Thermal head and manufacturing method thereof

A thermal head and head substrate technology, applied in printing and other directions, can solve problems such as large radius of curvature, influence on printing quality, thermal responsiveness lower than expected value, etc., and achieve superior thermal responsiveness and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

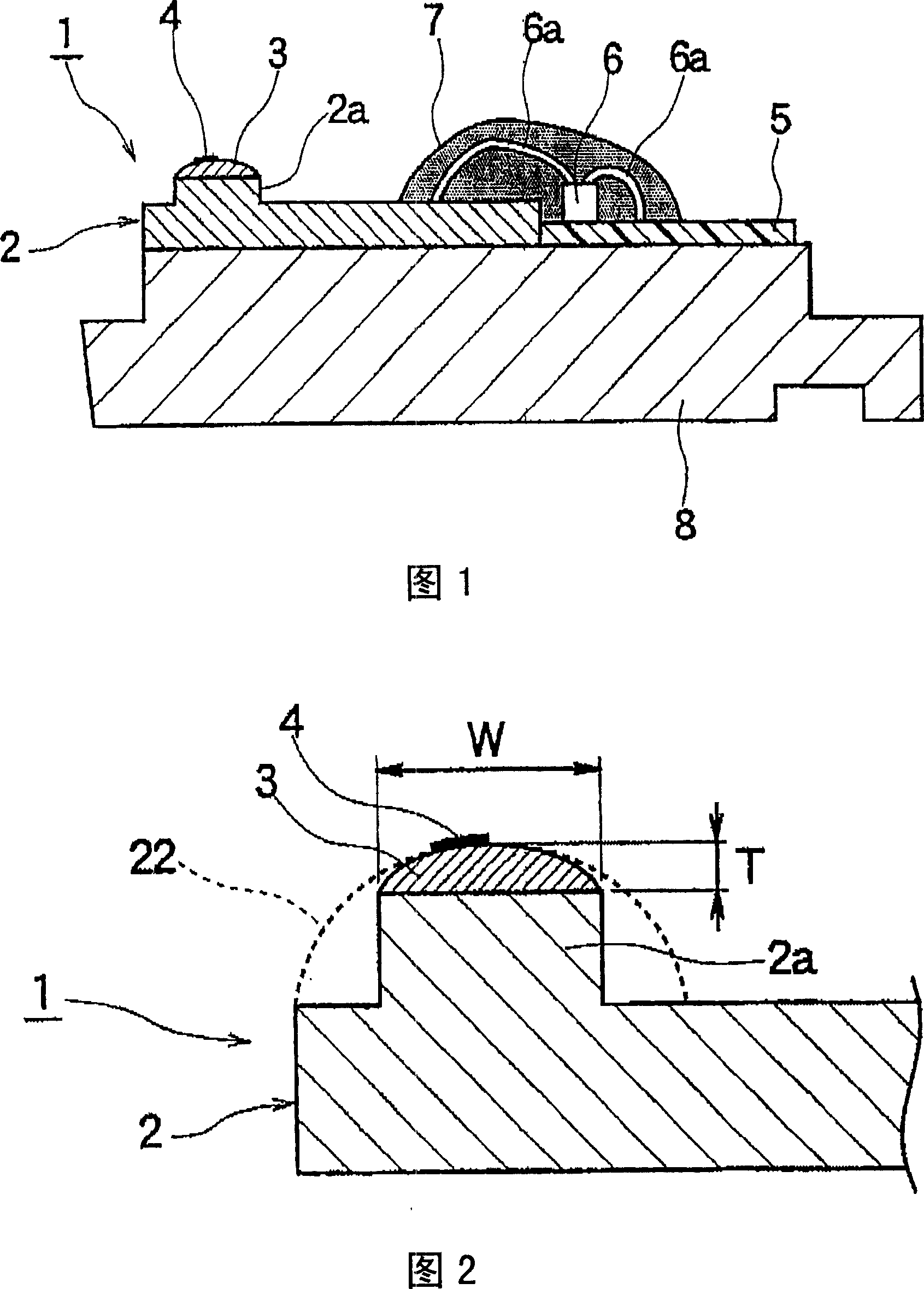

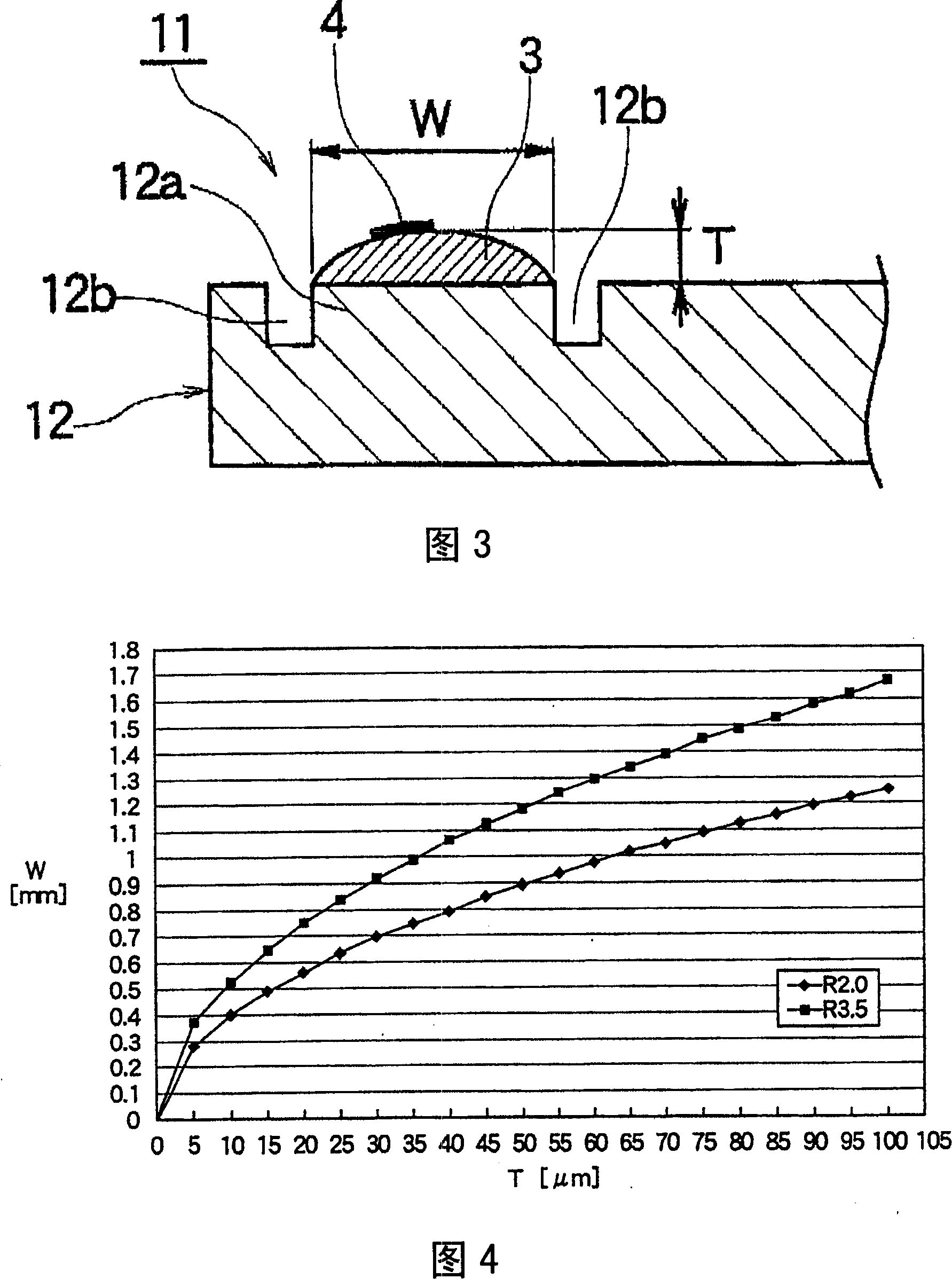

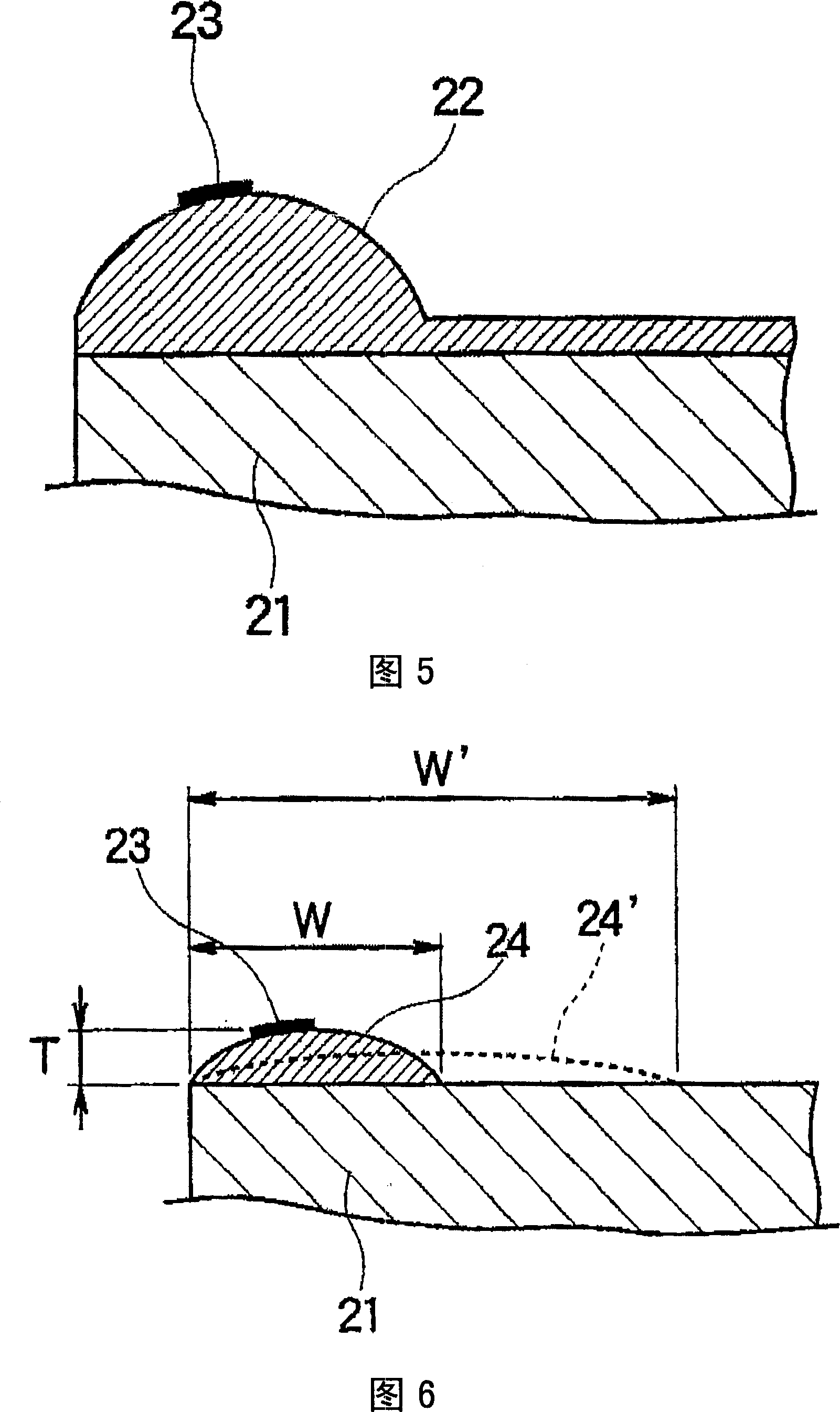

[0036] Hereinafter, embodiments of the thermal head and its manufacturing method according to the present invention will be described based on the drawings. 1 is a sectional view of a main part of a thermal head according to a first embodiment of the present invention, FIG. 2 is an enlarged sectional view of a main part of FIG. 1 , and FIG. 3 is an enlarged sectional view of a main part of a thermal head according to a second embodiment of the present invention. As a cross-sectional view, FIG. 4 is a graph showing the relationship between the arc-shaped radius of curvature, the width dimension, and the height dimension of the heat insulating layer of the present invention.

[0037] First, as shown in FIG. 1 , the thermal head 1 according to the first embodiment of the present invention is provided with an insulating head substrate 2 made of ceramics or the like, and the head substrate 2 is formed in a direction perpendicular to the paper surface. Long strip.

[0038] In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com