Patents

Literature

31results about How to "Control thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

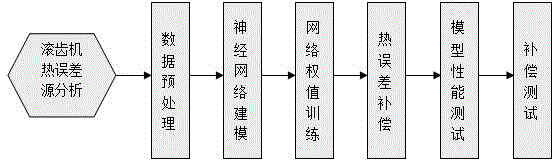

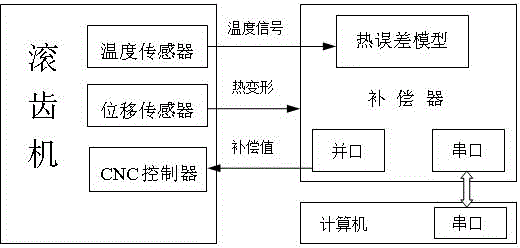

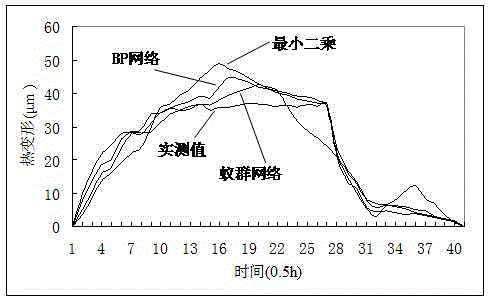

Machine tool thermal error modeling method based on ant colony neural network

InactiveCN105094053AImprove predictive performanceOvercome inherent flawsProgramme controlComputer controlHobbingThermal deformation

The invention relates to a data processing method in the field of precise machining technology, and particularly to a machine tool thermal error element modeling method based on an ant colony neural network. The machine tool thermal error modeling method comprises the steps of (1) analyzing a thermal error source of a hobbing machine; (2) establishing a neural network model; (3) performing network weights training based on an ant colony algorithm; and (4) performing a thermal error compensation experiment. The machine tool thermal error modeling method has advantages of high thermal error approximation ability, high prediction precision and high robustness. Thermal deformation of the hobbing machine can be effectively controlled, and furthermore a gear machining precision is improved.

Owner:SHANDONG UNIV OF TECH

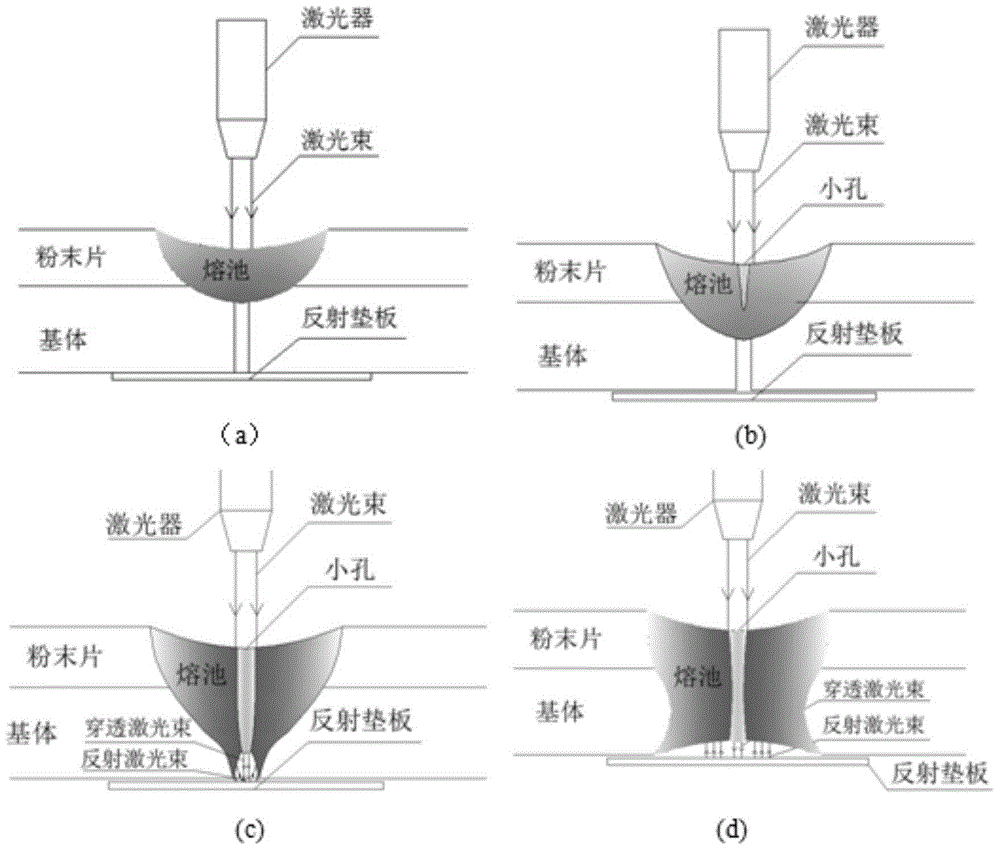

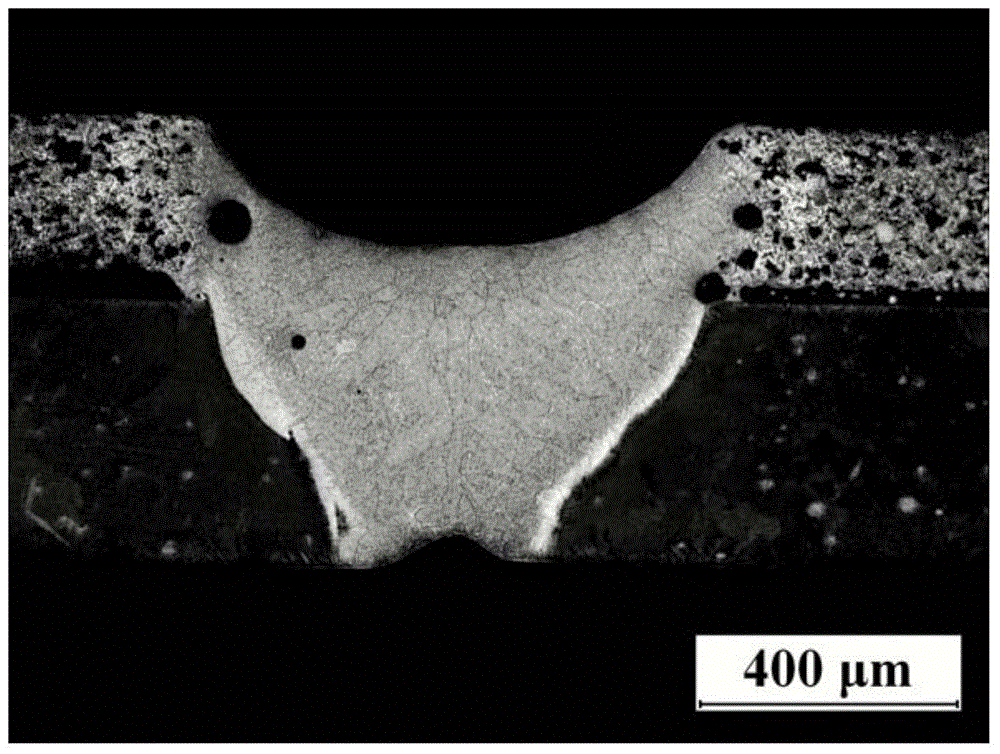

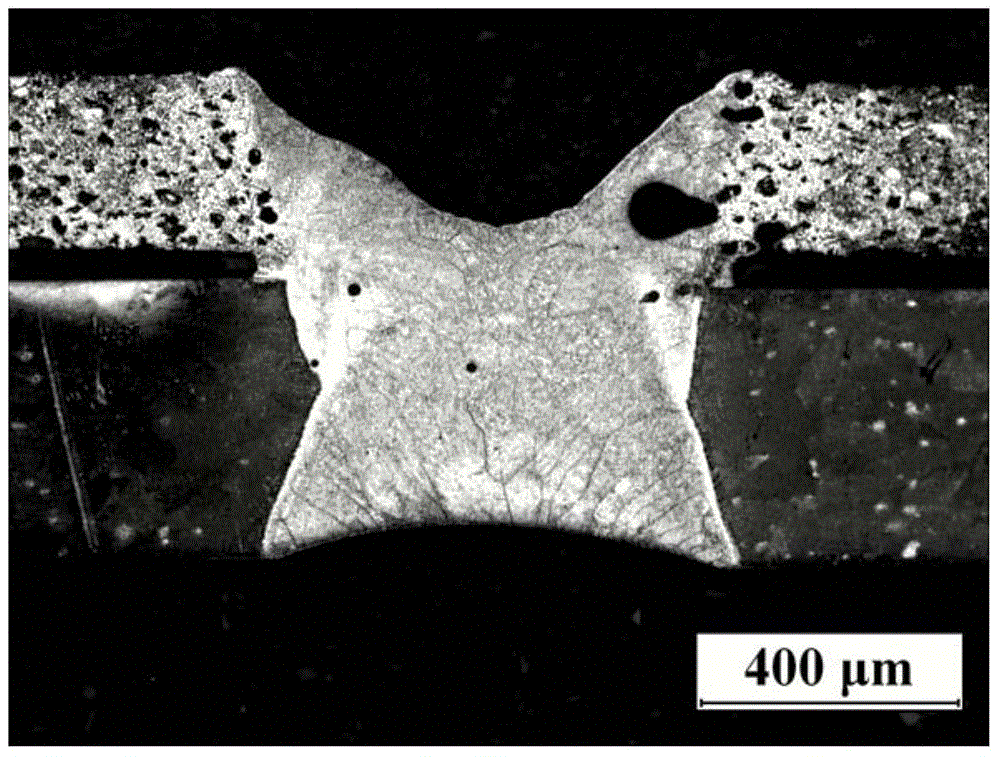

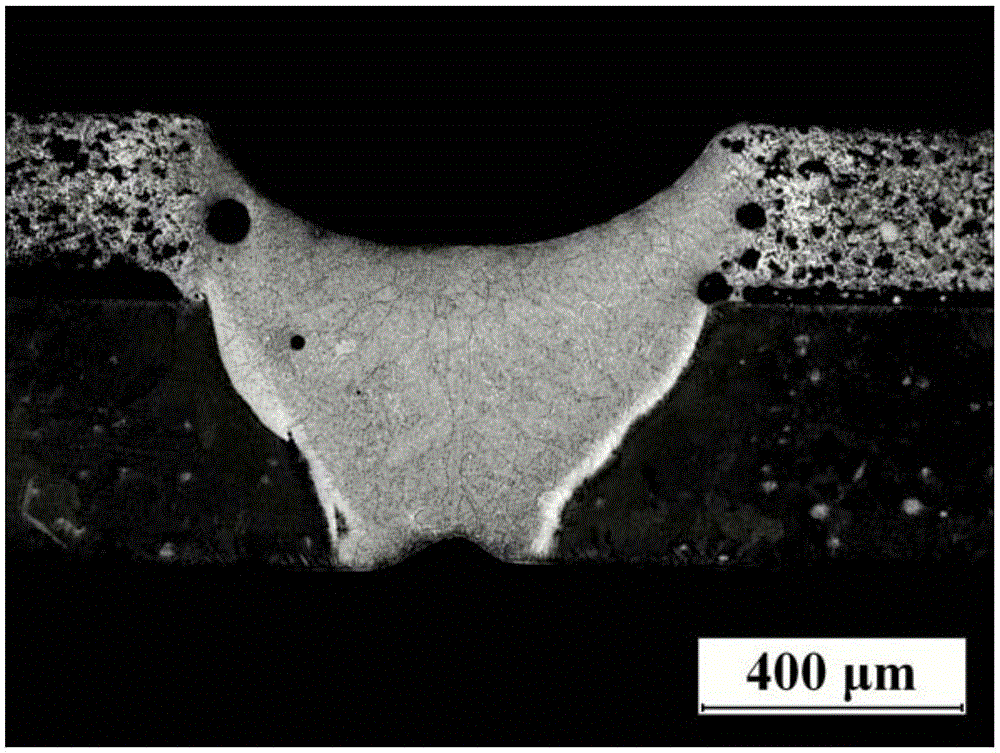

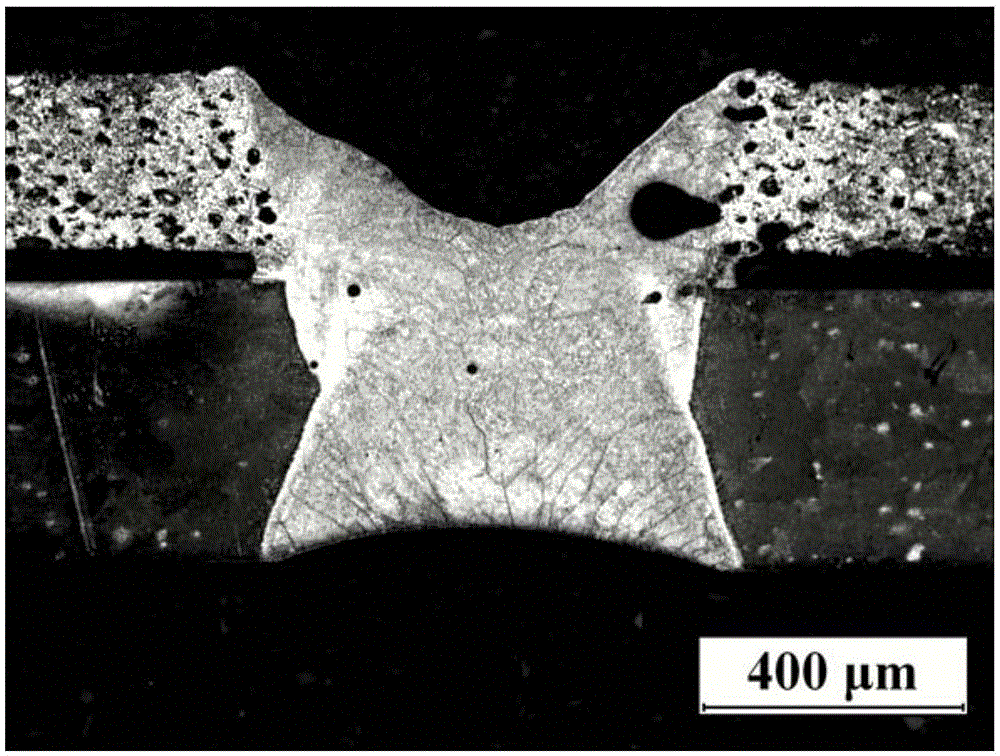

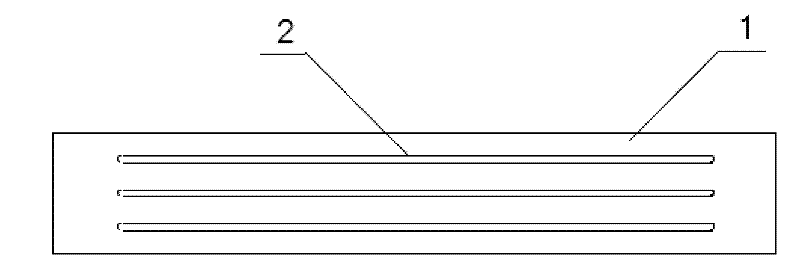

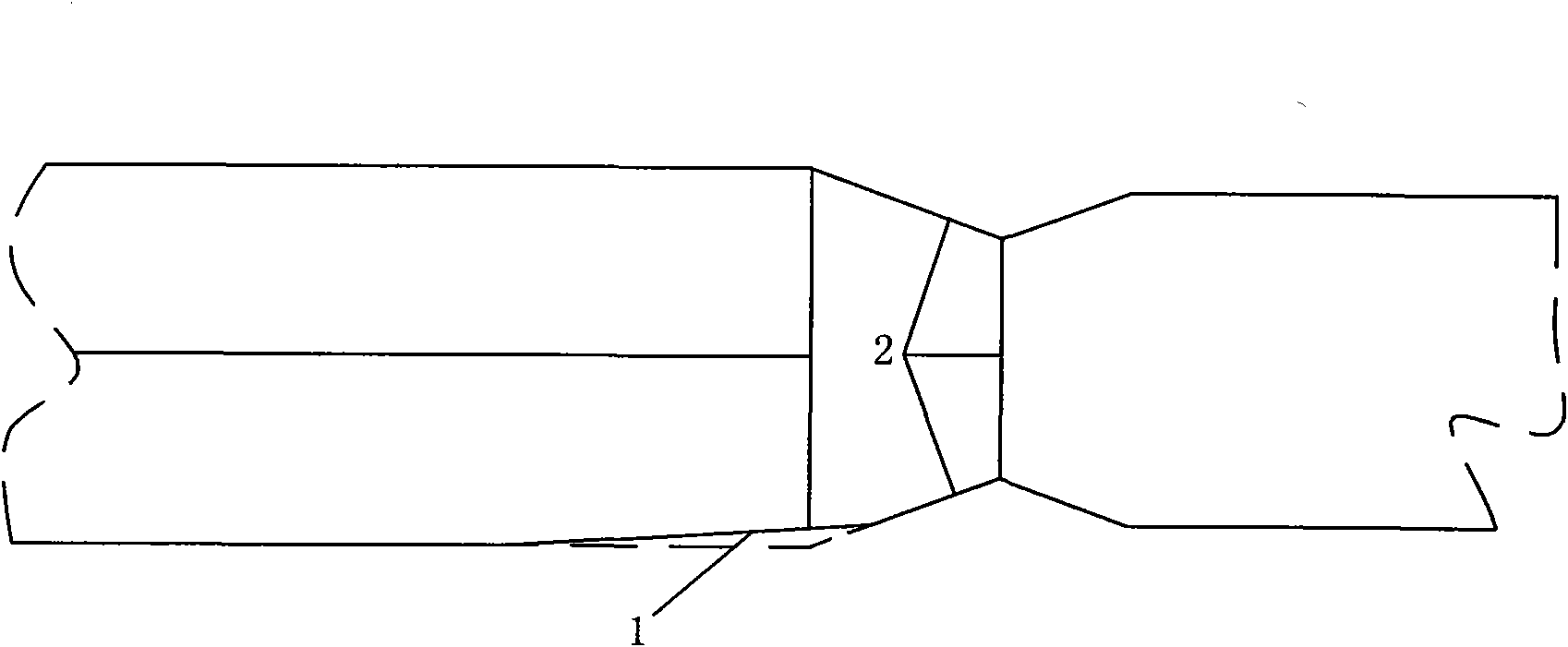

High-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding

ActiveCN103978309AControl thermal deformationControlling the heat-affected zoneWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneWeld seam

