High-temperature heat-response bentonite and high-temperature heat-response bentonite drilling fluid

A technology of bentonite and drilling fluid, which is applied in the field of high-temperature heat-responsive bentonite and high-temperature heat-responsive bentonite drilling fluid. Excellent thermal response, rheological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

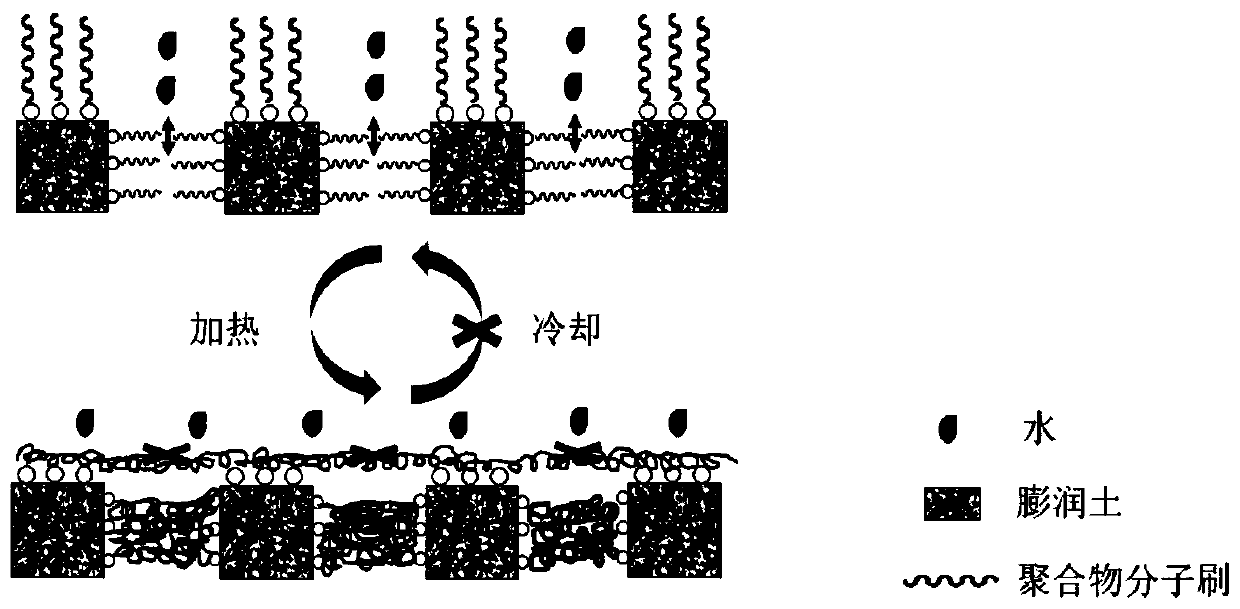

Method used

Image

Examples

Embodiment 1

[0046] A kind of high temperature thermal response bentonite, the preparation method comprises the following steps:

[0047] Step 1, bentonite acid activation to build activation sites.

[0048] Mix 3g of bentonite with 100mL of 7wt% hydrochloric acid aqueous solution to dredge the clay pores, build hydroxyl adsorption sites, and improve the adsorption of bentonite.

[0049] Step 2, drying and processing the bentonite.

[0050] Dry the bentonite at 120-150°C for 10-24 hours to remove hydrochloric acid and moisture in the bentonite.

[0051] Step three, ATRP modification.

[0052] The activated bentonite was miscible with 0.5mL (3-aminopropyl)trimethoxysilane (ATMS) and 10mL of methanol, and magnetically stirred at 42°C for 12-16h to provide ATRP modified activation sites.

[0053] Then, 10 mL of dichloromethane (containing 2% (v / v) pyridine) and 5 mL of 2-bromoisobutyryl bromide were added for ATRP modification. During the ATRP modification, add a solution containing 5 g o...

Embodiment 2

[0057] A kind of high temperature thermal response bentonite, the preparation method comprises the following steps:

[0058] Step 1, bentonite acid activation to build activation sites.

[0059] Mix 1g of bentonite with 100mL of 10wt% hydrochloric acid aqueous solution to dredge the clay pores, build hydroxyl adsorption sites, and improve the adsorption of bentonite.

[0060] Step 2, drying and processing the bentonite.

[0061] Dry the bentonite at 120-150°C for 10-24 hours to remove hydrochloric acid and moisture in the bentonite.

[0062] Step three, ATRP modification.

[0063] The activated bentonite was miscible with 0.5mL (3-aminopropyl)trimethoxysilane (ATMS) and 10mL methanol, and magnetically stirred at 35°C for 12h to provide ATRP modified activation sites.

[0064] Then, 10 mL of dichloromethane (containing 3% (v / v) pyridine) and 5 mL of 2-bromoisobutyryl bromide were added for ATRP modification. During ATRP modification, add 5-10 mL of p-xylene containing 5 g of ...

Embodiment 3

[0068] A kind of high temperature thermal response bentonite, the preparation method comprises the following steps:

[0069] Step 1, bentonite acid activation to build activation sites.

[0070] Mix 3g of bentonite with 100mL of 15wt% hydrochloric acid aqueous solution to dredge the clay pores, build hydroxyl adsorption sites, and improve the adsorption of bentonite.

[0071] Step 2, drying and processing the bentonite.

[0072] Dry the bentonite at 120-150°C for 10-24 hours to remove hydrochloric acid and moisture in the bentonite.

[0073] Step three, ATRP modification.

[0074] The activated bentonite was mixed with 1mL (3-aminopropyl)trimethoxysilane (ATMS) and 40mL of methanol, and magnetically stirred at 45°C for 16h to provide ATRP modified activation sites.

[0075] Then, 20 mL of dichloromethane (containing 5% (v / v) pyridine) and 10 mL of 2-bromoisobutyryl bromide were added for ATRP modification. During ATRP modification, add a solution containing 10 g of phenyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com