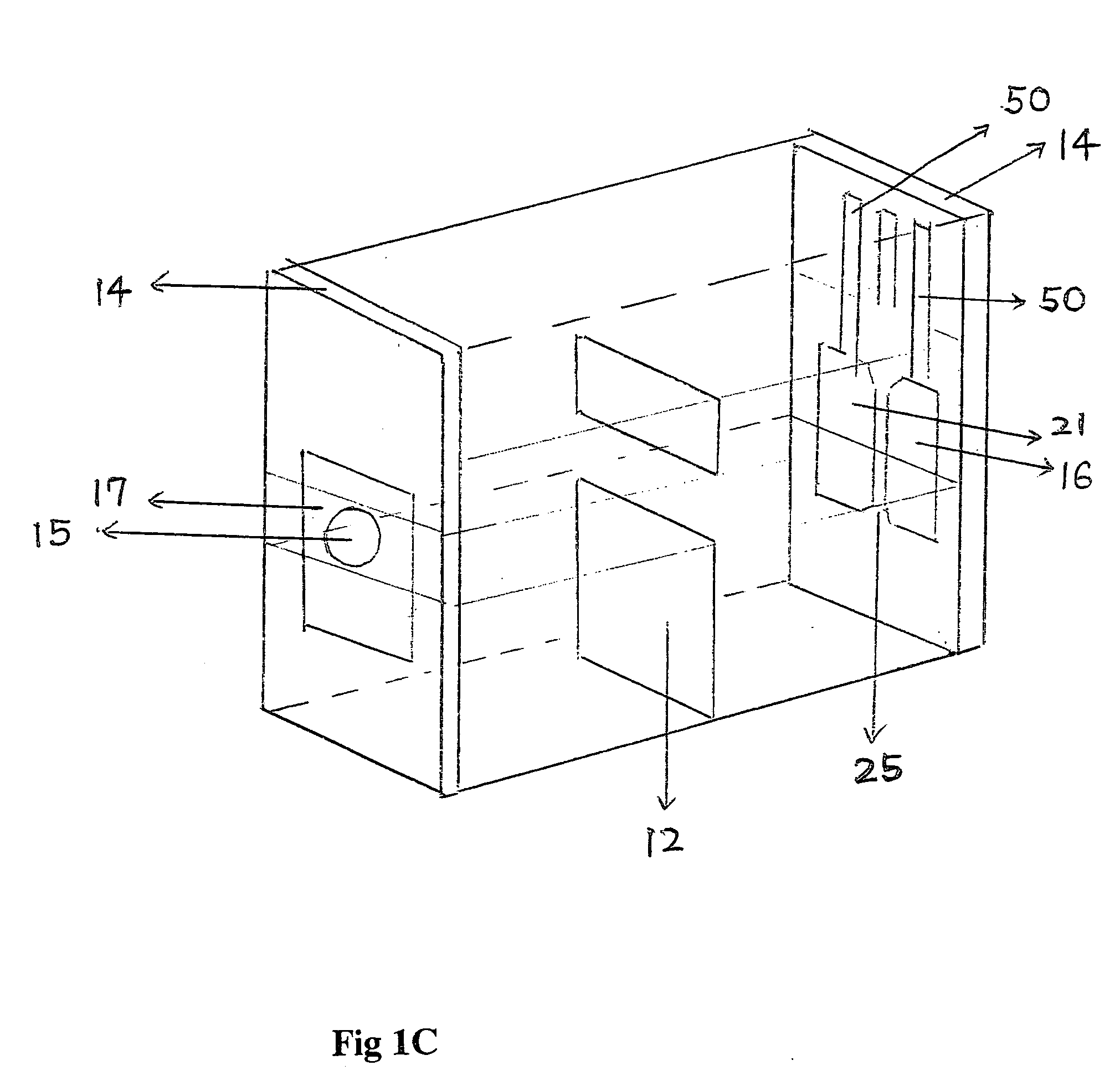

High sensitivity amperometric biosensor with side-to-side hybrid configuration

InactiveUS20050089944A1High sensitivityFast response timeMicrobiological testing/measurementEngineeringAmperometric biosensor

An amperometric glucose biosensor comprises a sensing electrode and a reference electrode arranged in a side-by-side parallel configuration on an electrically insulating sheet. A passive cover electrode is placed over the side-by-side sensing electrode and reference electrode so that the active surface of the passive cover electrode opposes the active surfaces of the side-by-side electrodes. Physical contact between the passive covering electrode and the side-by-side electrodes is prevented by insulating spacers. The sensing electrode comprises a conductive graphite track coated with a formulation comprising a redox mediator and enzyme and the reference electrode is a parallel track comprising an Ag / AgCl formulation while the passive cover electrode comprising a conductive graphite track coated with a formulation comprising the same redox mediator as used in the sensing electrode but not including an enzyme. An opening either located in the middle or at one side of the passive cover electrode allows a liquid test sample to be introduced into the sensor. The biosensor of the present invention exhibits a sensitivity and response time equal to or surpassing that of the simple face-to-face configuration while can be efficiently manufactured and permit use with conventional electrical connectors.

Owner:KS BIOMEDIX LTD

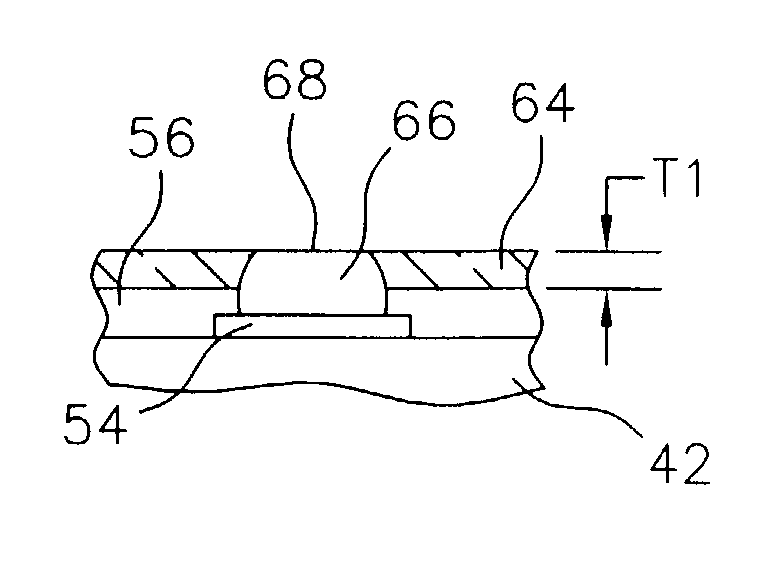

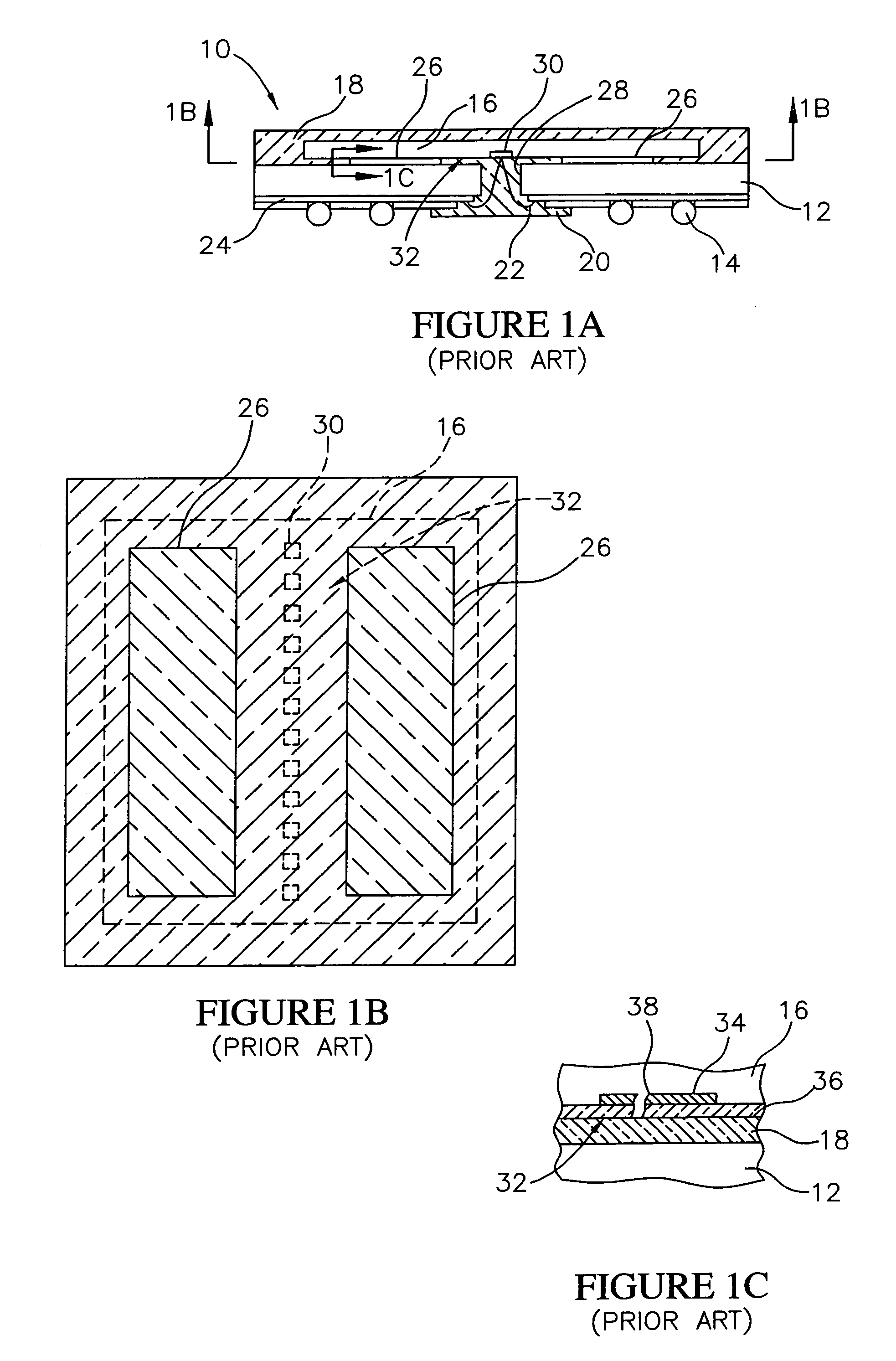

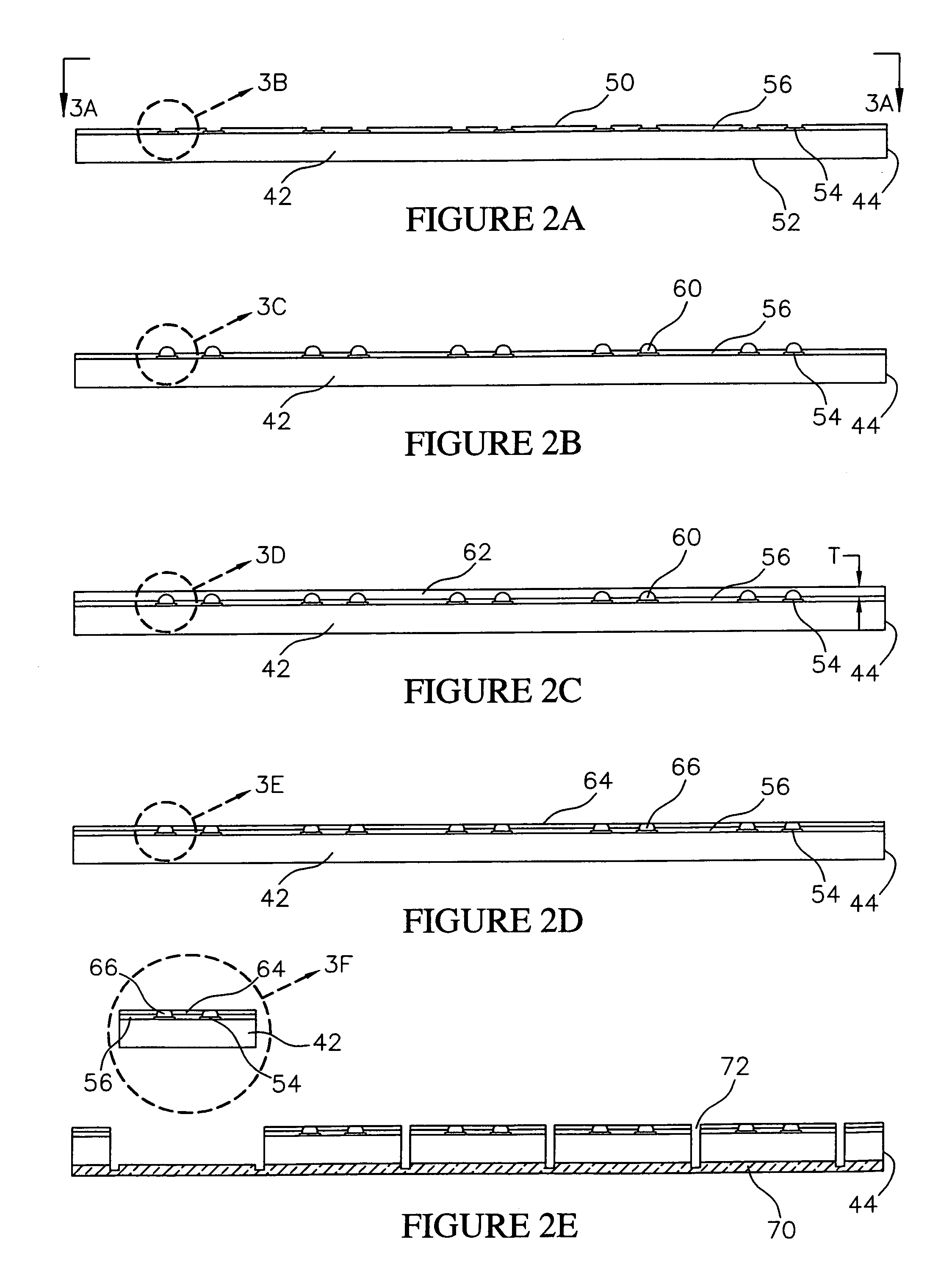

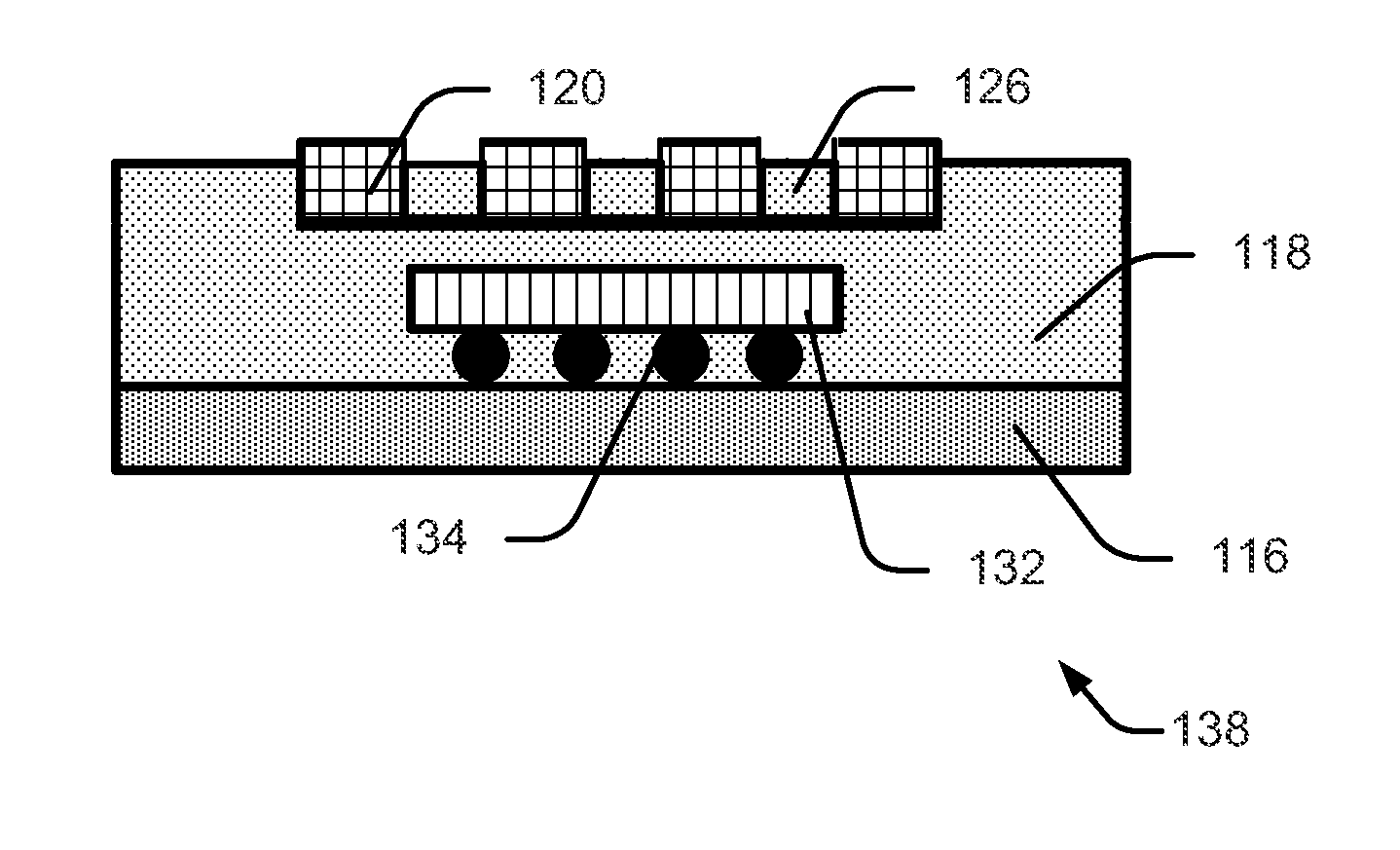

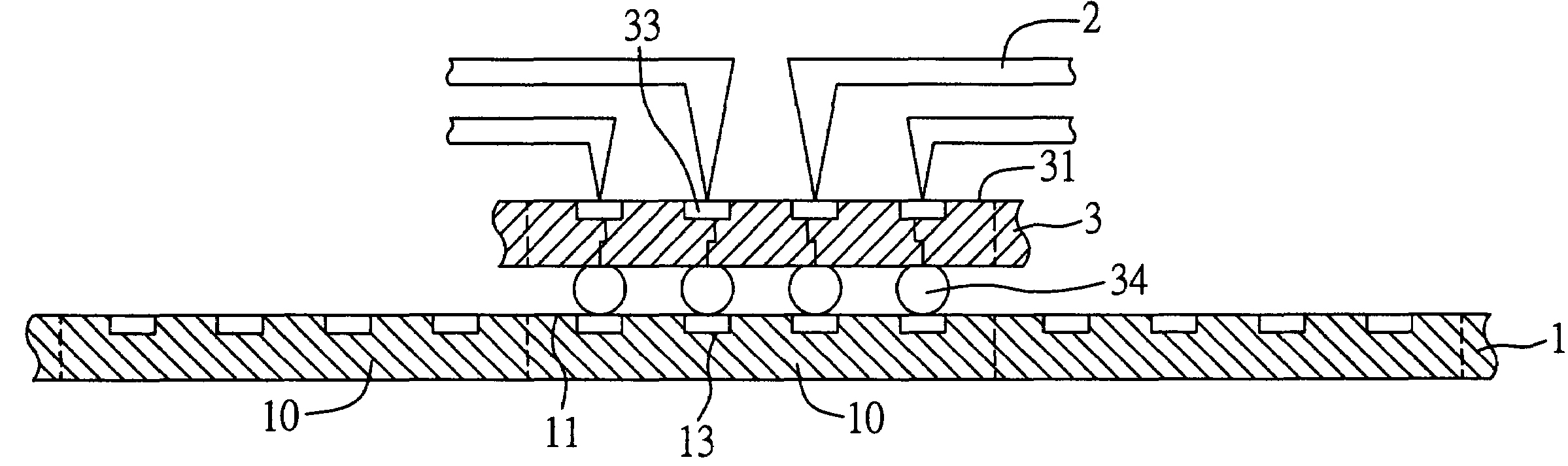

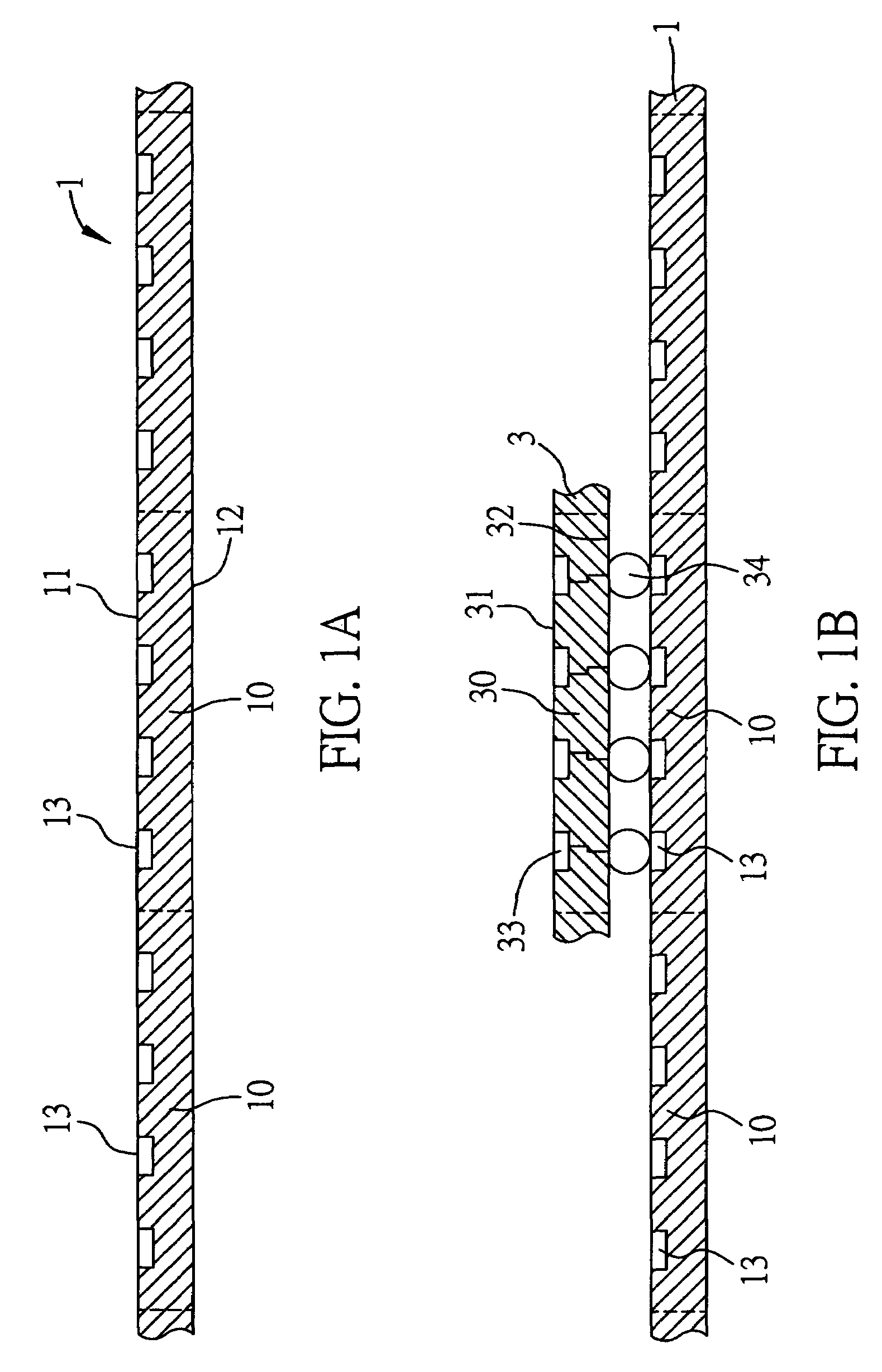

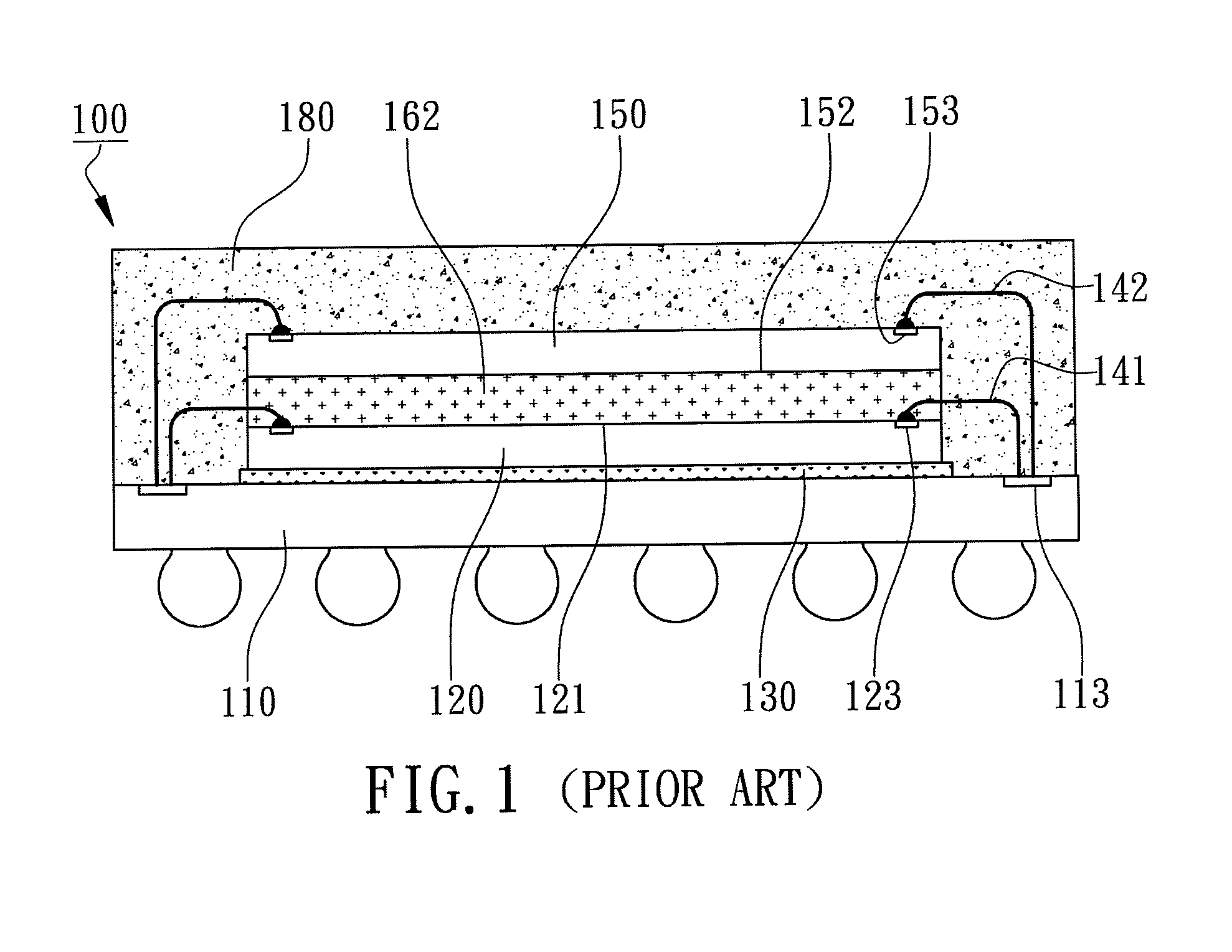

Semiconductor package with circuit side polymer layer and wafer level fabrication method

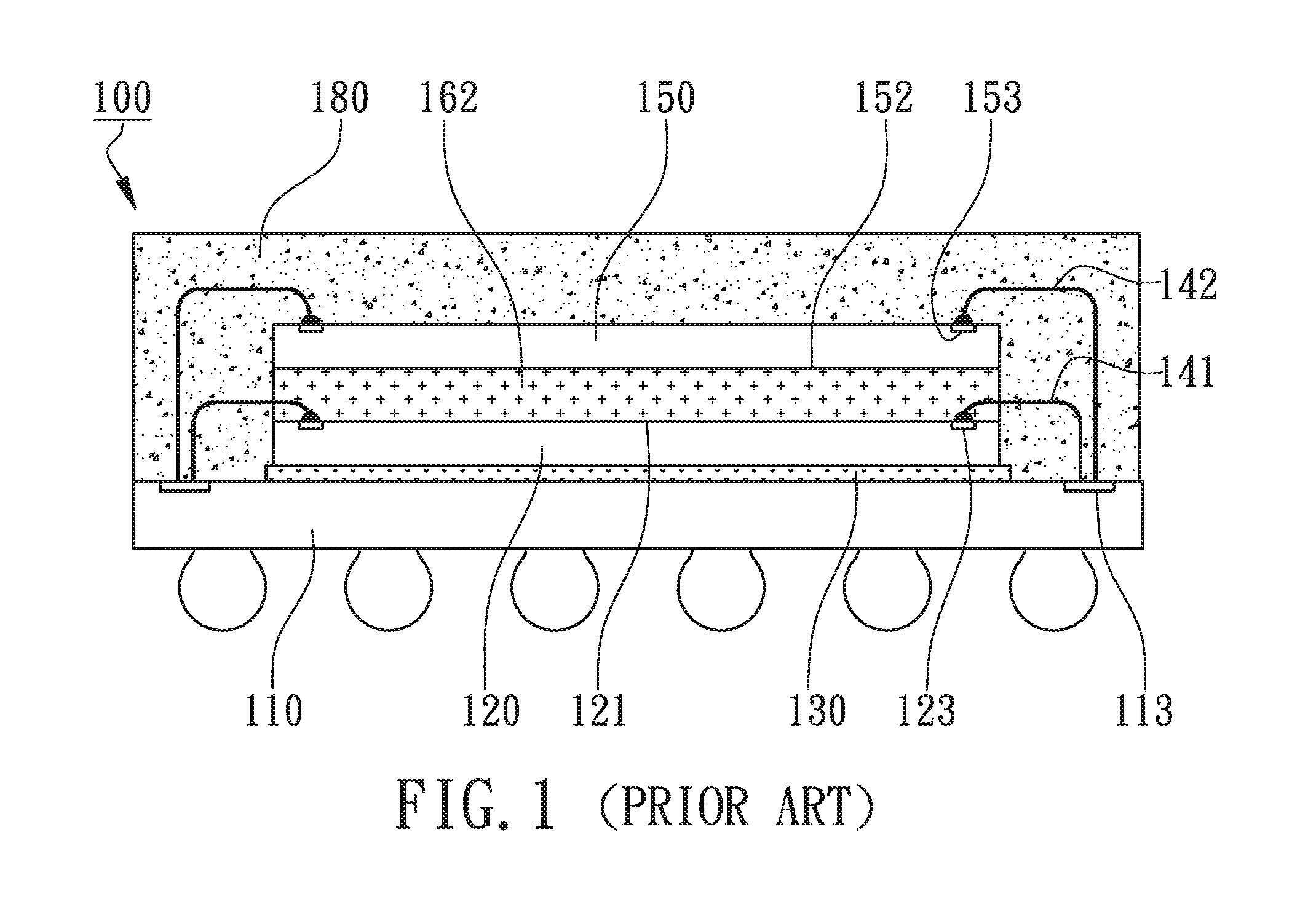

InactiveUS6995041B2Avoid physical contactDefect and stressSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a substrate, a die attached and wire bonded to the substrate, and a die encapsulant encapsulating the die. The die includes a circuit side having a pattern of die contacts, planarized wire bonding contacts bonded to the die contacts, and a planarized polymer layer on the circuit side configured as stress defect barrier. A method for fabricating the package includes the steps of forming bumps on the die, encapsulating the bumps in a polymer layer, and then planarizing the polymer layer and the bumps to form the planarized wire bonding contacts. The method also includes the steps of attaching and wire bonding the die to the substrate, and then forming the die encapsulant on the die.