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

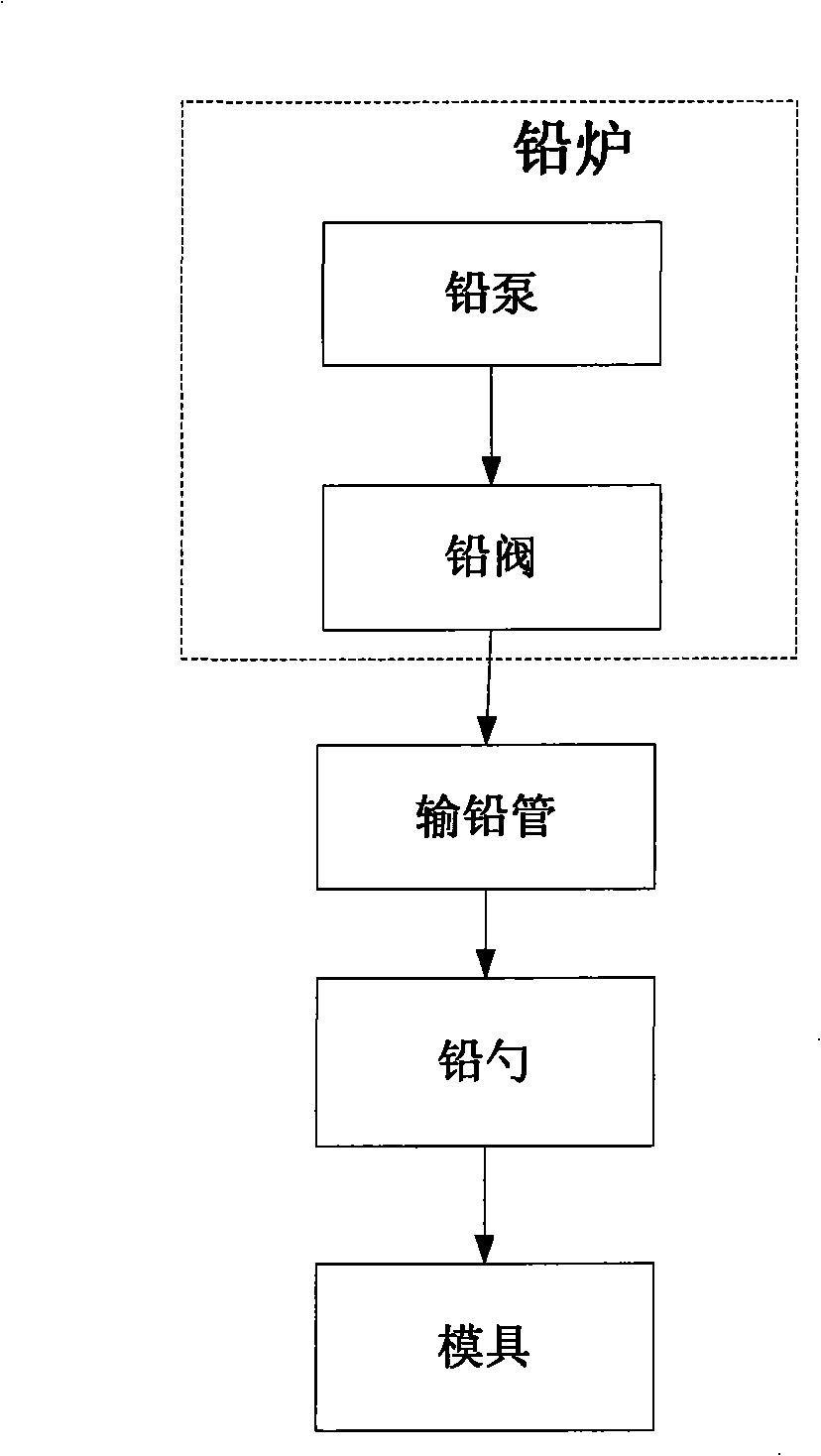

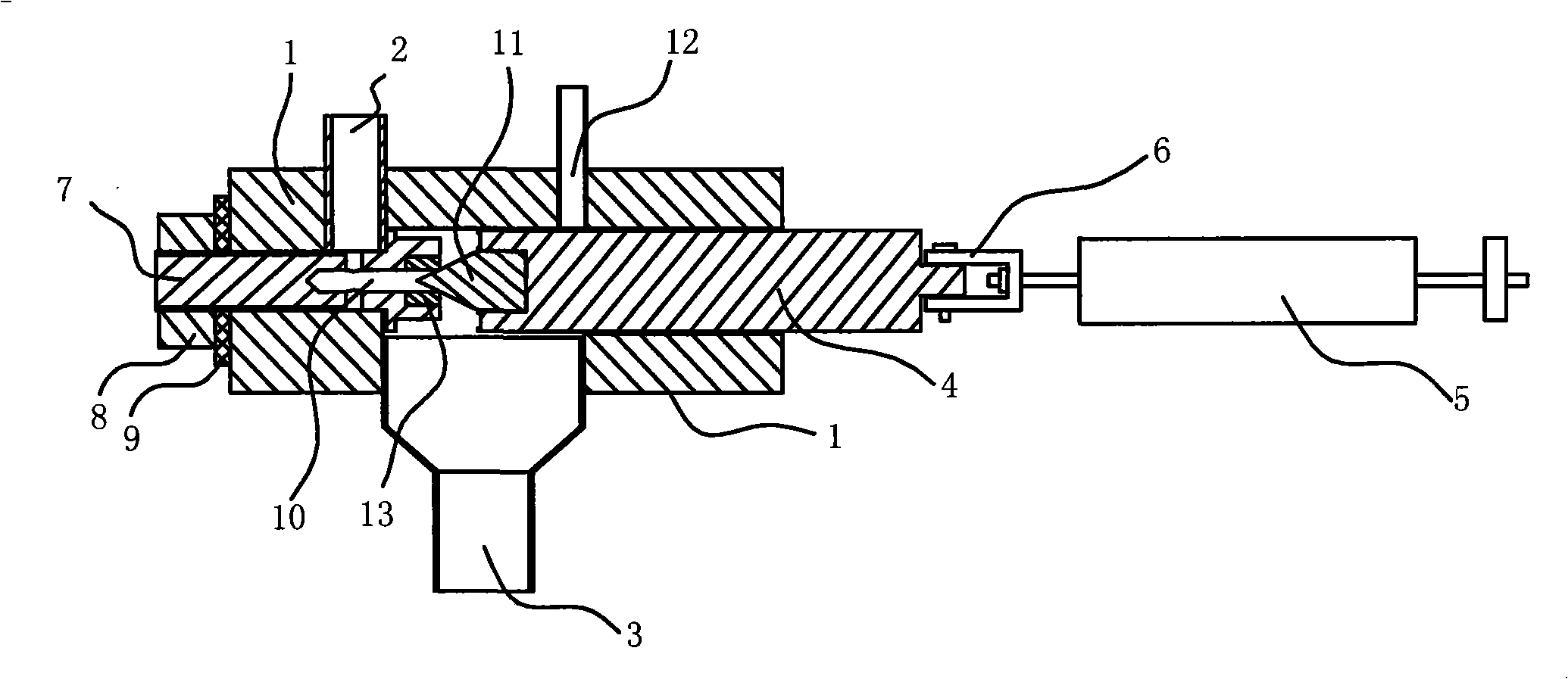

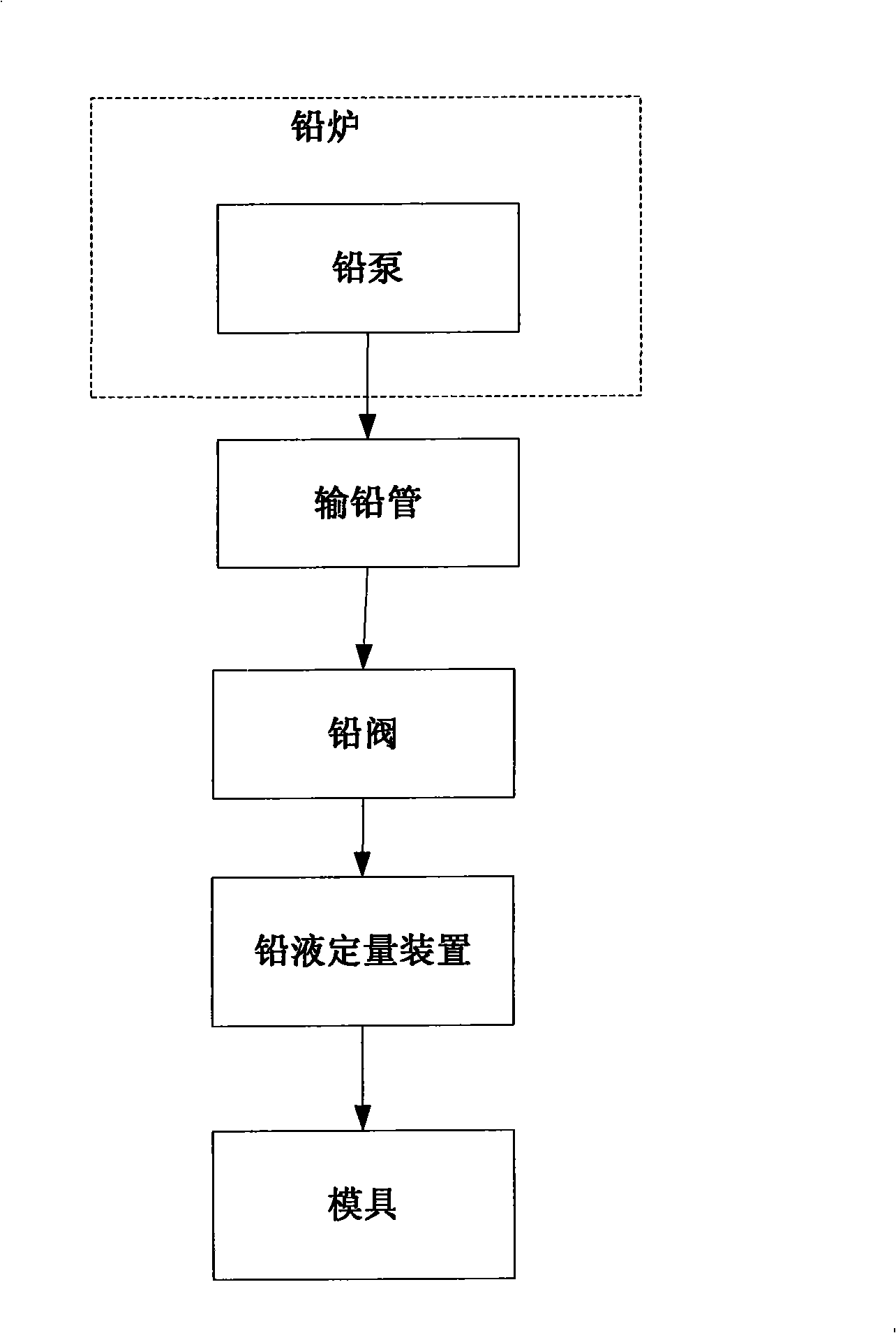

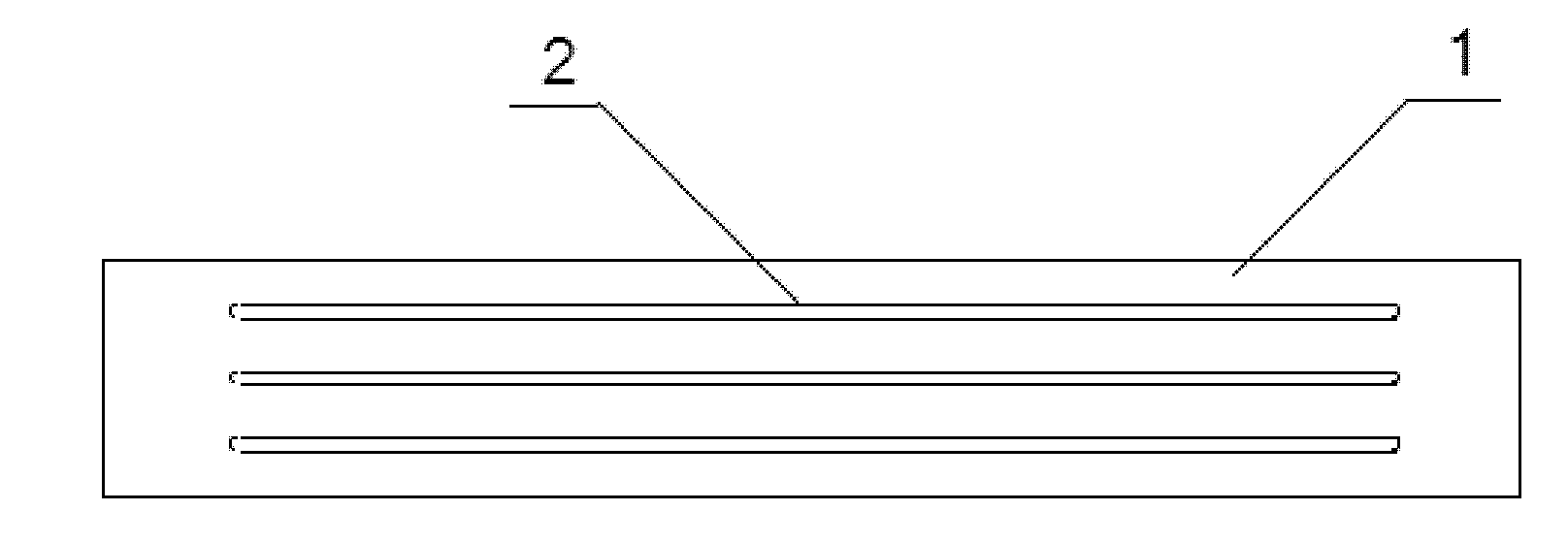

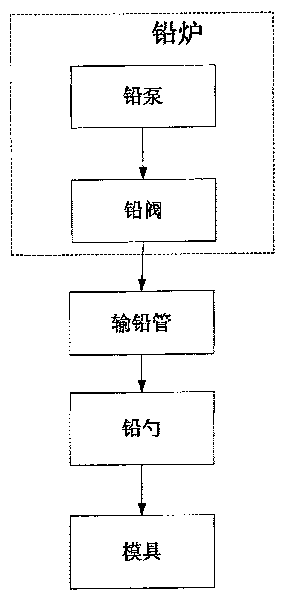

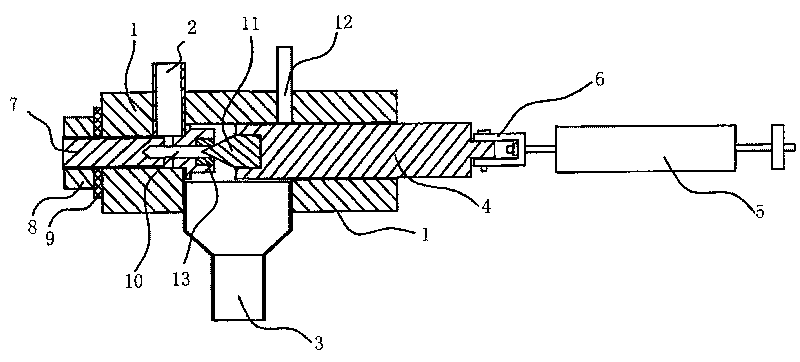

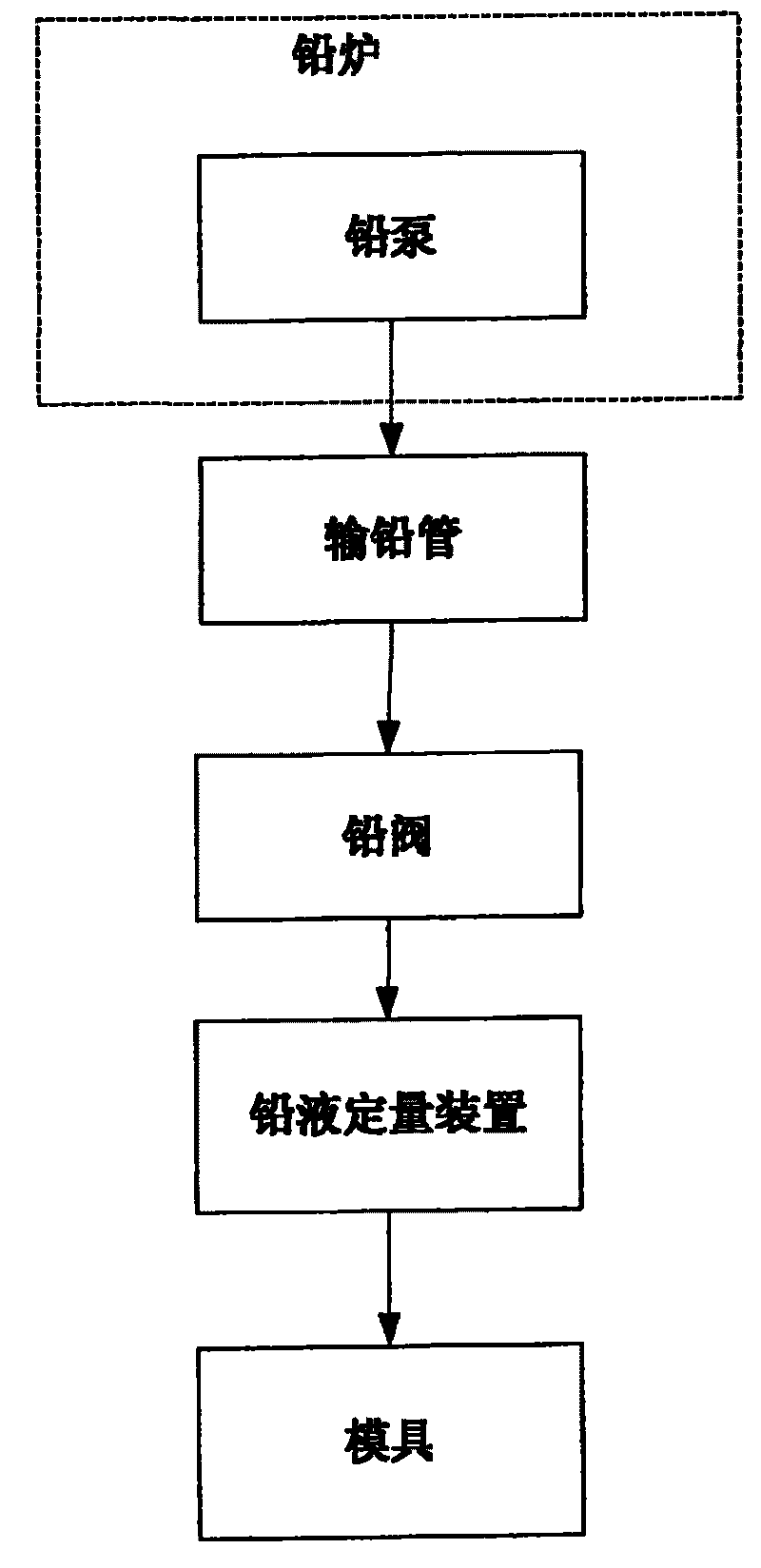

Lead liquid dosing device and plate-casting machine

The invention discloses a dosing device for liquid lead, which comprises a shell, a valve core, a valve stem and a quantitative cylinder. The shell is hollow and is provided with a lead inlet and a lead outlet; the valve core is positioned at one end inside the shell, a liquid lead channel for connecting the lead inlet and the lead outlet is arranged on the valve core. The valve stem is arranged at the other end inside the shell. One end of the valve stem is provided with a conical head for closing the liquid lead channel. The quantitative cylinder is connected at the other end of the valve stem. As the quantitative cylinder is adopted to control the valve stem to close the lead liquid channel of the valve core, the dosing device for the liquid lead by adopting the technical scheme of the invention has the advantages of simple structure, low cost and reliable working. As the using of the dosing device for the liquid lead, a casting plate device thereof has the advantages of more steady performance, more accurate dosing for the liquid lead, less waste and low cost. As the dosing device is arranged between a lead pipe and a lead ladle far away from a scorching lead furnace, the service life is longer and the maintenance is more convenient.

Owner:ZHAOQING LEOCH BATTERY TECH

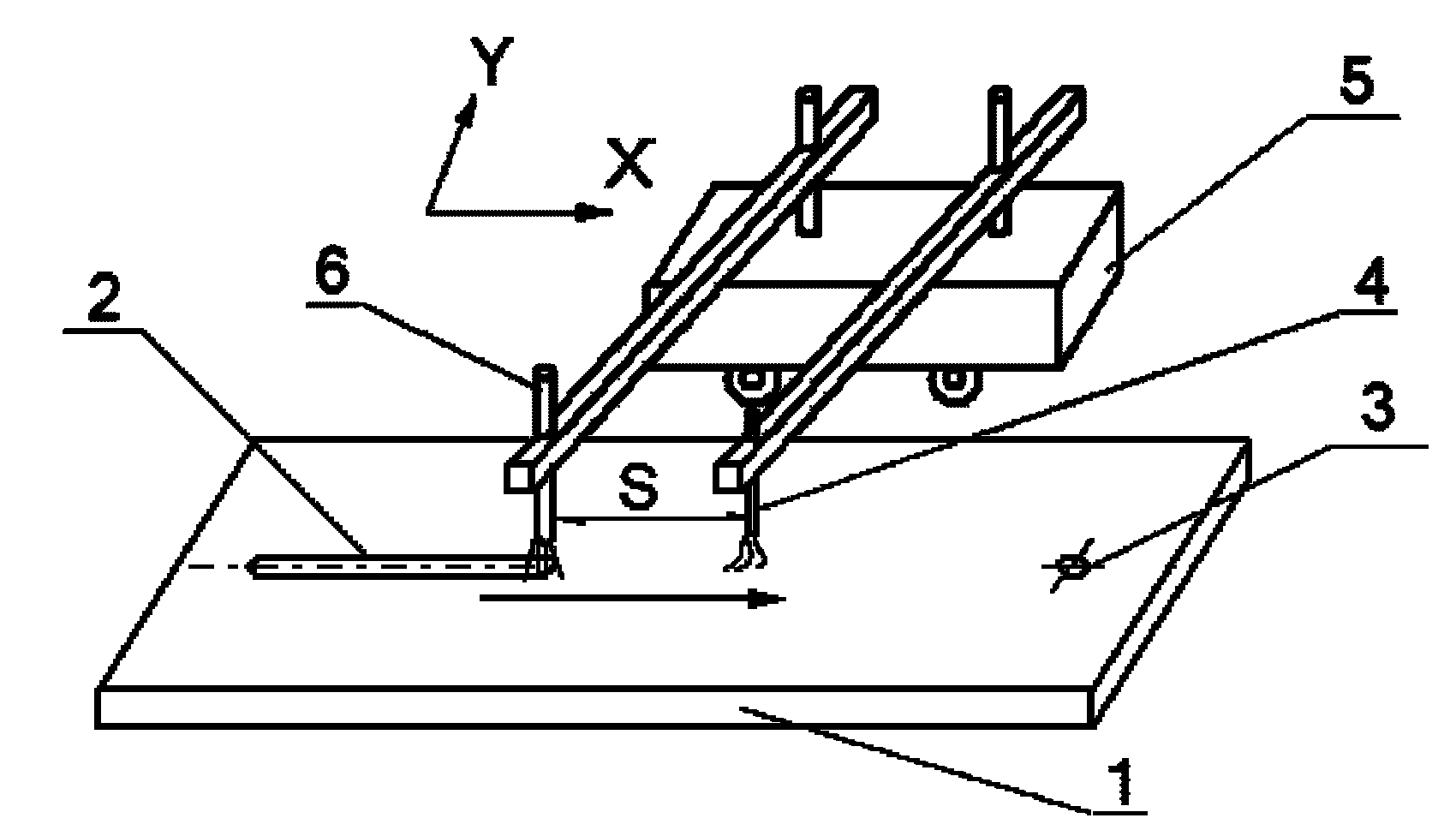

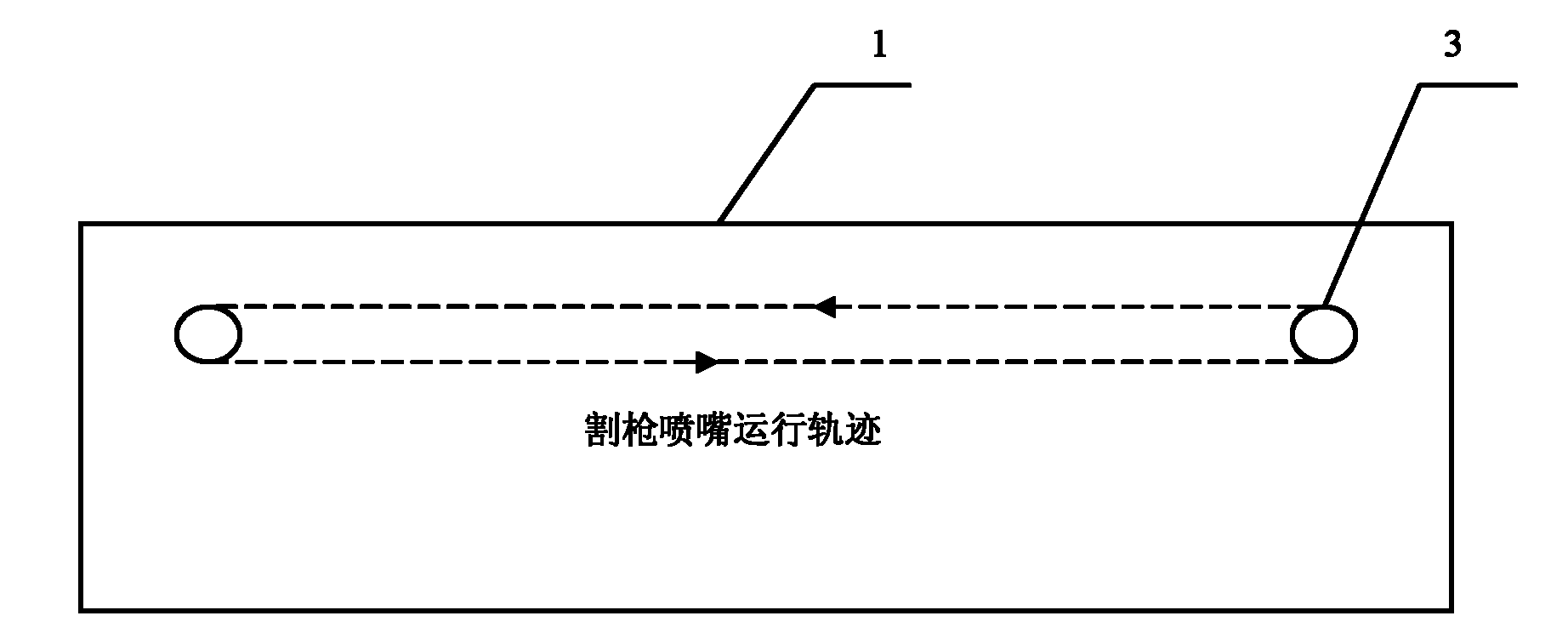

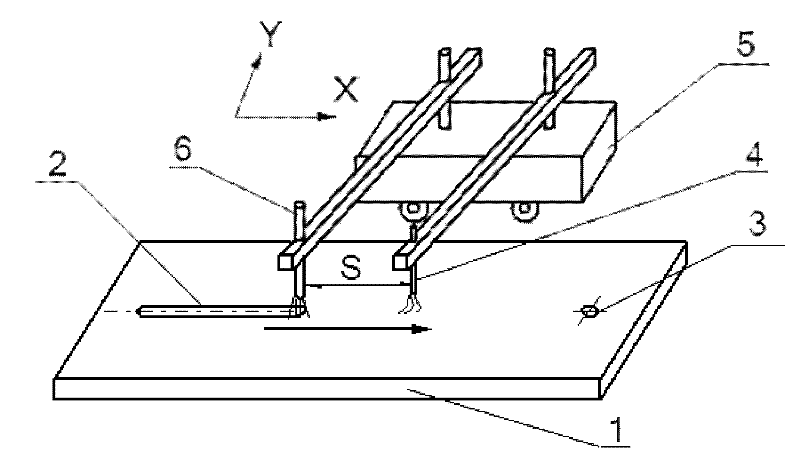

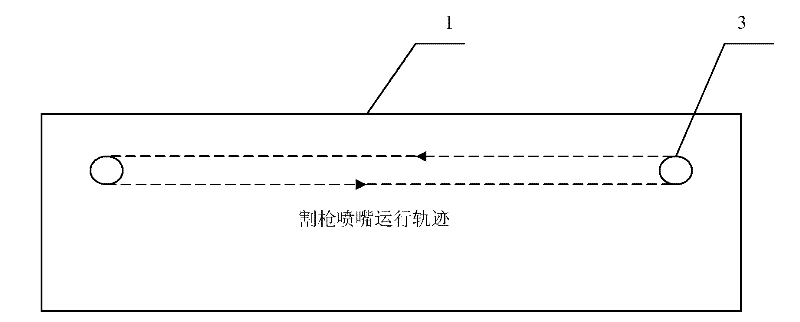

Method for processing transformer pulling plate magnet isolation tank

ActiveCN101786192ARapid coolingGuaranteed not to deformGas flame welding apparatusTransformerEngineering

The invention discloses a method for processing a transformer pulling plate magnet isolation tank, comprising the following processing steps: first, drilling technology holes with diameter being equal to the diameter to the tank width of the magnet isolation tank at the two ends of the X direction of the length of the pulling plate body; aligning the technology holes at one end of the X direction of the length of the pulling plate body with a nozzle of a flame cutting torch along the Y direction of the width of the pulling plate body, a cooling water pipe is arranged along the X direction and at the same line the flame cutting torch is located; the flame cutting torch and the cooling water pipe are connected with a moveable cart at one side of the Y direction of the width of the pulling plate body with two mutually parallel arms; the flame cutting torch is stated to facilitate the moveable cart move along the X direction at a speed of 300-500mm / min towards the technology holes at the other end of the X direction; meanwhile, the cooling water pipe is opened to continuously inject water forward along the movement direction of the flame cutting torch; when the flame cutting torch moves to the technology holes at the other end of the pulling plate; the technology holes at the end is aligned with the nozzle of the flame cutting torch along the outside of the Y direction to facilitate the moveable cart to move in the opposite direction until the cart returns to the previous technology holes.

