Heavy-duty gas turbine high-vortex tip clearance control structure

A gas turbine and control structure technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as unstable operation of gas turbines and affect the safe operation of gas turbines, and achieve the effect of reducing blade tip clearance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

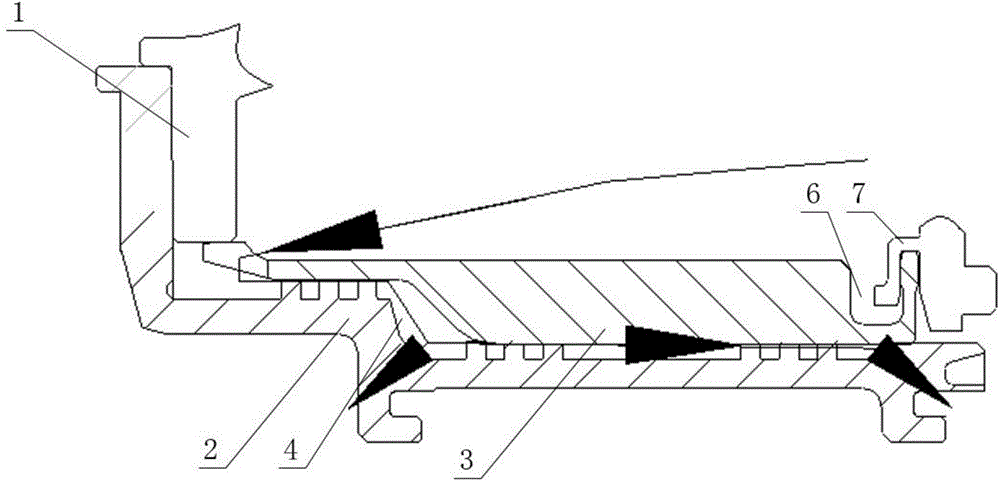

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as figure 1 As shown, the high-vortex blade tip clearance control structure of a heavy-duty gas turbine includes a full-ring outer shell 2 installed on the cylinder 1, and a full-ring shell 3 that is sleeved on the outside of the full-ring shell 2. The full-ring shell 3 and the whole There is a gap 4 between the ring casings 2, and a gap 5 is opened at the left end of the whole ring casing 3, the gap 5 communicates with the gap 4, and the gap 4 forms a cooling air flow channel. Preferably, the left end of the whole ring housing 3 is evenly provided with a plurality of notches 5 along the circumferential direction. In this embodiment, the left end of the whole ring housing 3 is evenly provided with 10 notches 5 along the circumferential direction.

[0024] The whole-ring outer casing 2 is facing the high-vortex blade tip, and the thermal deformation of the whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com