Owner:MICRON TECH INC

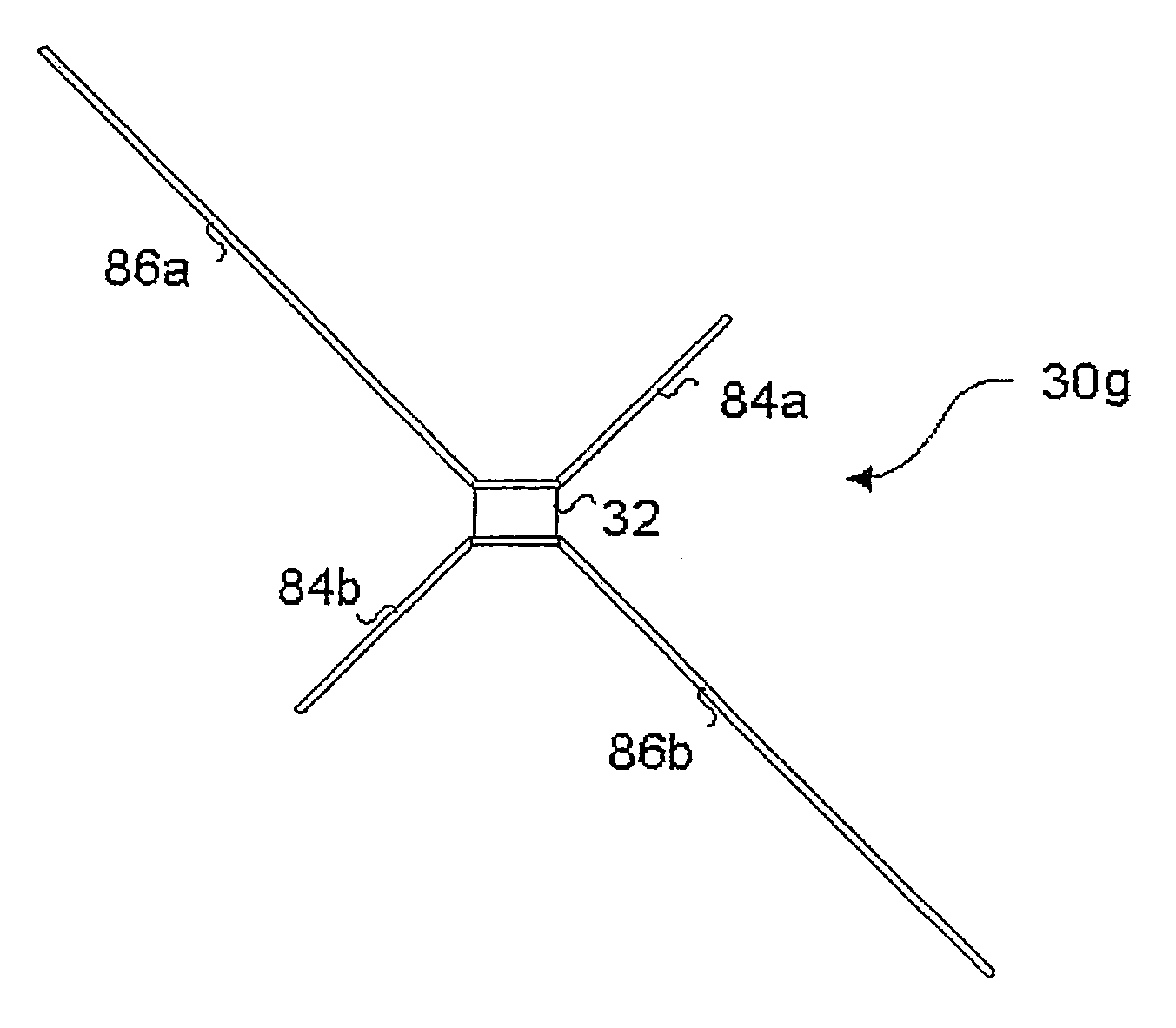

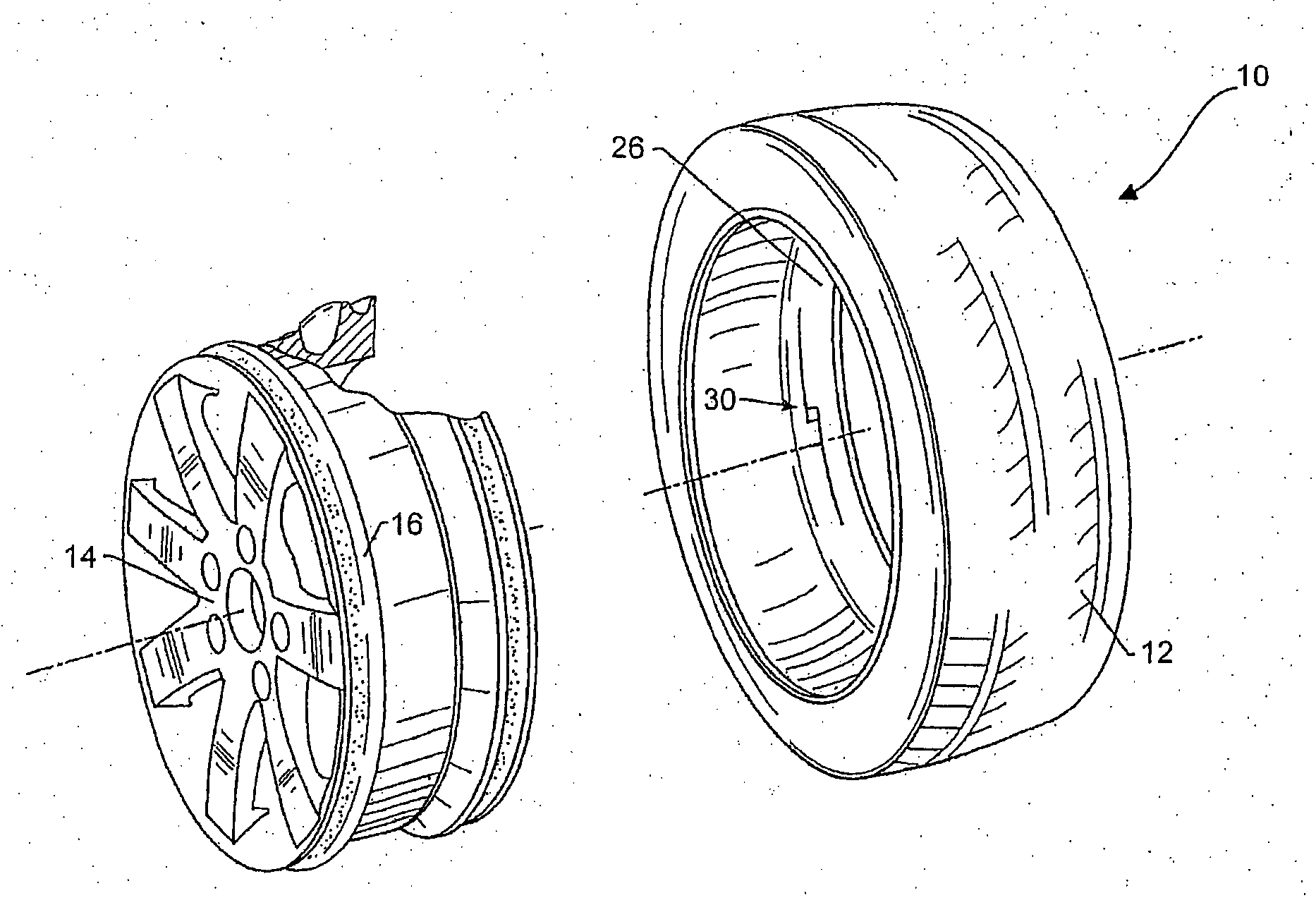

Methods for detecting, monitoring, and/or controlling behaviour of a tire in motion

InactiveUS7168308B2Uniform structureAvoid physical contactSuspensionsSubsonic/sonic/ultrasonic wave measurementElectricityMobile vehicle

A system for determining interaction between a tire and a contact surface during movement of a motor vehicle includes at least one first sensor and processing means. The at least one first sensor includes one or more first elongated piezoelectric elements which extend along at least a first portion of the tire. The at least one first sensor supplies a first signal to the processing means. The first signal is generated by rotation of the tire and is generated cyclically with each revolution of the tire. The processing means detects variations in time intervals between distinctive elements of the first signal. A tire including the system, a kit for detecting behaviour of a tire moving with respect to a contact surface, a method for monitoring events correlated with interactions between tires of a moving vehicle and a contact surface, and related systems, tires, methods, and vehicles are also disclosed.

Owner:PIRELLI TYRE SPA

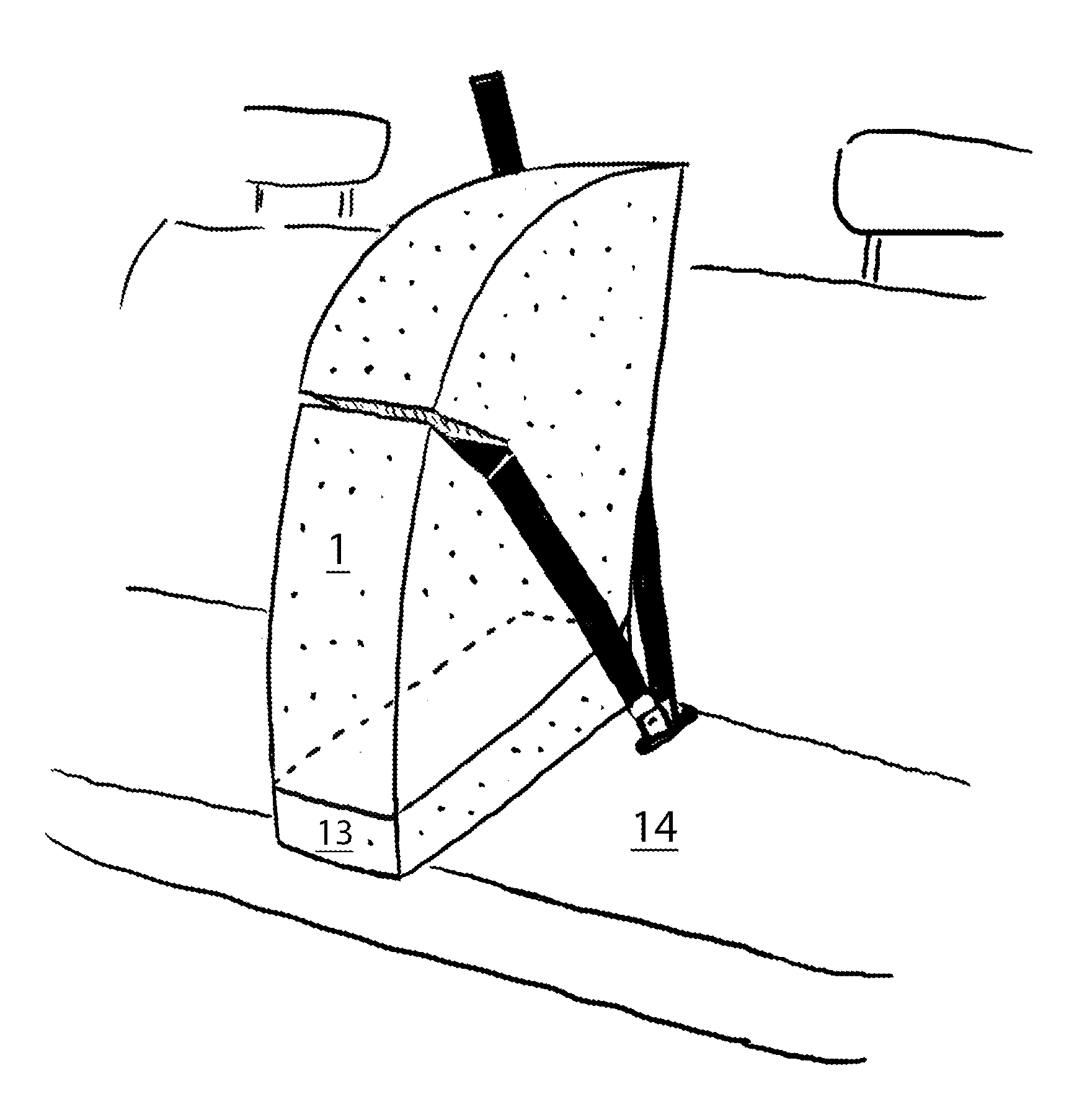

Automobile seat divider—the backseat buddy

InactiveUS9580031B2Simple and safe processQuick installationSeat coveringsPedestrian/occupant safety arrangementPhysical BarrierPrism

A divider configured to be secured in the seats of automobiles for forming a physical barrier between passengers is disclosed herein. The divider can be used for children, pets, or adults. A rectangular prism shaped booster may be provided below the divider for raising the height of the divider. The profile of the divider is designed to fit securely against the back of a seat and the bottom of the seat. The curved front side of the divider allows the driver to view all passengers, maintain views out the windows, and still be an effective barrier without being so large as to be in the way. A notch is provided in the curved front side of the divider for receiving a seat belt or strap for securing the divider. The divider and the booster may have removable covers with pockets for holding items, such as water bottles, tissues, and wipes.

Owner:KALIS JENNIFER

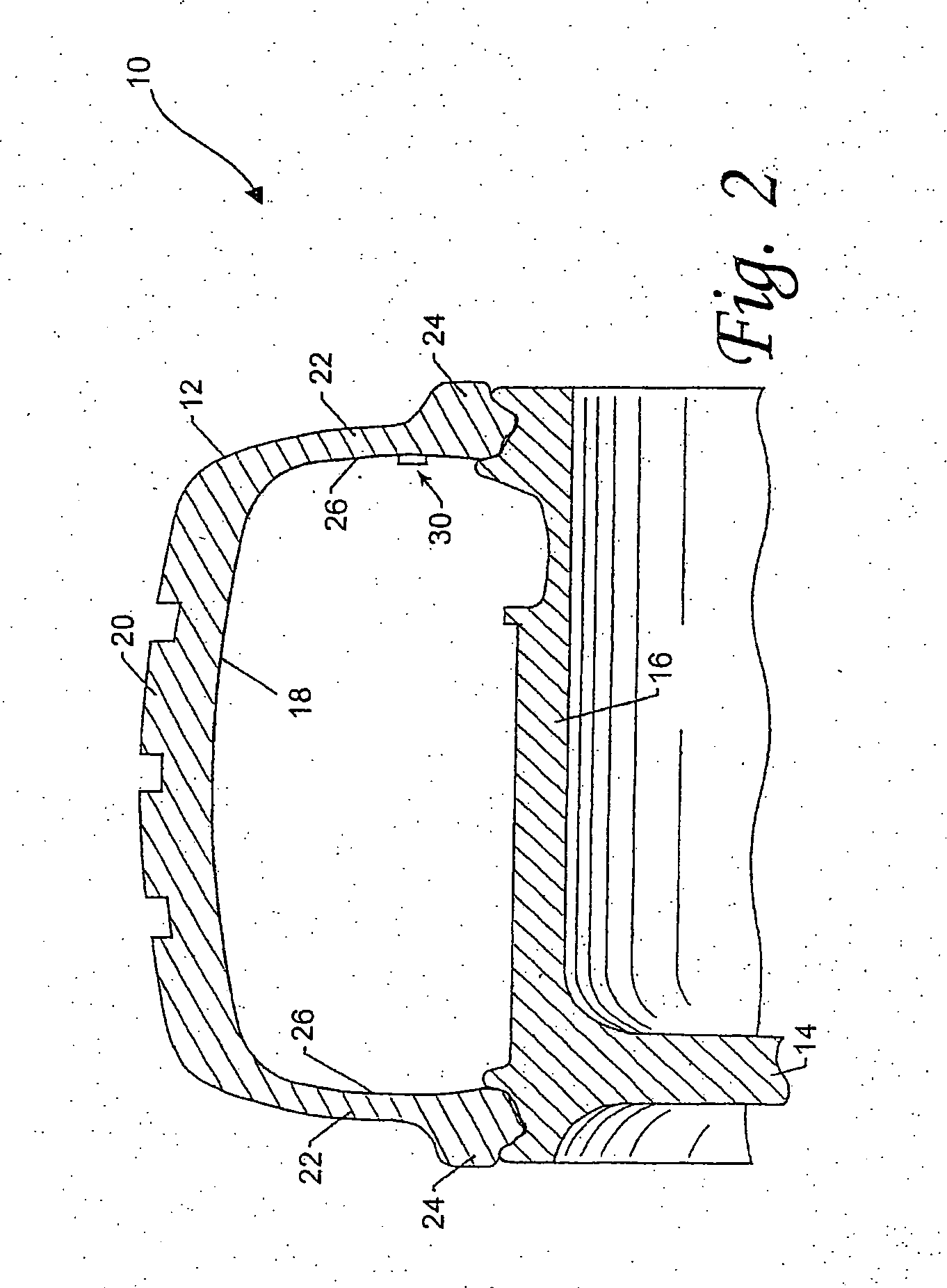

Tire electronics assembly having a multi-frequency antenna

ActiveUS7091841B2Easy to manufactureHigh mechanical strengthSimultaneous aerial operationsAntenna supports/mountingsIntegrated electronicsEngineering

A tire assembly with integrated electronic components includes a tire structure and an integrated electronics assembly, which preferably includes at least a radio frequency (RF) device and a multi-frequency antenna that enables wireless communication in at least first and second resonant frequency bands. Such multi-frequency antenna further comprises at least first and second antenna wires connected to the RF device, thus facilitating the transmission of RF signals which may include information such as tire identification information or measured condition information such as tire temperature, pressure, and other characteristics. The first and second antenna wires preferably function together as at least two dipole antennas, for example, two half-wave dipole antennas, or one half-wave dipole antenna and one three-half-wave dipole antenna. A two-wire configuration may be more readily implemented and also designed to reduce strains concentrated at the connection point(s) between the RF device and the antenna wires.

Owner:MICHELIN RECH & TECH SA

Method of monitoring a freeze drying process

InactiveUS6848196B2Minimal influenceAvoid physical contactDrying using combination processesDrying solid materials with heatFreeze-dryingSolvent

A method of monitoring a freeze-drying process in an apparatus (1) holding one or more samples (9) of a material to be freeze dried, comprises the steps of directing input radiation onto the sample (9), the input radiation forming output radiation by interaction with the sample (9); collecting at least part of the output radiation and leading the thus collected radiation to a radiation analyzer (11); and analyzing the collected radiation spectroscopically in the radiation analyzer (11) to obtain a measurement value of one or more freeze-drying parameters of the sample (9), such as the temperature of the sample (9) and / or the content of a solvent in the sample (9) and / or the structure of the sample (9).

Owner:ASTRAZENECA AB

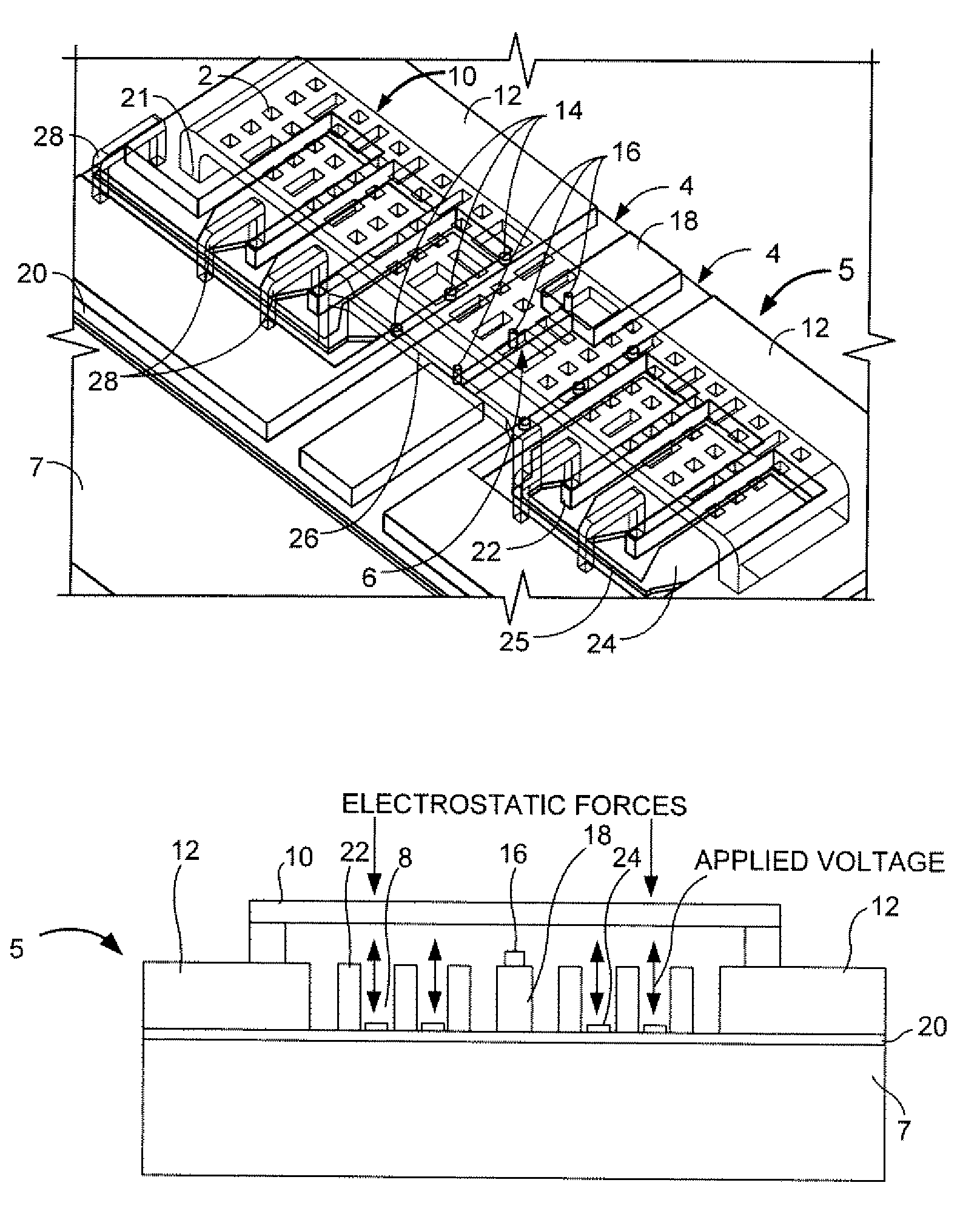

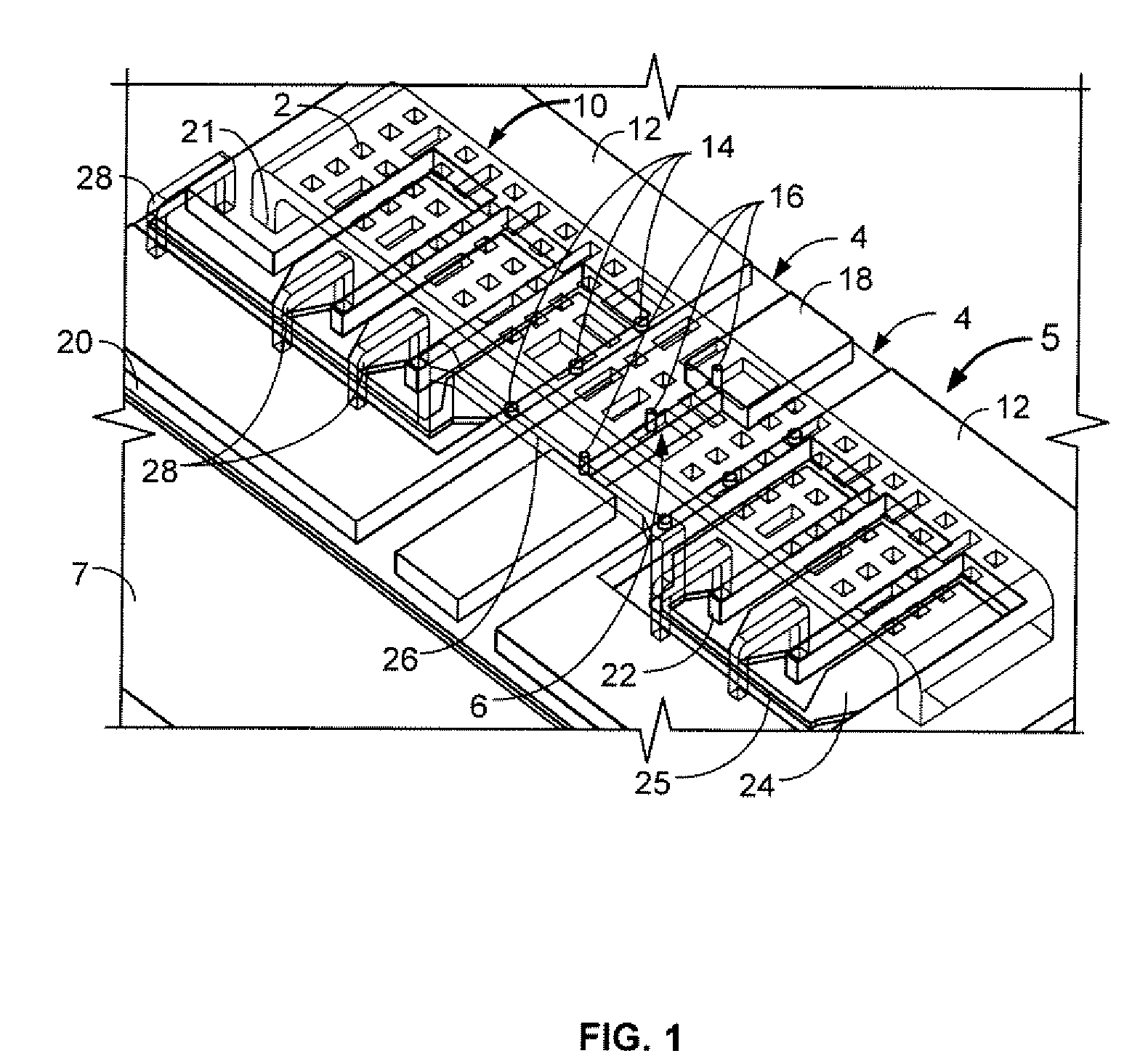

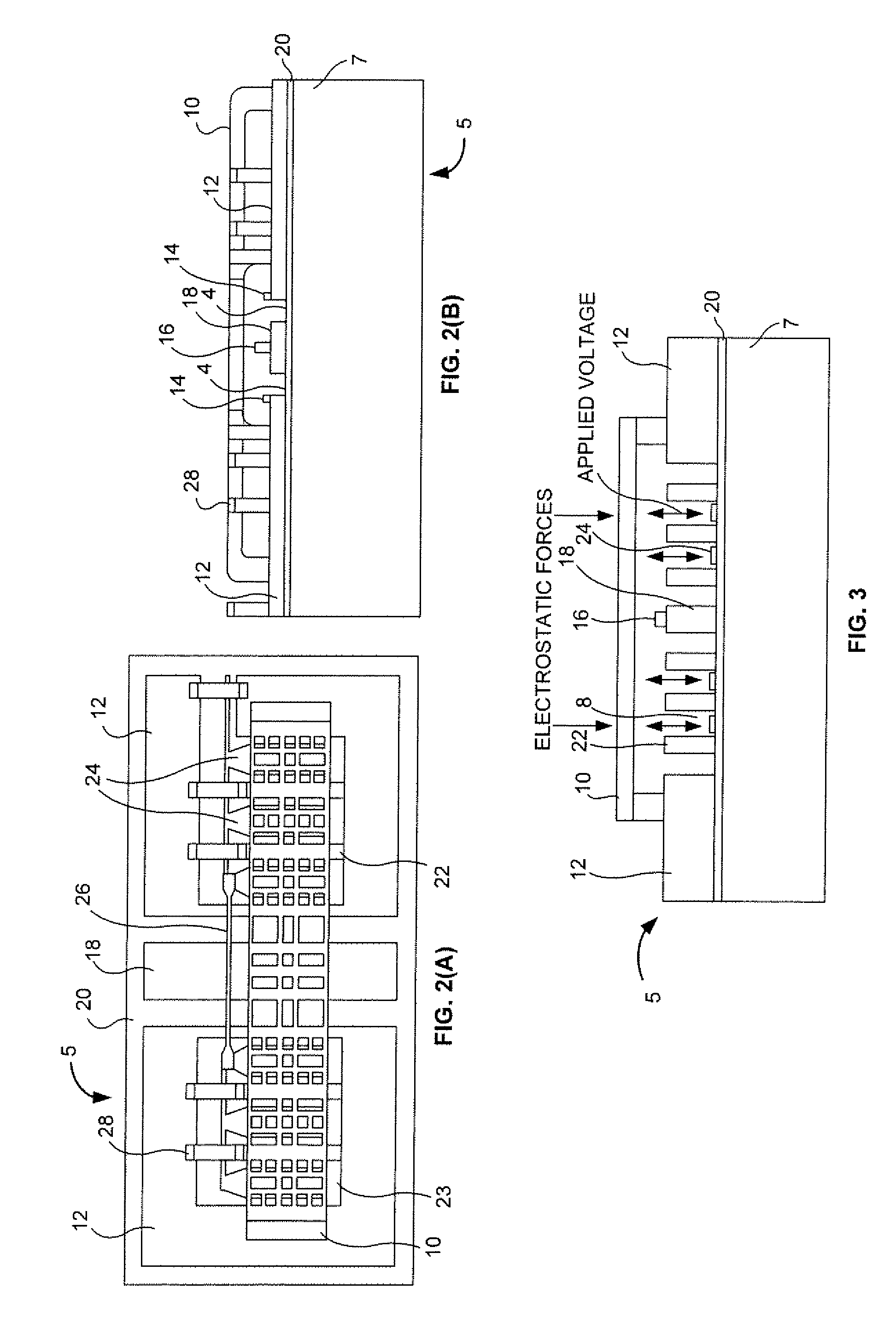

Electronic ohmic shunt RF MEMS switch and method of manufacture

InactiveUS8461948B2Avoid physical contactElectrostatic/electro-adhesion relaysElectric switchesCoplanar waveguideMicroelectromechanical systems