Owner:CHINA XD ELECTRIC CO LTD

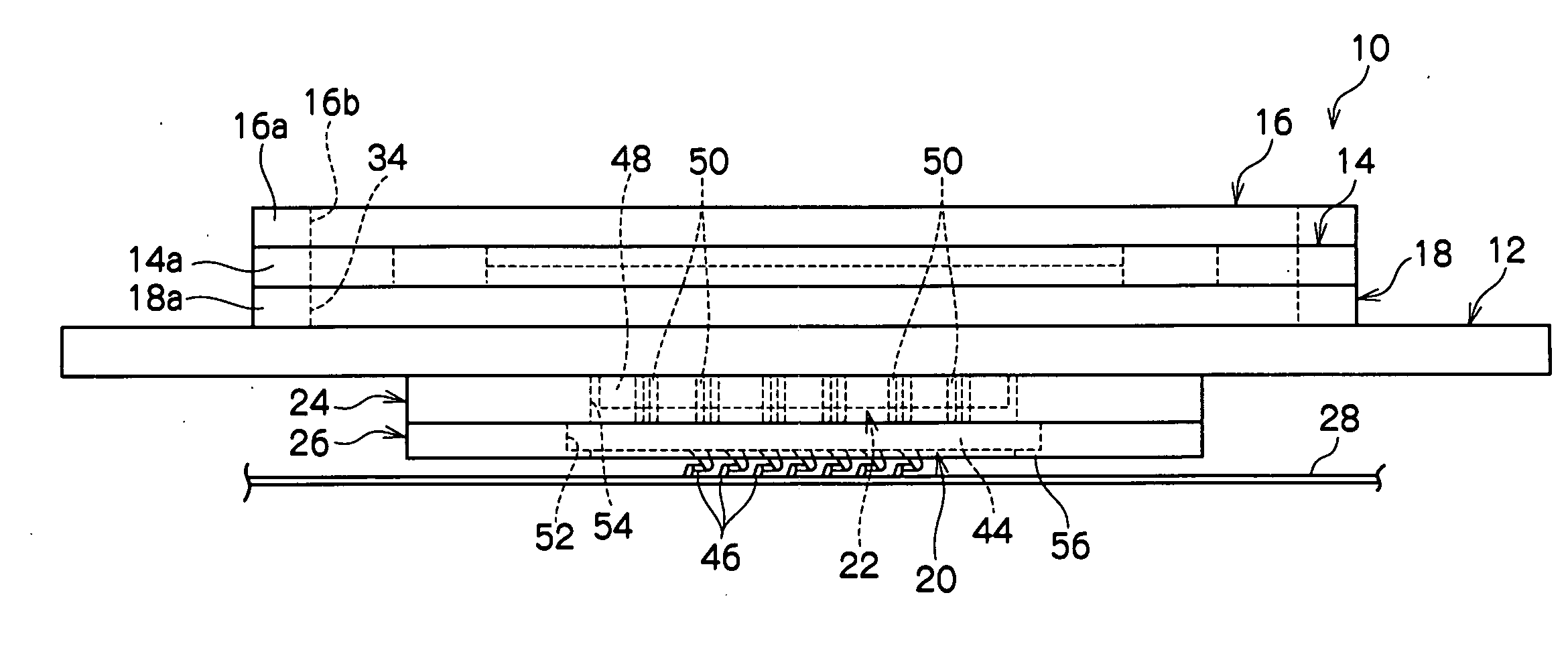

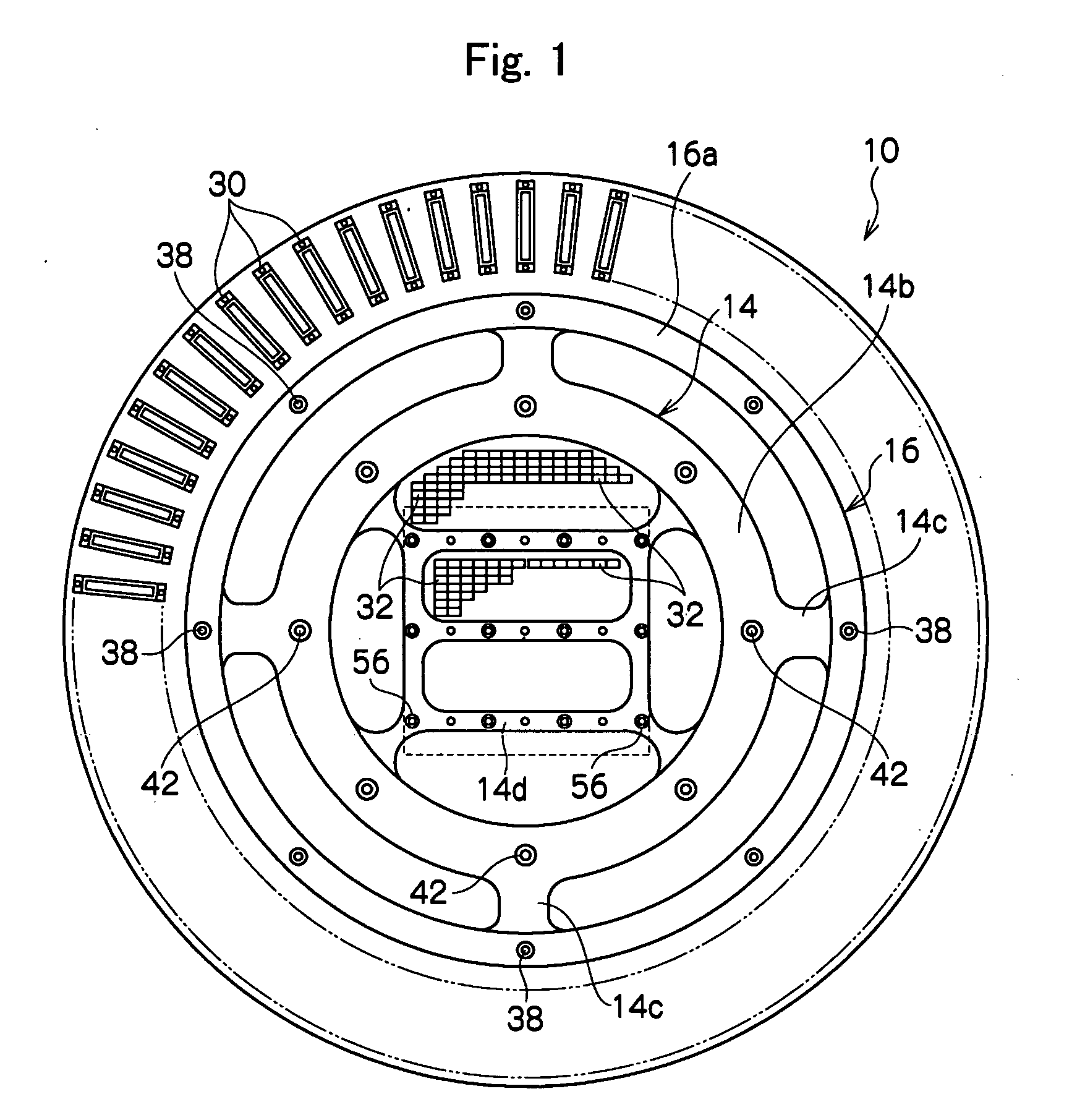

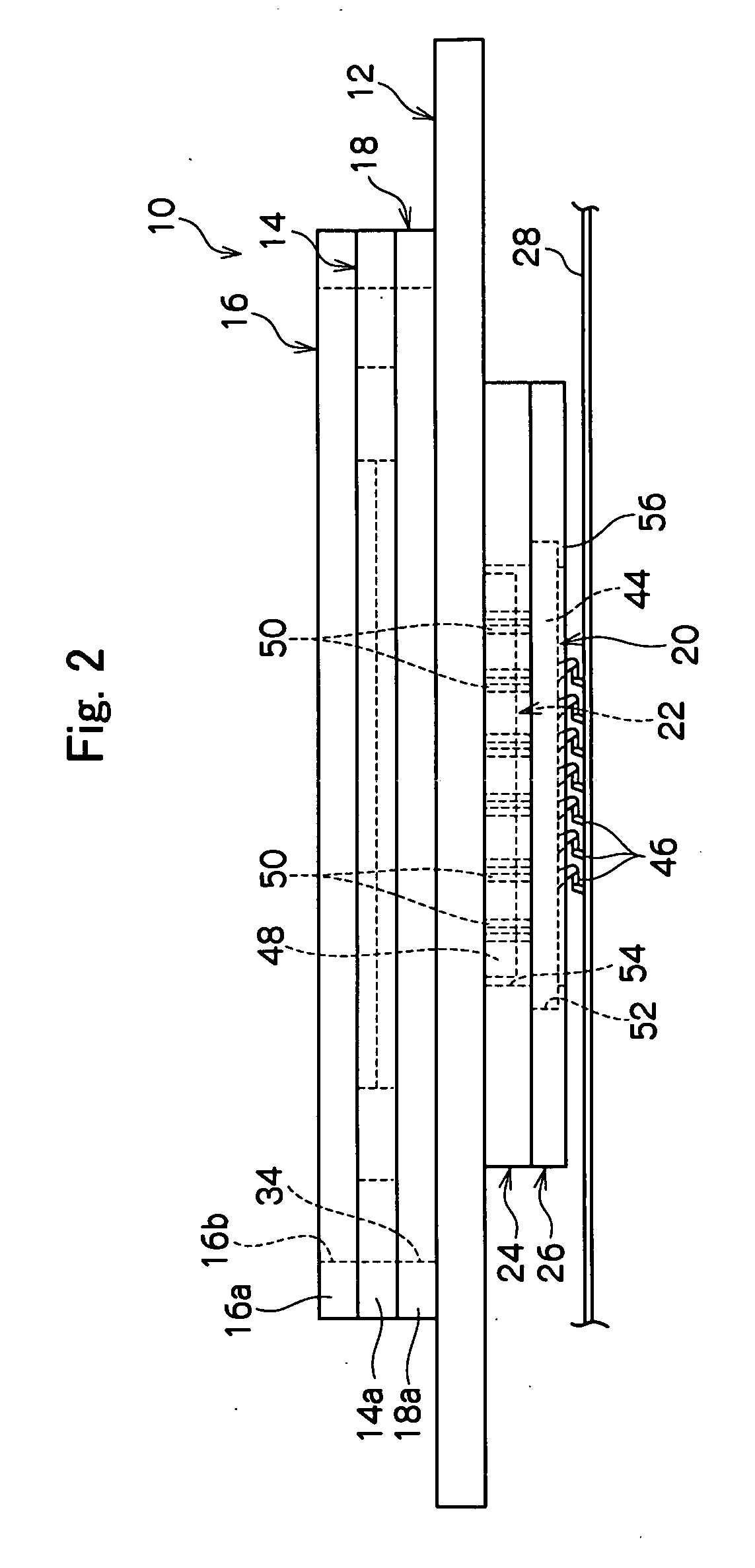

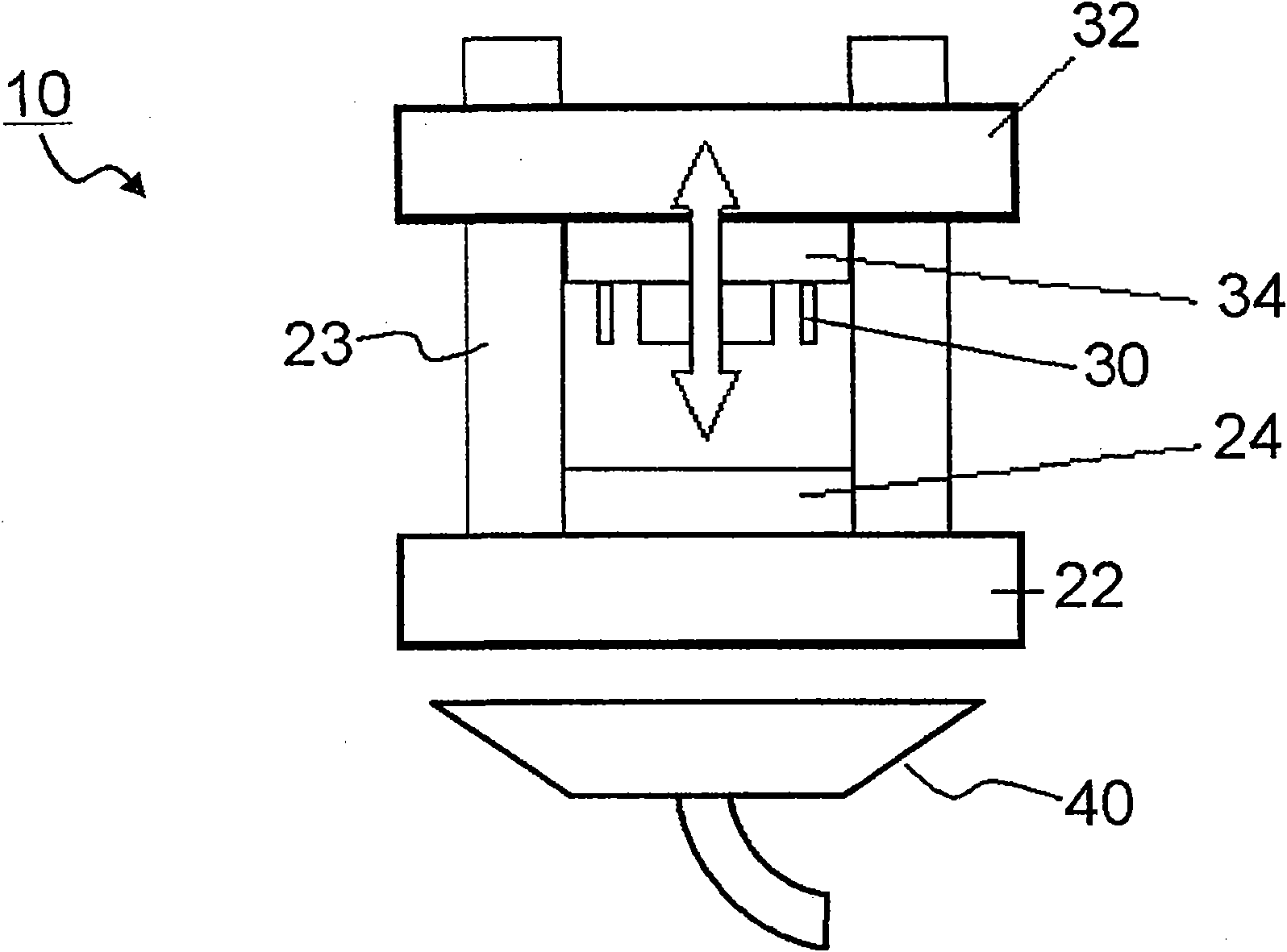

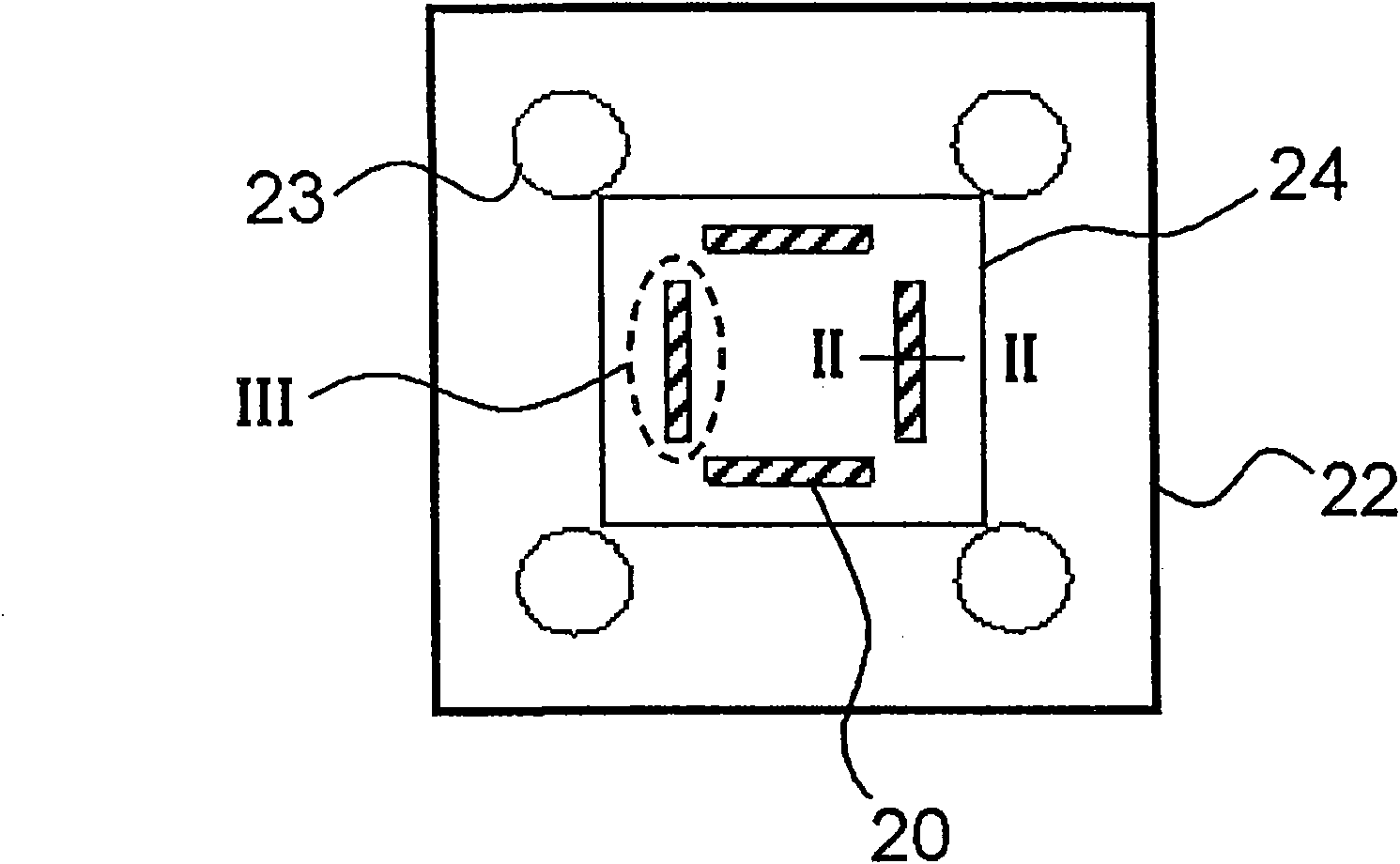

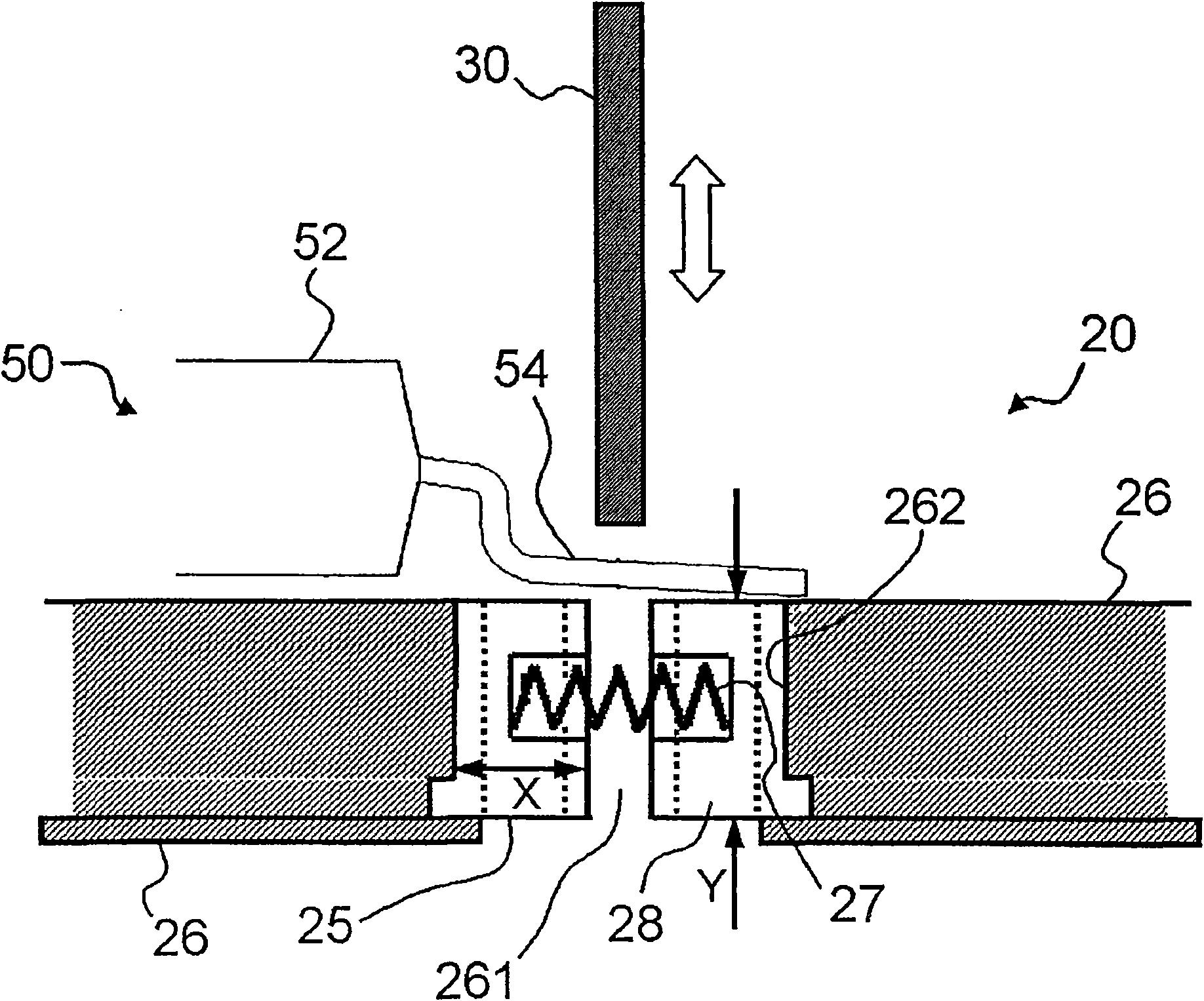

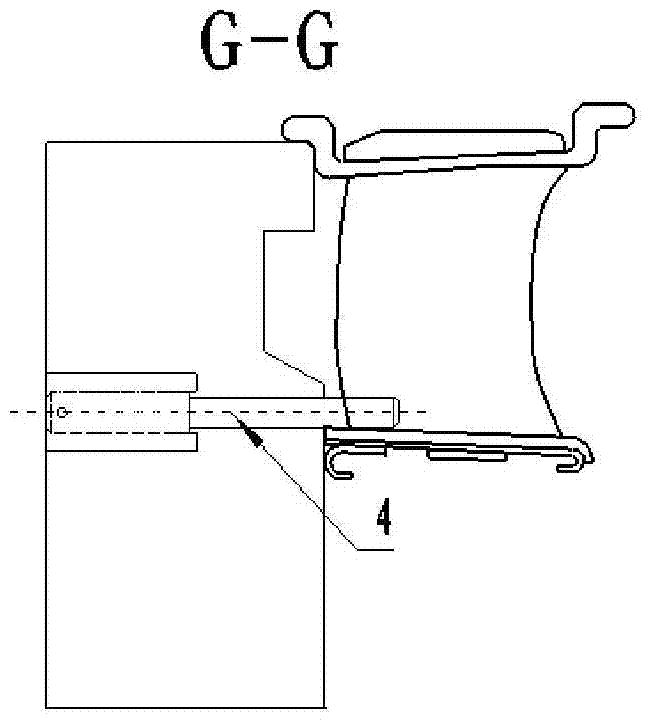

Electric connecting apparatus

ActiveUS20090160469A1Control thermal deformationCoupling device connectionsElectrical testingElectricityCoupling

In an electrical connecting apparatus, a thermal deformation restriction member, a reinforcing plate, and an auxiliary member are made of materials having smaller thermal expansion coefficients in this order, and a wiring board supporting a probe assembly is coupled with the reinforcing plate. The auxiliary member has a void inside the coupling region with the reinforcing plate. The void receives the deformed part when the center portion of the wiring board is deformed toward the reinforcing plate. Thus, the thermal deformation restriction member, the reinforcing plate, and the auxiliary member function as a three-layer bimetal having a sandwich structure, and the thermal deformation of the wiring board is restricted effectively.

Owner:NIHON MICRONICS

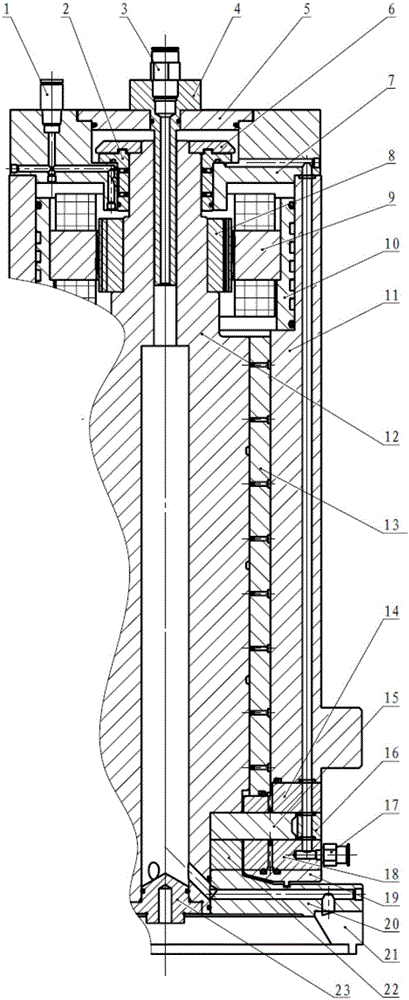

Motorized spindle with cooling liquid introduced in center for cooling and thinning machine

ActiveCN106493617AHigh working reliabilityAvoid destructionSemiconductor/solid-state device manufacturingPlane surface grinding machinesCooling fluidCoolant channel

The embodiment of the invention provides a motorized spindle with a cooling liquid introduced in the center for cooling and a thinning machine, wherein a first cooling liquid channel is arranged on a rotating shaft of the motorized spindle and is used for conveying the cooling liquid and controlling the flow direction of the cooling liquid; meanwhile, an air seal and an overflow channel are arranged on the periphery of the upper end of the rotating shaft of the motorized spindle and are used to prevent the cooling liquid from entering a motor rotor and other adjacent parts when the cooling liquid overflows from the upper end of the first cooling liquid channel under the abnormal conditions. According to the scheme, the motorized spindle is reliably and effectively cooled when the thinning machine works.

