Hot isostatic pressing forming method used for improving part surface quality

A technology of hot isostatic pressing and surface quality, applied in the field of static pressing, can solve the problems of uneven distribution of alloy elements and reduce the surface quality of parts, and achieve the effect of excellent comprehensive performance, reducing friction and ensuring material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

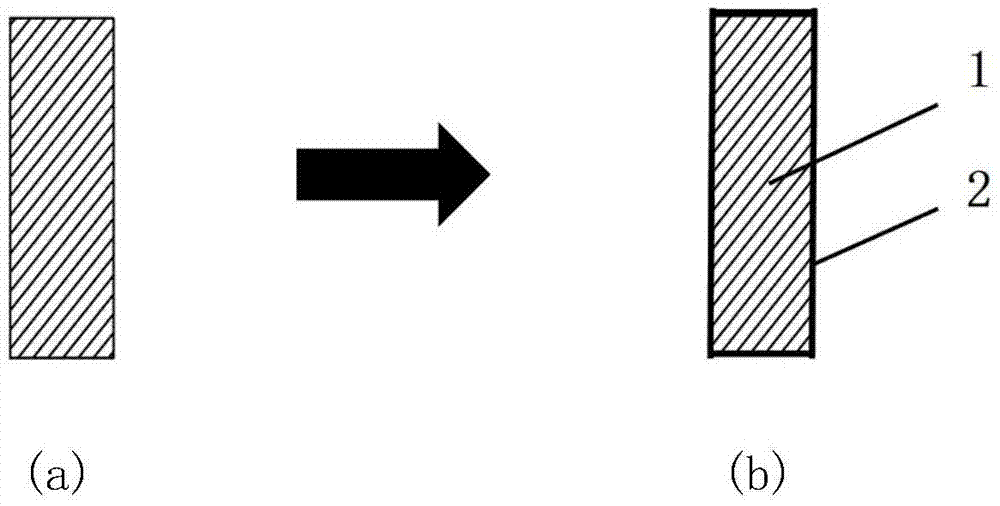

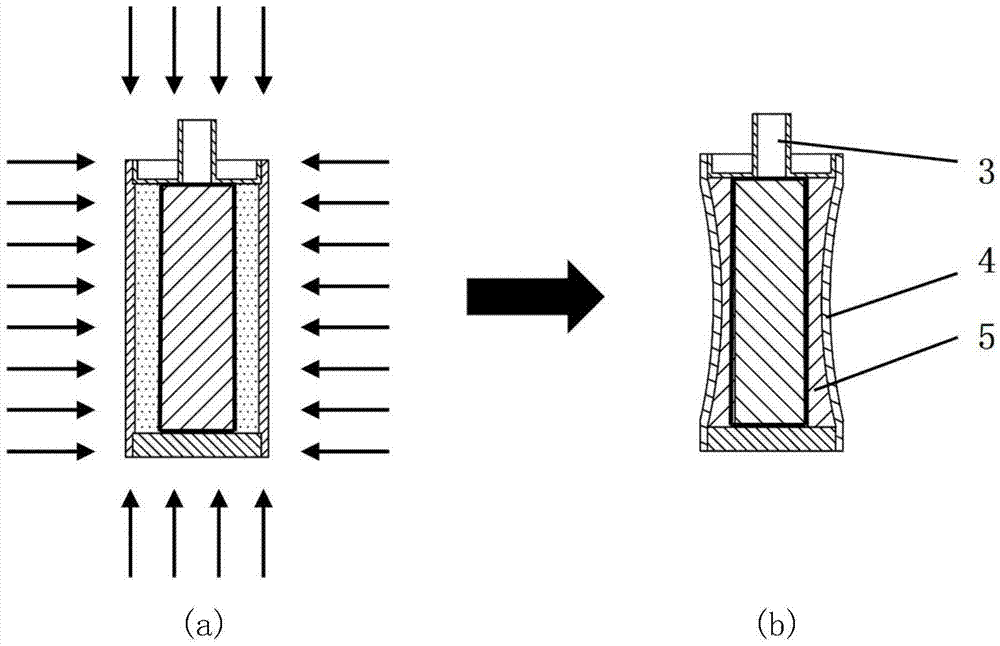

[0038] In this embodiment, FGH97 alloy powder is used as the base material to improve the high-temperature oxidation resistance and corrosion resistance of the alloy; AlTiN is used as the coating material, which has high hardness and wear resistance, and can also reduce the friction of the material . Since the solid solution temperature of the main strengthening phase of FGH97 is 1180°C, the hot isostatic pressing process parameter temperature is 1100°C, and the pressure is selected as 120MPa. Utilize the method of the present invention to manufacture aircraft engine and turbine blade parts according to above-mentioned parameter, concrete steps are as follows:

[0039] (1) According to the structure of the turbine blade parts, the matching hot isostatic pressure jacket and shape-controlling core are designed, and the lower part of the jacket is processed into a U shape, which can reduce the welding points at the bottom and reduce the risk of leakage caused by welding; shape-co...

Embodiment 2

[0046] Utilize the present invention to manufacture Inconel625 turbine disc parts. With the development of aerospace technology, the thrust-to-weight ratio of aeroengines is increasing, and the inlet temperature is also increasing. Nickel-based alloy is an excellent high-temperature alloy. More than 50% of modern gas turbine engines use high-temperature alloys, of which nickel-based materials account for about 40%. Nickel-based alloys are commonly used as materials for engine hot-end parts, and have excellent comprehensive properties under medium and high temperature conditions. However, with the increase of the thrust-to-weight ratio, higher requirements are placed on the high-temperature performance and surface quality of the material. In view of the above problems, the present invention uses Inconel625 powder as a raw material and TiN as a coating material to improve the high temperature strength, wear resistance and surface quality of the base material. Specific steps ar...

Embodiment 3

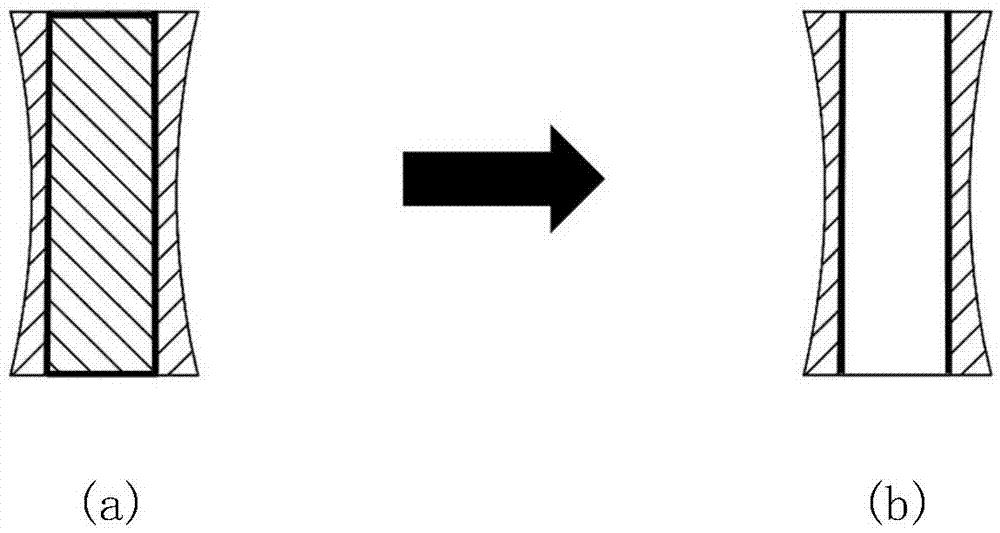

[0053] Utilize the present invention to improve wear resistance and surface quality of TC4 parts, concrete steps are as follows:

[0054] (1) Design the corresponding sheath and shape-controlling mold according to the shape of the part; select TC4 alloy powder with an average particle size of about 100 μm, and purify the powder before hot isostatic pressing;

[0055] (2) The shape-controlling core and sheath are processed by machining, and a layer of TiN coating is sprayed on the surface of the shape-controlling core by PVD method, and the thickness of the coating is 30 μm;

[0056] (3) Fix the shape-controlling core in the sheath, weld the upper and lower parts of the sheath together by welding; fill the powder into the inside of the sheath, vibrate it, and carry out air extraction treatment at a high temperature of 600°C. The vacuum degree in the sleeve reaches 10 -4 Pa, seal the exhaust port.

[0057] (4) Carry out hot isostatic pressing treatment on the sheath, the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com