Multi-component borosilicate glass and aluminum nitride low-temperature co-fired ceramic material and preparation method thereof

A technology of borosilicate glass and aluminum nitride ceramics, which is applied in the field of electronic packaging materials, can solve problems such as limited applications, and achieve the effects of low cost, simple process flow, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

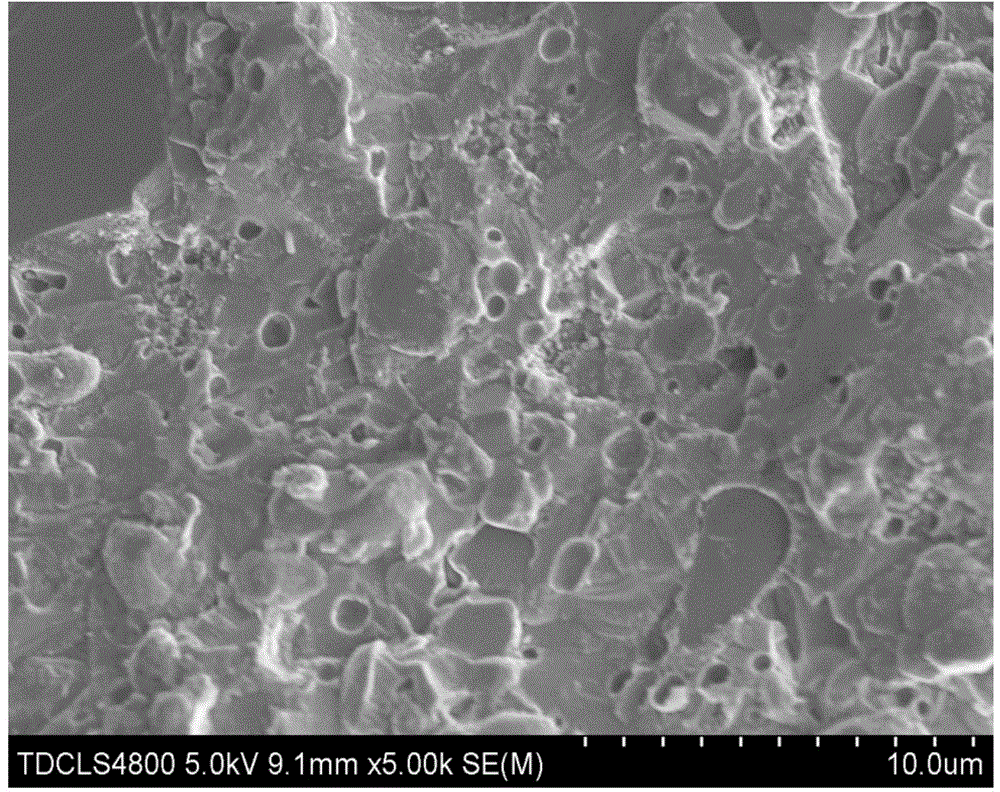

Image

Examples

Embodiment 1

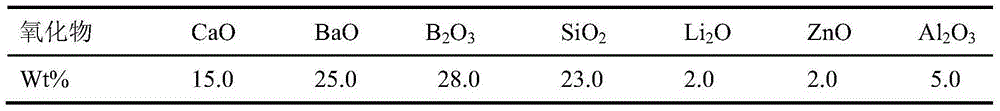

[0019] In a specific embodiment of the present invention, the mass percentage content of each oxide in the multi-component borosilicate glass is as follows:

[0020]

[0021] The preparation method of the low-temperature co-fired ceramic material in this embodiment comprises the following steps:

[0022] (1) Preparation of low-melting-point glass raw materials: weigh the corresponding amount of CaCO according to the mass percentage content of each oxide required for the above-mentioned low-melting-point glass phase 3 、BaCO 3 、H 3 BO 3 , SiO 2 , Li 2 CO 3 , ZnO, Al 2 o 3 ingredients, and mix well.

[0023] (2) Preparation of low-melting point glass: raise the high-temperature continuous glass melting furnace to 1450°C, then evenly add the above-mentioned mixed glass raw materials into the quartz crucible in the glass melting furnace, and use deionized water to accept the glass that flows out from the outlet of the quartz crucible. Glass melt to obtain glass frit. T...