Owner:CETC BEIJING ELECTRONICS EQUIP

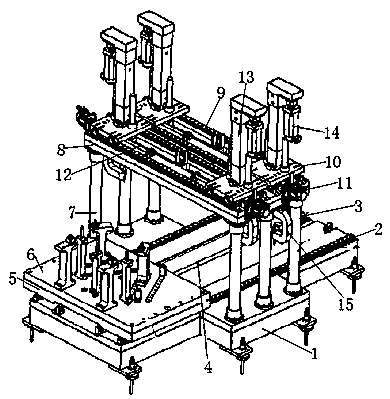

Aluminum alloy auxiliary frame shaping device

PendingCN109201778AAdapt to plastic needsSmall sizeMetal-working feeding devicesMetal working apparatusVehicle frameEngineering

The invention belongs to the technical field of auxiliary frame production equipment, and particularly relates to an aluminum alloy auxiliary frame shaping device which comprises a base, the front side and the rear side of the top of the base are provided with first bearing sliding rails, and a shaping workpiece positioning clamp is arranged at the top of a clamp mounting plate, stand columns areinstalled on the front side and the rear side of the center position of the top of the base, a top plate is arranged at the top of the stand columns, four second bearing sliding rails are sequentiallyarranged on the top of the top plate from left to right, second servo motors are arranged on the front side and the rear side of the front side wall and the rear side wall of the top plate, so that the size of the product can be effectively controlled, the heat deformation of the product in the casting process and the size of the heating deformation of the frame in the heat treatment process areeffectively controlled, and compared with a traditional control method, the device has the advantages that the production efficiency is greatly improved, the enterprise energy is reduced, and the detection function of the device is achieved, the size of the blank of the product is guaranteed, and the device can also be suitable for the shaping requirements of most of the auxiliary frames at present.

Owner:安徽万安汽车零部件有限公司

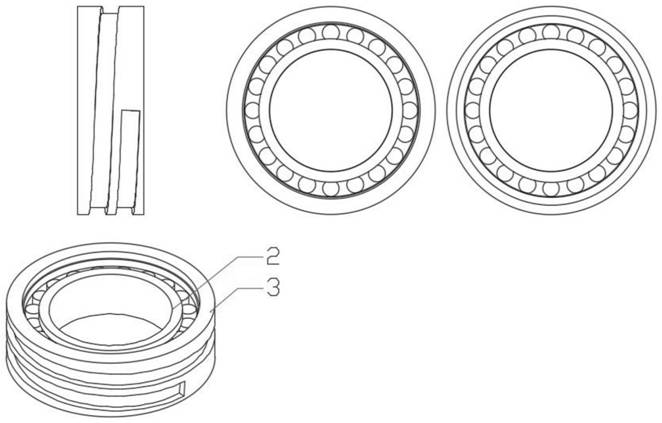

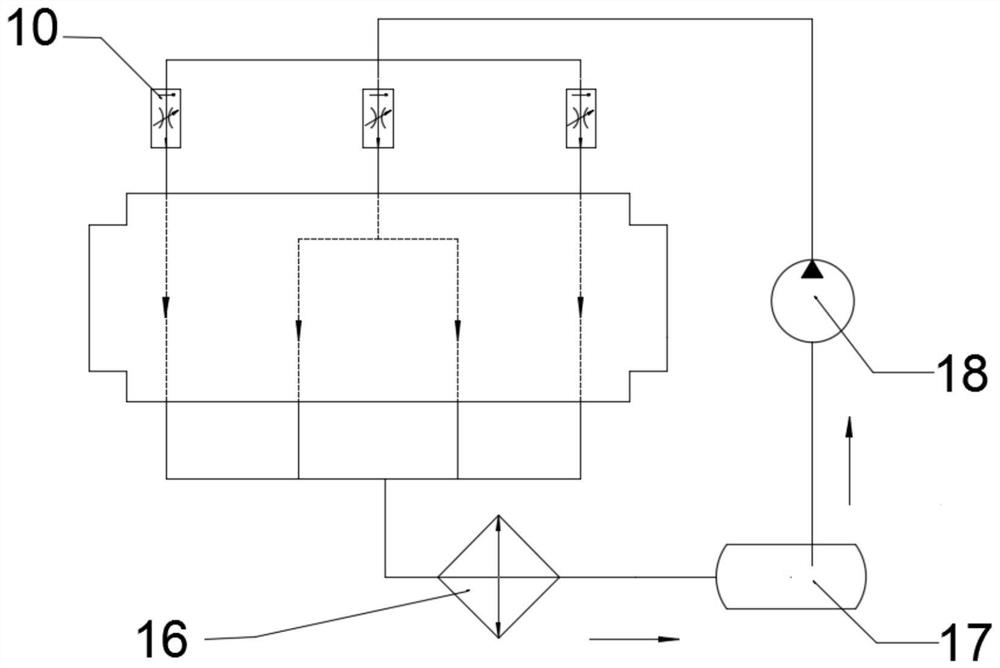

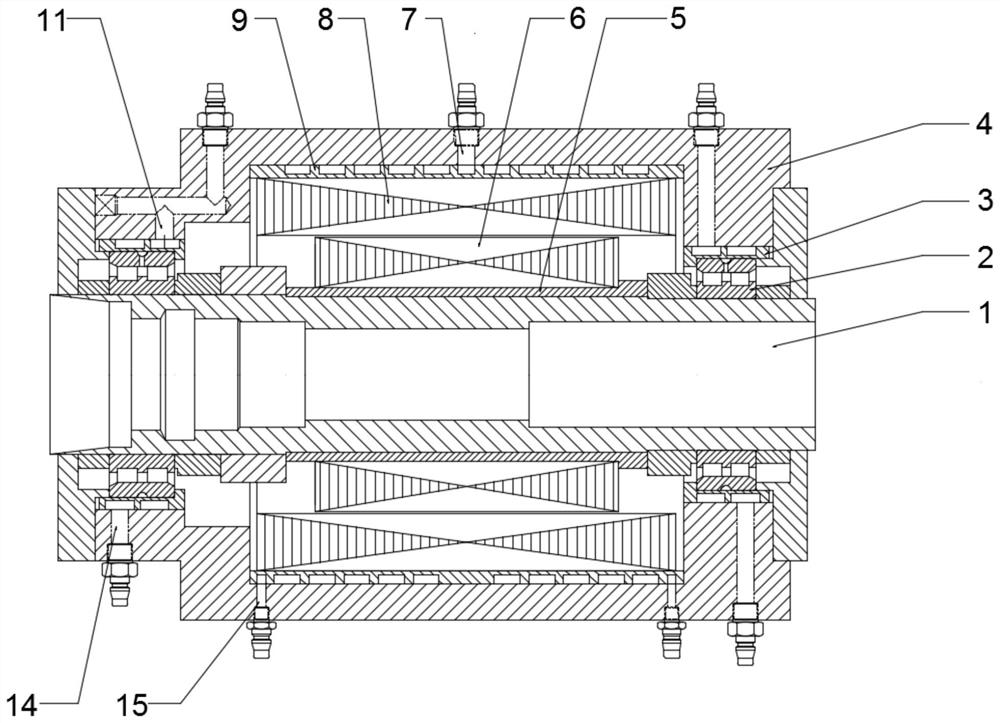

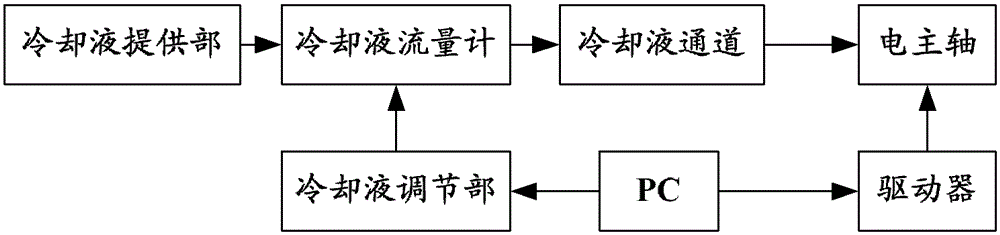

Cooling circulation system and method for reducing thermal errors of machine tool spindle

ActiveCN113098203ATemperature controlControl thermal deformationAssociation with control/drive circuitsElectric motor controlThermodynamicsRolling-element bearing

The invention relates to the field of machine tool spindle cooling, concretely relates to a cooling circulation system and method for reducing thermal errors of a machine tool spindle. The system comprises a spindle box body, a spindle arranged in the spindle box body, a motor arranged in the middle section of the spindle, and a motor cooling sleeve sleeved outside the motor, the motor cooling sleeve is provided with two sets of motor cooling flow channels in opposite directions, a plurality of temperature sensors are distributed on the motor, the front end and the rear end of the main shaft are respectively provided with a rolling bearing, the bearings are sleeved with a bearing cooling sleeve, the main shaft is provided with a rotating speed sensor, and the cooling assembly is connected with the cooling flow channels. A data processing controller is connected with the temperature sensor, the rotating speed sensor and the cooling assembly. The cooling efficiency can be improved, effective control over the temperature and thermal deformation of the machine tool spindle is achieved, the defects that a traditional cooling method is non-adjustable in cooling, unbalanced in cooling and low in cooling efficiency are overcome, and good engineering application prospects are achieved.