An electrostatic ohmic shunt radio frequency (RF) microelectromechanical system (MEMS) switch and method of manufacturing includes a co-planar waveguide (CPW) transmission line comprising a plurality of slots and a plurality of pillars, wherein a space between successive ones of the plurality of pillars is defined by one of the plurality of slots; a plurality of electrodes positioned in the slots; a conductive contact beam elevated over the CPW transmission line and the plurality of electrodes; and a plurality of conductive contact dimples positioned between the conductive contact beam and the CPW transmission line, wherein the plurality of pillars are adapted to prevent physical contact between the plurality of electrodes and the conductive contact beam.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Tire electronics assembly having a multi-frequency antenna

ActiveUS20050275518A1Easy to manufactureHigh mechanical strengthSimultaneous aerial operationsAntenna supports/mountingsIntegrated electronicsElectronic component

A tire assembly with integrated electronic components includes a tire structure and an integrated electronics assembly, which preferably includes at least a radio frequency (RF) device and a multi-frequency antenna that enables wireless communication in at least first and second resonant frequency bands. Such multi-frequency antenna further comprises at least first and second antenna wires connected to the RF device, thus facilitating the transmission of RF signals which may include information such as tire identification information or measured condition information such as tire temperature, pressure, and other characteristics. The first and second antenna wires preferably function together as at least two dipole antennas, for example, two half-wave dipole antennas, or one half-wave dipole antenna and one three-half-wave dipole antenna. A two-wire configuration may be more readily implemented and also designed to reduce strains concentrated at the connection point(s) between the RF device and the antenna wires.

Owner:MICHELIN RECH & TECH SA

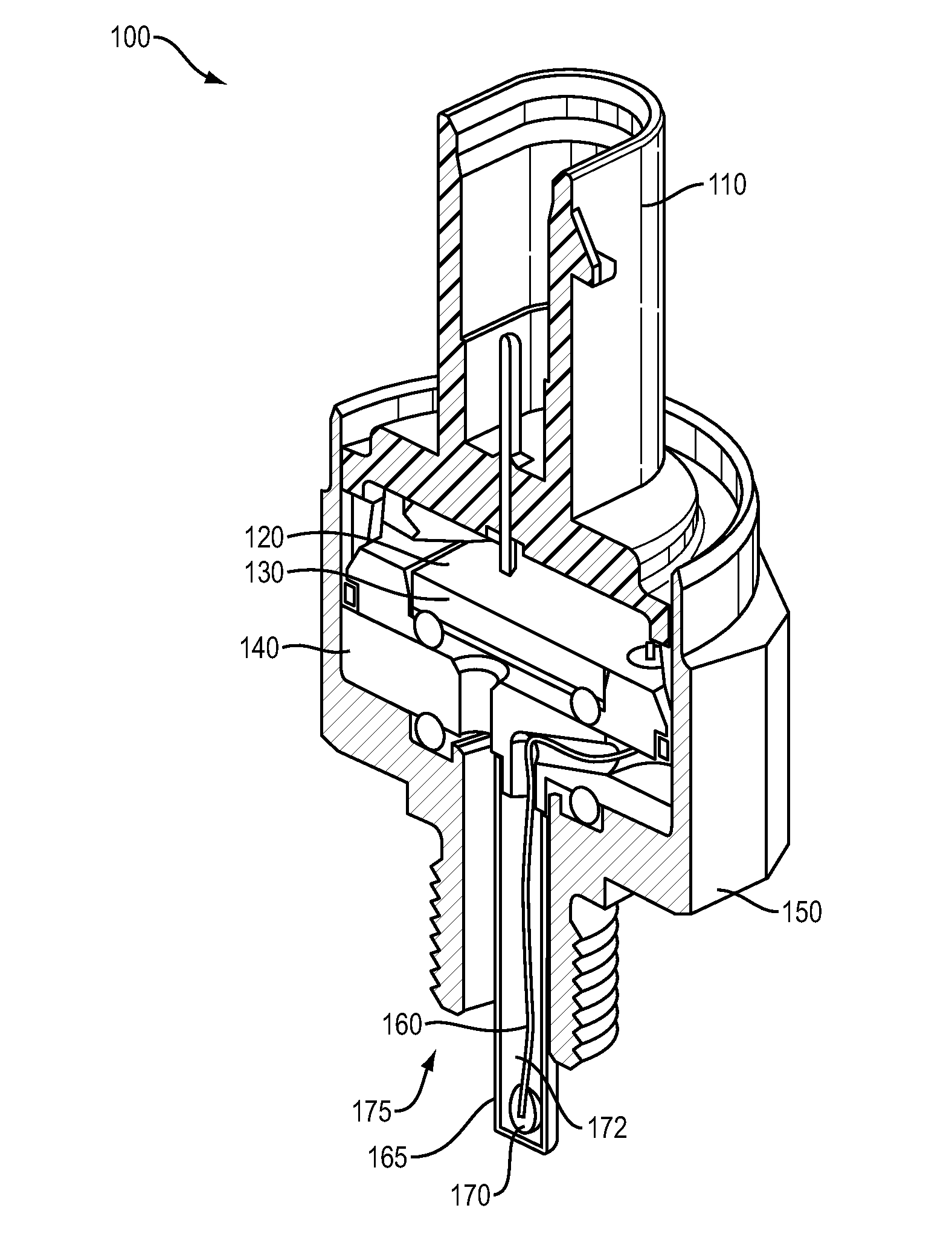

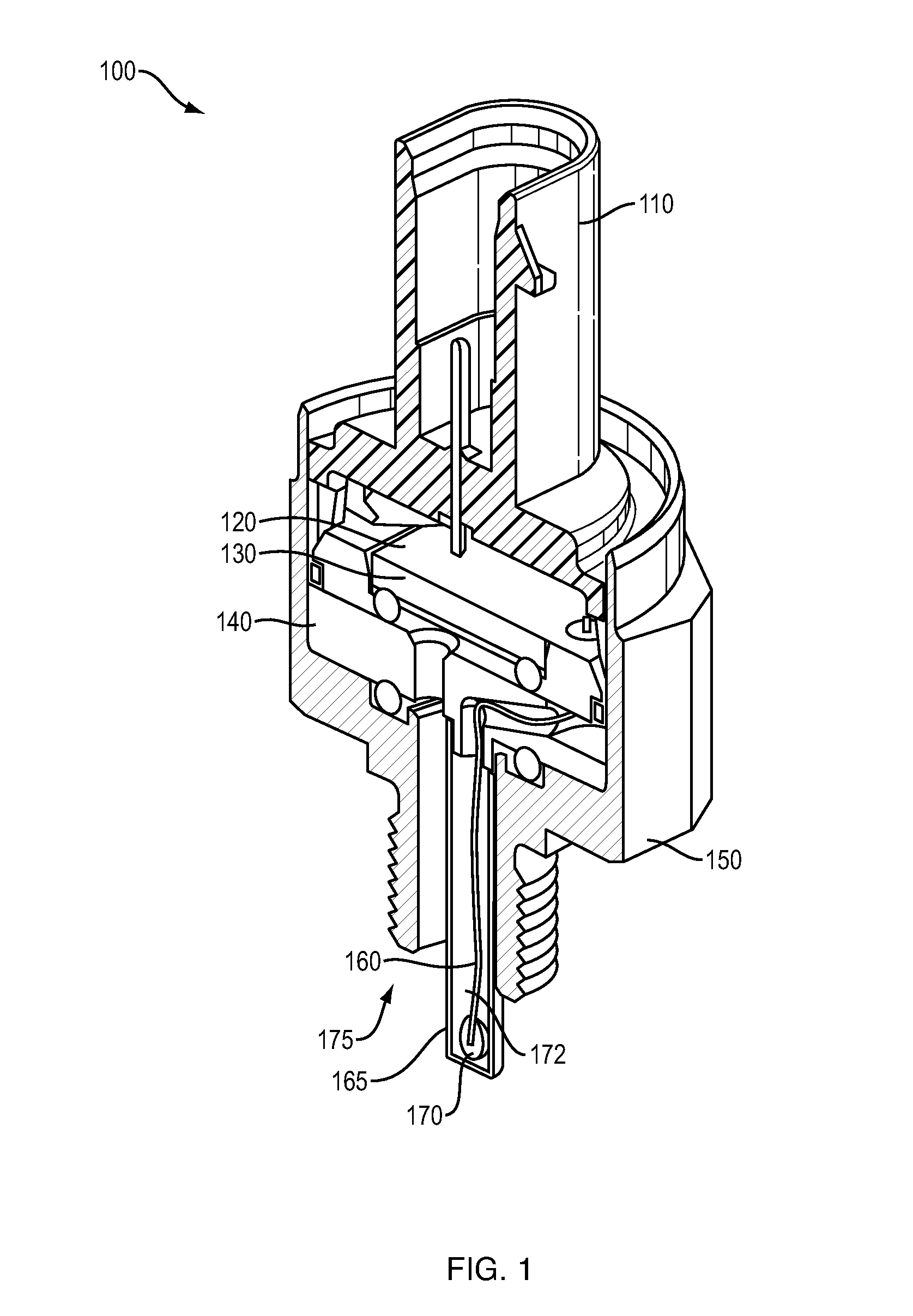

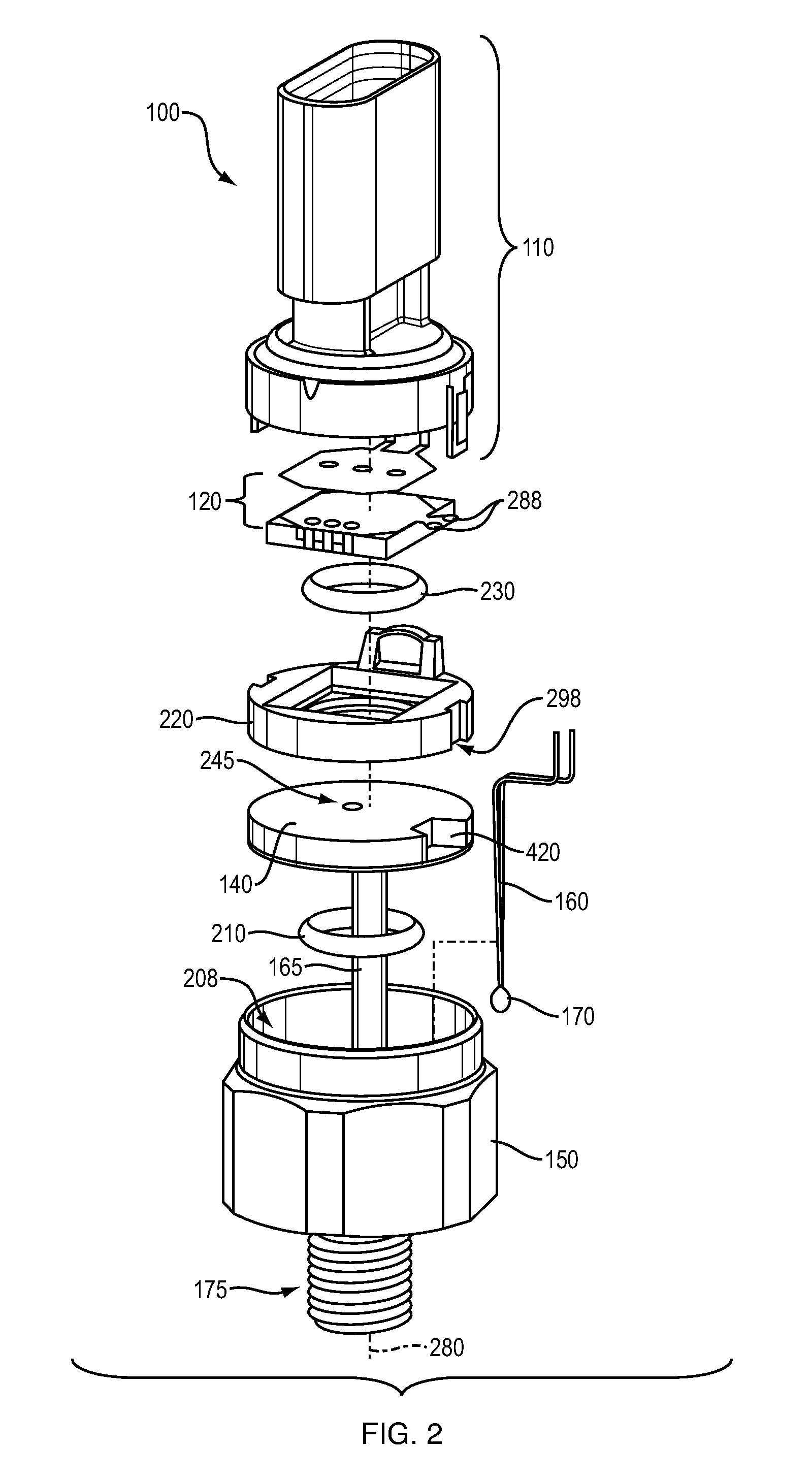

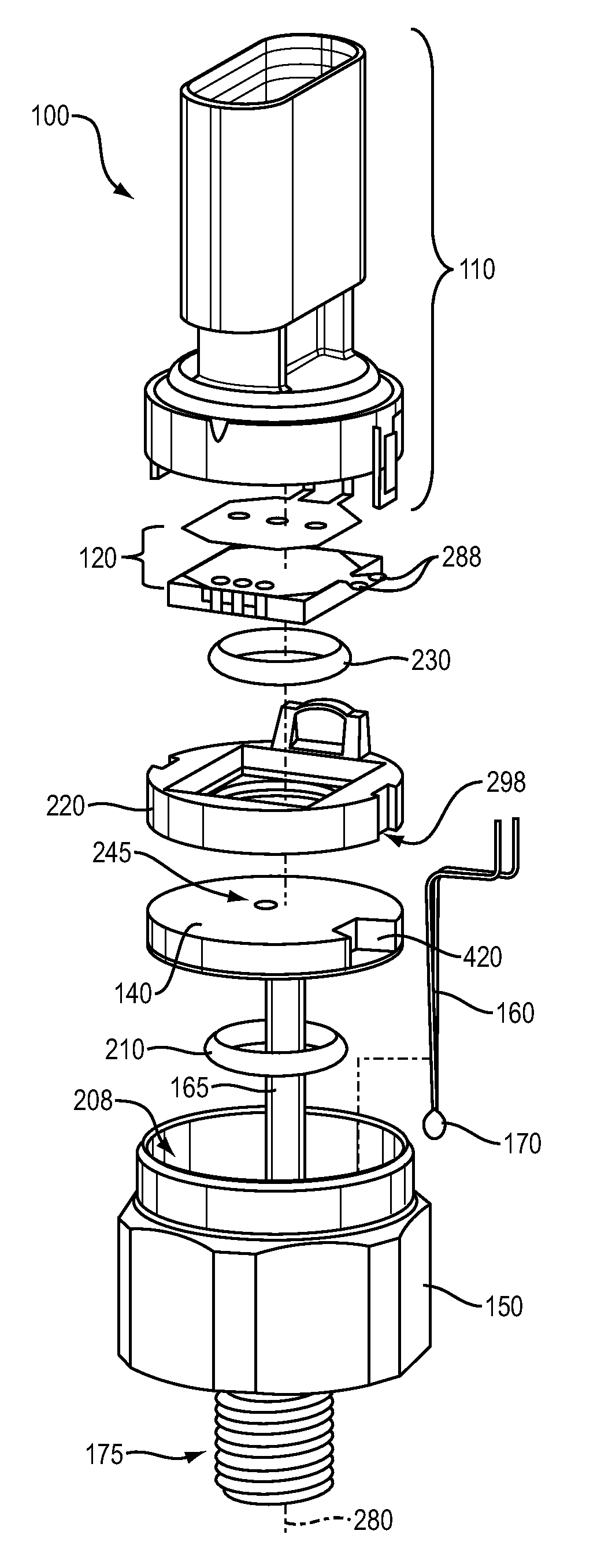

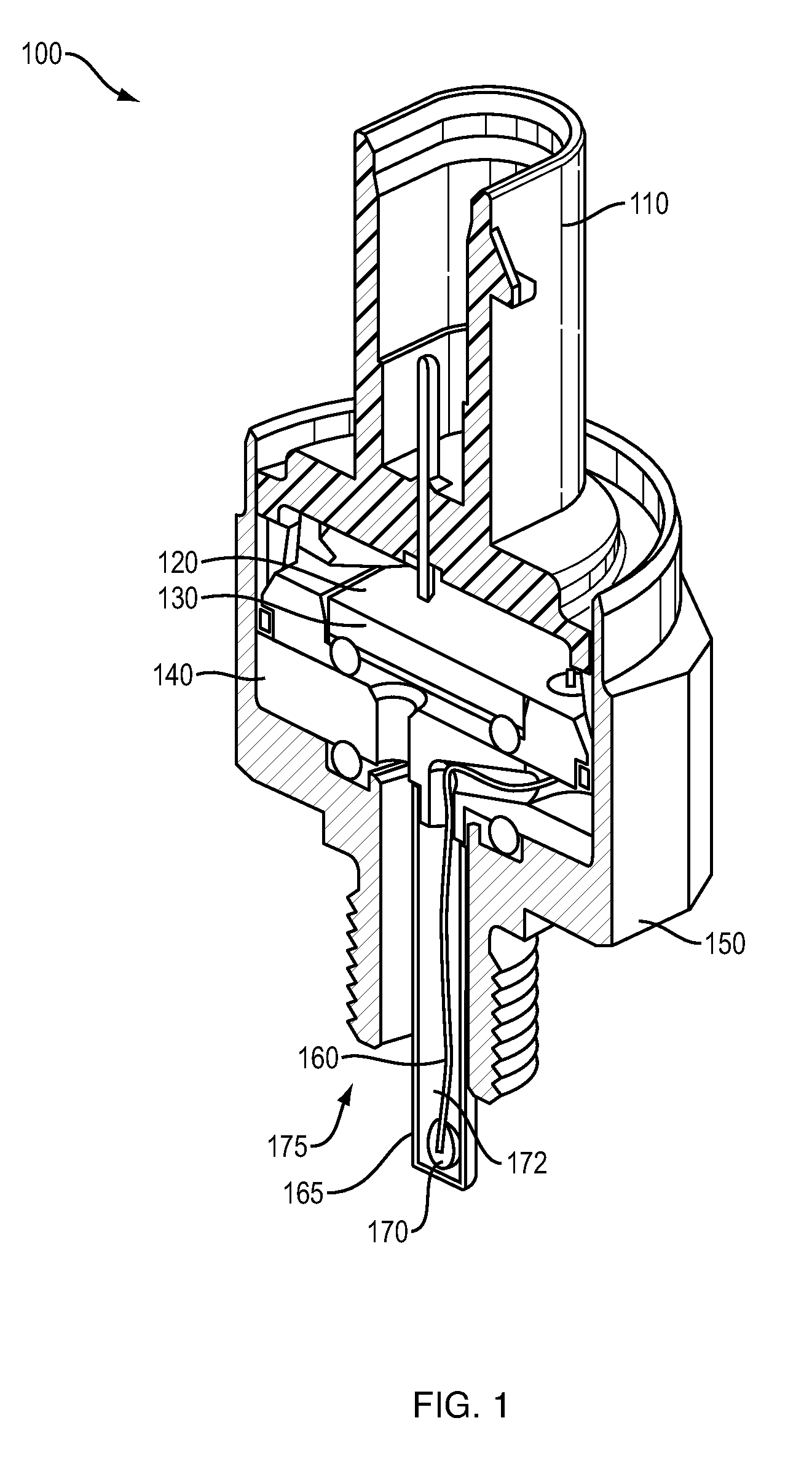

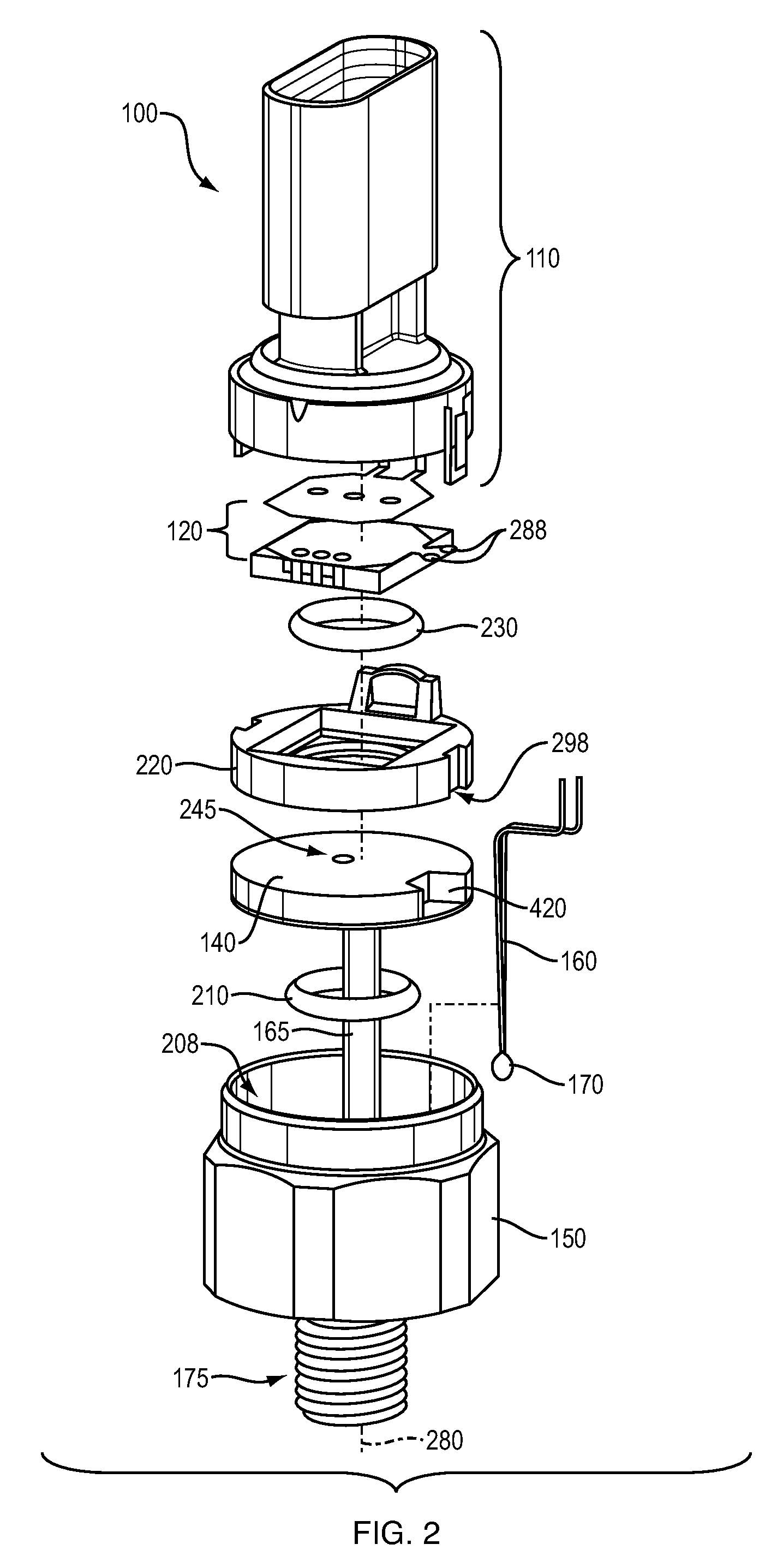

Combination pressure/temperature in a compact sensor assembly

ActiveUS20130047736A1Avoid physical contactGood thermal responseThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsElectricityForce sensor

A sensor assembly includes a rectangular-shaped pressure sensor element and an electronic circuitry coupled to receive a signal from the pressure sensor element. An open-ended fluid-tight passageway of the sensor assembly conveys fluid from a portal opening of the sensor assembly to a surface of the rectangular-shaped pressure sensor element. The sensor assembly further includes a closed-ended fluid-tight passageway, at least a portion of which is fabricated from metal. The closed-ended fluid tight passageway extends from at least from the portal opening of the sensor assembly to the electronic circuitry on at least a portion of a path adjacent to the rectangular-shaped ceramic pressure sensor element. The sensor assembly includes a temperature sensor element disposed in an end of the closed-ended fluid-tight passageway. Conductive links disposed in the closed-ended fluid tight passageway electrically couple the temperature sensor element to the electronic circuitry.