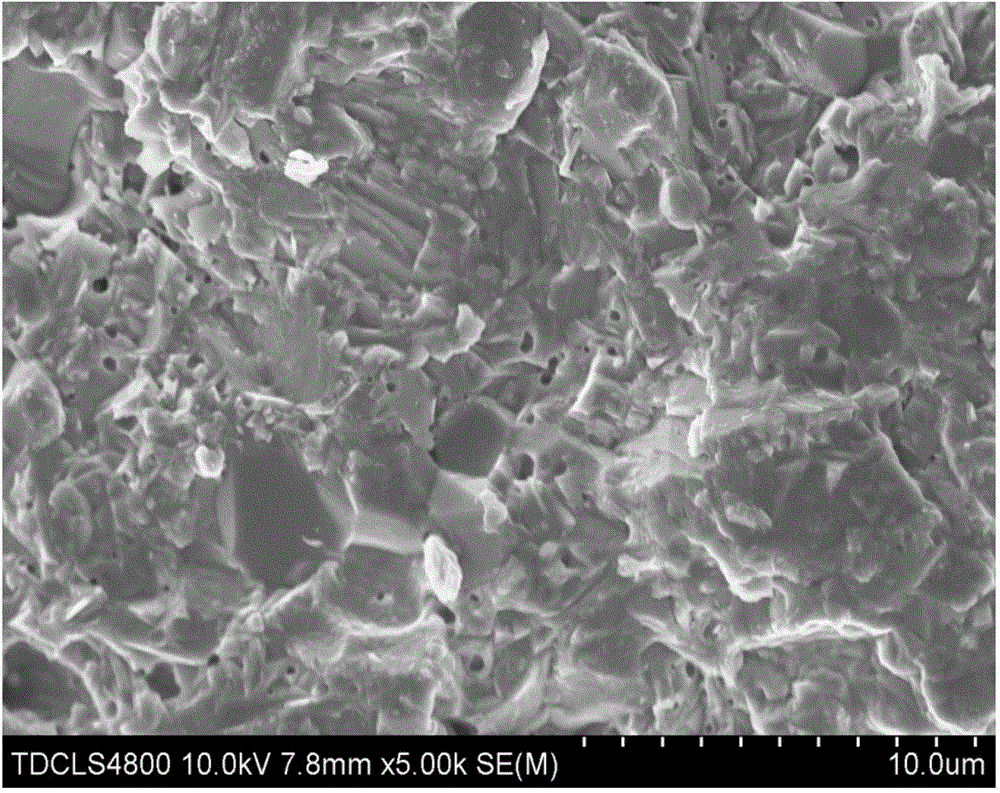

Embodiment 2

[0028] In a specific embodiment of the present invention, the mass percentage content of each oxide in the multi-component borosilicate glass is as follows:

[0029]

[0030] (1) Preparation of low-melting-point glass raw materials: weigh the corresponding amount of CaCO according to the mass percentage content of each oxide required for the above-mentioned low-melting-point glass phase 3 、BaCO 3 、H 3 BO 3 , SiO 2 , Li 2 CO 3 , ZnO, Al 2 o 3 ingredients, and mix well.

[0031] (2) Preparation of low-melting point glass: raise the high-temperature continuous glass melting furnace to 1450°C, then evenly add the above-mentioned mixed glass raw materials into the quartz crucible in the glass melting furnace, and use deionized water to accept the glass that flows out from the outlet of the quartz crucible. Glass melt to obtain glass frit. The obtained glass frit was first ground with an alumina mortar to obtain a uniform coarse glass powder, and then ball milled for 18 ...

Embodiment 3

[0037] In a specific embodiment of the present invention, the mass percentage content of each oxide in the multi-component borosilicate glass is as follows:

[0038]

[0039] (1) Preparation of low-melting-point glass raw materials: weigh the corresponding amount of CaCO according to the mass percentage content of each oxide required for the above-mentioned low-melting-point glass phase 3 、BaCO 3 、H 3 BO 3 , SiO 2 , Li 2 CO 3 , ZnO, Al 2 o 3 ingredients, and mix well.

[0040] (2) Preparation of low-melting point glass: raise the high-temperature continuous glass melting furnace to 1450°C, then evenly add the above-mentioned mixed glass raw materials into the quartz crucible in the glass melting furnace, and use deionized water to accept the glass that flows out from the outlet of the quartz crucible. Glass melt to obtain glass frit. The obtained glass frit was first ground with an alumina mortar to obtain a uniform coarse glass powder, and then ball milled for 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com