Owner:湖北谷城县东华机械股份有限公司

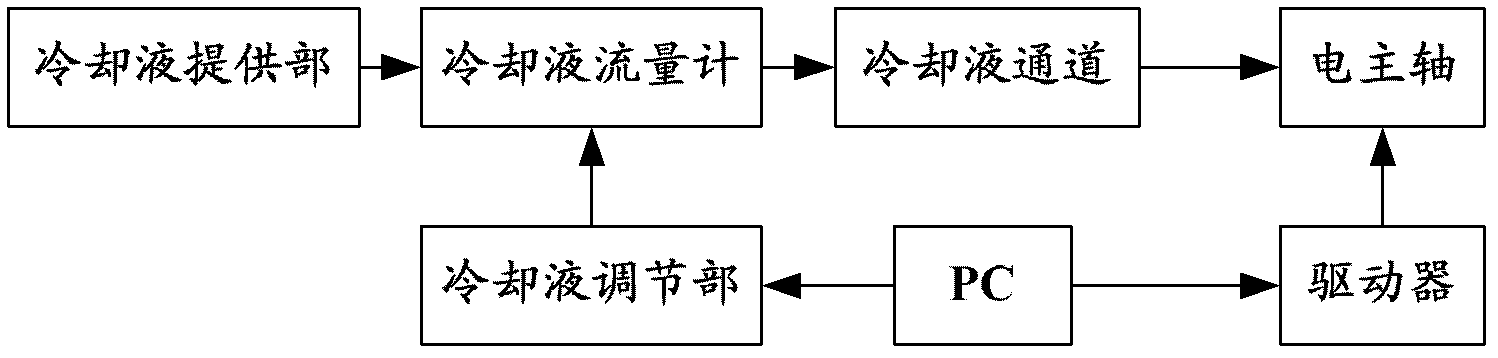

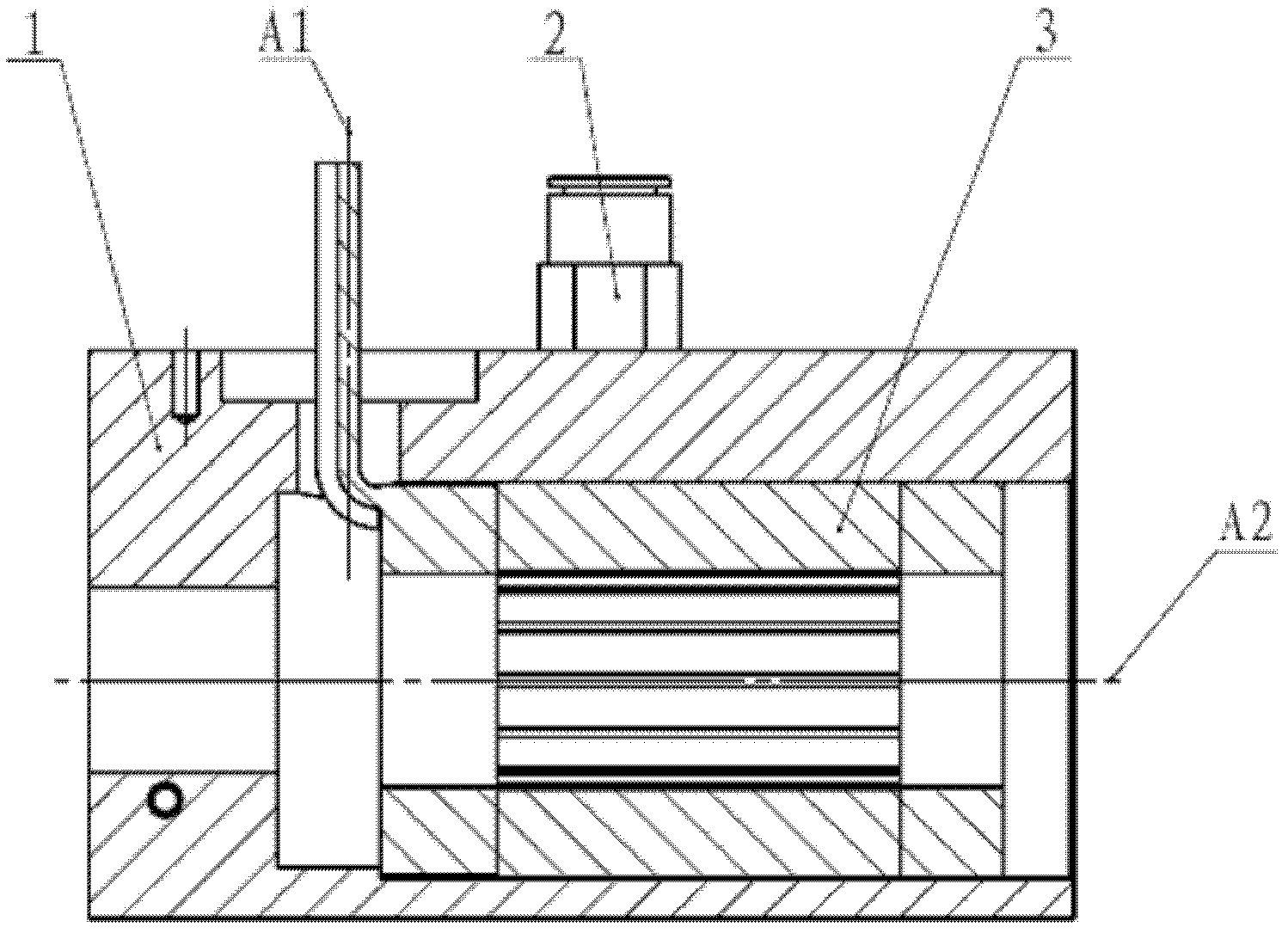

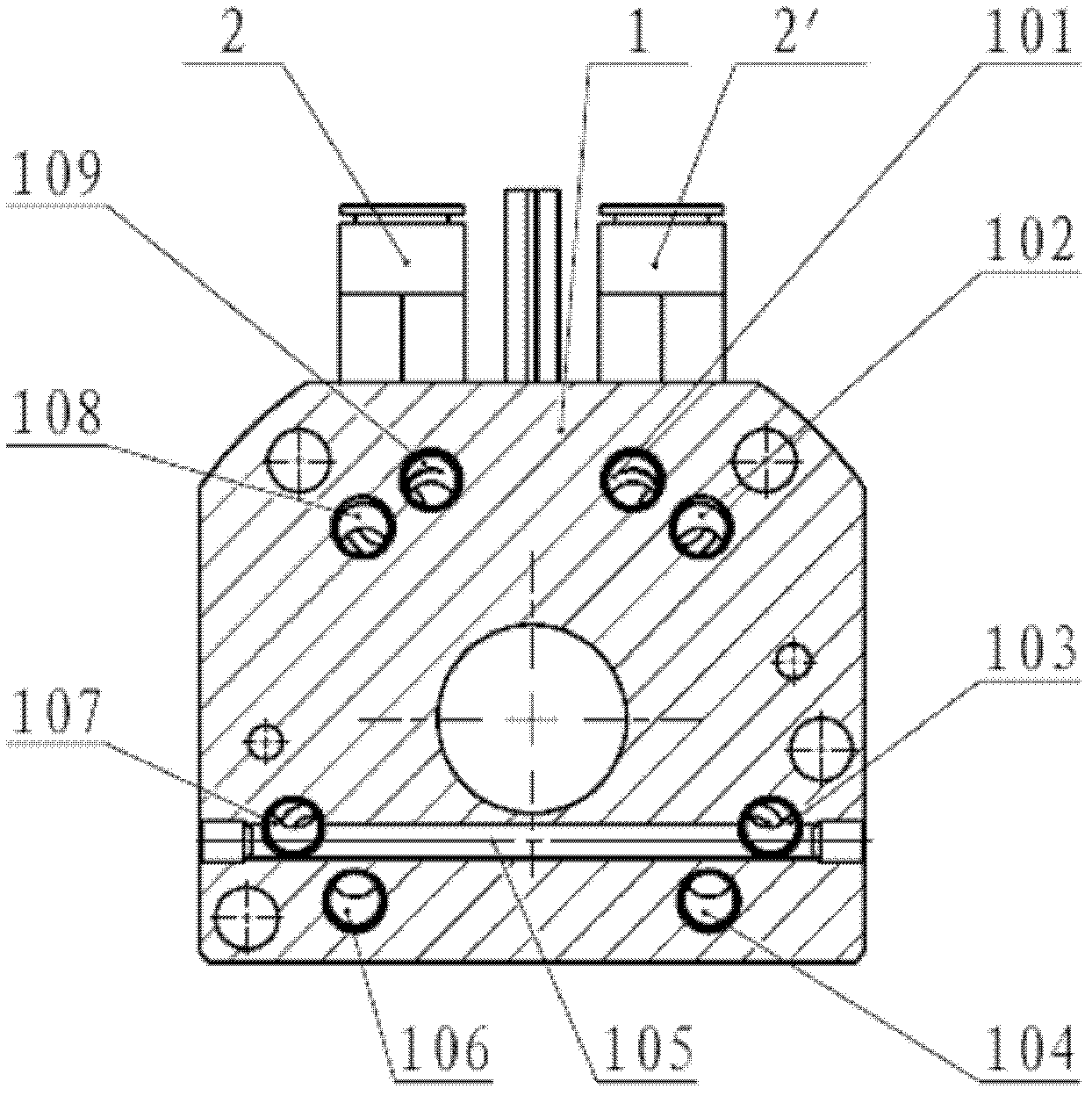

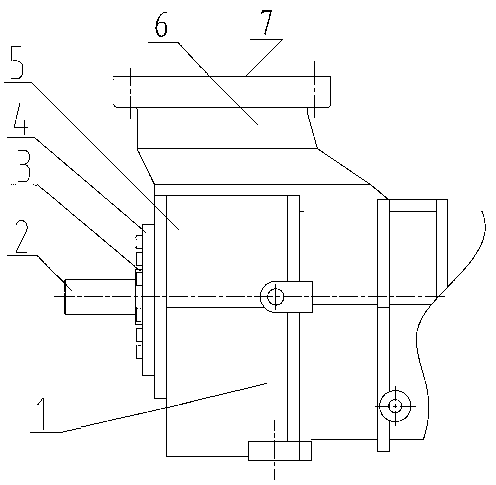

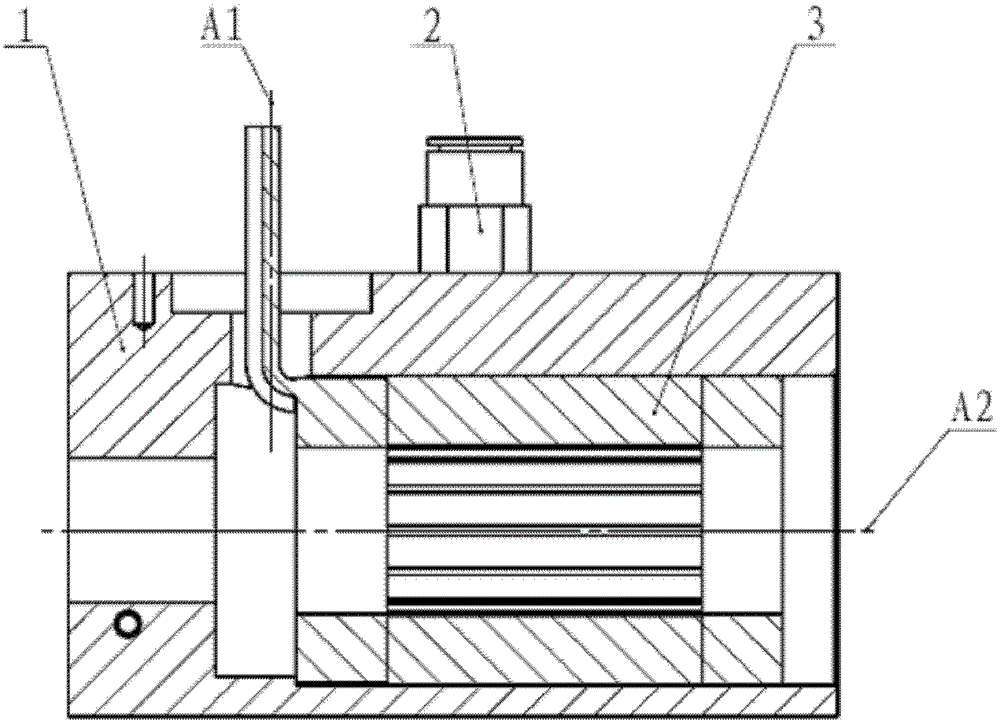

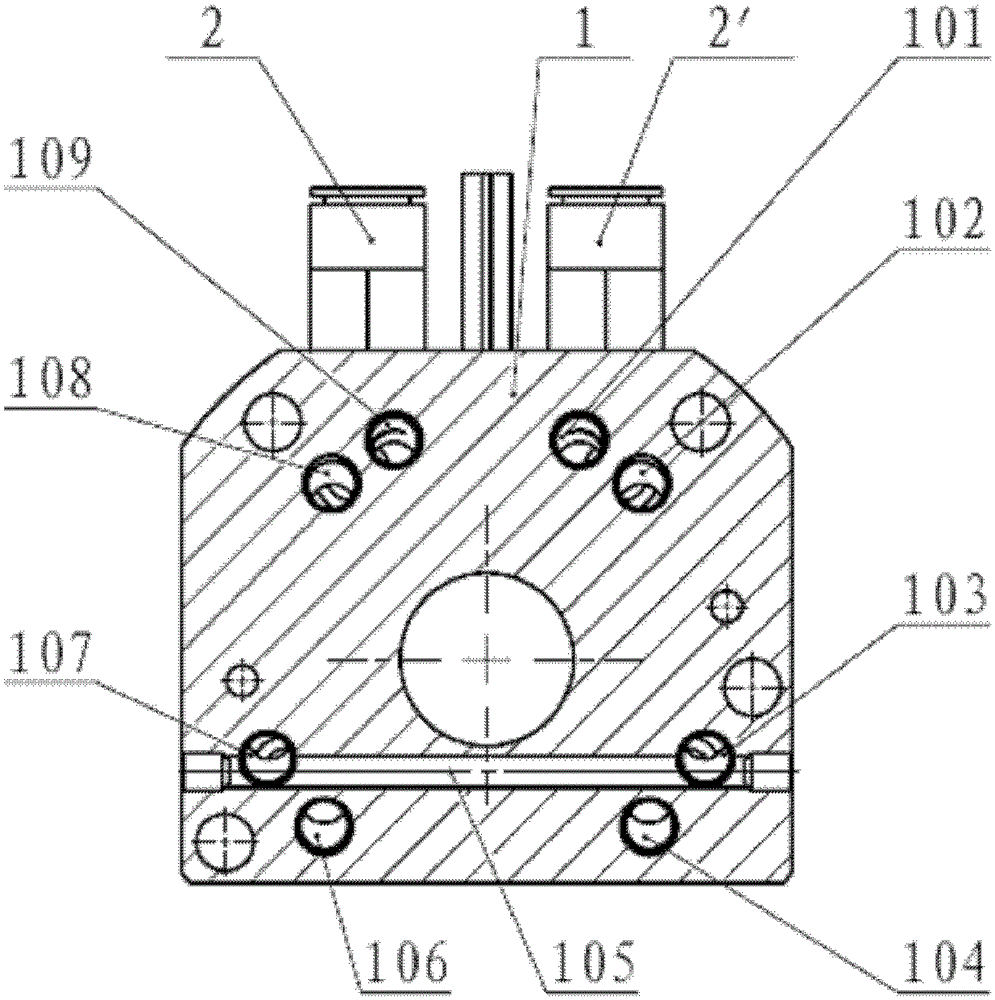

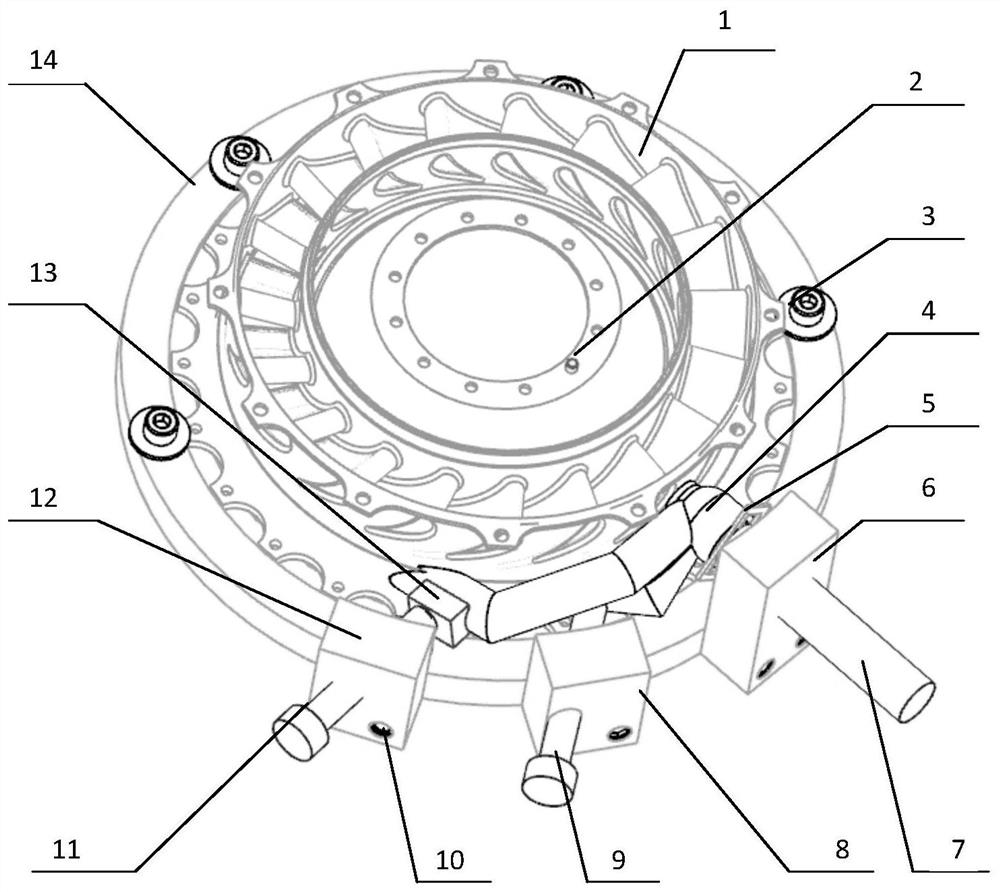

Cooling device of built-in motor of motorized spindle and dicing machine

ActiveCN103138489AControl thermal deformationControl work precisionCooling/ventillation arrangementEngineeringCooling fluid

The invention provides a cooling device of a built-in motor of a motorized spindle and a dicing machine. The cooling device comprises a cooling liquid providing part which is used for providing cooling liquid and a cooling liquid passage which is used for inputting the cooling liquid which is provided by the cooling liquid providing part and controlling the flow direction of the cooling liquid. The cooling device of the built-in motor of the motorized spindle and the dicing machine can stably cool the motor of the spindle when the motorized spindle is working.

Owner:CETC BEIJING ELECTRONICS EQUIP

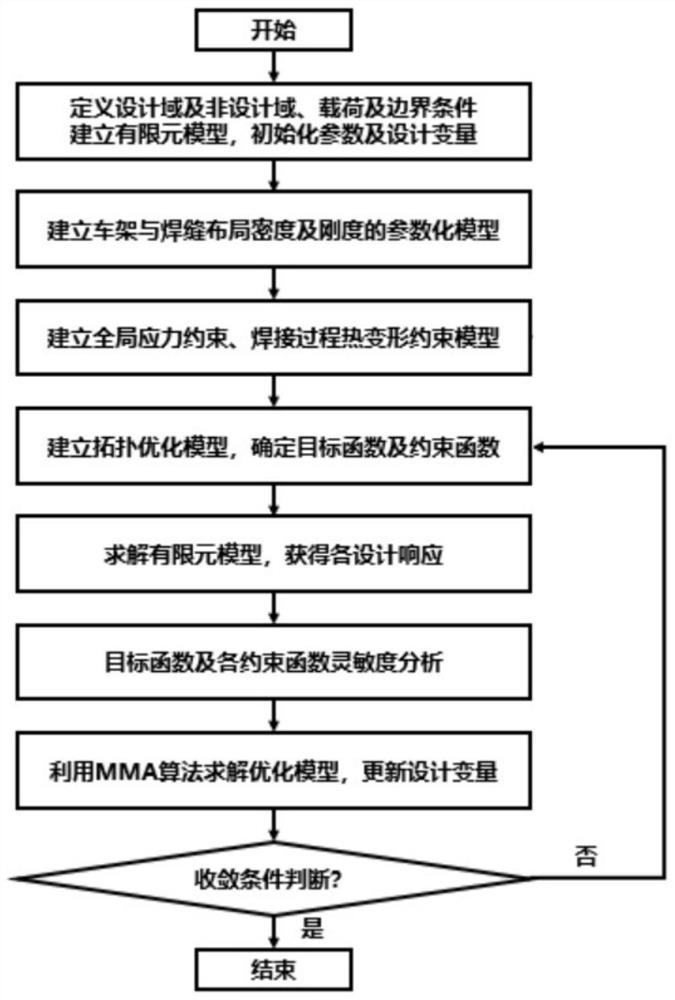

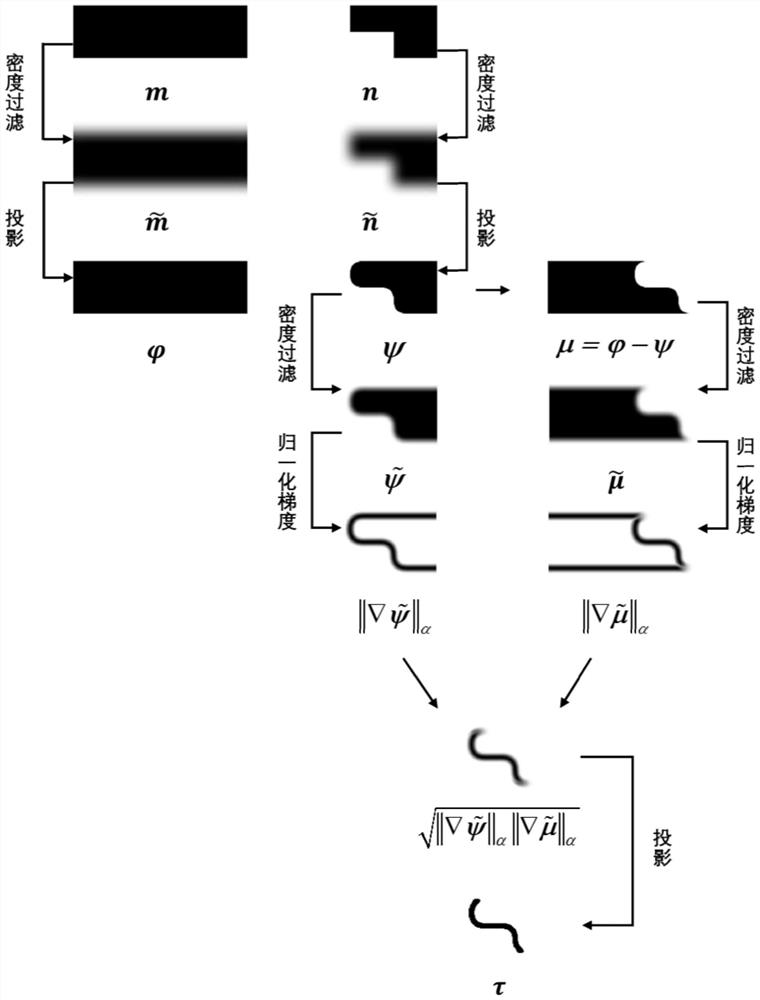

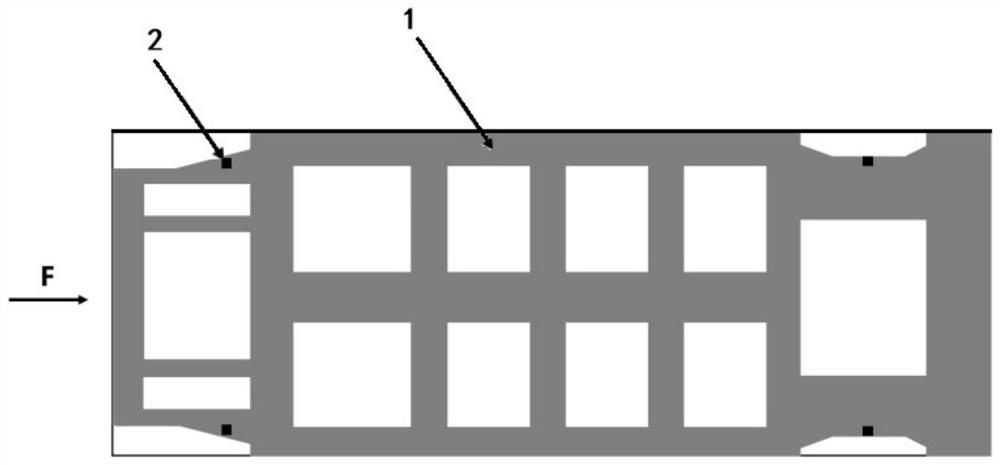

Electric vehicle chassis welding seam layout reliability optimization method

PendingCN114861480ASatisfy the bearing safety performanceBearer Safety Performance GuaranteeGeometric CADInternal combustion piston enginesVehicle frameThermal deformation

The invention discloses an electric vehicle chassis welding seam layout reliability optimization method, which relates to the field of electric vehicle chassis structure design and manufacture integration, and is characterized by comprising the following steps: 1, initializing design conditions and optimization parameters; 2, carrying out unit density interpolation modeling; 3, carrying out structure global stress constraint modeling; 4, thermal deformation constraint modeling is conducted in the welding process; 5, topological optimization modeling is carried out; 6, design response solution is carried out; step 7, sensitivity analysis; 8, optimization solution is carried out; step 9, judging a convergence condition; and step 10, performing post-processing on an optimization result. According to the method, collaborative optimization of the chassis frame and the welding seam layout is achieved, under the condition that overall structure stress distribution and welding thermal deformation are considered, an optimized configuration which is light and meets the reliability requirements of bearing safety and the like is obtained, the rejection rate can be reduced, the mass production efficiency can be improved, the number of design iterations can be reduced, and the development period can be shortened. The development cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Lead cutter and method of cutting lead

InactiveCN101556912AControl thermal deformationSuppression of fluctuations in cutting intervalsSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

The present invention relates to a lead cutter and a method of cutting lead. Specifically, there is provided a lead cutter that enables micro-adjusting a cutting clearance between a punch and a die with high accuracy. The lead cutter includes a die on which the lead provided in an encapsulating resin enclosing a semiconductor chip is to be placed, a punch that vertically moves relative to the die to thereby cut the lead, and a temperature controller that controls a temperature of at least one of the punch and the die, so as to adjust a clearance between the punch and the die.

Owner:RENESAS ELECTRONICS CORP

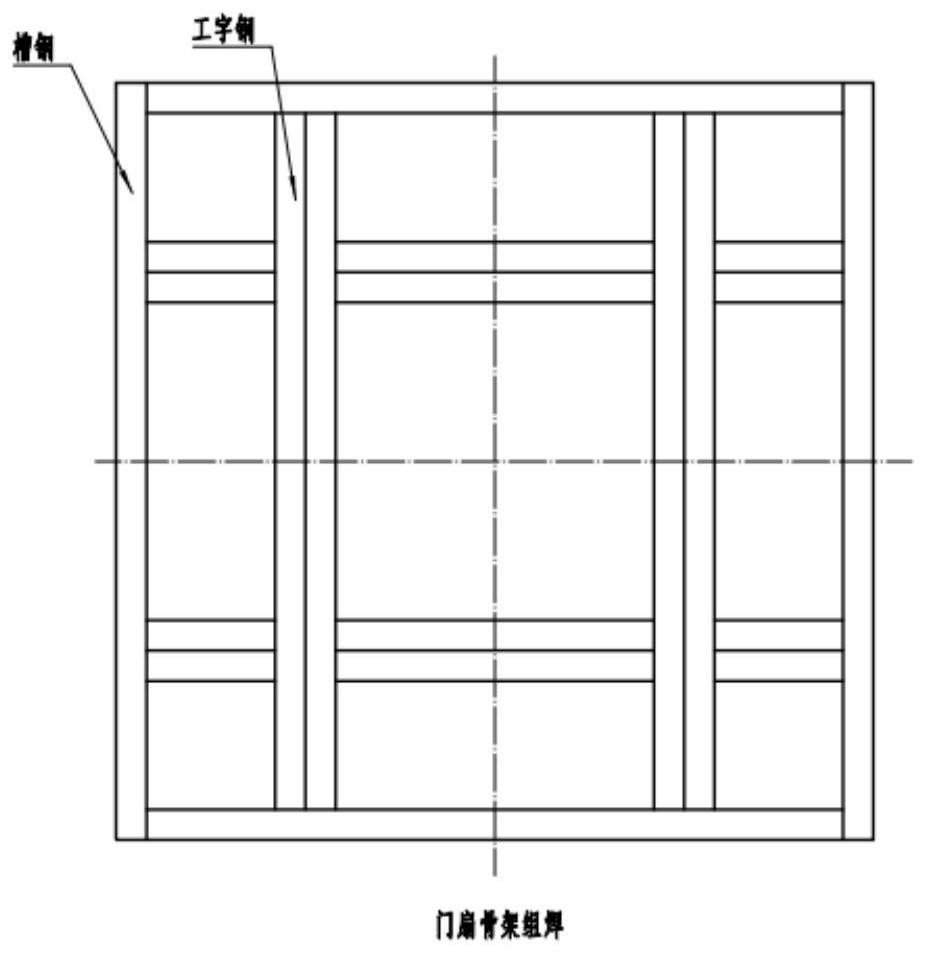

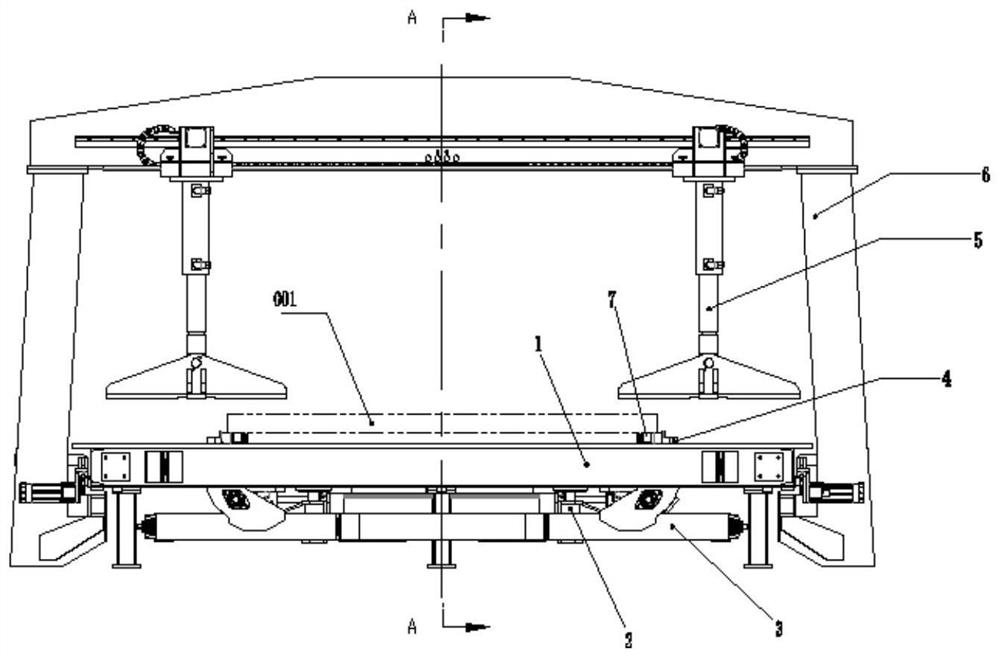

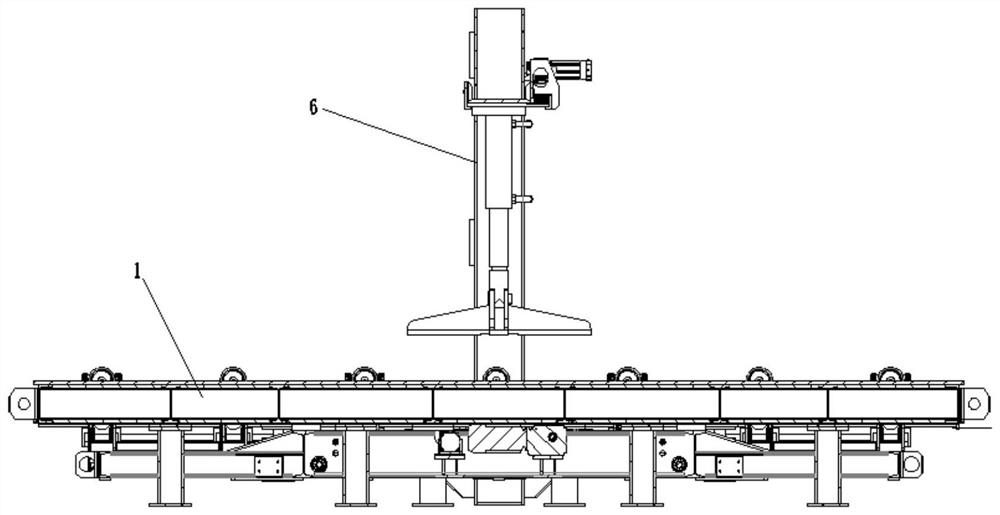

Multifunctional steel structure assembling and welding assembly line platform

ActiveCN113601082AEasy to useSolve the cumbersome process of manual liftingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention provides a multifunctional steel structure assembling and welding assembly line platform, which comprises a working platform body (1); a lifting oil cylinder (2) is arranged below the working platform body (1); the upper end of the lifting oil cylinder (2) is fixedly connected with the lower bottom face of the working platform body (1); the lower end of the lifting oil cylinder (2) is fixedly connected with a lifting roller conveying mechanism (3); the lifting oil cylinder (2) stretches out and draws back to drive the lifting roller conveying mechanism (3) to move up and down, so that multiple rollers move up and down and make contact with or be separated from a steel structure product (001) arranged above the working platform body (1); when the multiple rollers (302) move upwards to jack up a product (001), the multiple rollers are driven to rotate to make the product (001) move; gantry walking mechanisms (6) are arranged on the left side and the right side of the working platform body (1); and hydraulic pressing devices (5) are arranged below cross beam rails of the gantry walking mechanisms (6).

Owner:SHANDONG ZHONGHAO HLDG GRP

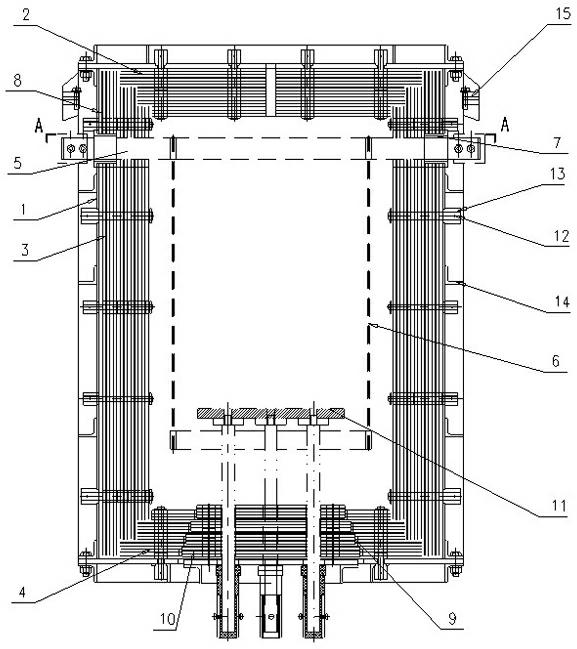

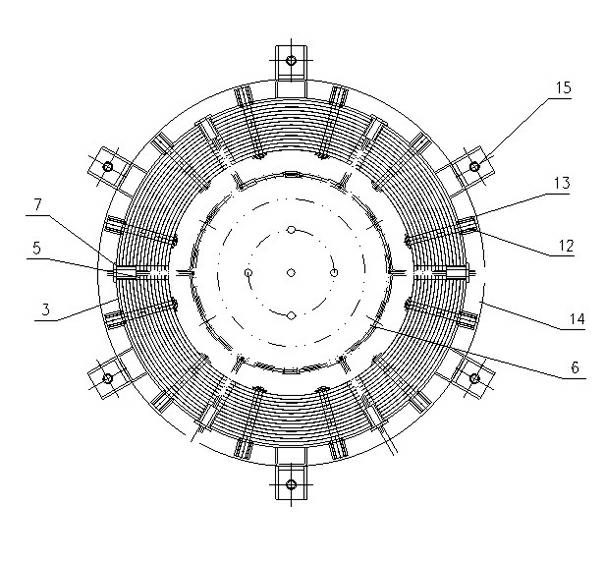

High-temperature vacuum furnace heating chamber

ActiveCN102435065BReduce volumeGood assembly locationMuffle furnacesRetort furnacesThermal insulationMaterials science

The invention discloses a high-temperature vacuum furnace heating chamber. The high-temperature vacuum furnace heating chamber comprises a cylindrical stainless steel outer shell, an upper thermal insulation screen, a side thermal insulation screen and a lower insulation screen, wherein the upper thermal insulation screen, the side thermal insulation screen and the lower insulation screen are arranged in the outer shell; a plurality of lead-out notches used for positioning a heater are formed in the side wall of the outer shell and the side thermal insulation screen; through-feeding openings are formed in the bottom of the outer shell and the lower thermal insulation screen; a moveable stainless steel plate is arranged in the feeding openings; the moveable stainless steel plate is provided with a moveable thermal insulation screen; a material-placing seat is arranged on the moveable thermal insulation screen; each thermal insulation screen comprises a plurality of thermal insulation single layers; the thermal insulation single layers respectively are a tungsten thermal insulation piece, a high temperature molybdenum thermal insulation piece and a molybdenum thermal insulation piece; cushion blocks are respectively arranged among the thermal insulation pieces; and the thermal insulation pieces are integrally connected by a tungsten pull rod and are fixed on the outer shell through an insulating ceramic ring at the end of the tungsten pull rod. The high-temperature vacuum furnace heating chamber is suitable for a high-temperature high vacuum environment, has small deformation after the temperature being raised, and has convenient use and long service life.