Owner:SENSATA TECHNOLOGIES INC

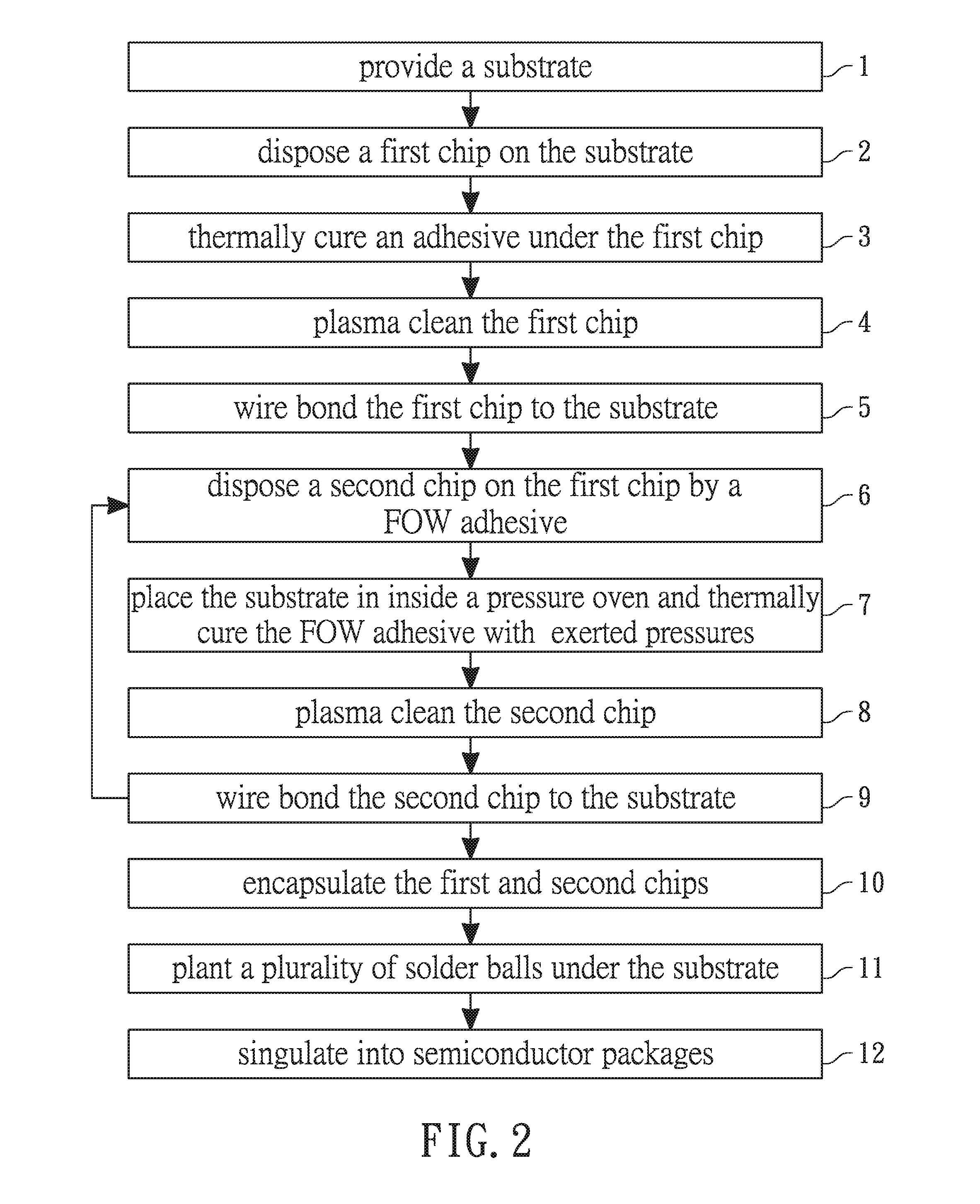

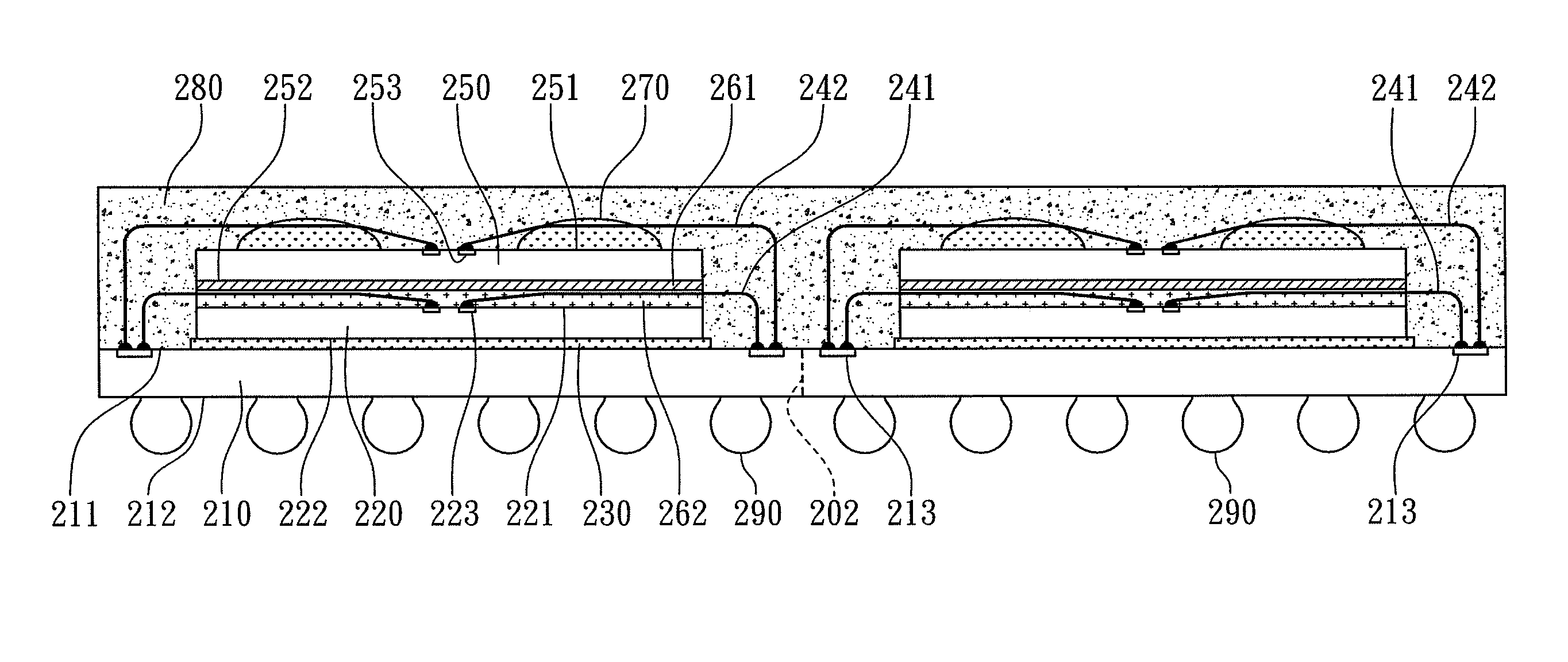

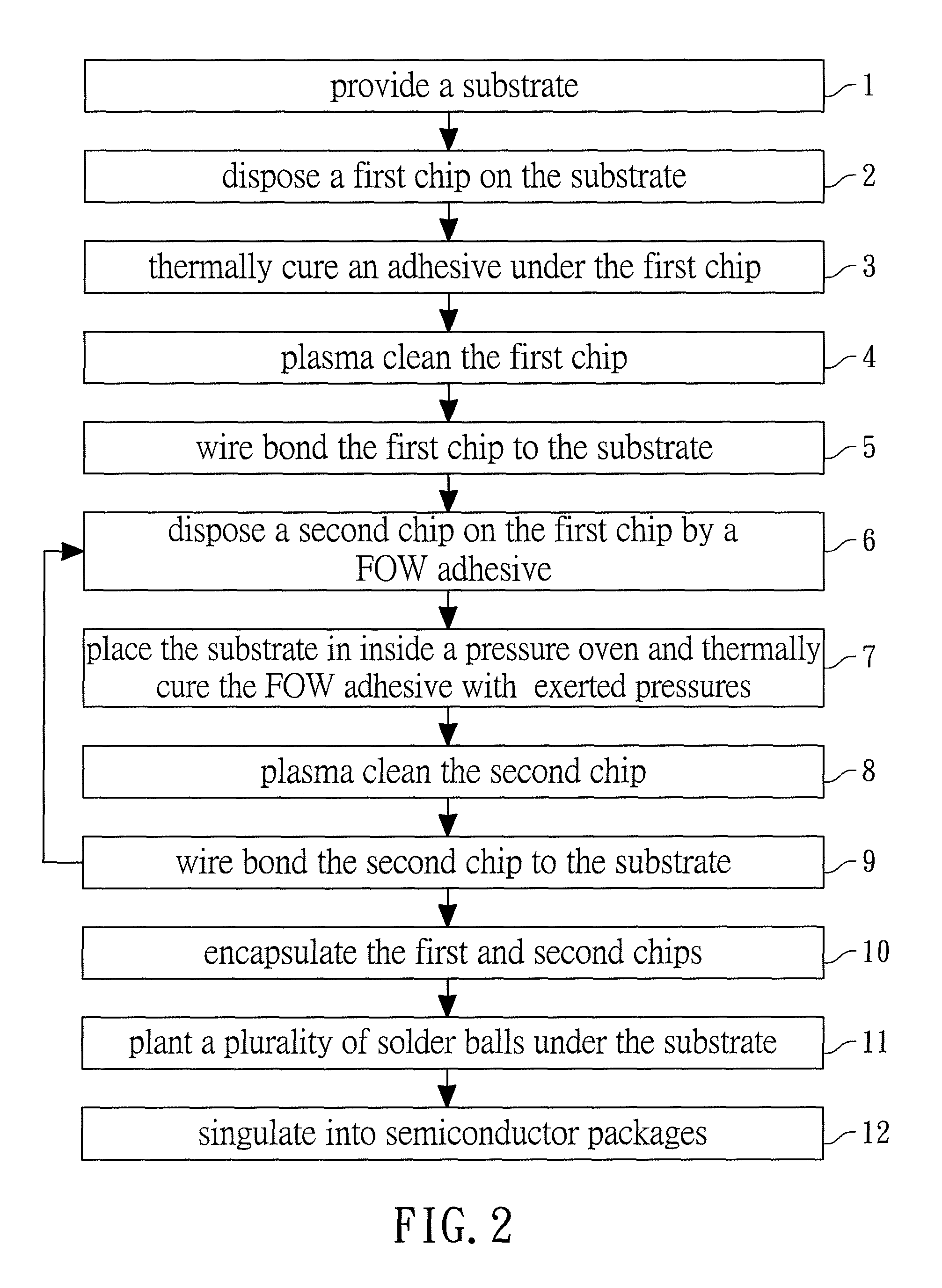

Multi-chip stacking method to reduce voids between stacked chips

InactiveUS20120115277A1Reduce voidsPoor adhesionSemiconductor/solid-state device detailsSolid-state devicesEngineeringAdhesive

A multi-chip stacking method to reduce voids between stacked chips is revealed. A first chip is disposed on a substrate, and a plurality of first bonding wires are formed by wire bonding to electrically connect the first chip and the substrate. A second chip is disposed on an active surface of the first chip where a FOW (film over wire) adhesive is formed on a back surface of the second chip. The FOW adhesive partially encapsulates the first bonding wires and adheres to the active surface of the first chip. Then, the substrate is placed in a pressure oven to provide a positive pressure greater than one atm during thermally curing the FOW adhesive with exerted pressures. Accordingly, voids can be reduced inside the FOW adhesive during the multi-chip stacked processes where issues of poor adhesion and popcorn between chips can be avoided.

Owner:WALTON ADVANCED ENG INC

Mat for heated items with cutting indicia

InactiveUS20070082164A1Avoid heat damagePreserving aesthetic appealStampsFlexible coversElastomerThermal insulation

A multi-purpose, heat-resistant mat that comprises a single, flexible, thin body of elastomer material, which is preferably silicone, to provide thermal insulation. The solid planar body of elastomer material of the mat further includes numerous indicia providing grooves that score the bottom surface of the elastomer material for indicia aligned visual reference to permit cutting the original mat to a smaller size for custom fitting a particular pan or bowl. The mat may be cut linearly along one or more grooves to reduce the mat to a shape and size desired by the user. The mat also acts to cushion heated dishes and breakable cookware on hard surfaces so as to prevent damage to or breakage of the dishes against the hard surface while protecting the countertop surface from burning, scorching, and other physical abrasions.

