Preparation method of zero-expansion LAS/SiC composite material

A composite material and zero-expansion technology, applied in the field of composite material preparation, can solve problems such as large internal stress of structures and parts, micro-crack structure of parts, transmission failure, etc., achieve high densification, homogeneous structure, and save preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in combination with specific embodiments.

[0025] The particle size of LAS powder prepared in the following 10 examples, the particle size of selected SiC powder and the mass ratio of SiC / LAS are shown in Table 1, the specific sintering process parameters of each example are shown in Table 2, and the performance tests of the obtained samples are shown in Table 3 .

[0026] Table 1: LAS, SiC powder particle size and SiC / LAS mass ratio selected in each example

[0027]

[0028] Table 2: Sintering process parameters of LAS / SiC composite materials in various examples

[0029]

[0030]

[0031] Table 3: Measured performance values of LAS / SiC composite samples obtained in various examples

[0032]

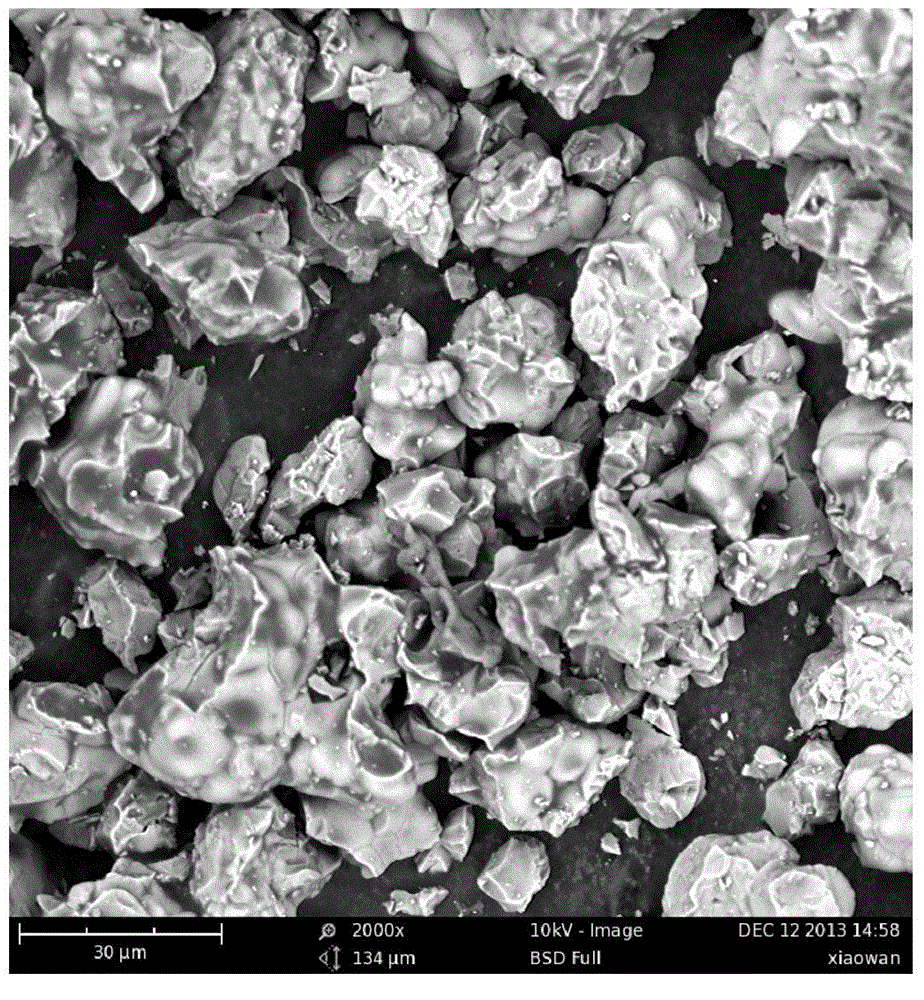

[0033] figure 1 The SEM photograph of the prepared LAS powder morphology shows that the particle size of the LAS powder prepared by reaction sintering is uniform, with an average size of 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com