Owner:CSSC SHENGHUI EQUIP

High-efficiency laser deep penetration welding method for single-sided welding and double-sided forming of metal sheets

ActiveCN103978309BControl thermal deformationTaking into account the mechanical propertiesWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneEngineering

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

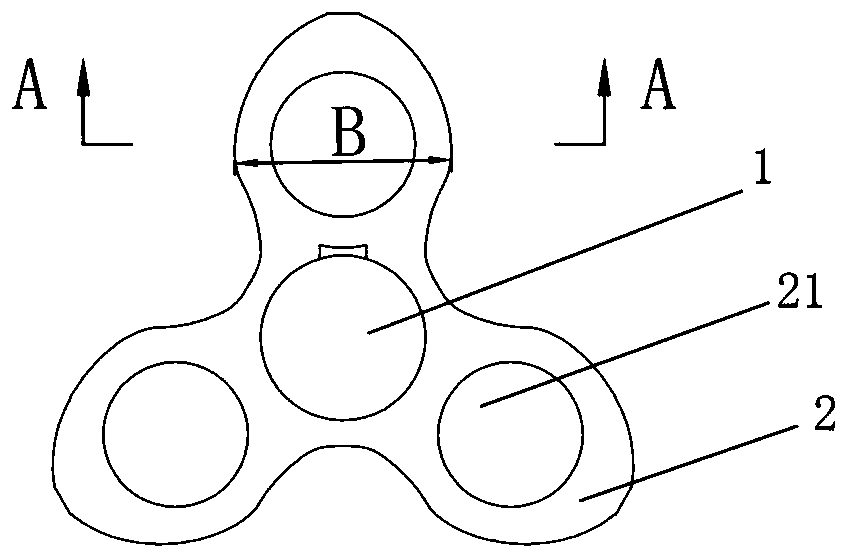

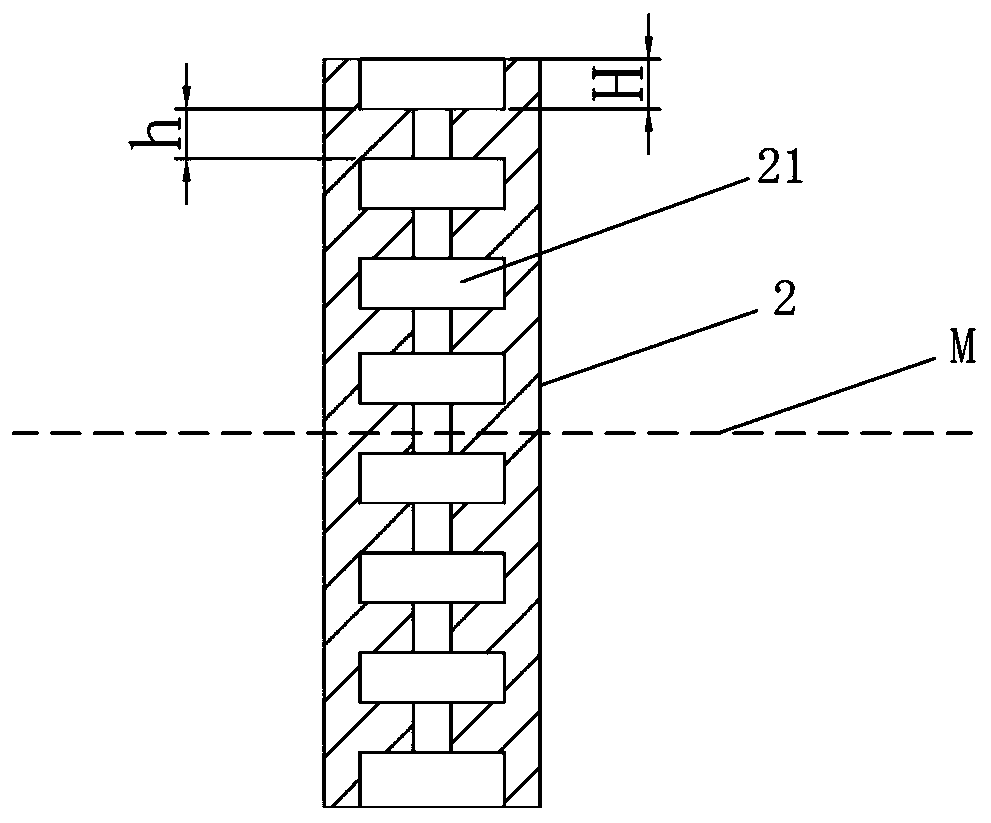

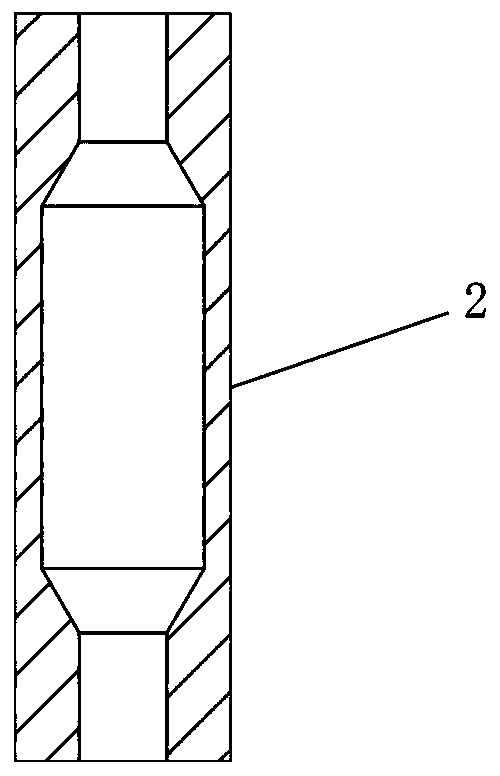

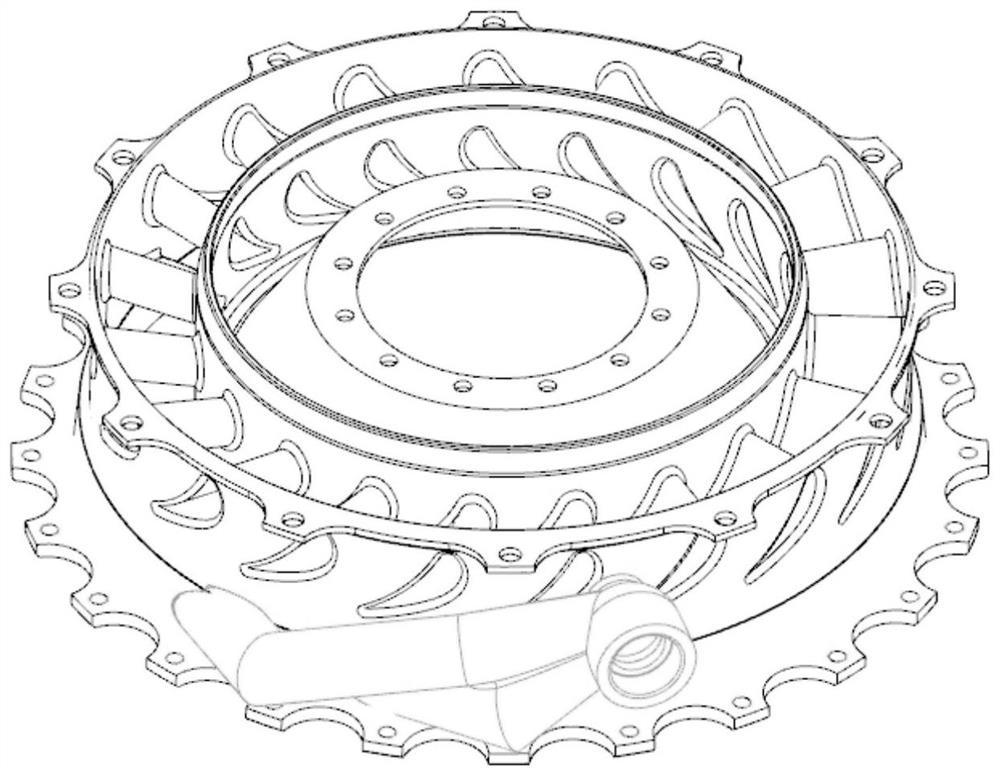

A Roots blower impeller

InactiveCN108678950BControl thermal deformationControl the amount of thermal deformationRotary piston pumpsRotary piston liquid enginesImpellerThermal deformation

The invention discloses a roots blower impeller. The roots blower impeller is of a central symmetry structure. An impeller shaft sleeve hole is formed in the center of the roots blower impeller, multiple impeller blades are arranged in the circumferential direction of the impeller shaft sleeve hole, each of the impeller blades is provided with a balance hole, and the balance holes are stepped cylindrical holes which are formed by alternately stacking of large cross-sectional columnar holes and small cross-sectional columnar holes in the axial direction. The roots blower impeller has the advantages of the improved balance hole structure and control over the amount of thermal deformation of the impeller.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

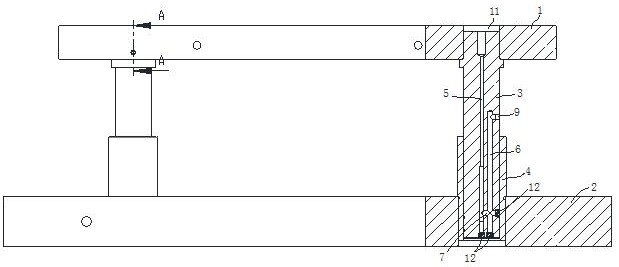

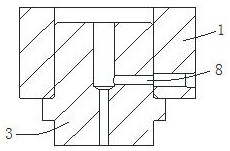

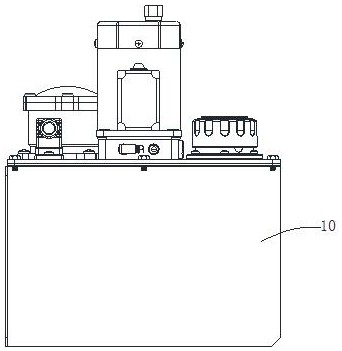

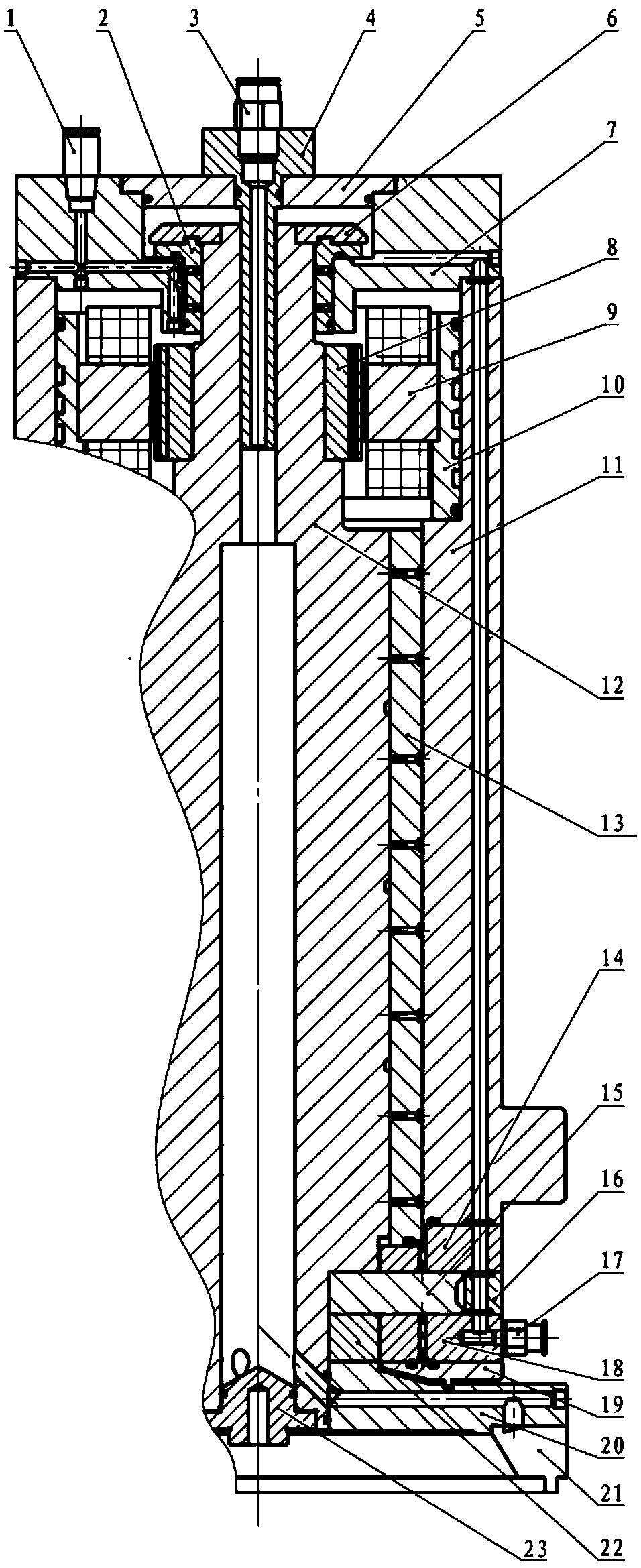

Novel precision correcting mechanism of punching machine

The invention relates to a novel precision correcting mechanism of a punching machine. The novel precision correcting mechanism comprises an upper template, a lower template, a guide pillar arranged between the upper template and the lower template, and a guide sleeve arranged on the guide pillar in a sleeving mode; a first cooling oil flow guide channel and a second cooling oil flow guide channel are arranged in the guide pillar; the first cooling oil flow guide channel and the second cooling oil flow guide channel communicate through a connecting hole; the guide pillar is provided with a cooling oil inlet and a cooling oil outlet which are connected with the first cooling oil flow guide channel or the second cooling oil flow guide channel; and a cooling oil machine is connected between the cooling oil inlet and the cooling oil outlet. Cooling oil guided in from the cooling oil inlet flows back into the first cooling oil flow guide channel and the second cooling oil flow guide channel while lubricating the guide pillar and the guide sleeve, the flowing cooling oil takes away friction heat, meanwhile, a cooling effect is achieved, thermal deformation is controlled, the operation stability of the guide sleeve is improved, and after being cooled by the cooling oil machine, the oil enters the flow guide channels through the cooling oil inlet, so that the circulating cooling effect is achieved.

Owner:宁波满信机械工贸有限公司

An electric spindle and thinning machine cooled by cooling liquid through the center

ActiveCN106493617BHigh working reliabilityAvoid destructionSemiconductor/solid-state device manufacturingPlane surface grinding machinesElectricityEngineering

The embodiment of the invention provides a motorized spindle with a cooling liquid introduced in the center for cooling and a thinning machine, wherein a first cooling liquid channel is arranged on a rotating shaft of the motorized spindle and is used for conveying the cooling liquid and controlling the flow direction of the cooling liquid; meanwhile, an air seal and an overflow channel are arranged on the periphery of the upper end of the rotating shaft of the motorized spindle and are used to prevent the cooling liquid from entering a motor rotor and other adjacent parts when the cooling liquid overflows from the upper end of the first cooling liquid channel under the abnormal conditions. According to the scheme, the motorized spindle is reliably and effectively cooled when the thinning machine works.

Owner:CETC BEIJING ELECTRONICS EQUIP

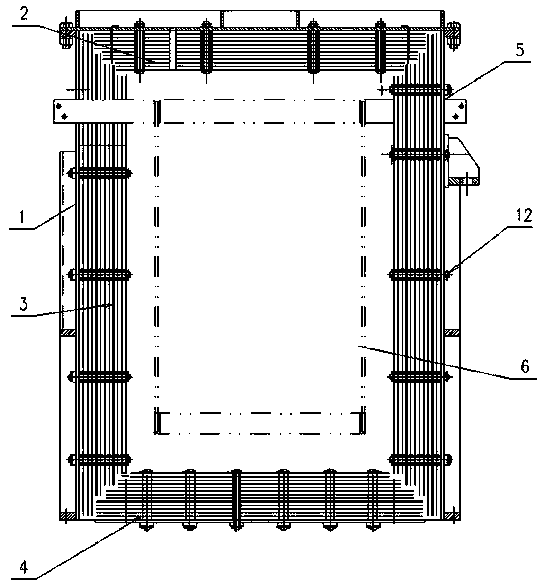

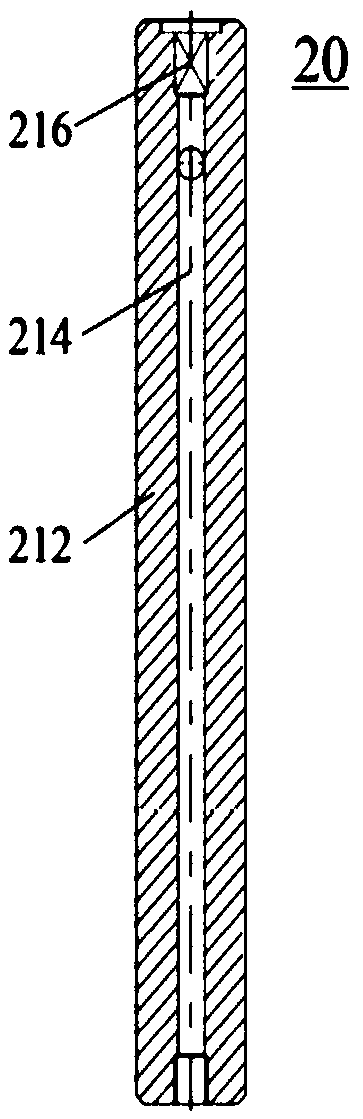

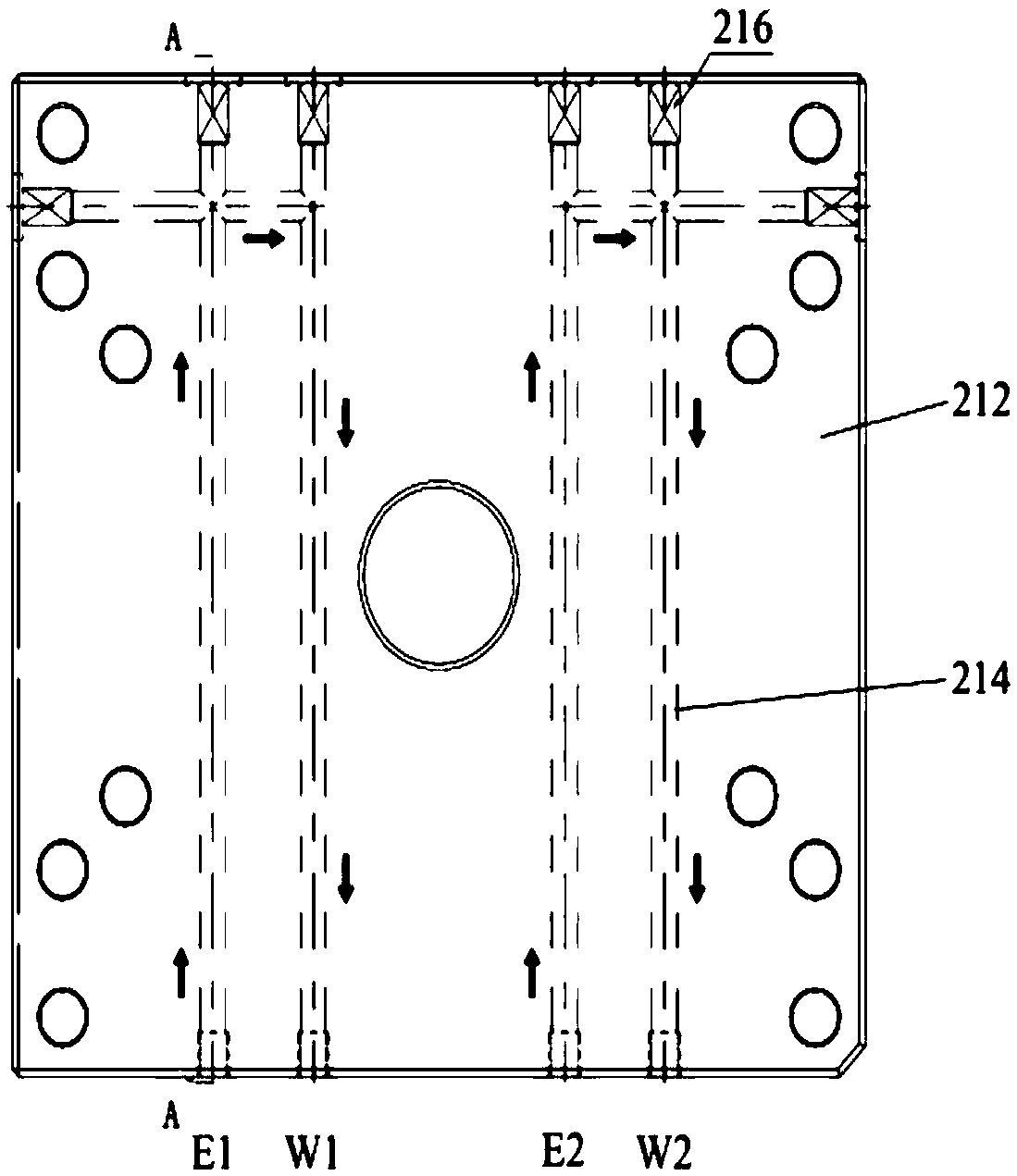

Heat insulating structure device, injection molding machine and method for controlling heat transfer and deformation quantity to be consistent

InactiveCN111113832ASymmetrical distributionSymmetrically or evenly distributedMolding machineHeat transmission

The invention provides a heat insulating structure device, an injection molding machine and a method for controlling heat transfer and the deformation quantity to be consistent. The heat insulating structure device can comprise a base plate. The base plate can be made of a metal material. One or more fluid passageways can be formed in the base plate, so that fluid flows in the base plate through the one or more fluid passageways in a circulating manner. The injection molding machine can comprise two heat insulating structure devices, wherein one heat insulating structure device can be arrangedbetween a fixed side safety bar and a fixed side die portion of the injection molding machine, and the other heat insulating structure device can be arranged between a movable side safety bar and a movable side die portion of the injection molding machine. The heat insulating structure device is high in flatness, controllable in temperature and uniform in heating. According to the injection molding machine adopting the heat insulating structure device, the coincidence error of die closure can be effectively reduced, heat losses of dies are reduced, the injection molding production stability is improved, and the service life of the dies is prolonged.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

Refrigeration screw compressor with air suction port in shell shaft seal end

InactiveCN103104500ARelieve stressRelieve pressurePumpsRotary/oscillating piston pump componentsDrive shaftRefrigeration

The invention relates to an F25B refrigeration machine, a refrigeration device or system class in international patent classification (IPC) through searching, and particularly belongs to a refrigeration screw compressor with an air suction port in a shell shaft seal end. According to the technical scheme provided by the invention, the refrigeration screw compressor comprises a shell (1), a drive shaft (2), a shaft seal (3), a shaft seal cover (4) and a shell shaft seal end (5) and is characterized in that an air suction base (6) is made on the shell shaft seal end (5), and an air suction hole (7) is formed in the air suction base (6). The refrigeration screw compressor has the beneficial effects that the defects of the conventional structure design of the compressor are overcome to ensure that the pressure borne by the shaft seal when the compressor works is reduced, and the temperature is lowered, and thus the temperature of lubricating oil is reduced, the viscosity of the lubricating oil is increased, the lubricating effect of the shaft seal is improved, and the service life of the compressor shaft seal is prolonged.

Owner:FUJIAN SNOWMAN COMPRESSOR TECH

Method for processing transformer pulling plate magnet isolation tank

The invention discloses a method for processing a transformer pulling plate magnet isolation tank, comprising the following processing steps: first, drilling technology holes with diameter being equal to the diameter to the tank width of the magnet isolation tank at the two ends of the X direction of the length of the pulling plate body; aligning the technology holes at one end of the X directionof the length of the pulling plate body with a nozzle of a flame cutting torch along the Y direction of the width of the pulling plate body, a cooling water pipe is arranged along the X direction andat the same line the flame cutting torch is located; the flame cutting torch and the cooling water pipe are connected with a moveable cart at one side of the Y direction of the width of the pulling plate body with two mutually parallel arms; the flame cutting torch is stated to facilitate the moveable cart move along the X direction at a speed of 300-500mm / min towards the technology holes at the other end of the X direction; meanwhile, the cooling water pipe is opened to continuously inject water forward along the movement direction of the flame cutting torch; when the flame cutting torch moves to the technology holes at the other end of the pulling plate; the technology holes at the end is aligned with the nozzle of the flame cutting torch along the outside of the Y direction to facilitate the moveable cart to move in the opposite direction until the cart returns to the previous technology holes.

Owner:CHINA XD ELECTRIC CO LTD

High-temperature vacuum furnace heating chamber

ActiveCN102435065AReduce volumeGood assembly locationMuffle furnacesRetort furnacesThermal insulationMaterials science

The invention discloses a high-temperature vacuum furnace heating chamber. The high-temperature vacuum furnace heating chamber comprises a cylindrical stainless steel outer shell, an upper thermal insulation screen, a side thermal insulation screen and a lower insulation screen, wherein the upper thermal insulation screen, the side thermal insulation screen and the lower insulation screen are arranged in the outer shell; a plurality of lead-out notches used for positioning a heater are formed in the side wall of the outer shell and the side thermal insulation screen; through-feeding openings are formed in the bottom of the outer shell and the lower thermal insulation screen; a moveable stainless steel plate is arranged in the feeding openings; the moveable stainless steel plate is provided with a moveable thermal insulation screen; a material-placing seat is arranged on the moveable thermal insulation screen; each thermal insulation screen comprises a plurality of thermal insulation single layers; the thermal insulation single layers respectively are a tungsten thermal insulation piece, a high temperature molybdenum thermal insulation piece and a molybdenum thermal insulation piece; cushion blocks are respectively arranged among the thermal insulation pieces; and the thermal insulation pieces are integrally connected by a tungsten pull rod and are fixed on the outer shell through an insulating ceramic ring at the end of the tungsten pull rod. The high-temperature vacuum furnace heating chamber is suitable for a high-temperature high vacuum environment, has small deformation after the temperature being raised, and has convenient use and long service life.