Owner:SELLERS JENNA

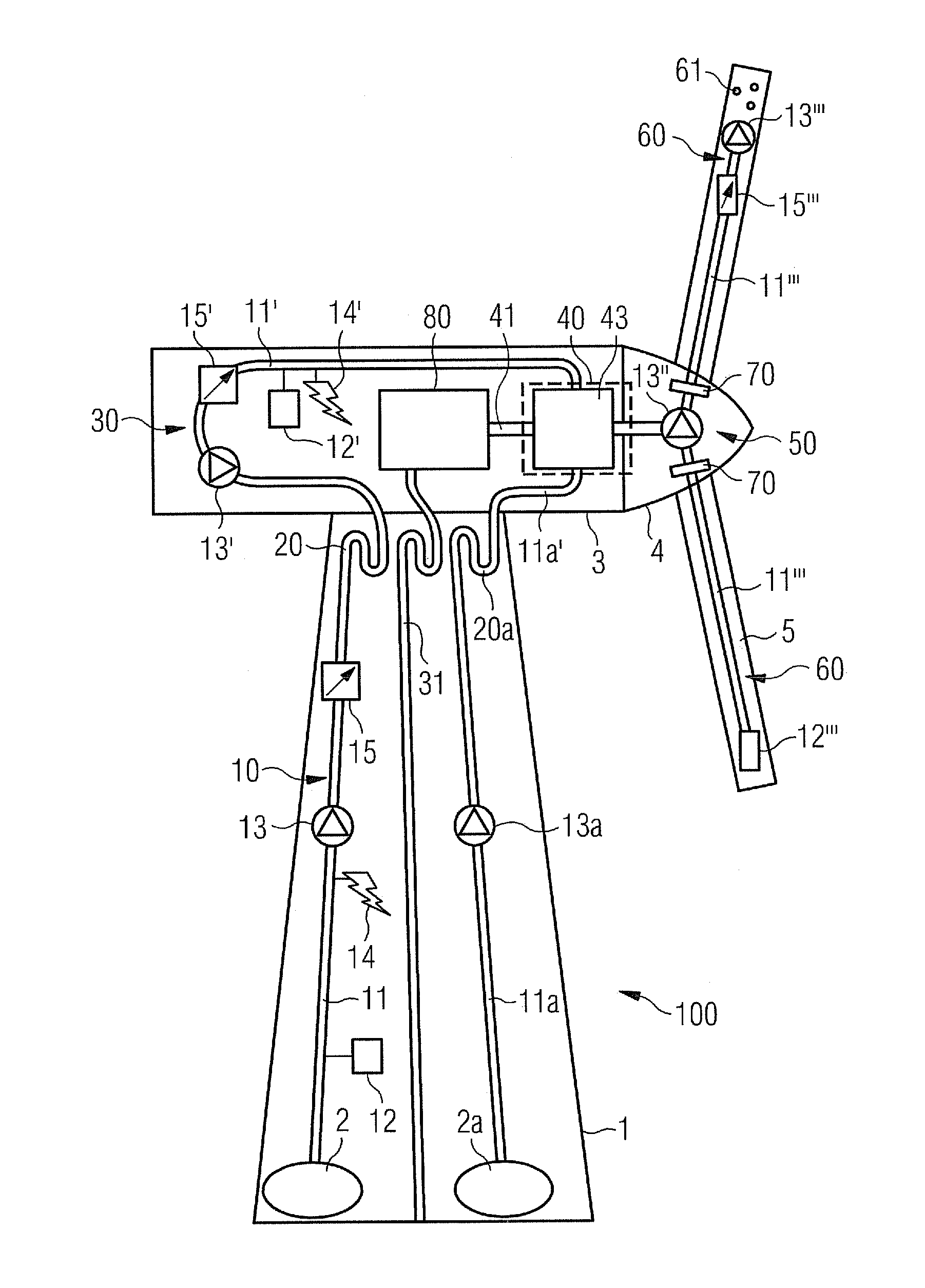

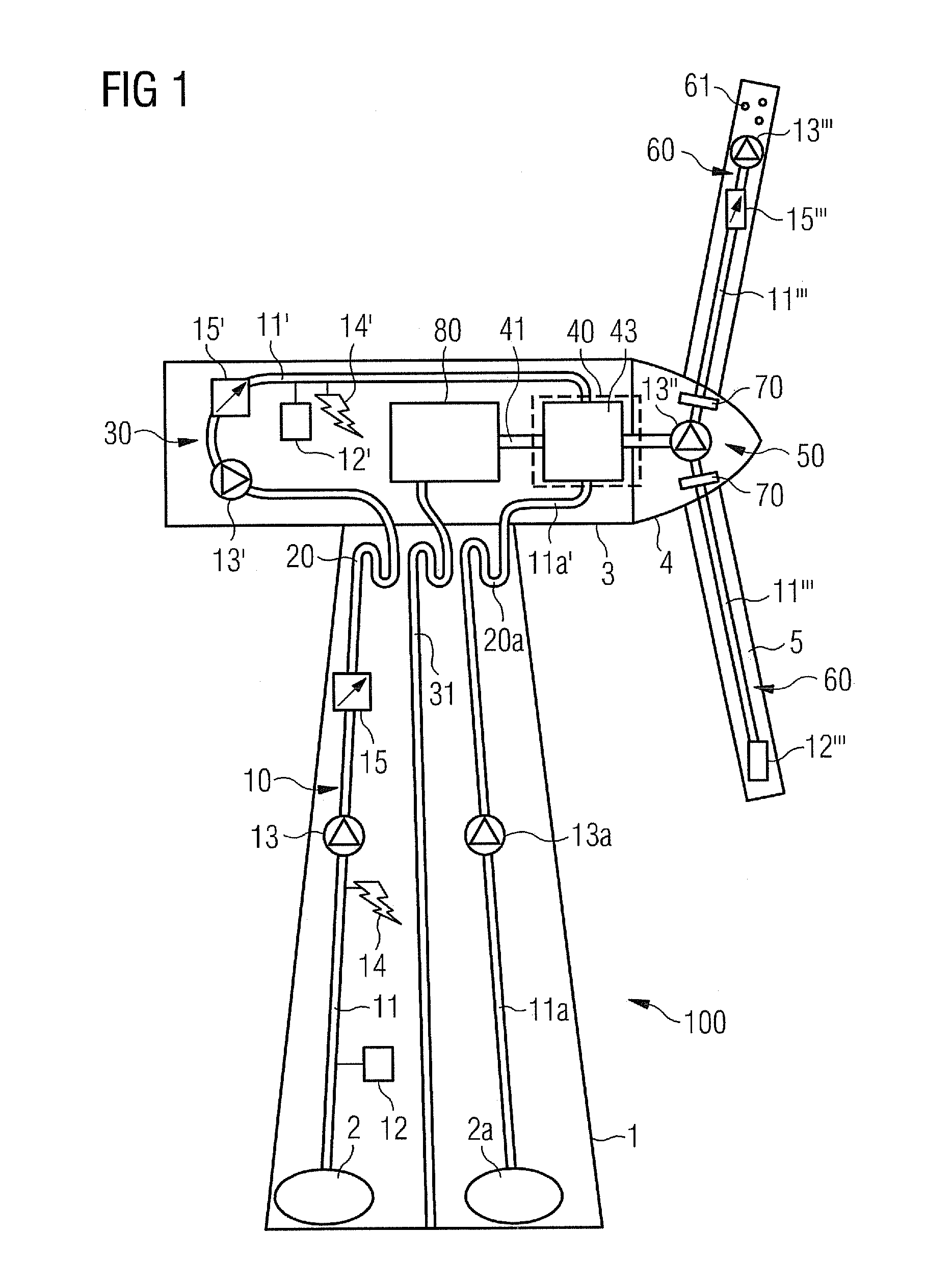

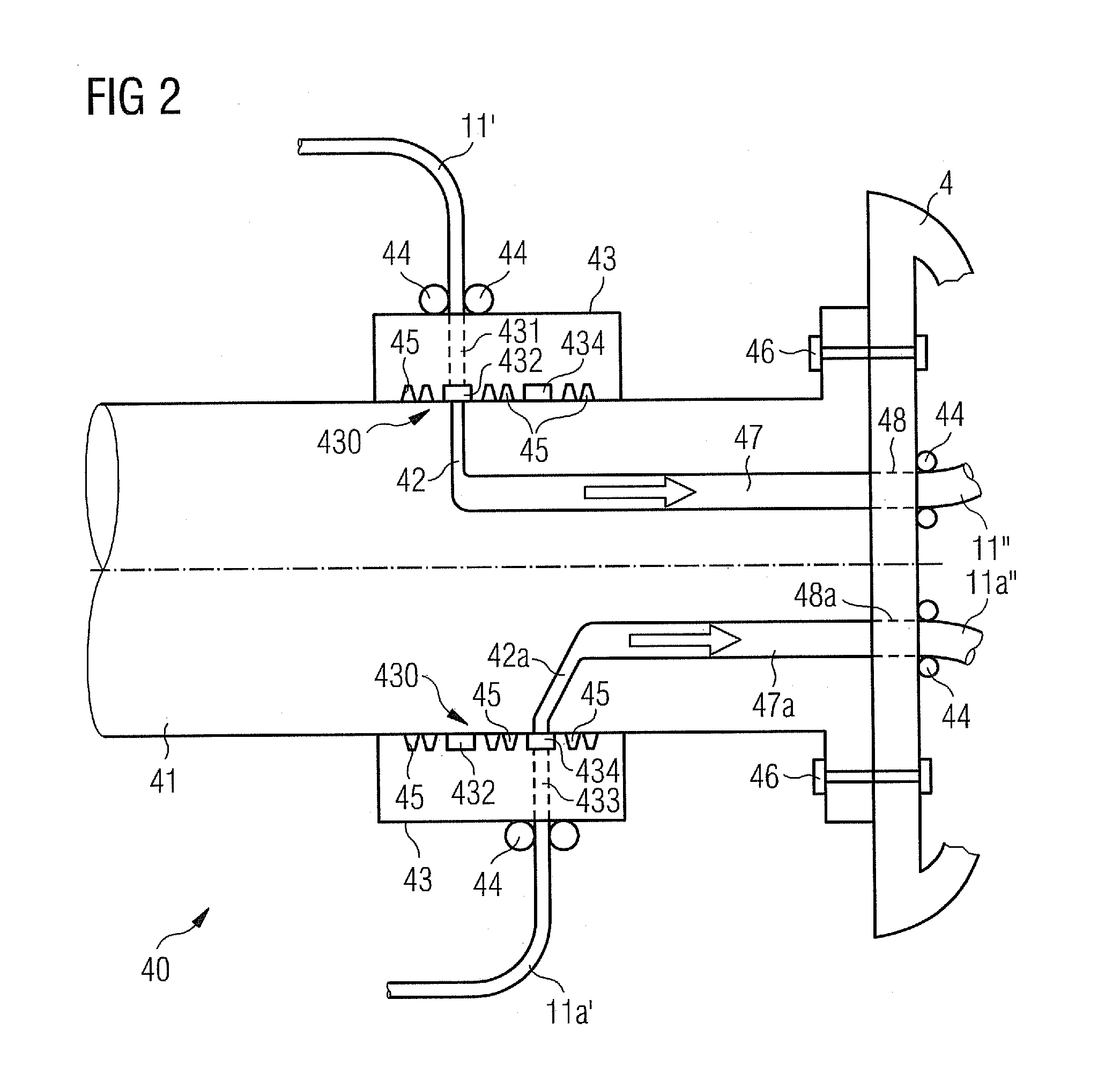

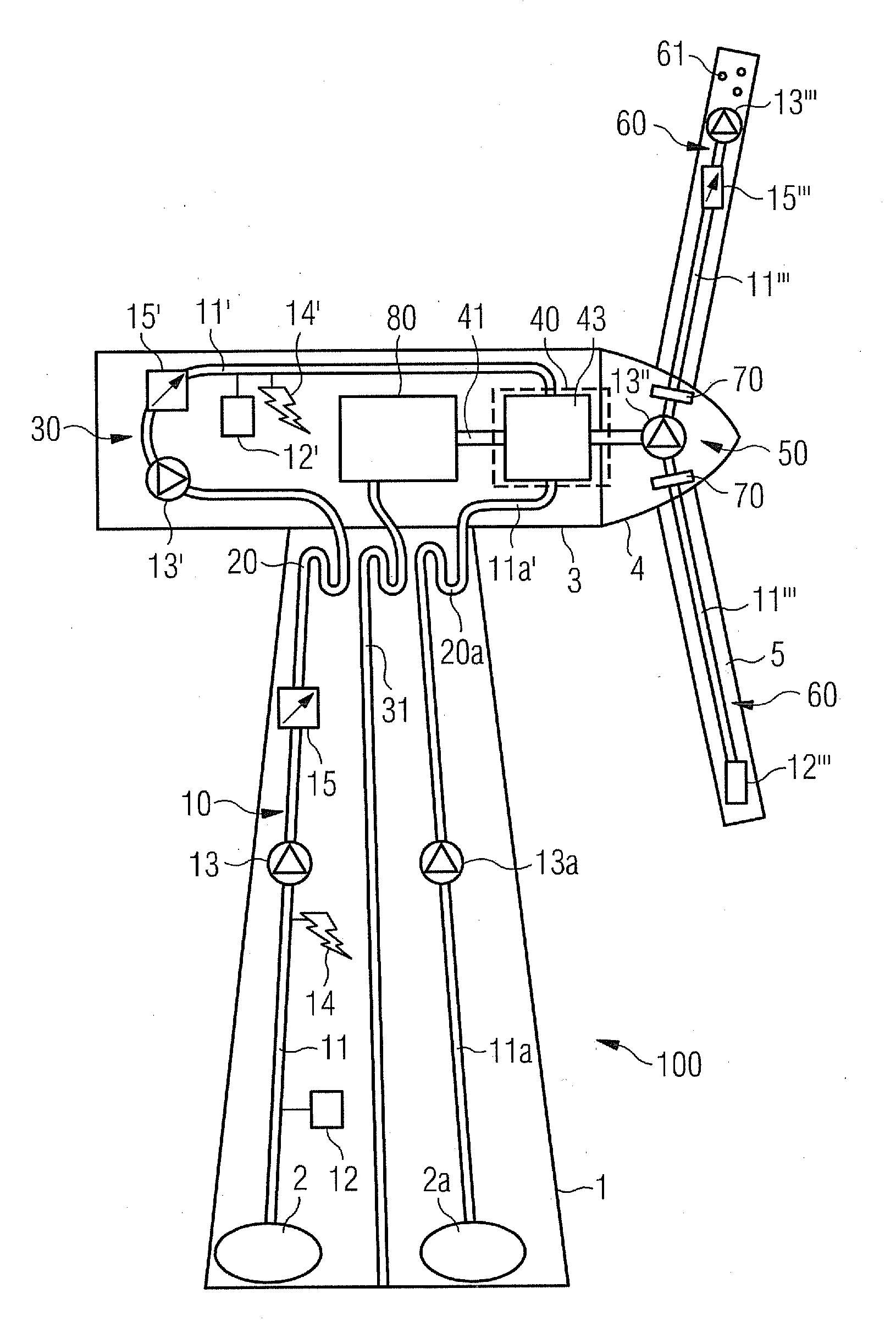

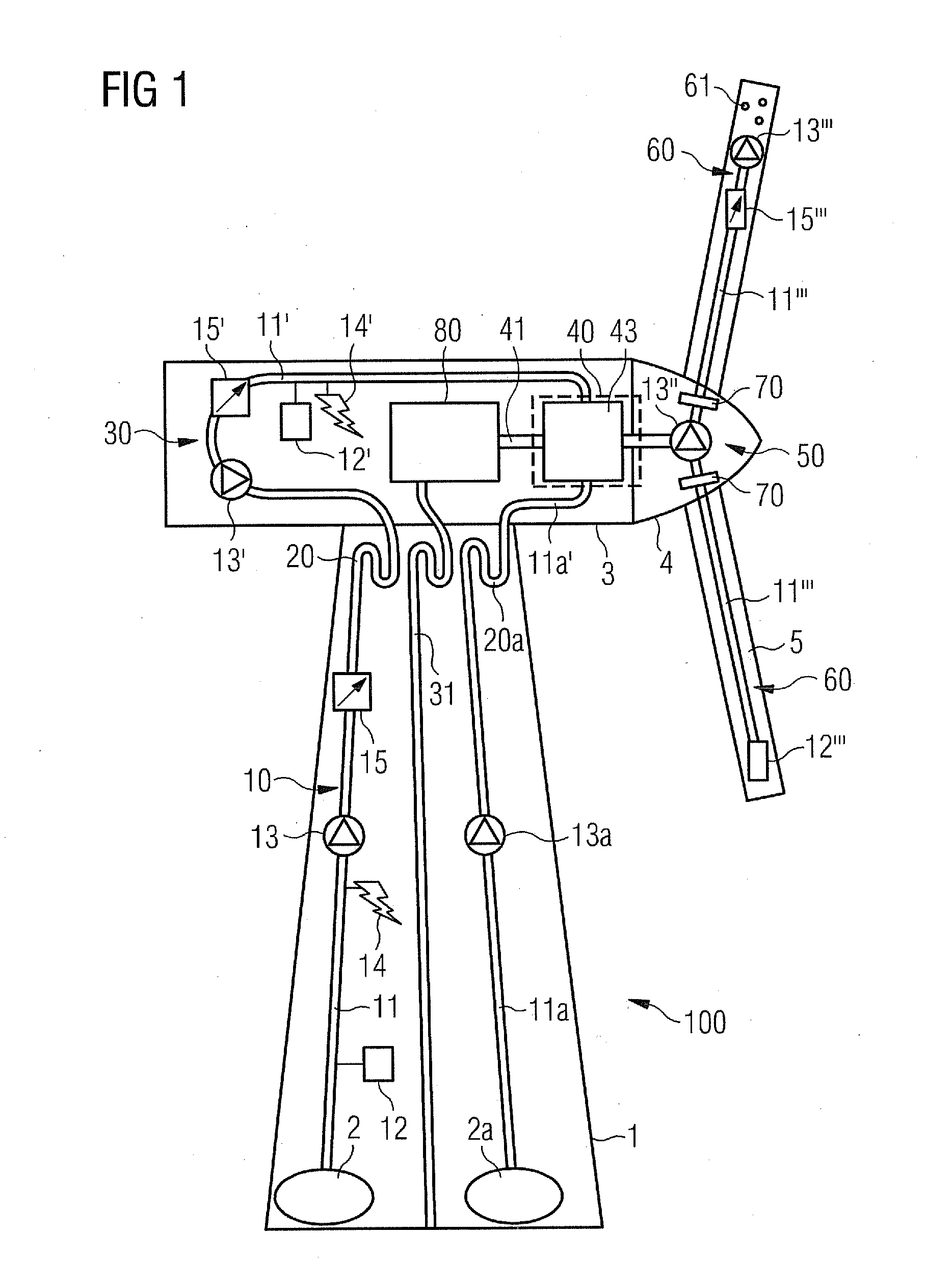

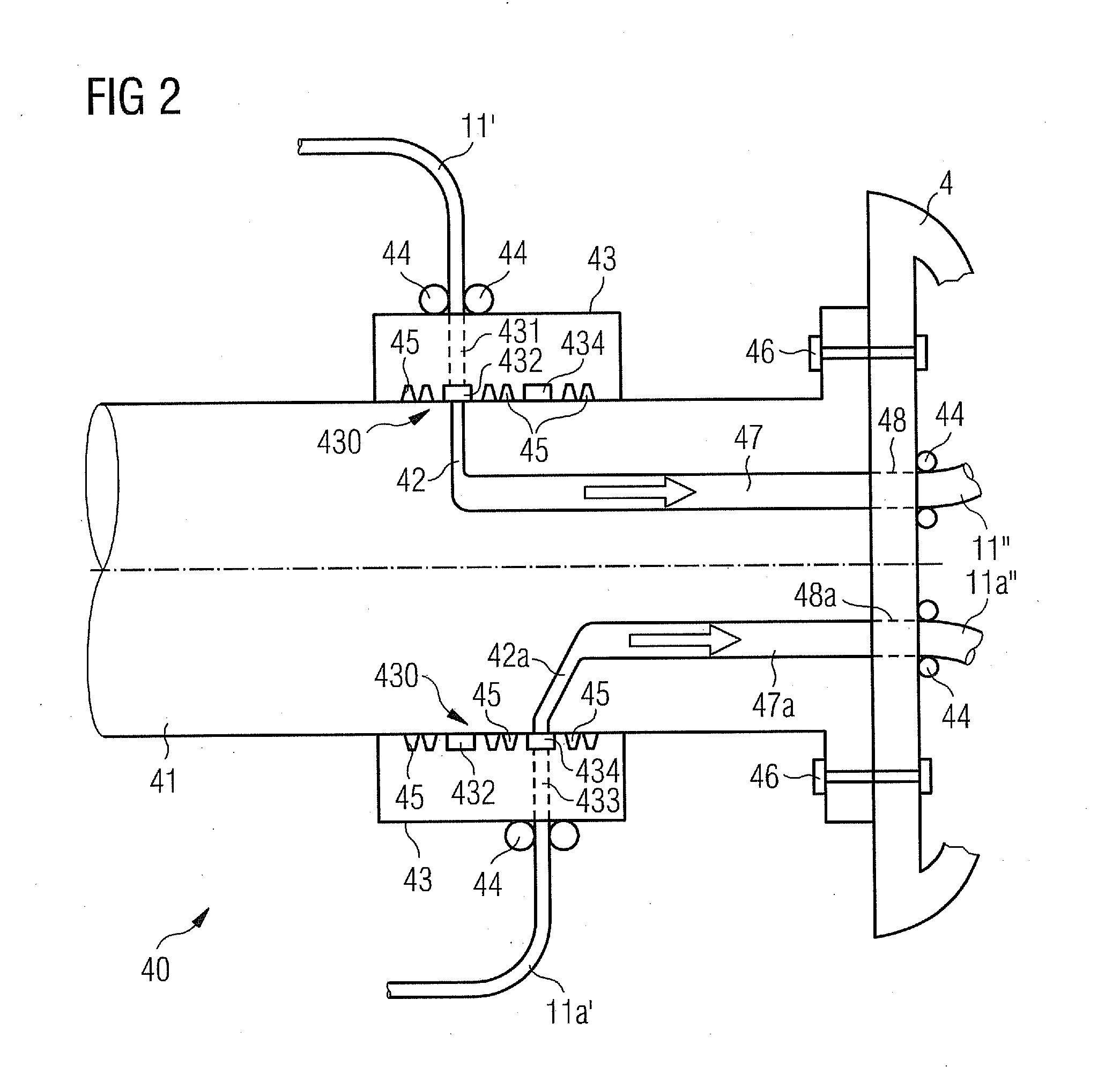

Wind turbine with liquid medium distribution system

A wind turbine with a tower, a nacelle, a main shaft, a hub and blades is provided. The wind turbine also includes a liquid medium distribution system for transport of liquid medium in the wind turbine. The liquid medium distribution system has a first distribution sub-system located in the tower, a second distribution sub-system located in the nacelle, a third distribution sub-system located in the hub, a tower-nacelle-interface connecting the first distribution sub-system to the second distribution sub-system, and a nacelle-hub-interface connecting the second distribution sub-system to the third distribution sub-system. Further, a method of transporting liquid medium in a wind turbine is provided.

Owner:SIEMENS AG

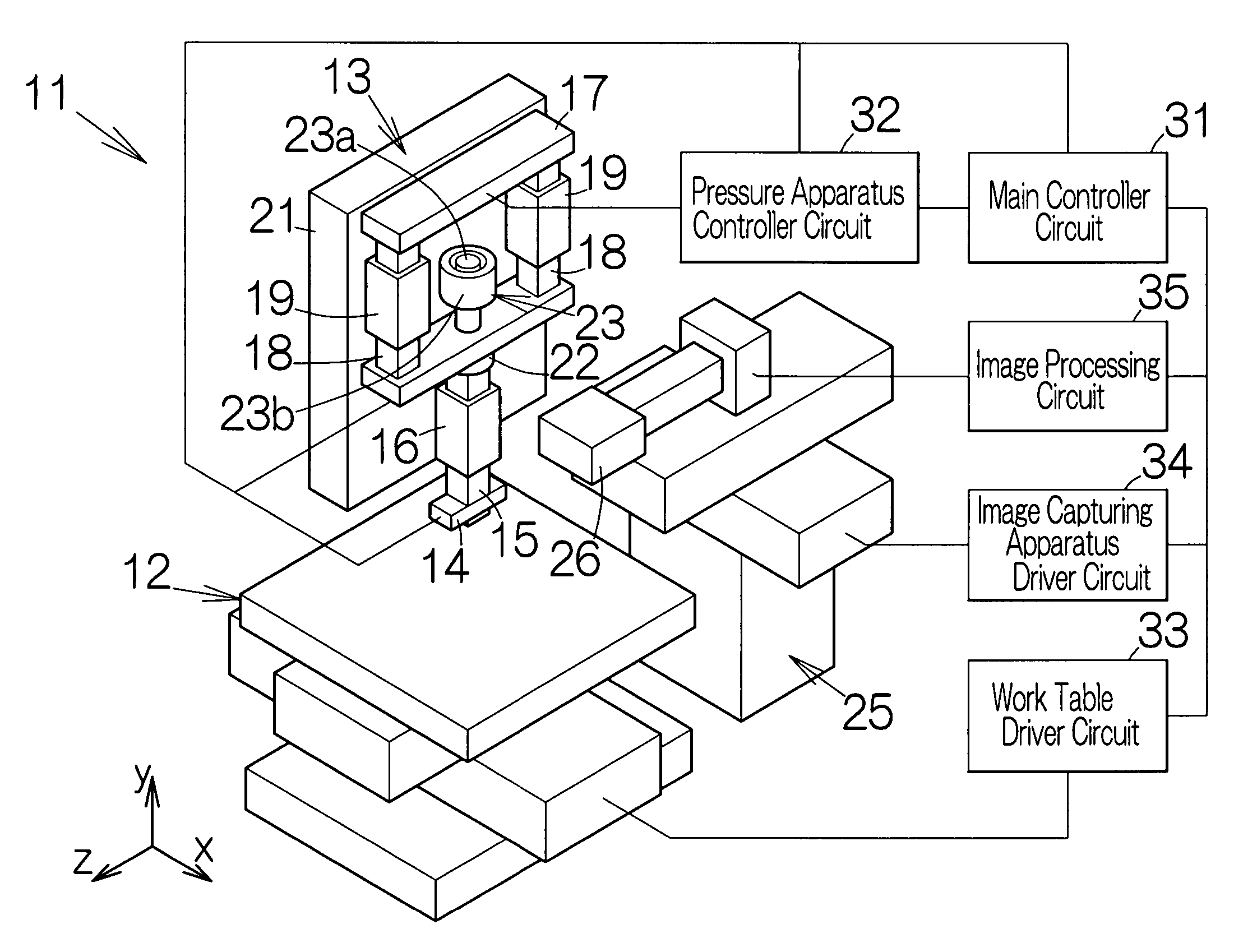

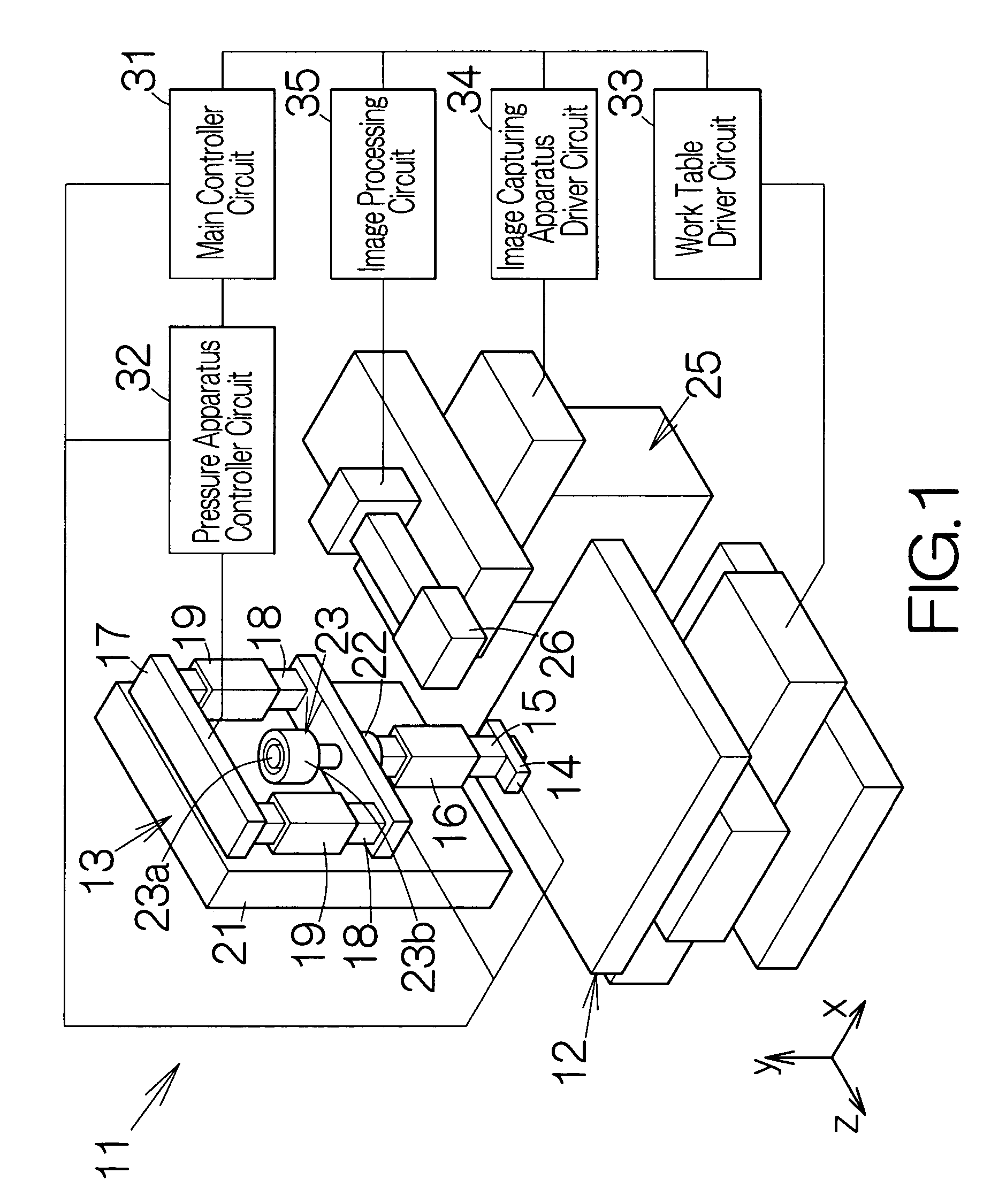

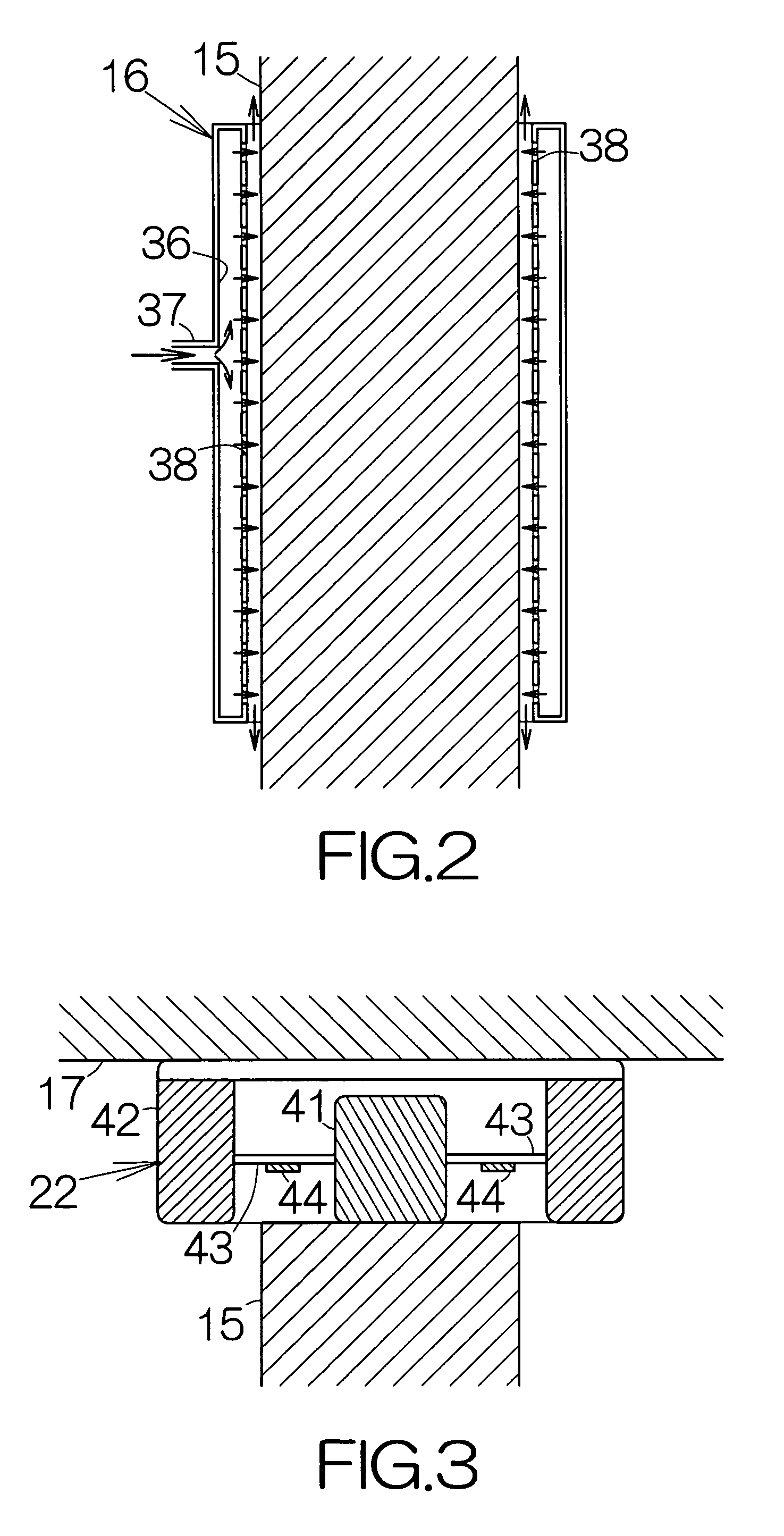

Pressure apparatus and chip mounter

InactiveUS7325298B2Shorten the maintenance periodShorten the timeGripping headsKitchen equipmentResonanceEngineering

A contact member is supported on the support shaft. A force sensor is coupled to the support shaft. A movable member is coupled to the force sensor. The pressure apparatus allows the movable member to cause the axial movement of the support shaft. A first guide serves to guide the axial movement of the support shaft. The first guide is supported on the support member. The support member stands still during the movement of the movable member. Accordingly, the movement of the movable member is restrained in the axial direction. The contact member is thus prevented from suffering from a swinging movement around the force sensor. Servo control of a higher frequency bandwidth can be applied to the movement of the contact member. The contact member moves at a higher velocity. Occurrence of resonance is still avoided in the contact member. The tact time can be shortened.

Owner:FUJITSU LTD

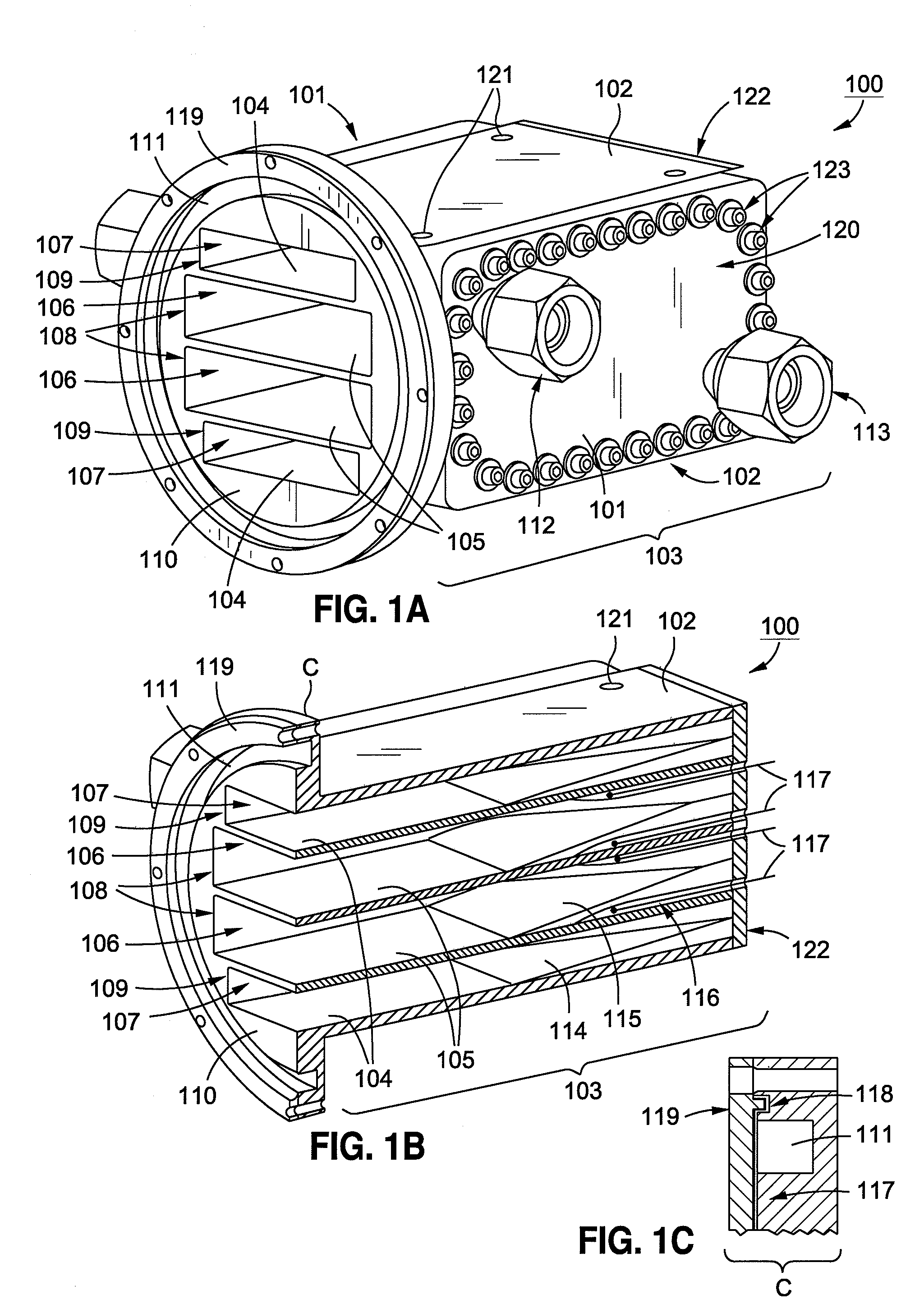

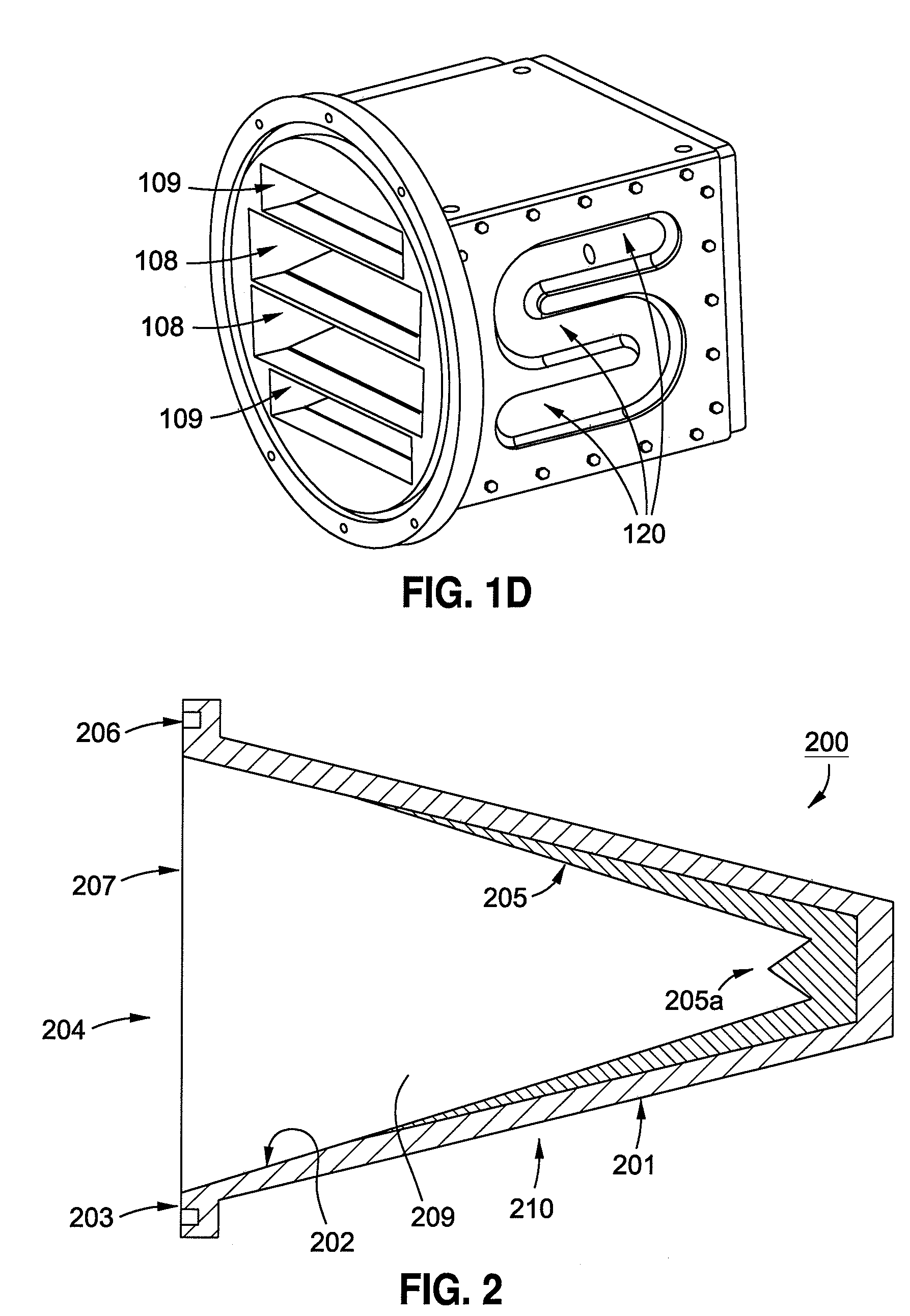

Generic pick-up horn for high power thermal vacuum testing of satellite payloads at multiple frequency bands and at multiple polarizations

InactiveUS20080191949A1Good return lossMinimal reflected powerWaveguide hornsElectromagentic field characteristicsMaterials scienceSatellite

Methods, systems, and apparatus are disclosed for high power thermal vacuum testing of satellite payloads using pick-up horns. Such pick-up horns can include at least one outer metal wall forming a metal body and at least one interior surface disposed in the metal body, forming at least one chamber in the metal body. The pick-up horn further includes a front metal surface disposed at a front end of the metal body, having at least one opening corresponding to the at least one chamber, and at least one high-power absorbing load disposed within the at least one chamber and in contact with the at least one interior surface. A pick-up horn may further include a serpentine coolant path disposed within the metal body between an outer surface of the at least one outer metal wall and the at least one high-power absorbing load. Related systems and methods are described.

Owner:LOCKHEED MARTIN CORP

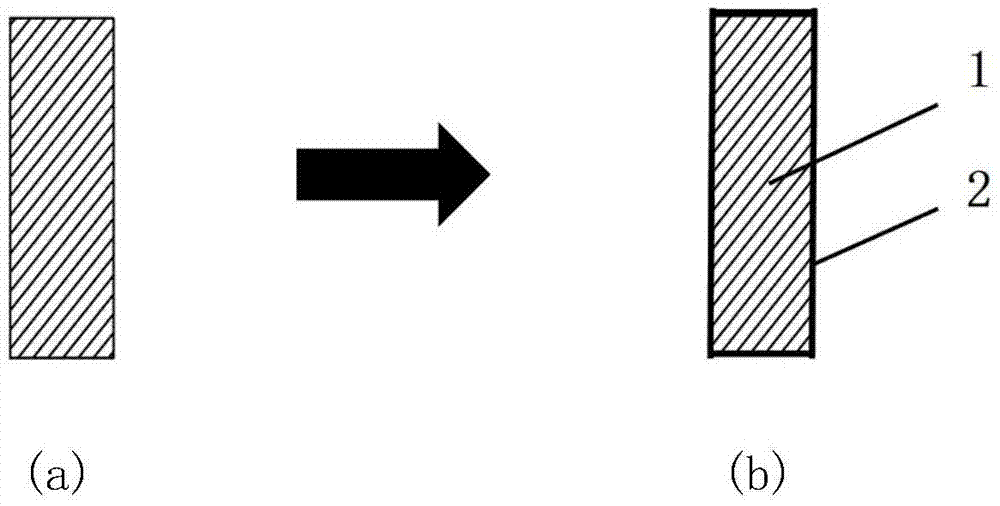

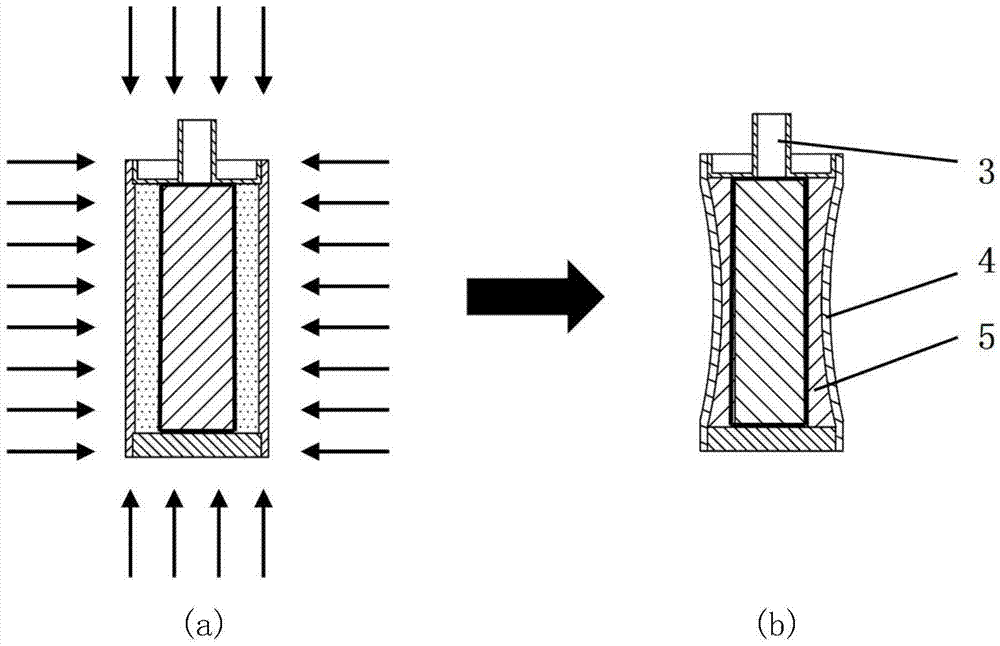

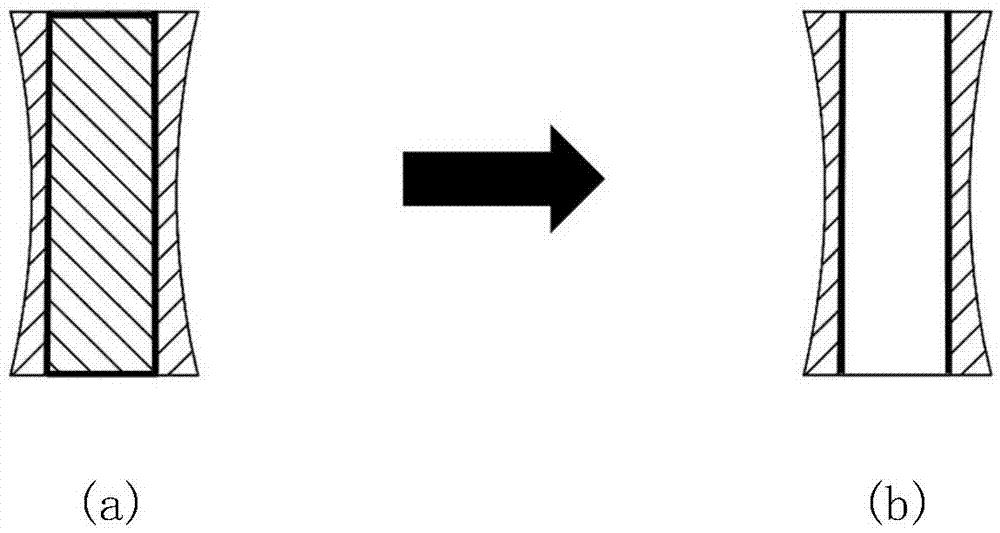

Hot isostatic pressing forming method used for improving part surface quality

ActiveCN105436505AImprove creep deformation efficiencyHigh degree of densificationCeramic coatingHigh pressure

The invention discloses a hot isostatic pressing forming method used for improving the part surface quality. The hot isostatic pressing forming method comprises the following steps that three-dimensional models of a wrapping sleeve and a shape control die core are designed according to the shape and size of a formed part; the stainless steel wrapping sleeve and the carbon steel shape control die core are manufactured according to the manufactured three-dimensional models; a ceramic coating is sprayed on the surface of the shape control die core through a physical vapor deposition (PVD) method; the shape control die core is fixed in the wrapping sleeve, and the wrapping sleeve is filled with powder and shaken to be compacted; the wrapping sleeve is subjected to air exhausting and heating treatment, sealing welding is conducted when the vacuum degree in the wrapping sleeve reaches a certain degree; the wrapping sleeve is subjected to hot isostatic pressing treatment through a technique that the temperature is increased at first and then the pressure is increased so as to make the powder be tightened and compacted under the action of the high temperature and the high pressure; and the wrapping sleeve and the shape control die core are removed to obtain the final part. According to the hot isostatic pressing forming method, the carbon steel die core with the coating serves as the shape control die core, and element diffusion between carbon steel cores and the powder can be effectively prevented; element segregation of the alloy surface due to diffusion is avoided, and the alloy surface quality is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

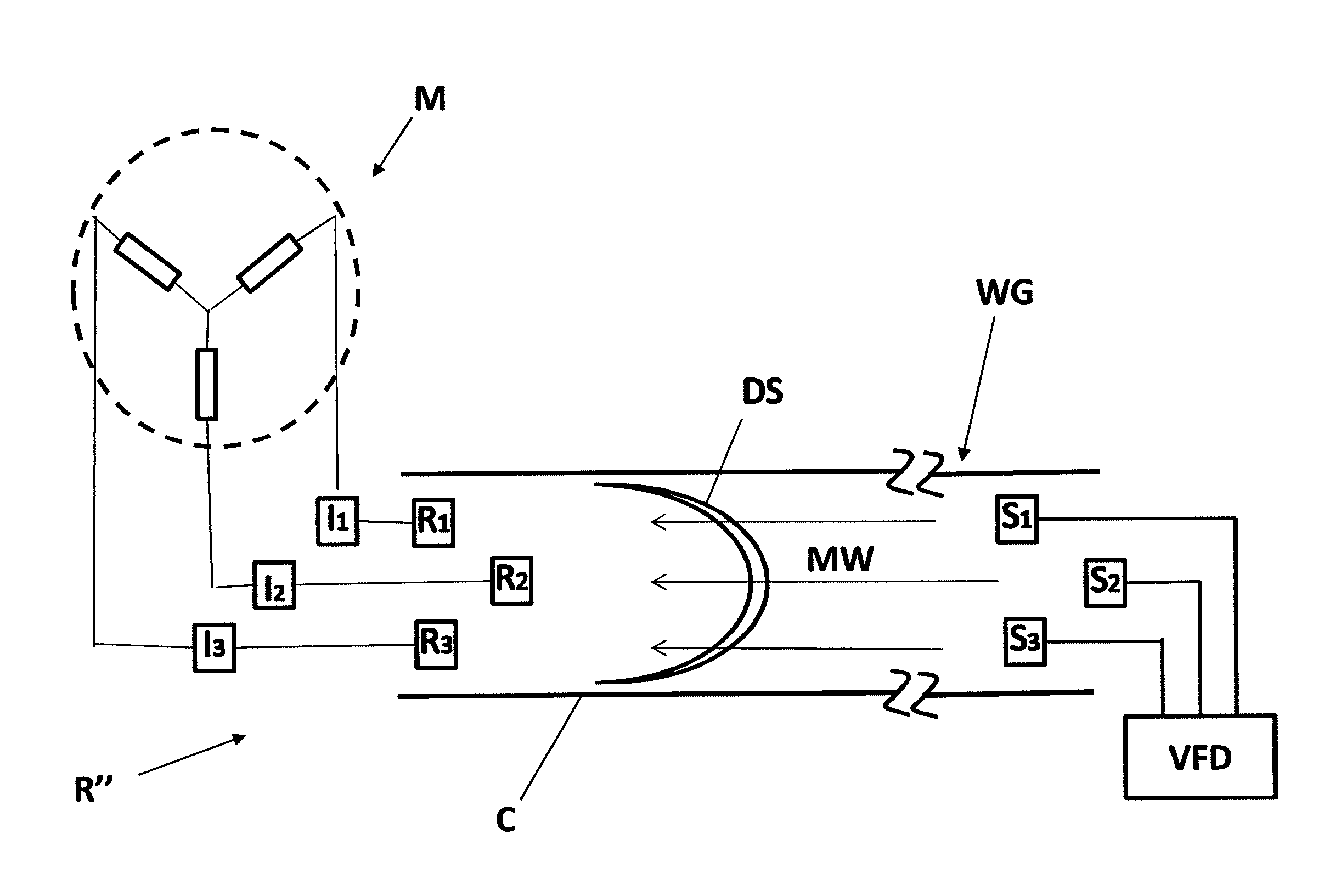

Power supply system and method for a movable vehicle within a structure

ActiveUS20160229297A1Reduce resistanceGreat potential vehicle speedPropulsion by batteries/cellsVehicular energy storageEngineeringFixed position

A power supply system and method for a vehicle movable within a structure is provided. The power supply system includes at least one energy source arranged at a fixed location within the structure to transmit energy within the structure, and a receiver, arranged on the vehicle to receive the energy transmitted from the energy source, being configured to convert the energy to electrical power and / or thrust.

Owner:HYPERLOOP TECH INC

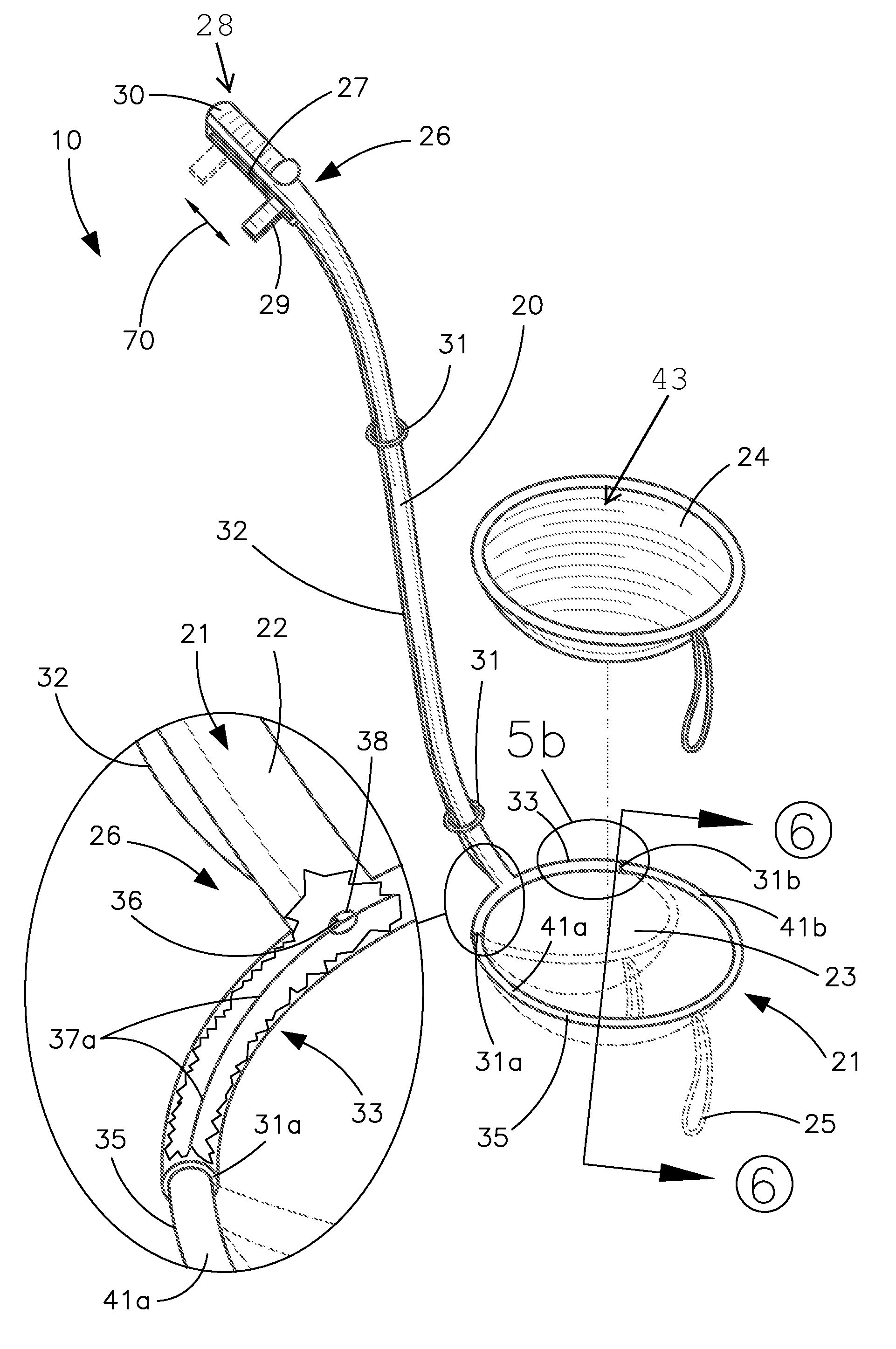

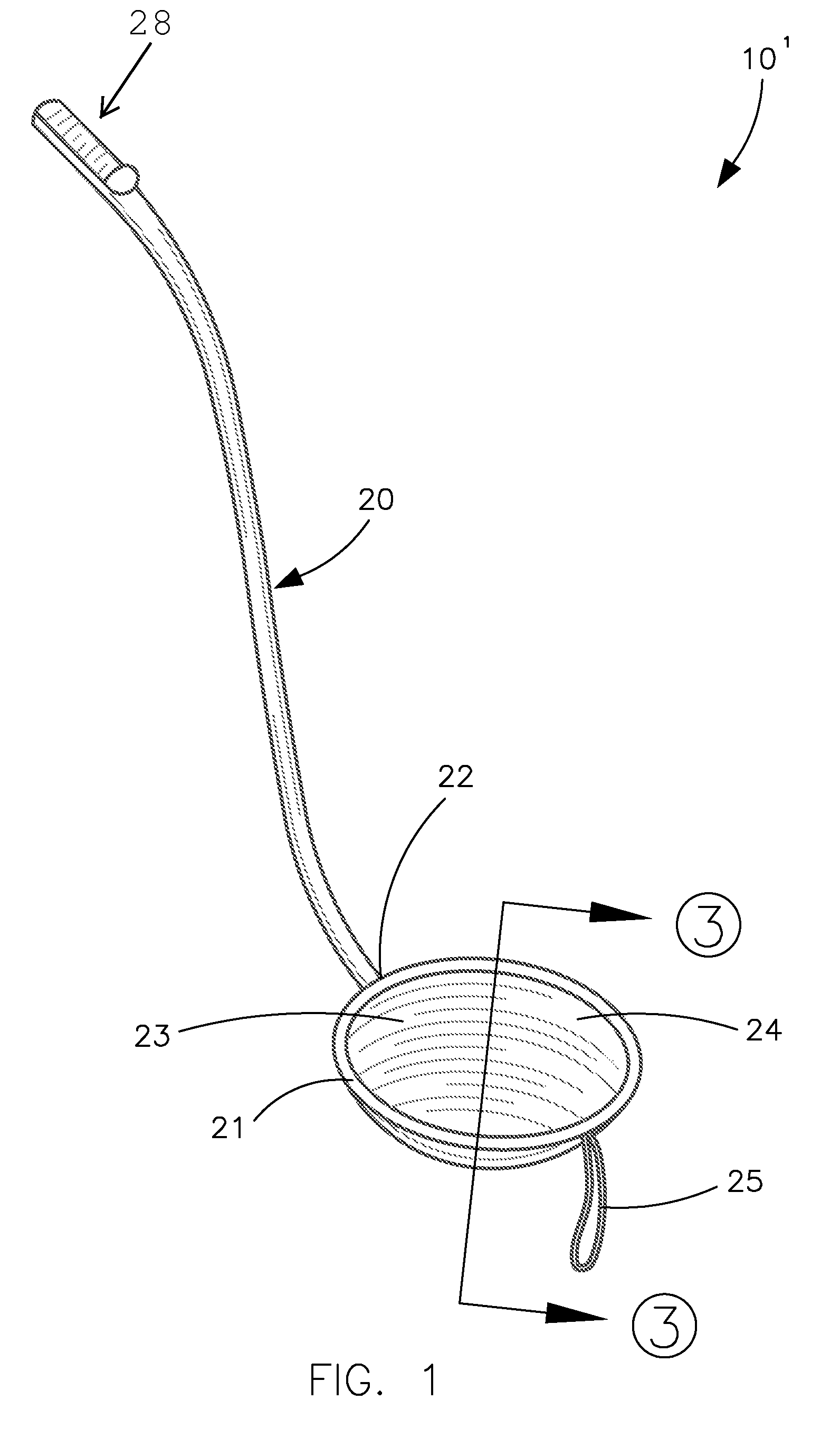

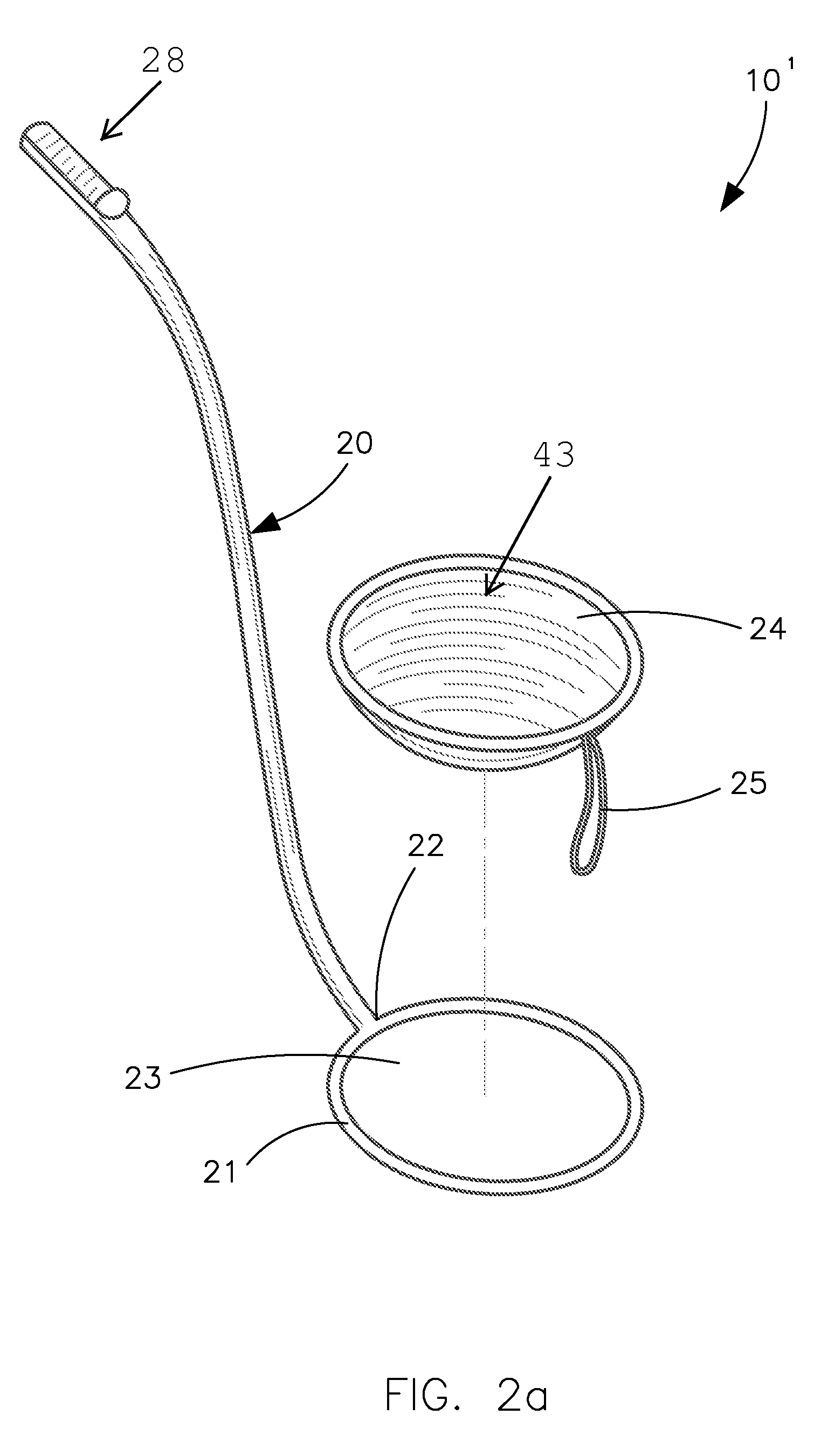

Sanitary collection apparatus for pet feces and associated method

InactiveUS7950707B1Convenient distanceConvenient and hands-free captureOther apparatusTaming and training devicesAnimal fecesEngineering

A hand-operable feces collection apparatus for catching animal excrements prior to reaching a ground surface may include an elongated curvilinear handle and an annular ring attached to a distal end thereof. A retention bag may be attached directly to the annular ring in such a manner that the retention bag is maintained at a substantially stable position while receiving the animal excrements therein. The apparatus may also include a mechanism for resiliently adjusting a diameter of the annular ring such that the retention bag is caused to automatically disengage the annular ring. Such a mechanism may be activated by a lever attached to the proximal end of the handle. The annular ring may be composed of a semi-circular solid male core and a hollow female sleeve. The male core is urged along the female sleeve as the mechanism is activated, causing the diameter of the annular ring to adjust.

Owner:LAPOLLA JOHN

Wind turbine with liquid medium distribution system

A wind turbine with a tower, a nacelle, a main shaft, a hub and blades is provided. The wind turbine also includes a liquid medium distribution system for transport of liquid medium in the wind turbine. The liquid medium distribution system has a first distribution sub-system located in the tower, a second distribution sub-system located in the nacelle, a third distribution sub-system located in the hub, a tower-nacelle-interface connecting the first distribution sub-system to the second distribution sub-system, and a nacelle-hub-interface connecting the second distribution sub-system to the third distribution sub-system. Further, a method of transporting liquid medium in a wind turbine is provided.

Owner:SIEMENS AG

Combination pressure/temperature in a compact sensor assembly

ActiveUS8935961B2Avoid physical contactGood thermal responseThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsElectricityEngineering

Owner:SENSATA TECHNOLOGIES INC

Placing heat sink into packaging by strip formation assembly

ActiveUS8581374B1Avoid physical contactSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Embodiments of the present disclosure describe semiconductor device packaging techniques and devices that incorporate a heat spreader into the insulating material of a packaged semiconductor device. In one embodiment, a device comprising a semiconductor device is coupled to a substrate, and insulating material covers (i) a portion of the semiconductor device and (ii) a portion of the substrate. The device also comprises a heat spreader embedded in the insulating material and the heat spreader is isolated from the substrate at least in part by the insulating material.

Owner:MARVELL ASIA PTE LTD

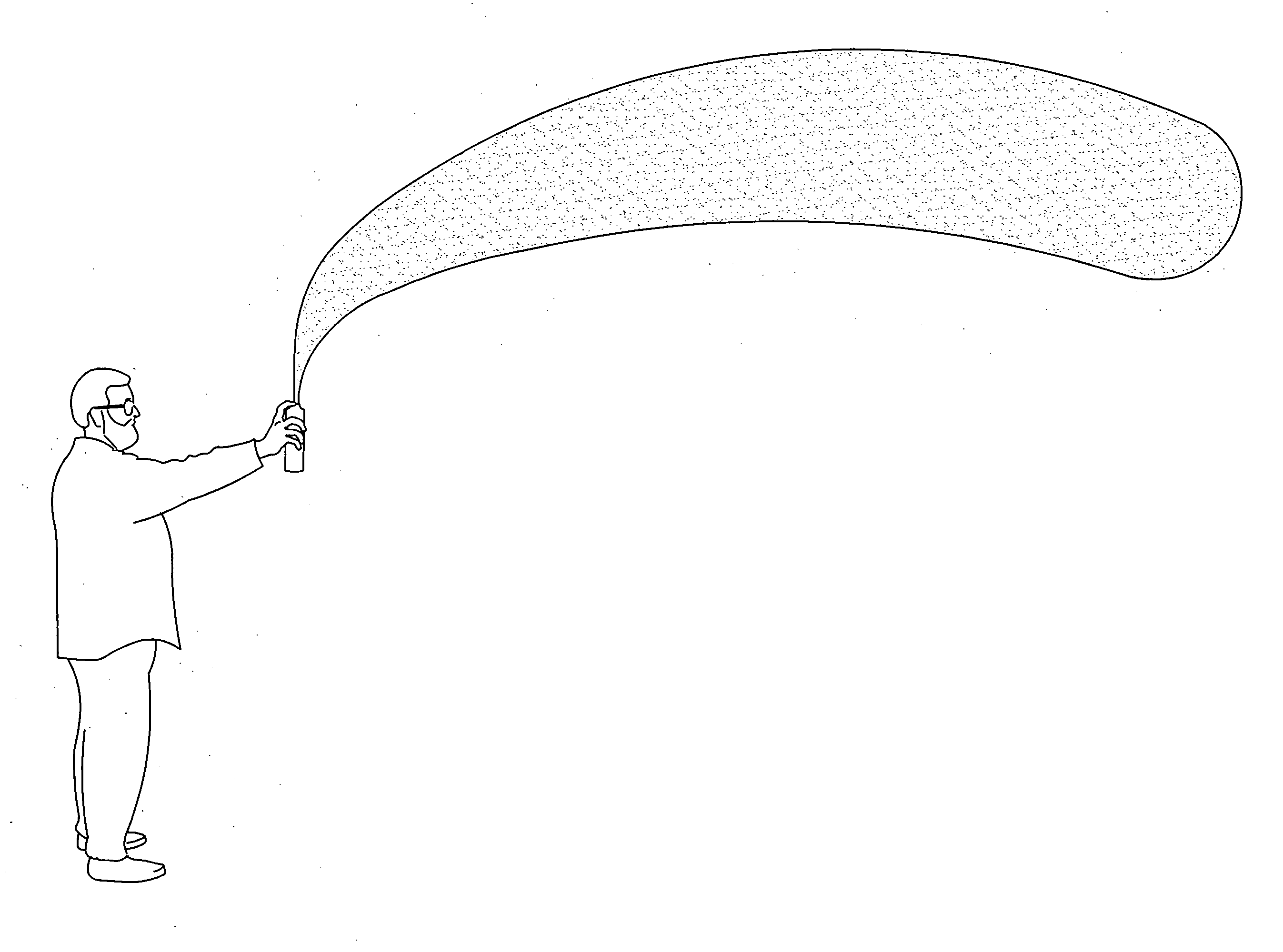

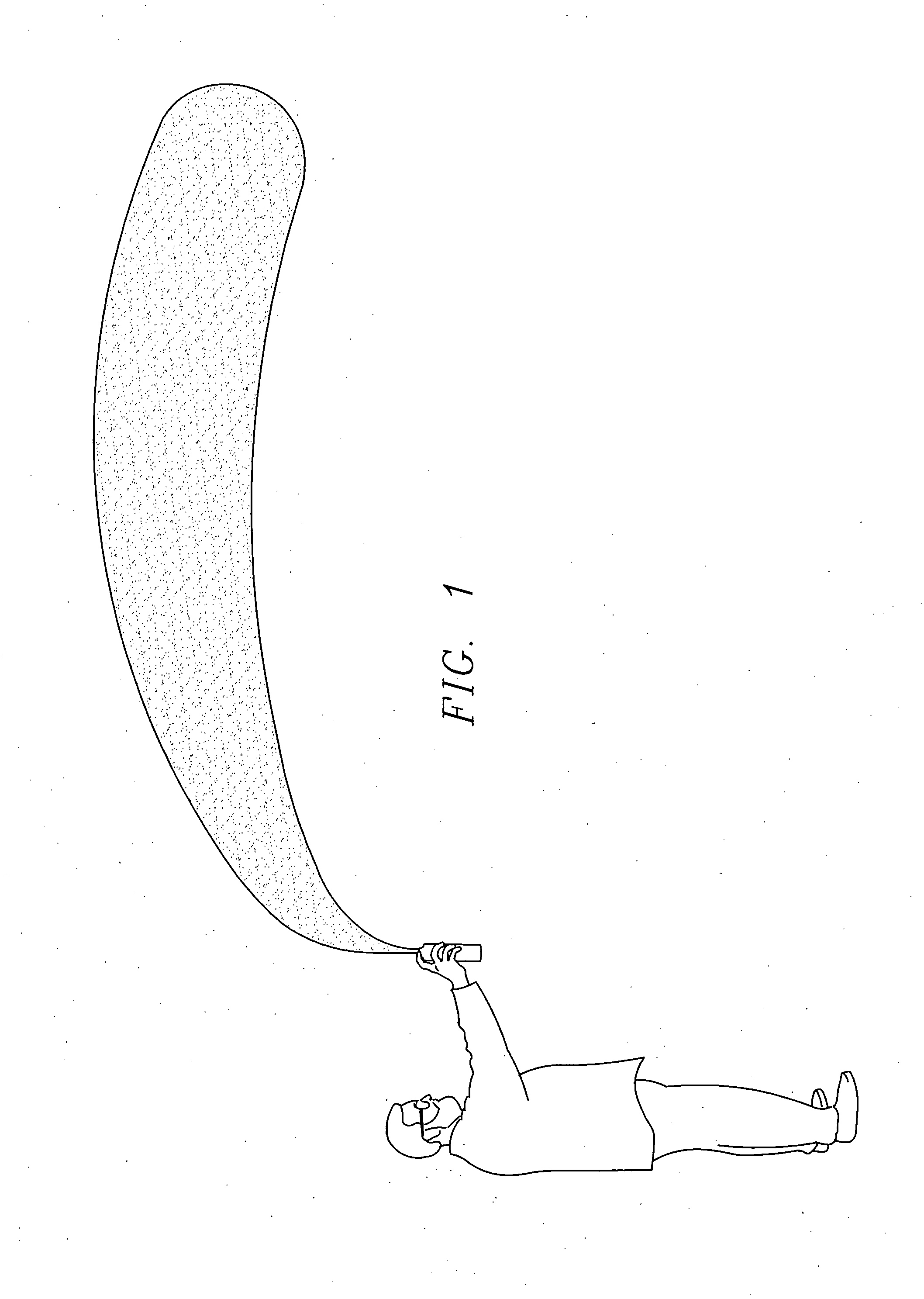

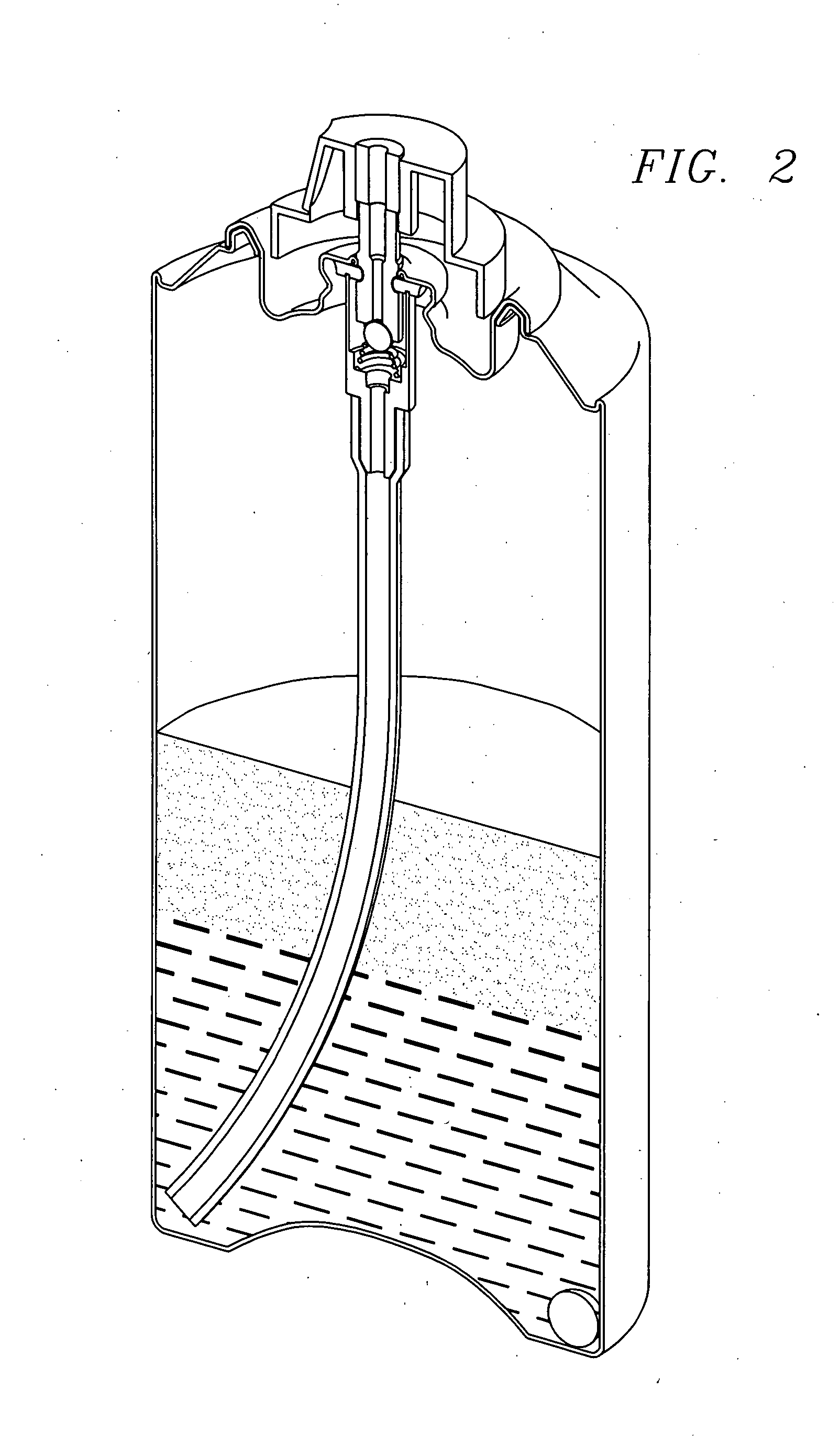

Visible animal scent and dispersion system

InactiveUS20090260271A1Simple and economical and reliableAvoid physical contactPowder deliveryAnimal huntingEngineeringDomestic animal

An animal scent composition contains animal generated scents and a visual indicator to allow visualization of scent travel and application. The scent may be used for repelling wild and domestic animals, for attracting game animals, and for masking the scent of humans. Dispersing means provide a pressurized aerosol canister with a dispersing nozzle axially aligned with the aerosol canister to prevent clogging of the nozzle by agglomerated visual indicator particles when the scent composition is dispersed.