Owner:CSSC SHENGHUI EQUIP

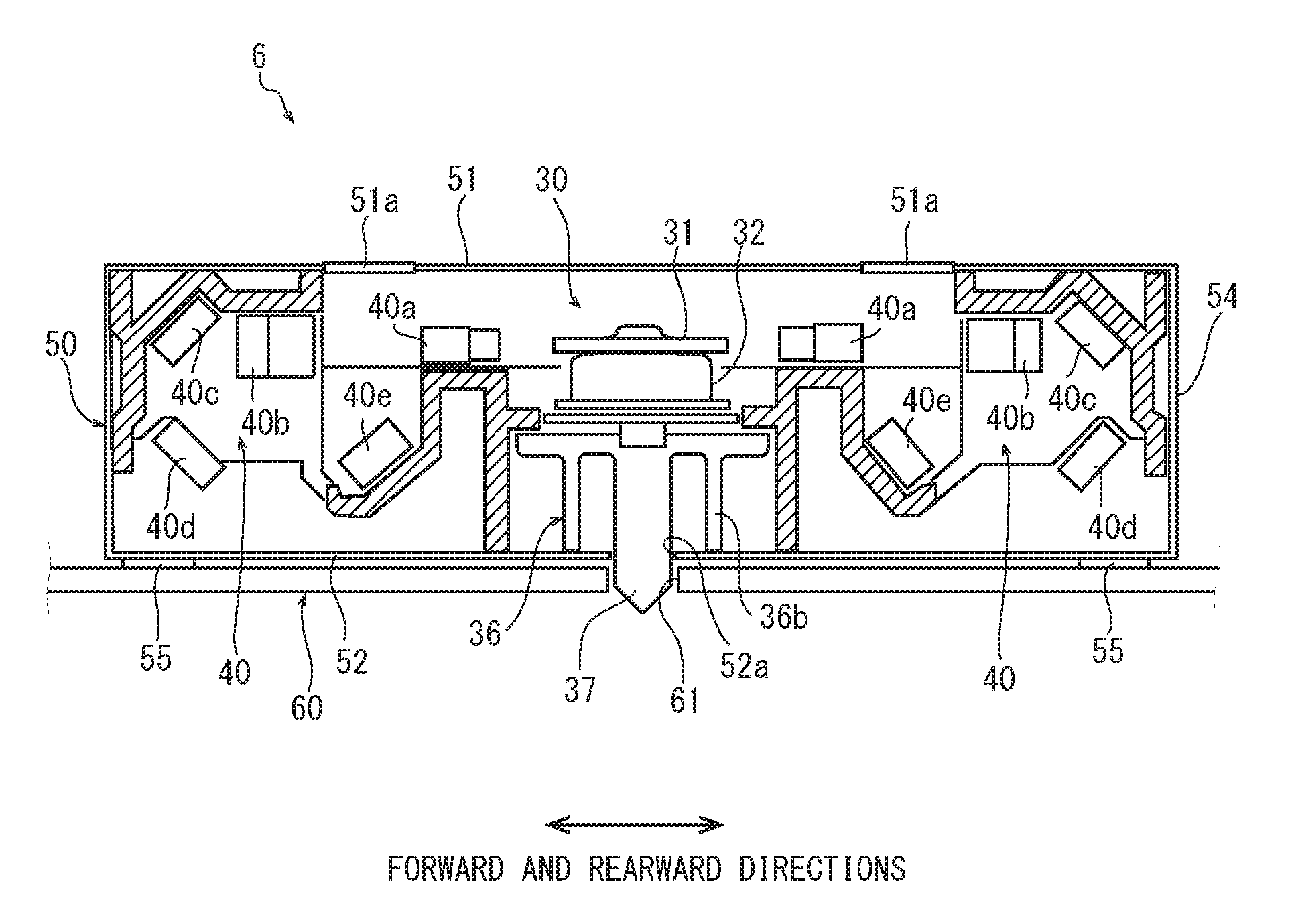

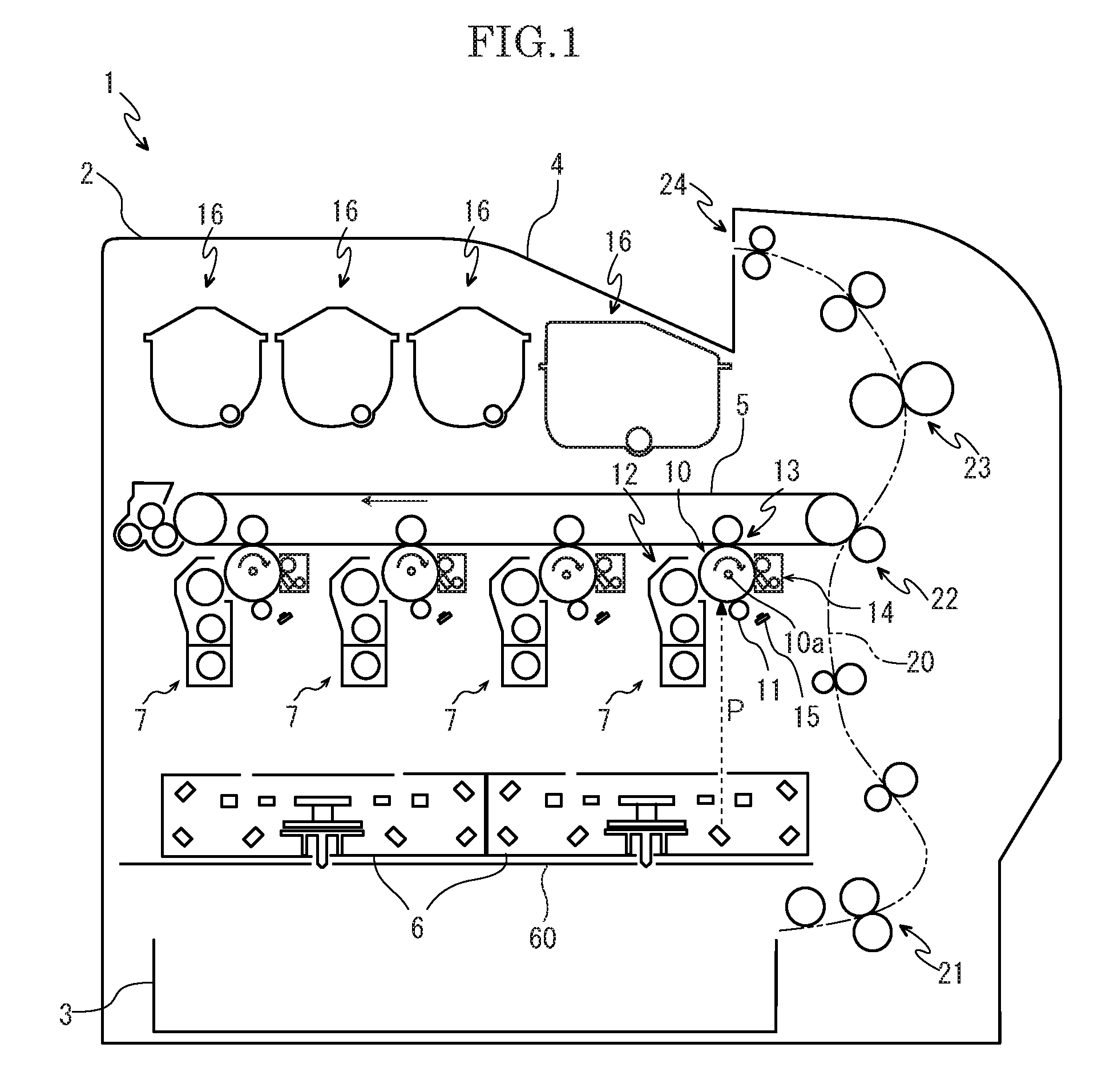

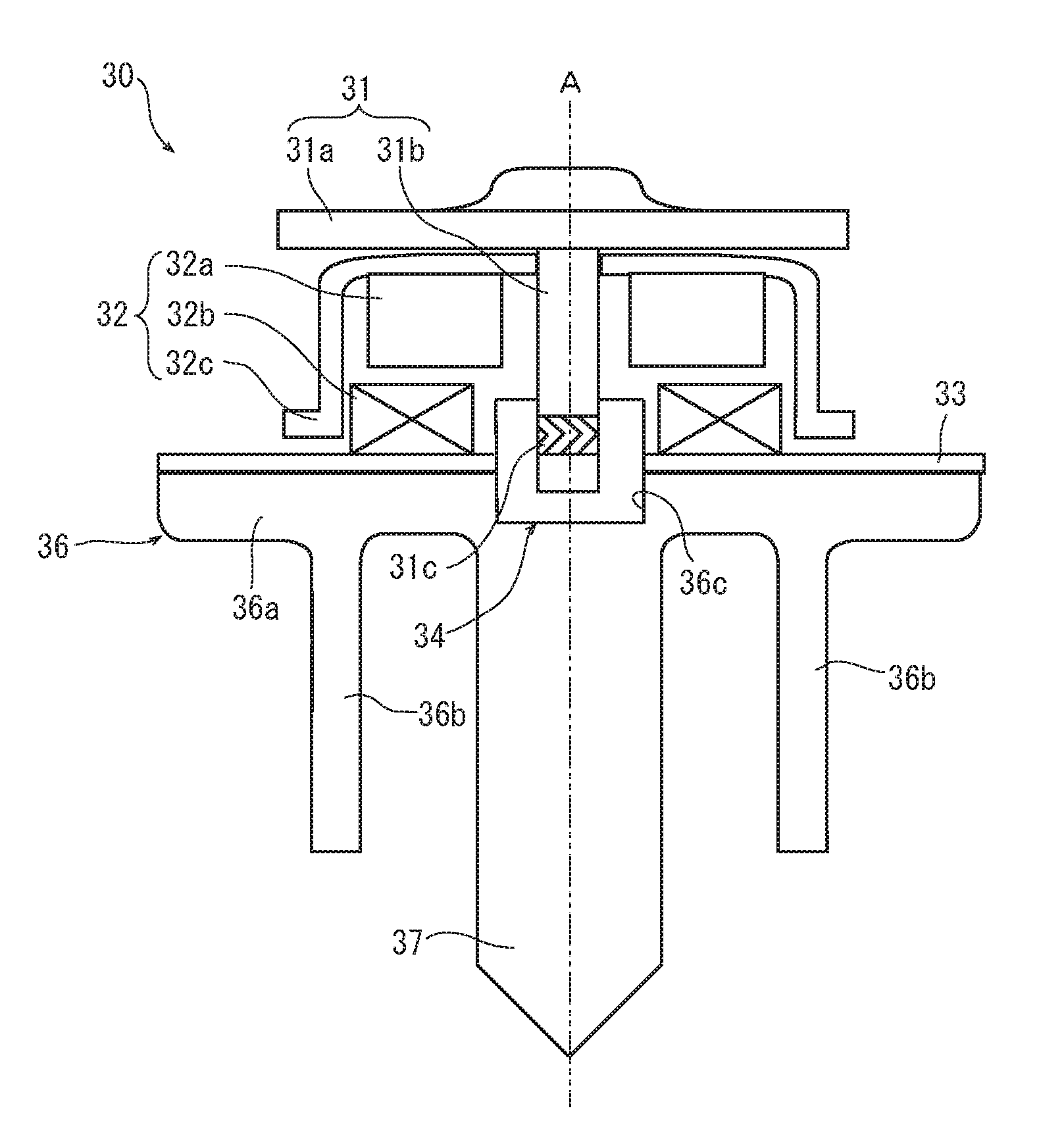

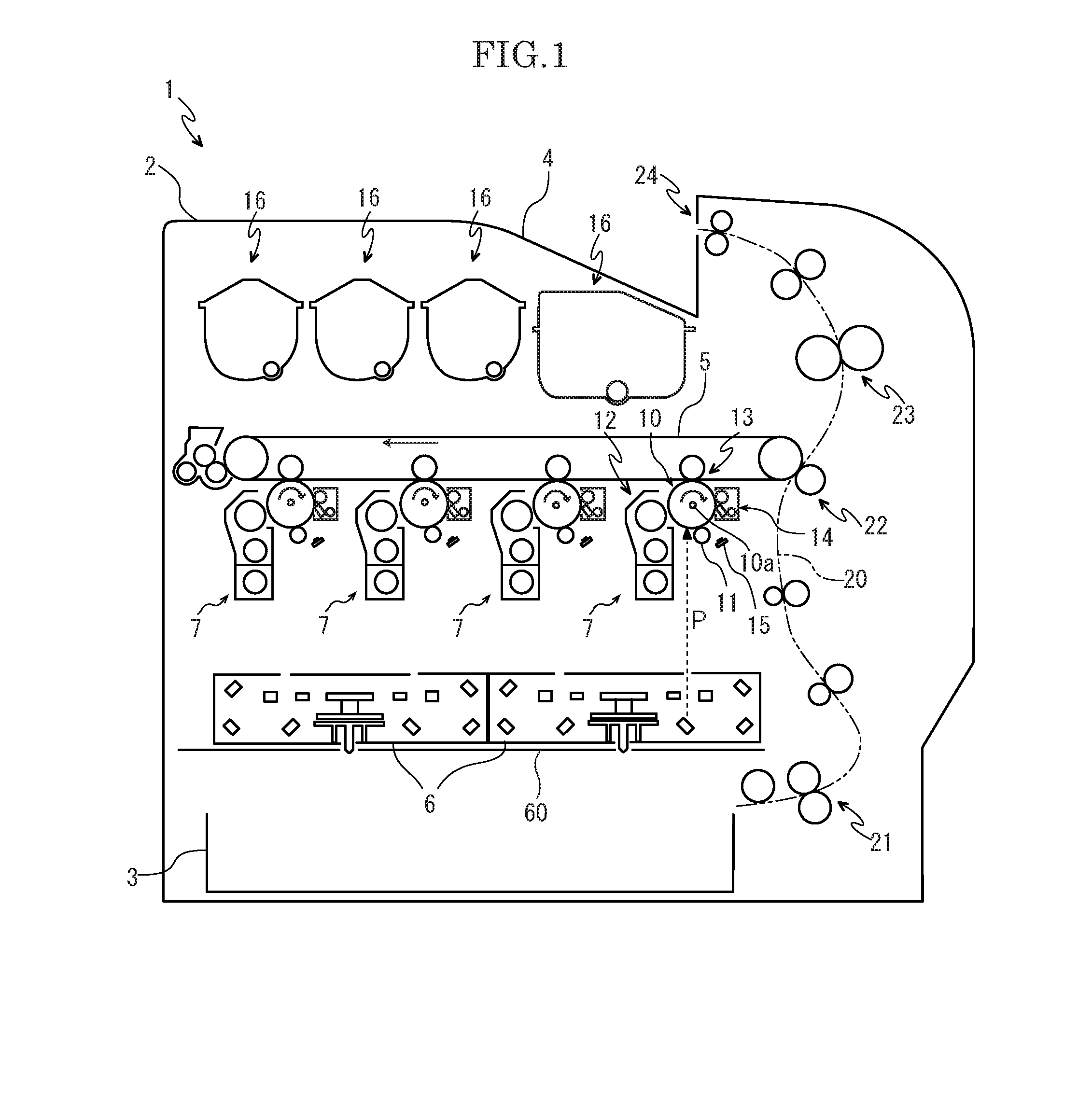

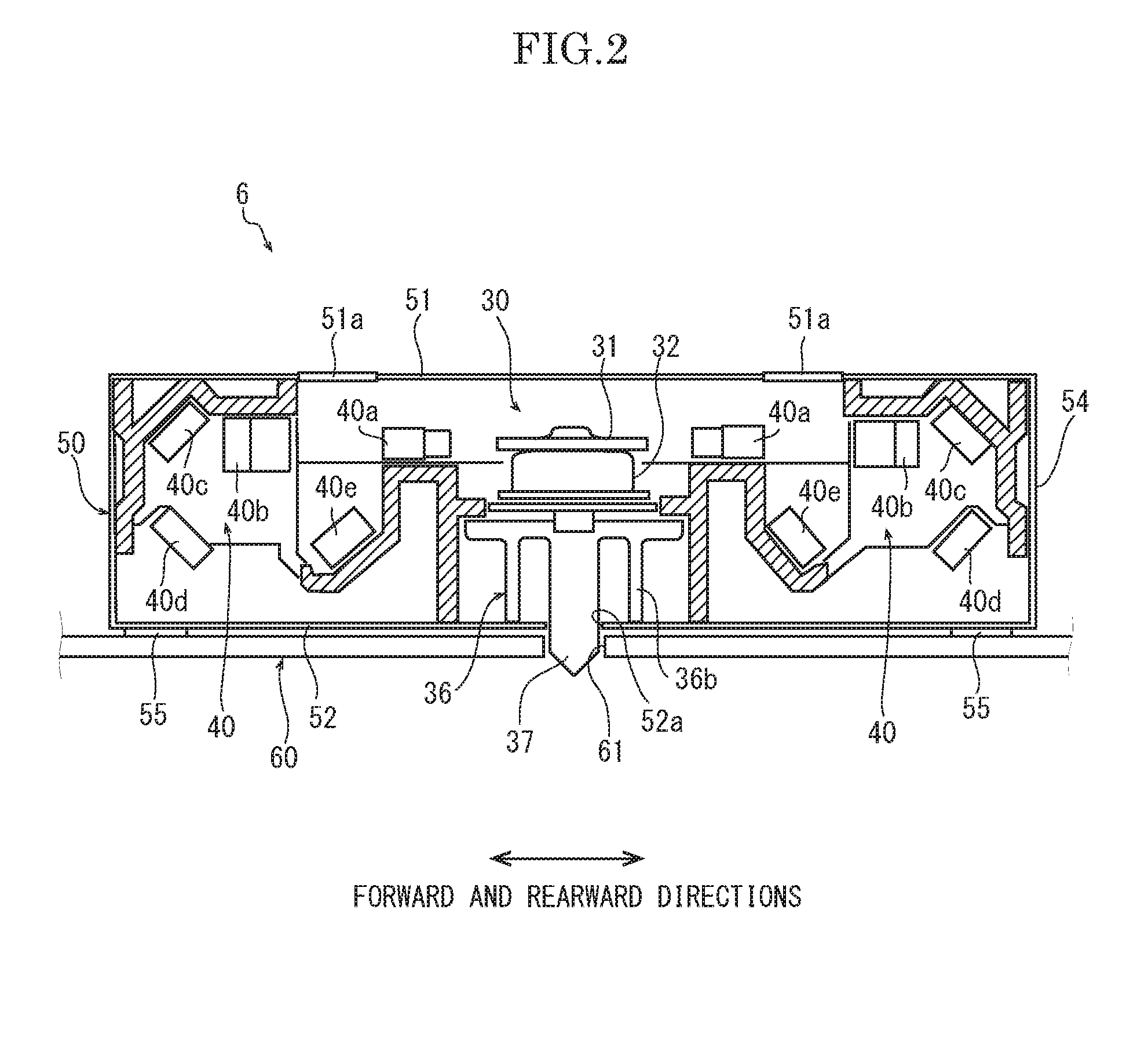

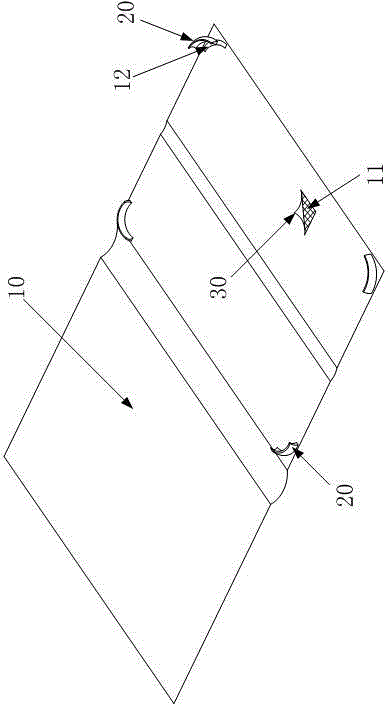

Image forming apparatus having scanning optical device

ActiveUS9541897B2Easy to controlReduce vibration exertedElectrographic process apparatusPictoral communicationEngineeringImaging equipment