Owner:BAILEY DON

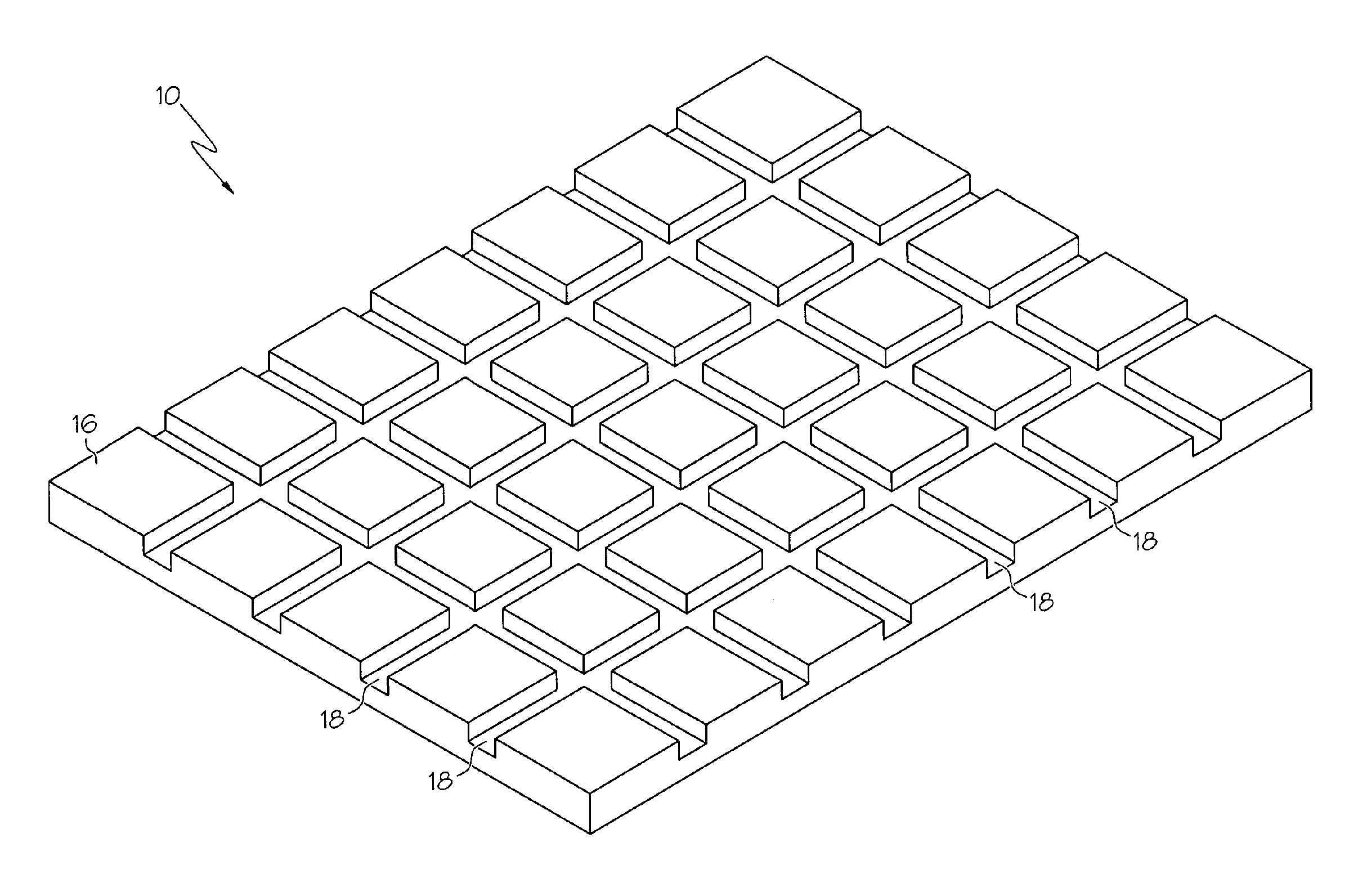

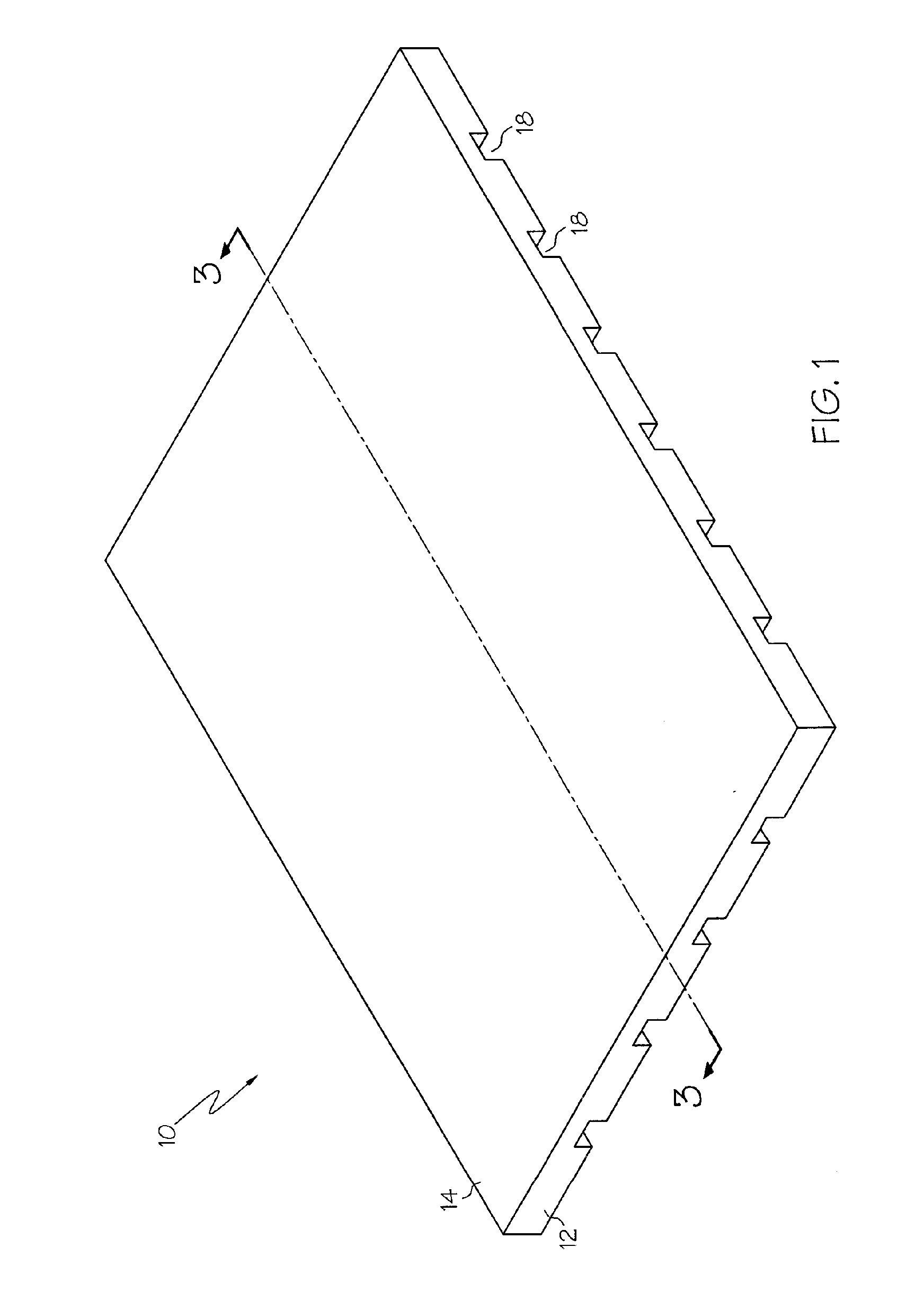

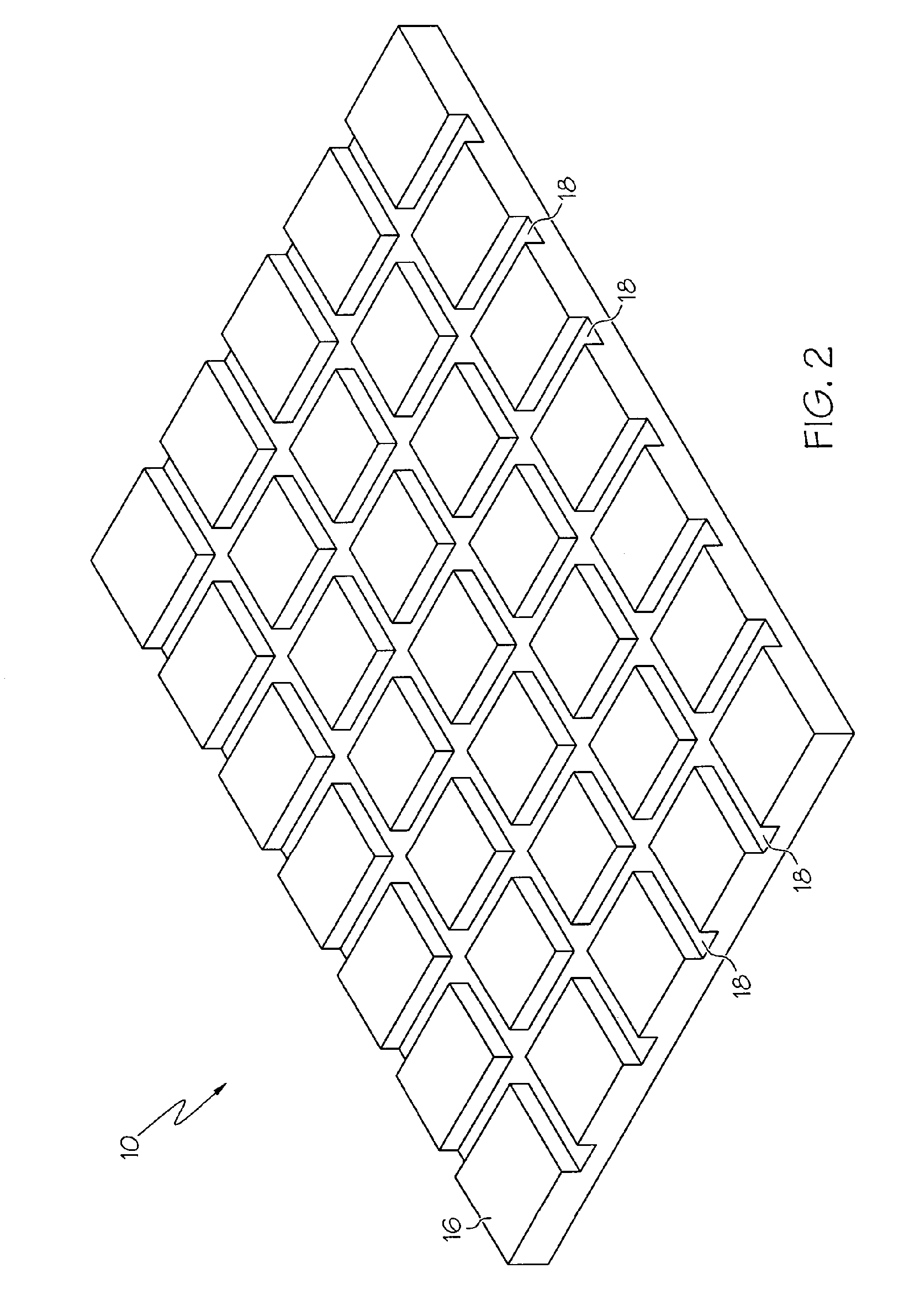

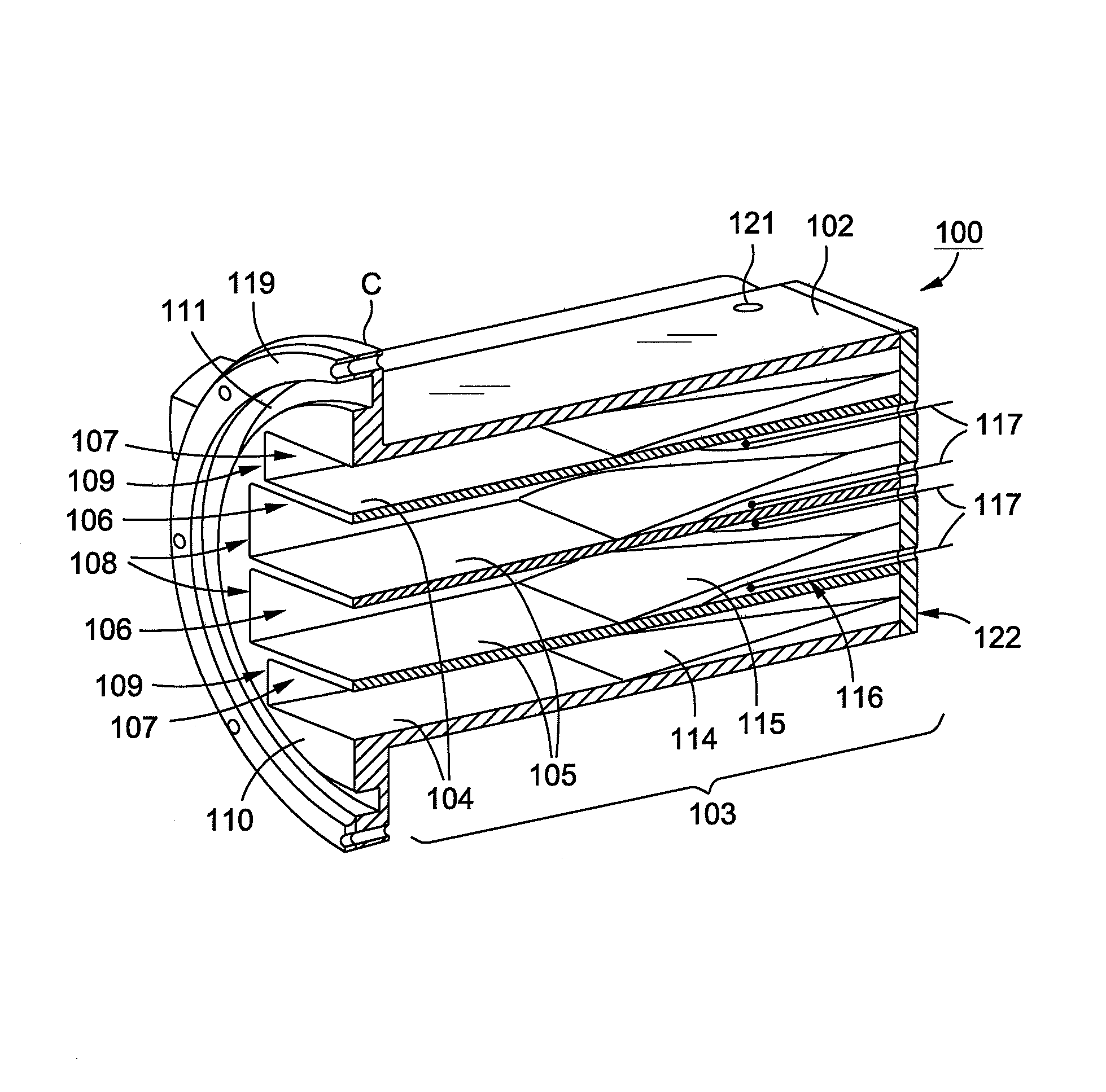

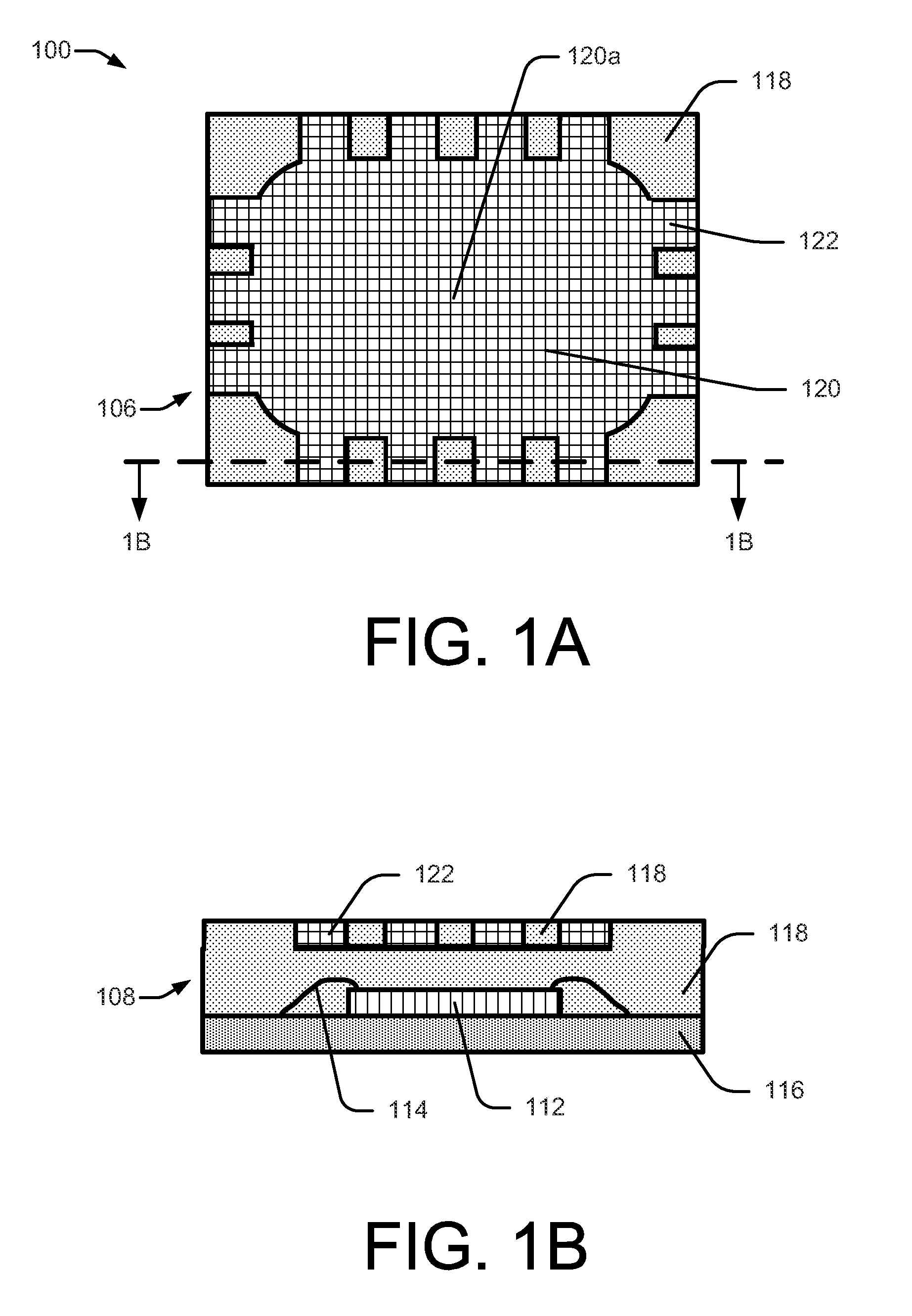

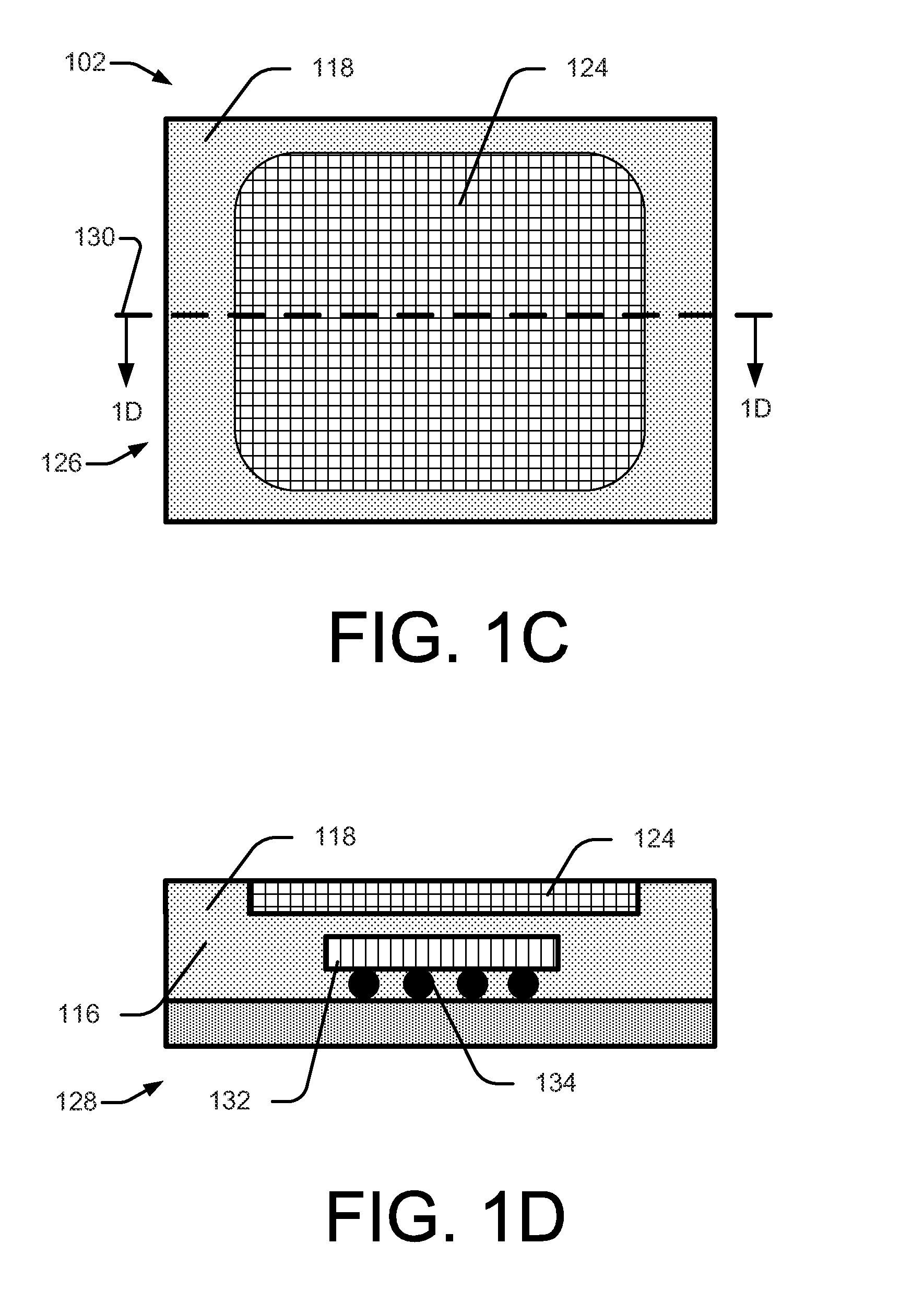

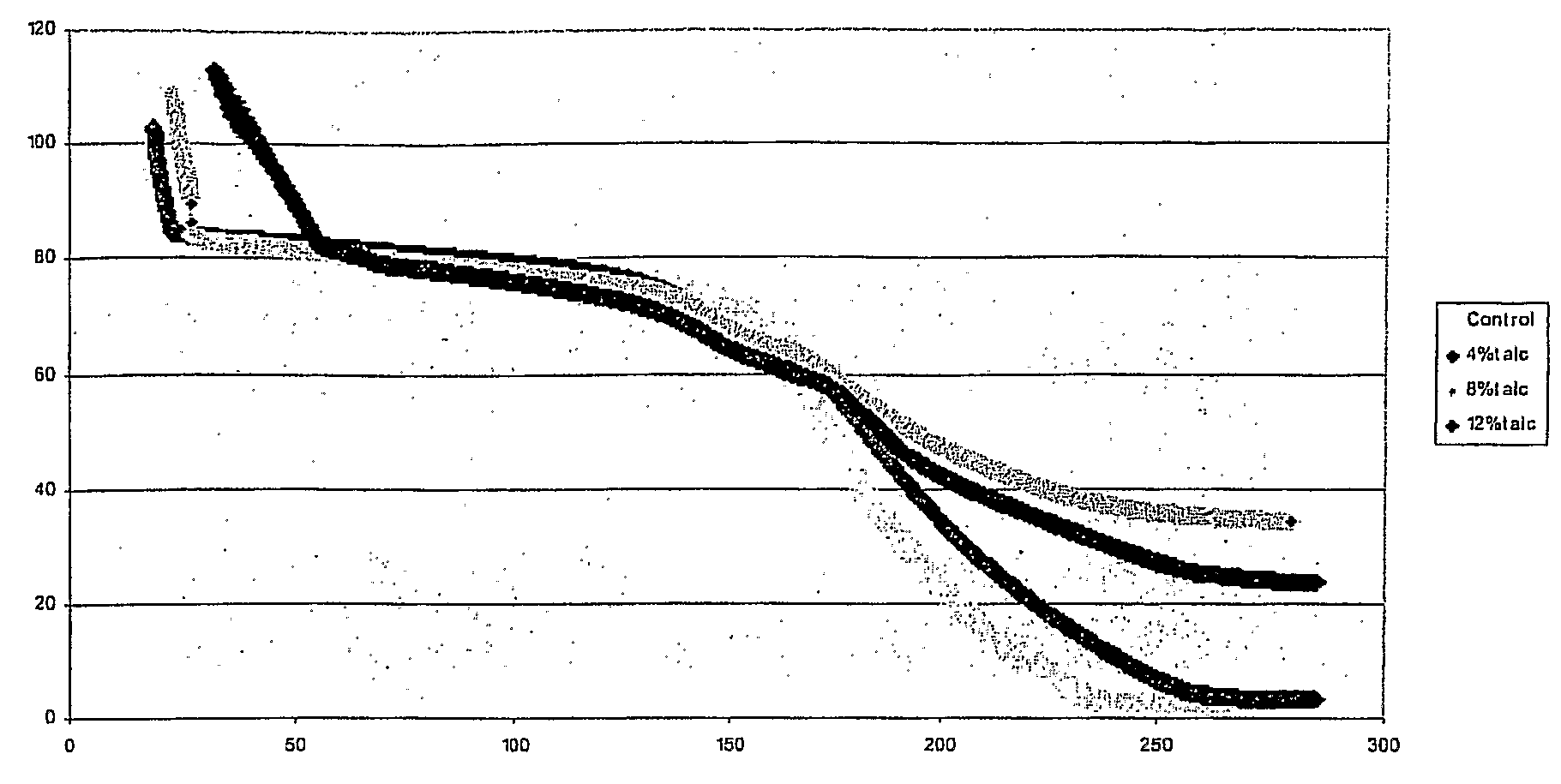

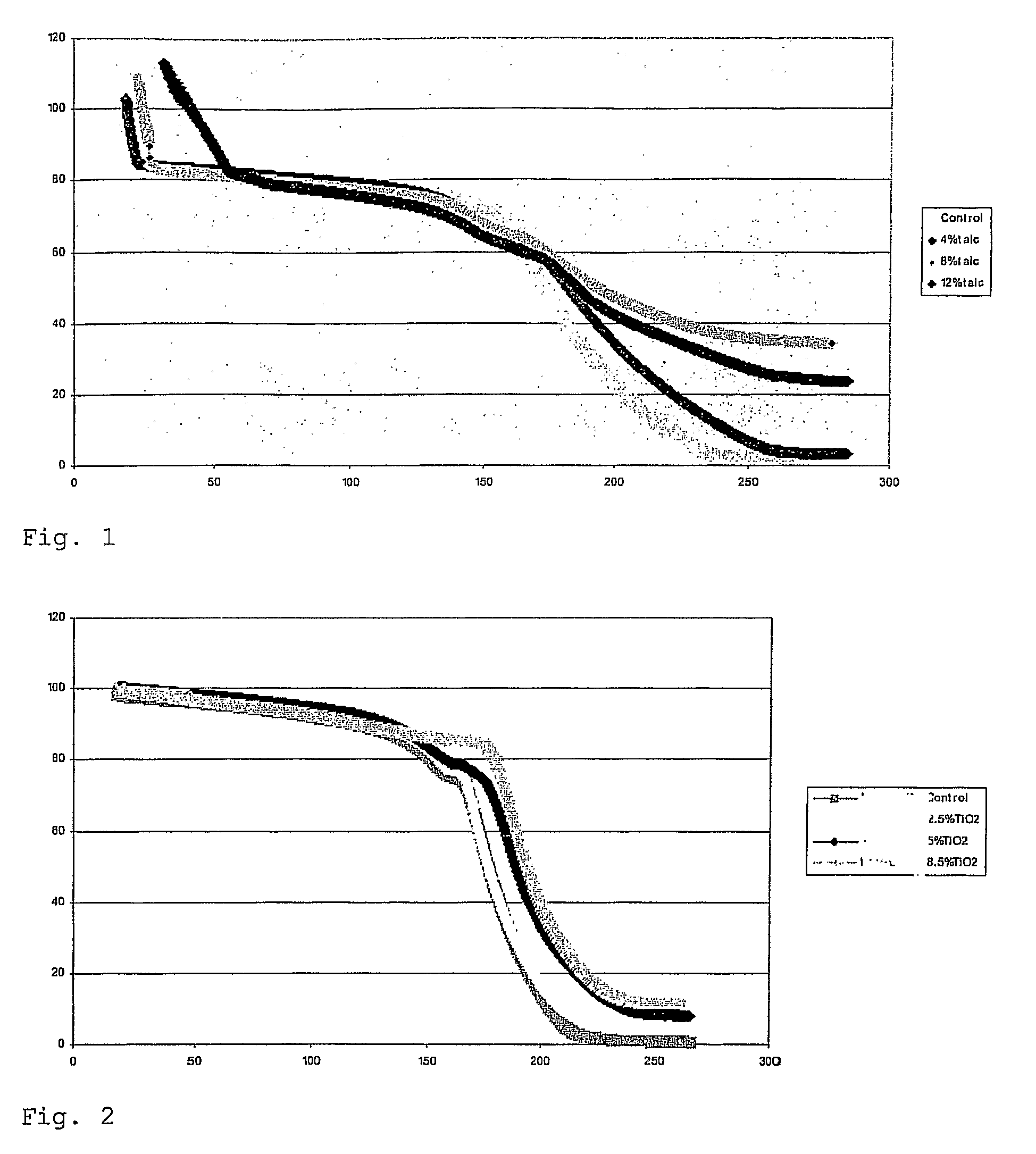

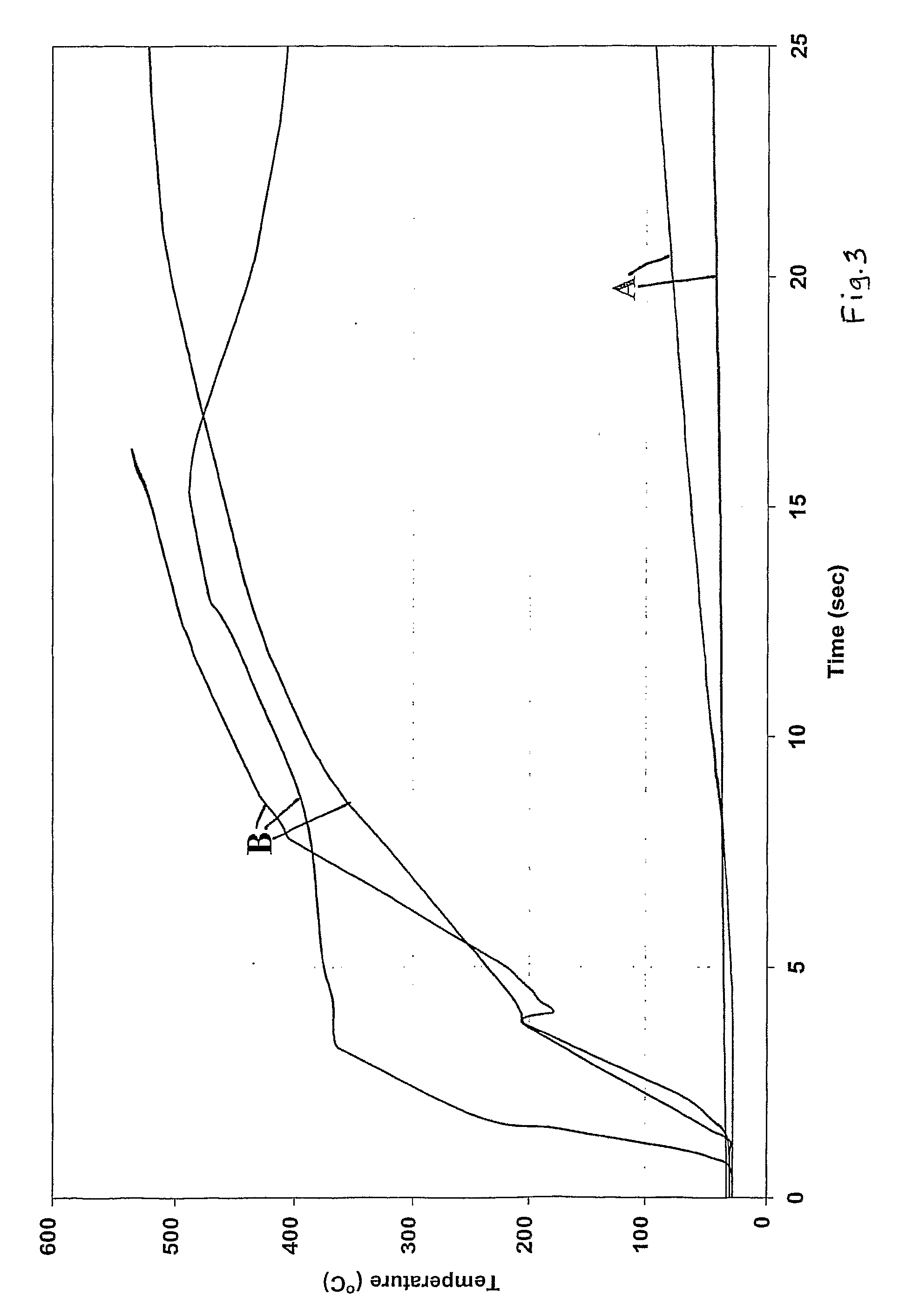

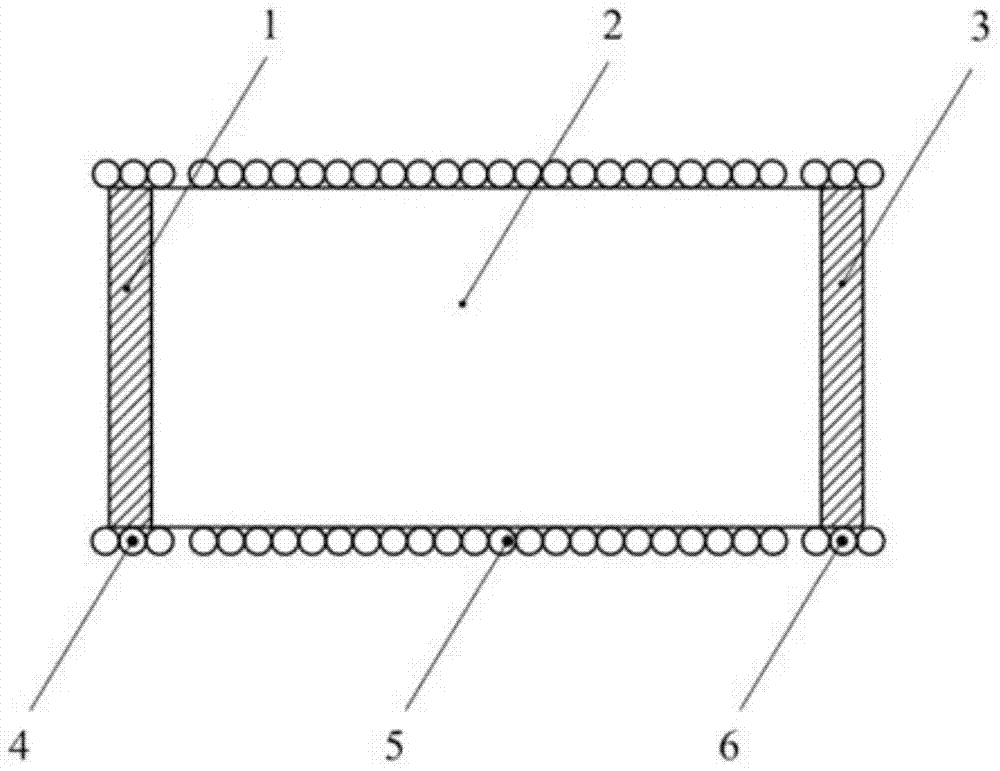

Battery Separator With Z-Direction Stability

ActiveUS20080268345A1Preventing and reducing sudden thermal runawayAvoid physical contactCell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesParticulatesMembrane thickness

A battery separator is a microporous membrane. The membrane has a major volume of a thermoplastic polymer and a minor volume of an inert particulate filler. The filler is dispersed throughout the polymer. The membrane exhibits a maximum Z-direction compression of 95% of the original membrane thickness. Alternatively, the battery separator is a microporous membrane having a TMA compression curve with a first substantially horizontal slope between ambient temperature and 125° C., a second substantially horizontal slope at greater than 225° C. The curve of the first slope has a lower % compression than the curve of the second slope. The curve of the second slope is not less than 5% compression. The TMA compression curve is graphed so that the Y-axis represents % compression from original thickness and the X-axis represents temperature.

Owner:CELGARD LLC

Wafer test method utilizing conductive interposer

ActiveUS7057405B2Not causing damageReduce manufacturing costElectronic circuit testingIndividual semiconductor device testingContact testInterposer

A wafer test method is performed for a wafer prior to forming bumps on the wafer, using a conductive interposer having one side with test pads and the other side with test bumps electrically connected to the test pads. The conductive interposer is mounted on the wafer having a plurality of chips, wherein the test bumps are in electrical contact with bond pads on active surfaces of the chips. Test probes are used to contact the test pads to perform tests for the chips. This wafer test method is beneficially performed prior to forming bumps on the wafer, such that the prior-art drawback of damaging bumps on the wafer by contacting test probes with the bumps on the wafer can be eliminated, and the conductive interposer mounted on the wafer prevents the test probes from physical contact with the bond pads on the chips, thereby not damaging the bond pads.

Owner:SILICONWARE PRECISION IND CO LTD

Multi-chip stacking method to reduce voids between stacked chips

ActiveUS8093104B1Poor adhesionReduce voidsSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

A multi-chip stacking method to reduce voids between stacked chips is revealed. A first chip is disposed on a substrate, and a plurality of first bonding wires are formed by wire bonding to electrically connect the first chip and the substrate. A second chip is disposed on an active surface of the first chip where a dielectric layer and a FOW adhesive (film over wire) adhesive are attached onto a back surface of the second chip. The FOW adhesive partially encapsulates the first bonding wires and adheres to the active surface of the first chip. Then, the substrate is placed in a pressure oven to provide a positive pressure greater than one atm during thermally curing the FOW adhesive with exerted pressures. Accordingly, voids can be reduced inside the FOW adhesive during the multi-chip stacked processes where issues of poor adhesion and popcorn between chips can be avoided.

Owner:WALTON ADVANCED ENG INC

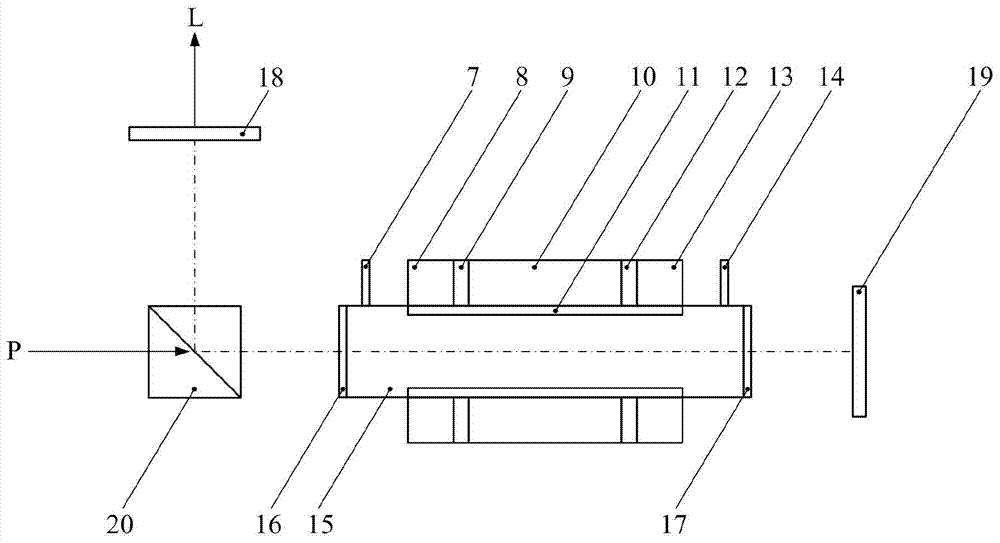

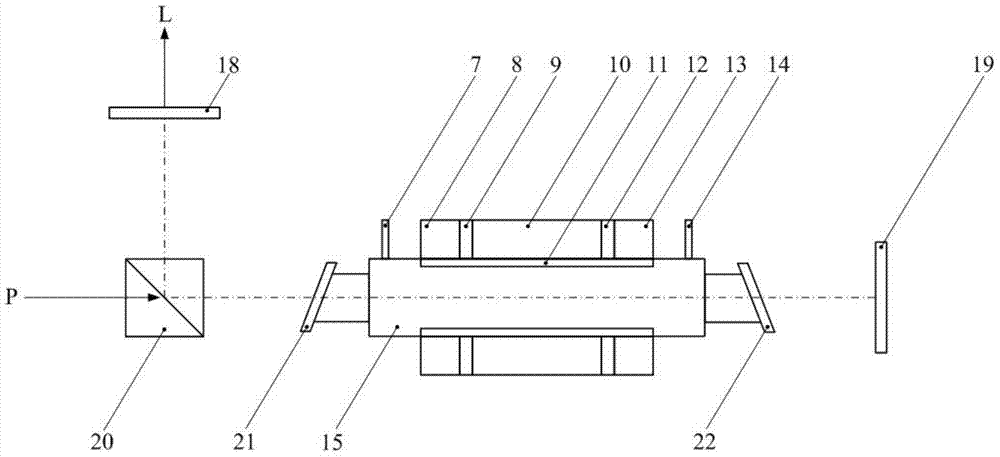

Heat-pipe-type alkali-metal vapor laser device

InactiveCN103928824AAvoid physical contactIncrease lossActive medium shape and constructionGas laser constructional detailsResonant cavityThermal insulation

The invention belongs to the technical field of lasers, and discloses a heat-pipe-type alkali-metal vapor laser device which is used for solving the problem that vapor coagulates on windows in an existing alkali-metal vapor laser device. A gain unit is designed to be of a heat pipe structure. A left window and a right window are arranged at the two ends of a pipe shell and sealed. The center of the pipe shell is sleeved with a heater. A left refrigerator and a right refrigerator are symmetrically arranged at equidistant positions of the two ends of the heater. The space between the left refrigerator and the heater is filled with a left thermal insulation material layer, and the space between the right refrigerator and the heater is filled with a right thermal insulation material layer. The pipe shell is lined with a liquid absorption core, and the liquid absorption core extends from the left end of the left refrigerator to the right end of the right refrigerator in the length direction. A left inflation inlet is formed between the left window and the left refrigerator and is adjacent to the left window, and a right inflation inlet is formed between the right window and the right refrigerator and is adjacent to the right window. A resonant cavity is of an L-shaped structure formed by an output mirror, a totally-reflecting mirror and a polarization beam splitter, the output mirror is arranged above the polarization beam splitter, and the totally-reflecting mirror is arranged on the right of the polarization beam splitter. The gain unit is placed between the polarization beam splitter and the totally-reflecting mirror.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

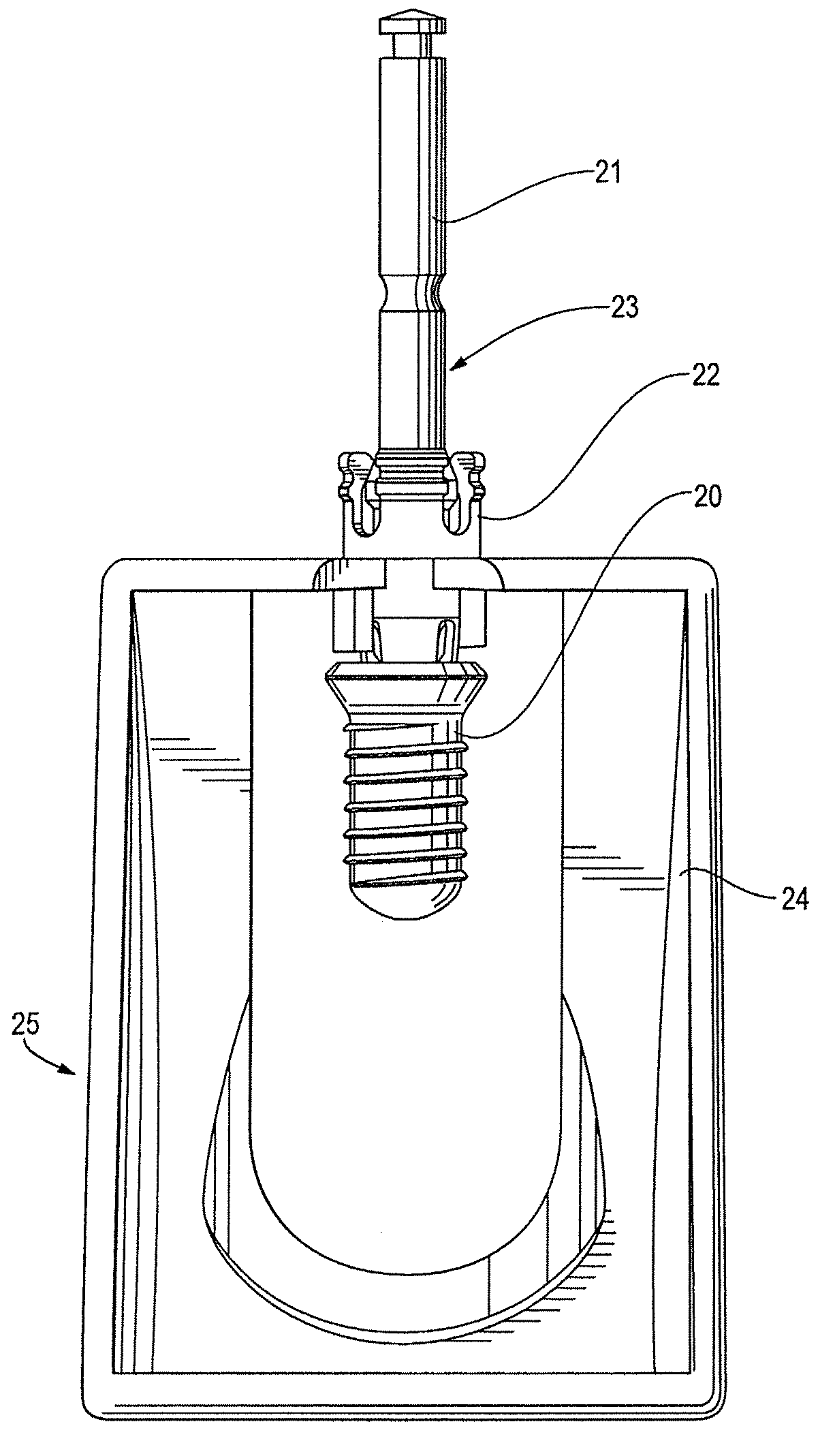

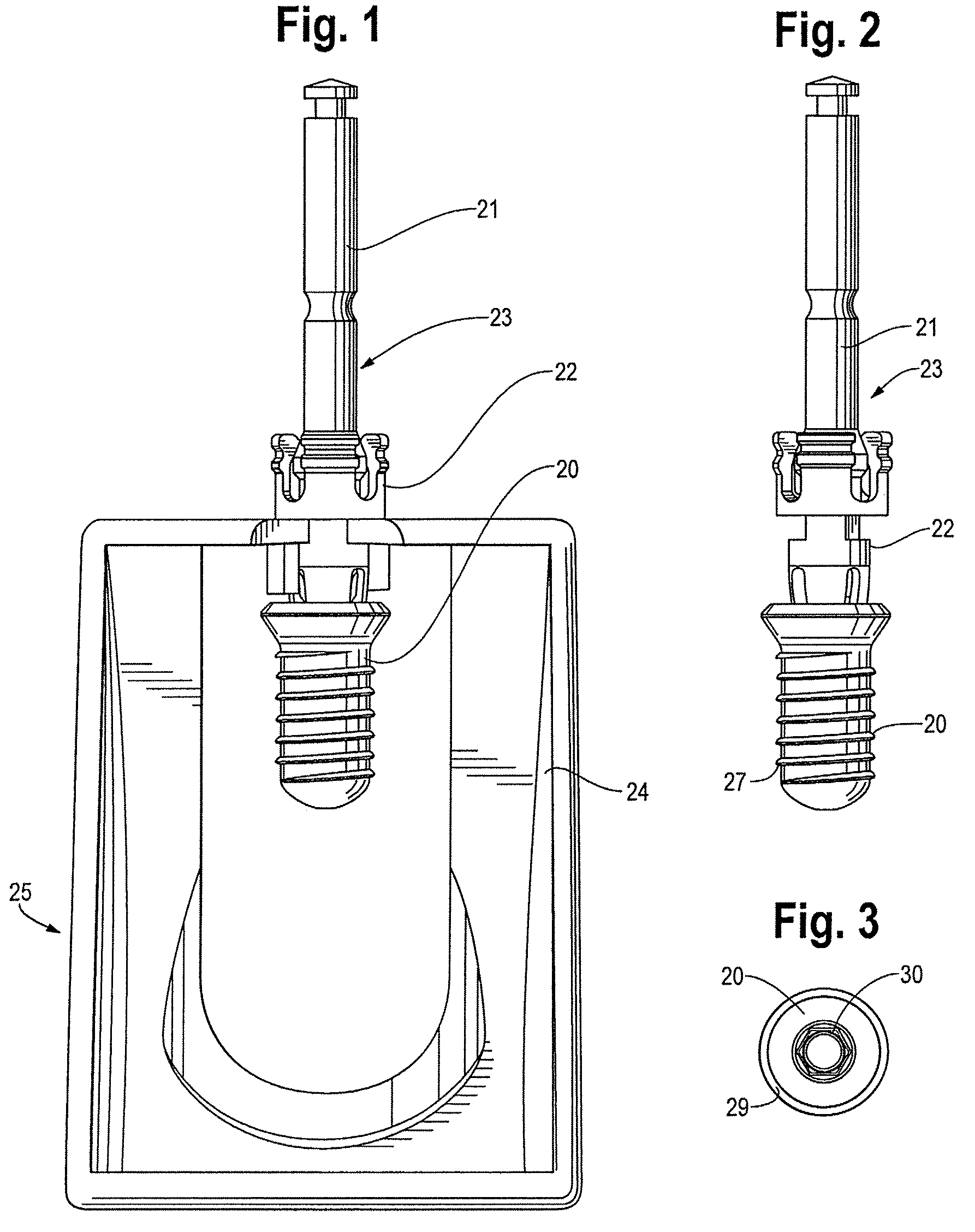

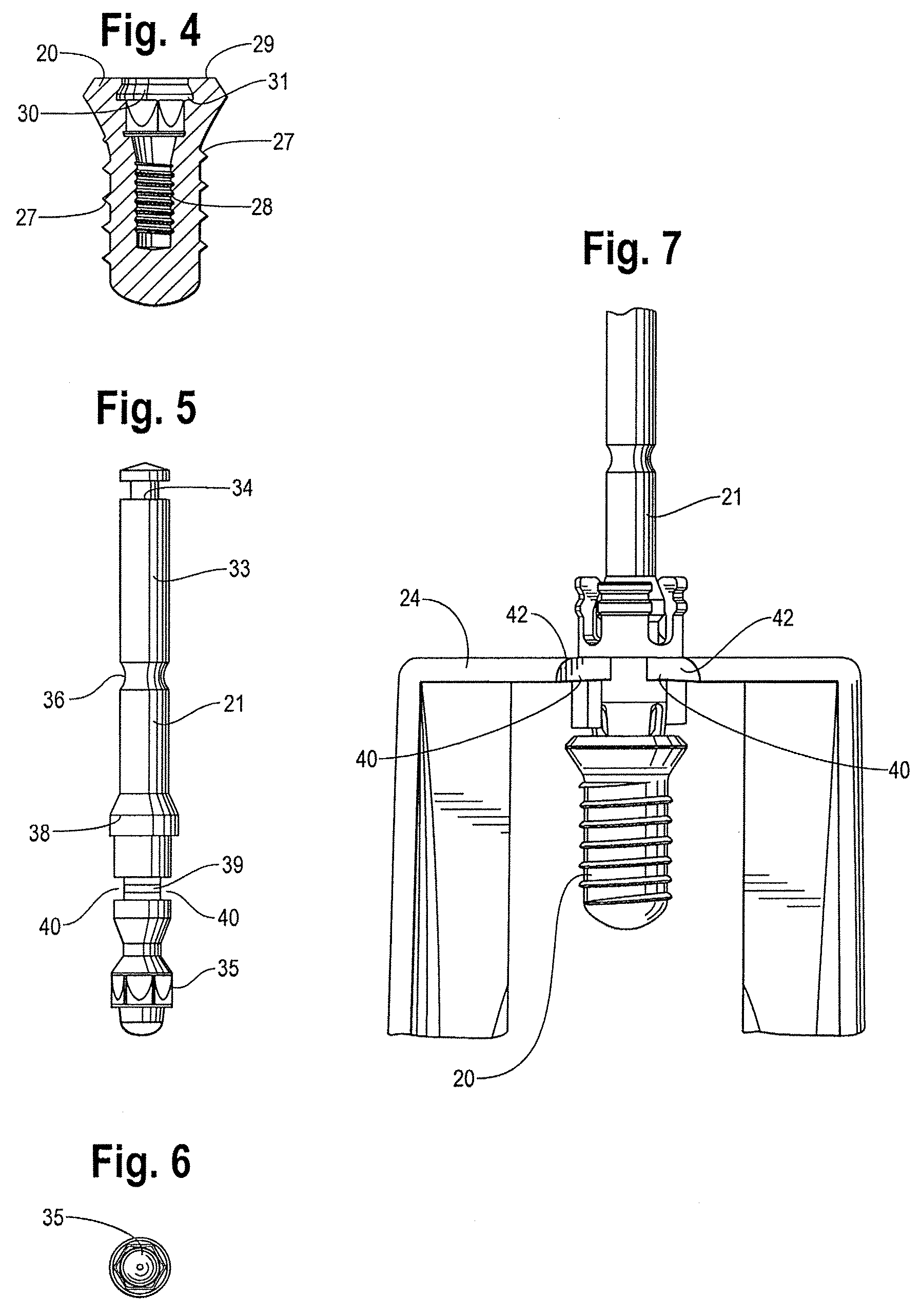

Implant-driver assembly

InactiveUS7887325B2Avoid physical contactReduce decreaseDental implantsDental toolsBiomedical engineeringImplant fixation

Owner:KEYSTONE DENTAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com