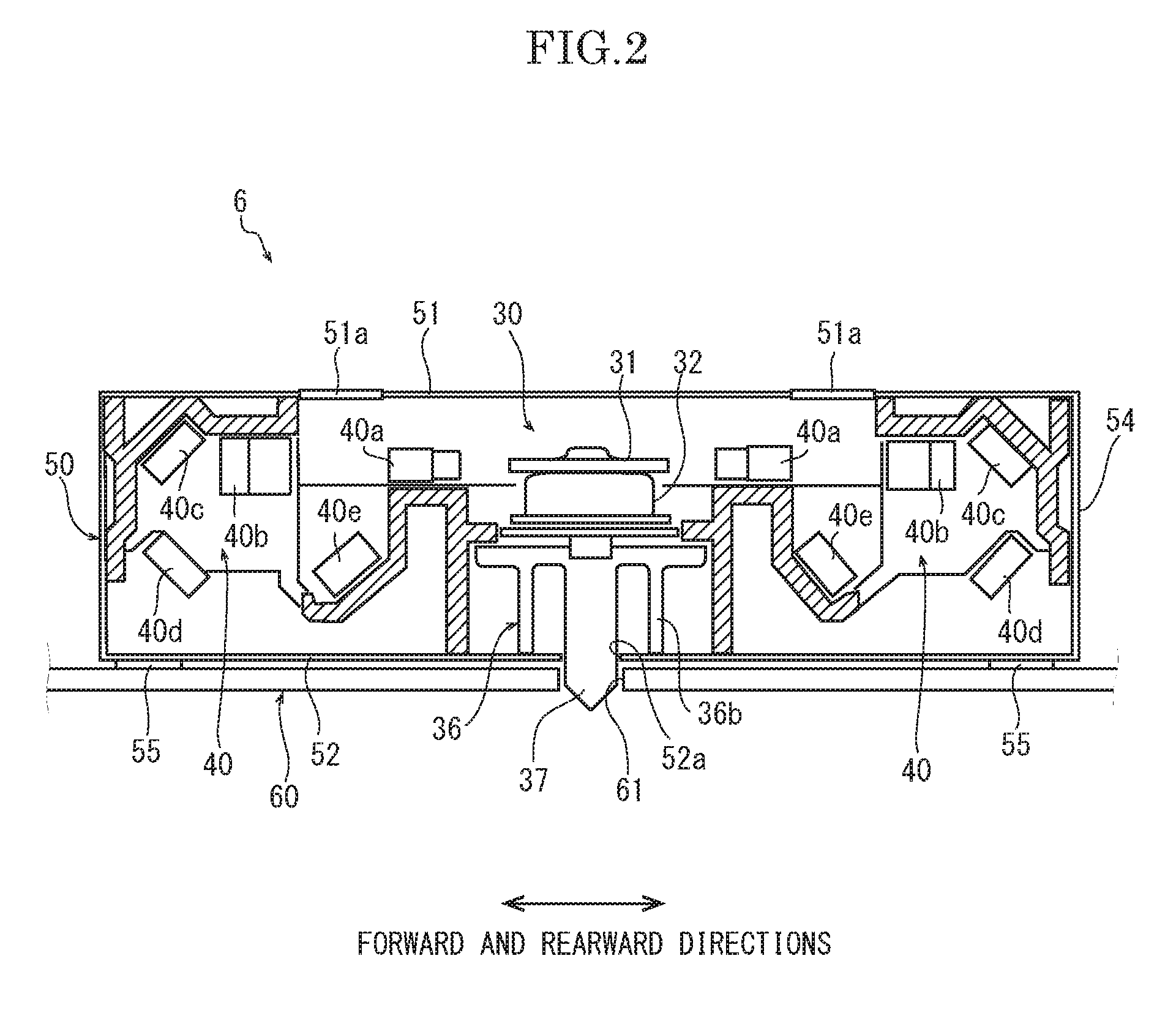

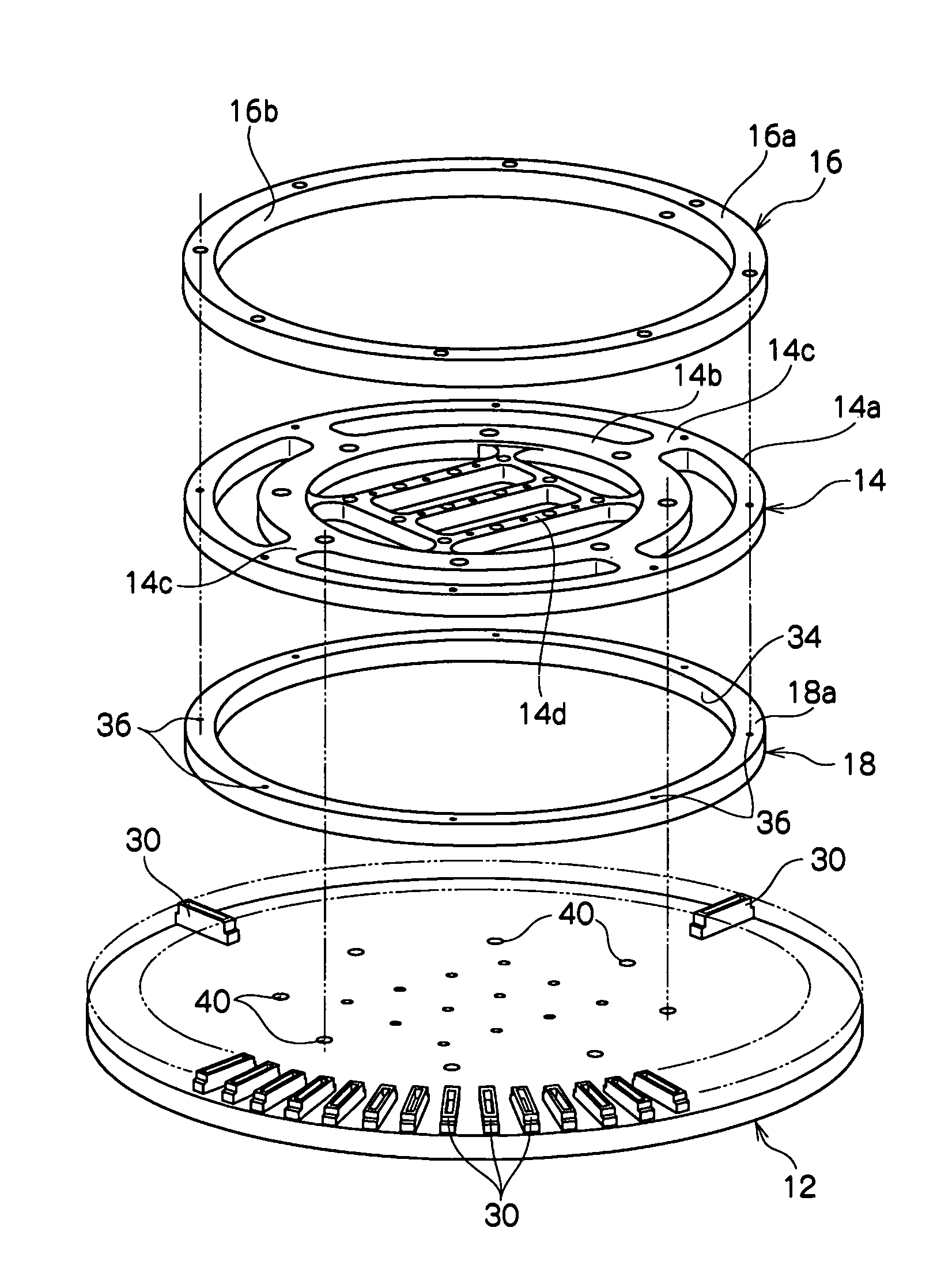

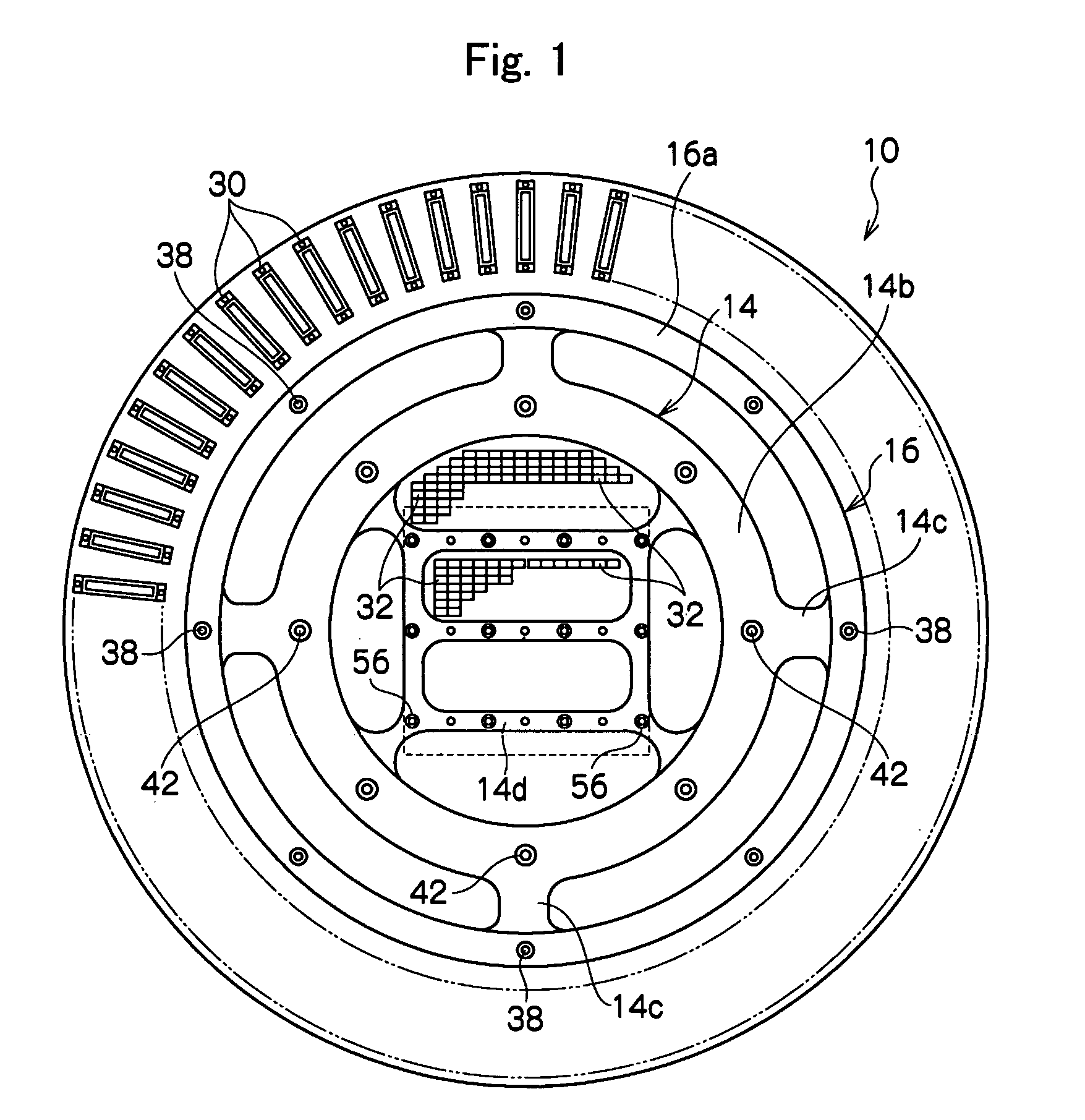

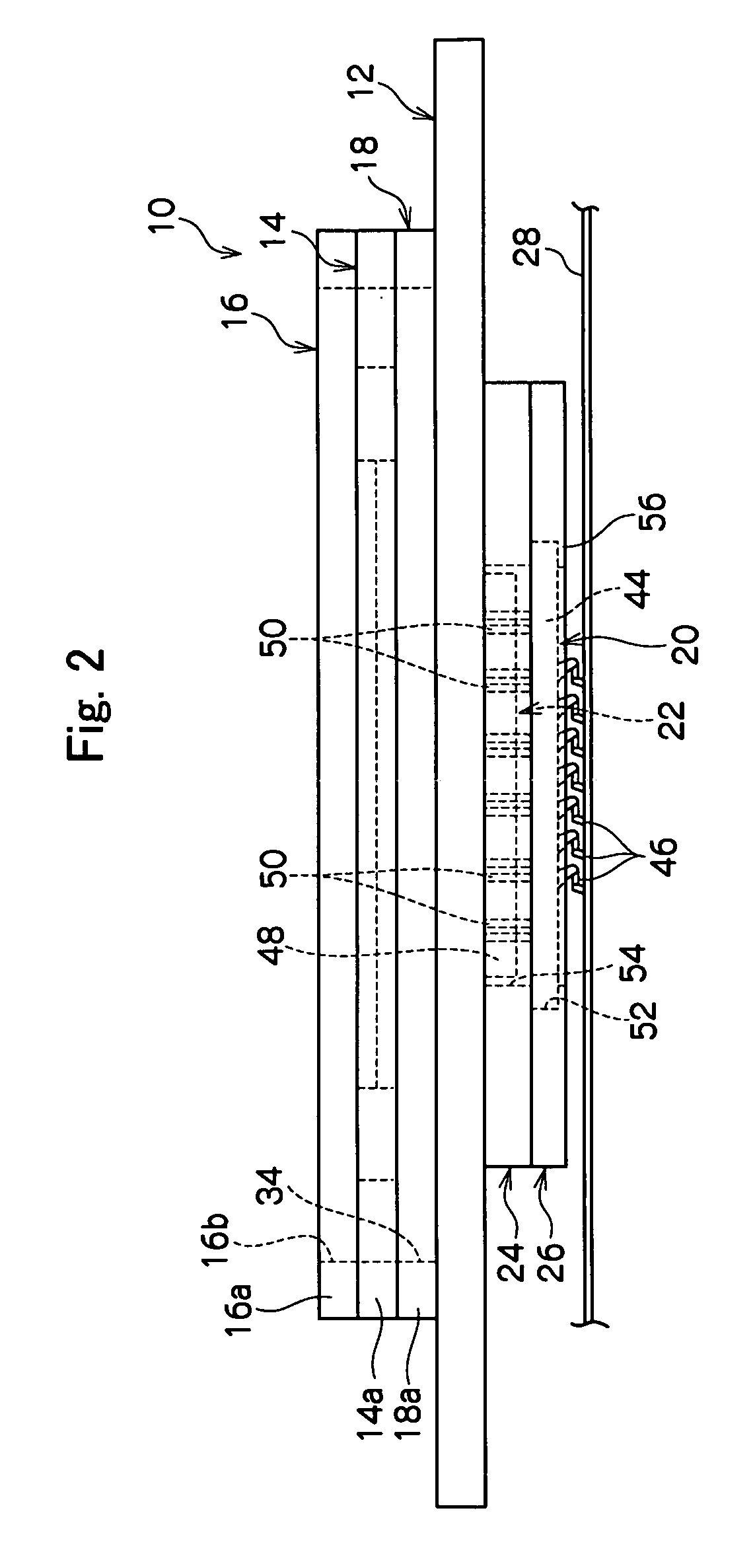

The scanning optical device (6) includes a light source, a deflector (30) configured to rotate on a horizontal surface around a rotating shaft extending in a vertical direction and an optical box (50) in which the light source, the deflector (30), and the optical components groups (40) are housed and supported by the frame (60). A heat sink (36) is disposed between the deflector (30) and the frame (60). A first protrusion (37) extending on an extension line of the rotating shaft of the deflector (30) is formed in the heat sink (36). A first engaging hole (61) with which the first protrusion (37) engages is formed in the frame (60).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Electric connecting apparatus

ActiveUS7924034B2Control thermal deformationCoupling device connectionsElectrical testingElectricityCoupling

Owner:NIHON MICRONICS

Cooling device and dicing machine with built-in motor of electric spindle

ActiveCN103138489BControl thermal deformationHigh degree of automationCooling/ventillation arrangementElectric machineEngineering

The invention provides a cooling device of a built-in motor of a motorized spindle and a dicing machine. The cooling device comprises a cooling liquid providing part which is used for providing cooling liquid and a cooling liquid passage which is used for inputting the cooling liquid which is provided by the cooling liquid providing part and controlling the flow direction of the cooling liquid. The cooling device of the built-in motor of the motorized spindle and the dicing machine can stably cool the motor of the spindle when the motorized spindle is working.

Owner:CETC BEIJING ELECTRONICS EQUIP

Lead liquid dosing device and plate-casting machine

The invention discloses a dosing device for liquid lead, which comprises a shell, a valve core, a valve stem and a quantitative cylinder. The shell is hollow and is provided with a lead inlet and a lead outlet; the valve core is positioned at one end inside the shell, a liquid lead channel for connecting the lead inlet and the lead outlet is arranged on the valve core. The valve stem is arranged at the other end inside the shell. One end of the valve stem is provided with a conical head for closing the liquid lead channel. The quantitative cylinder is connected at the other end of the valve stem. As the quantitative cylinder is adopted to control the valve stem to close the lead liquid channel of the valve core, the dosing device for the liquid lead by adopting the technical scheme of theinvention has the advantages of simple structure, low cost and reliable working. As the using of the dosing device for the liquid lead, a casting plate device thereof has the advantages of more steadyperformance, more accurate dosing for the liquid lead, less waste and low cost. As the dosing device is arranged between a lead pipe and a lead ladle far away from a scorching lead furnace, the servicelife is longer and the maintenance is more convenient.

Owner:ZHAOQING LEOCH BATTERY TECH

Image forming apparatus

ActiveUS20160259296A1Easy to controlReduce vibration exertedElectrographic process apparatusPictoral communicationImage formationEngineering

The scanning optical device (6) includes a light source, a deflector (30) configured to rotate on a horizontal surface around a rotating shaft extending in a vertical direction and an optical box (50) in which the light source, the deflector (30), and the optical components groups (40) are housed and supported by the frame (60). A heat sink (36) is disposed between the deflector (30) and the frame (60). A first protrusion (37) extending on an extension line of the rotating shaft of the deflector (30) is formed in the heat sink (36). A first engaging hole (61) with which the first protrusion (37) engages is formed in the frame (60).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

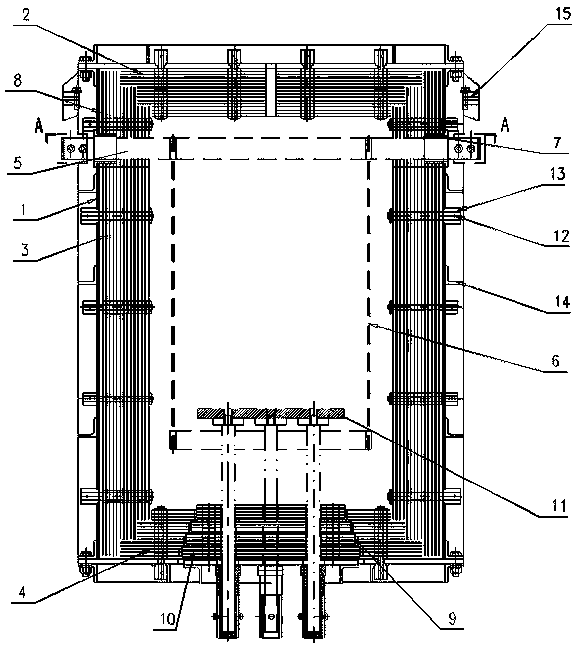

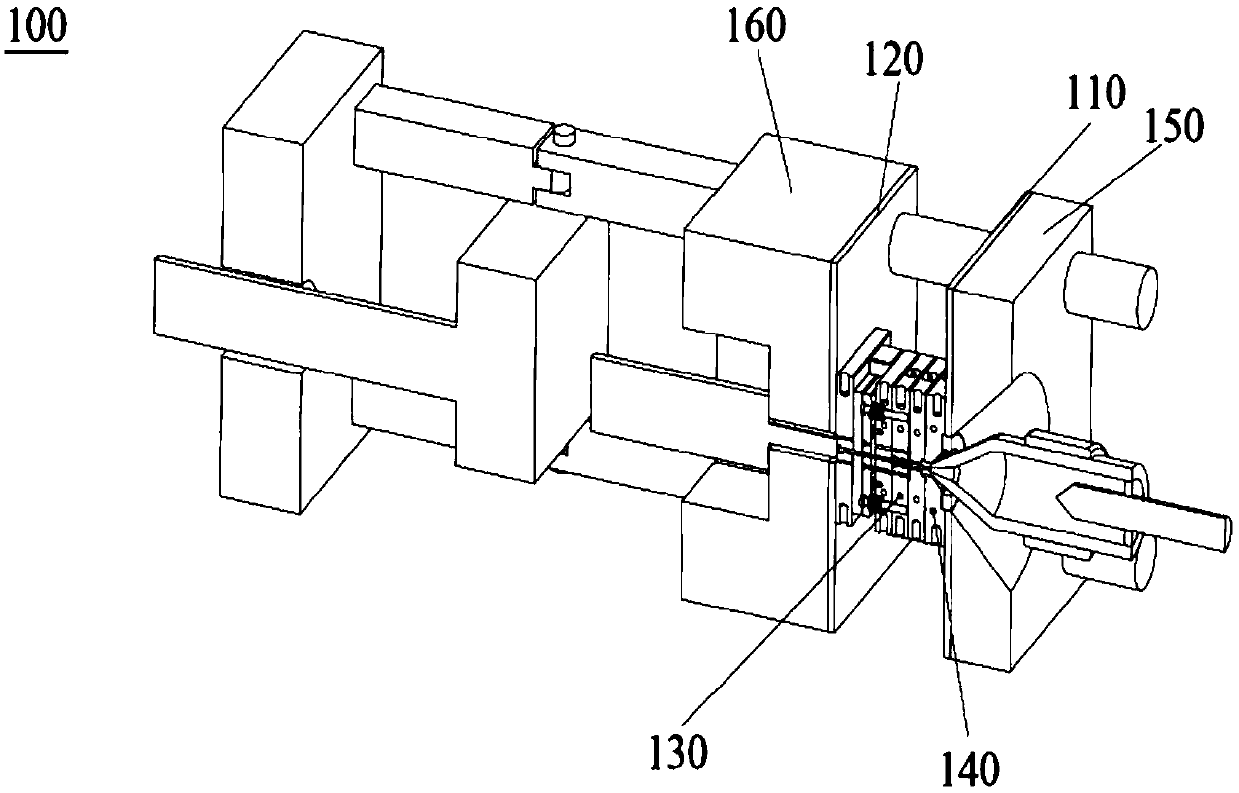

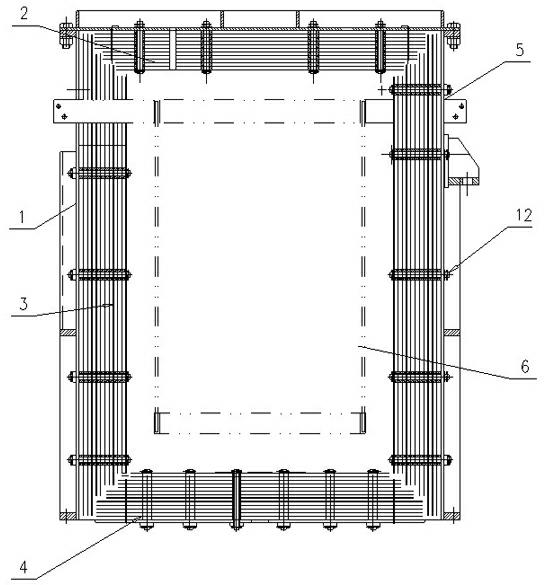

A thermal deformation control device for a multi-degree-of-freedom space structure

ActiveCN108098100BAchieve fixationRealize thermal expansion and pressure reliefWelding/cutting auxillary devicesAuxillary welding devicesSpatial structureThermal deformation

The invention discloses a thermal deformation control device of a multiple-degree-of-freedom spatial structure in a brazing high-temperature environment. The thermal deformation control device comprises a base, locating blocks, locating forcing screws, connecting screws and an auxiliary profiling press block. Peripheral equipment comprises a guide device to be welded and a startup spraying pipe tobe welded. The guide device is fixed to the base after angular locating is conducted on the guide device. The locating blocks are fixedly connected to the base through the connecting screws. The locating forcing screws pass through threaded through holes formed in the locating blocks, point to the direction of thermal deformation of the startup spraying pipe and tightly press the auxiliary profiling press block on the surface of the startup spraying pipe. The pressing force is applied in the normal directions of the excircle surfaces, close to matched portions, of two branch-shaped pipe portions of a workpiece through the locating forcing screws and the auxiliary profiling press block, and therefore the purpose of controlling thermal deformation is achieved. By the adoption of the thermaldeformation control device of the multiple-degree-of-freedom spatial structure, the phenomenon that due to thermal deformation, the gap of a brazing seam is enlarged in the high-temperature environment is avoided, then the phenomenon that the incomplete-penetration defect exists is avoided, and the brazing quality is substantially improved.

Owner:BEIJING POWER MACHINERY INST

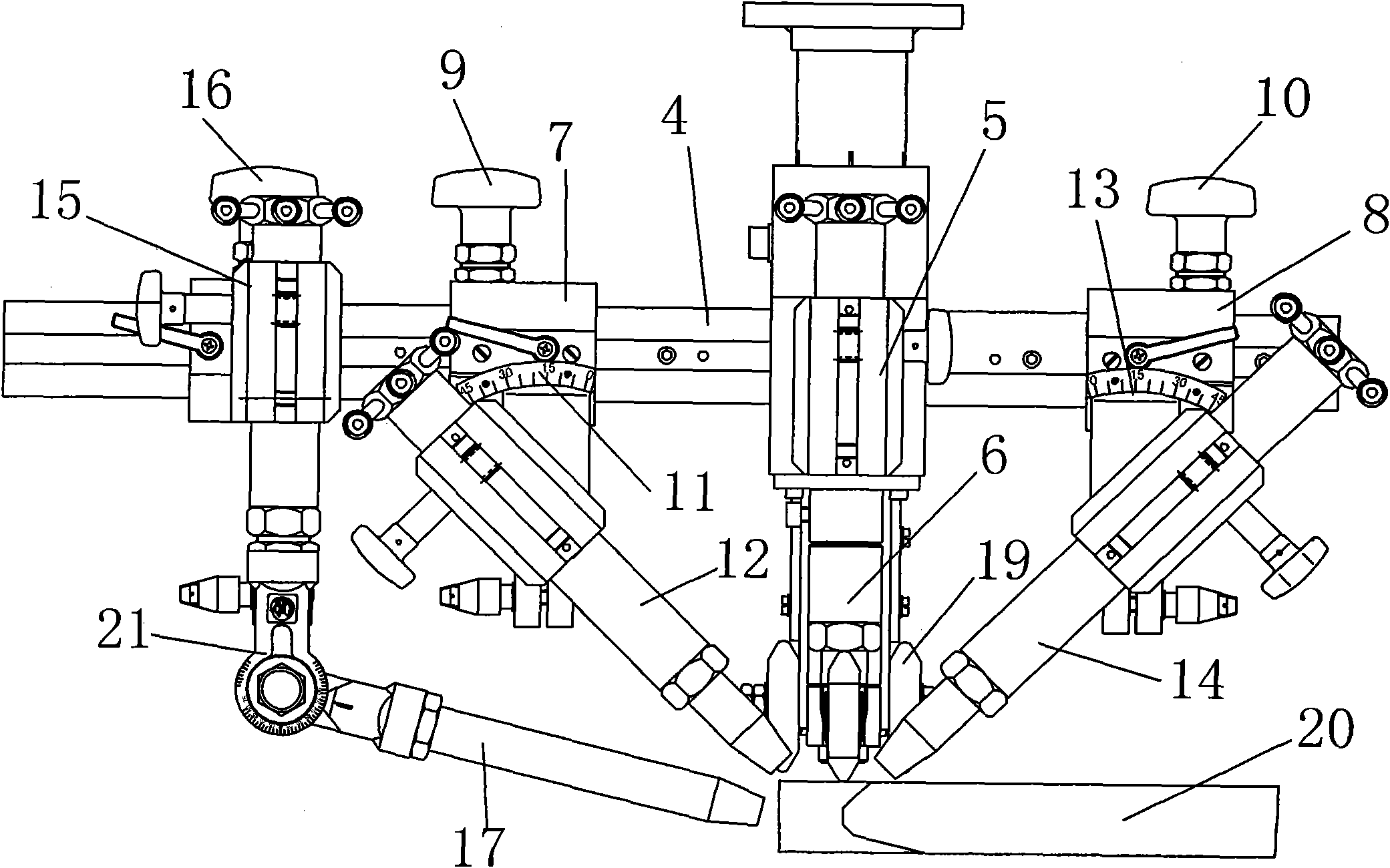

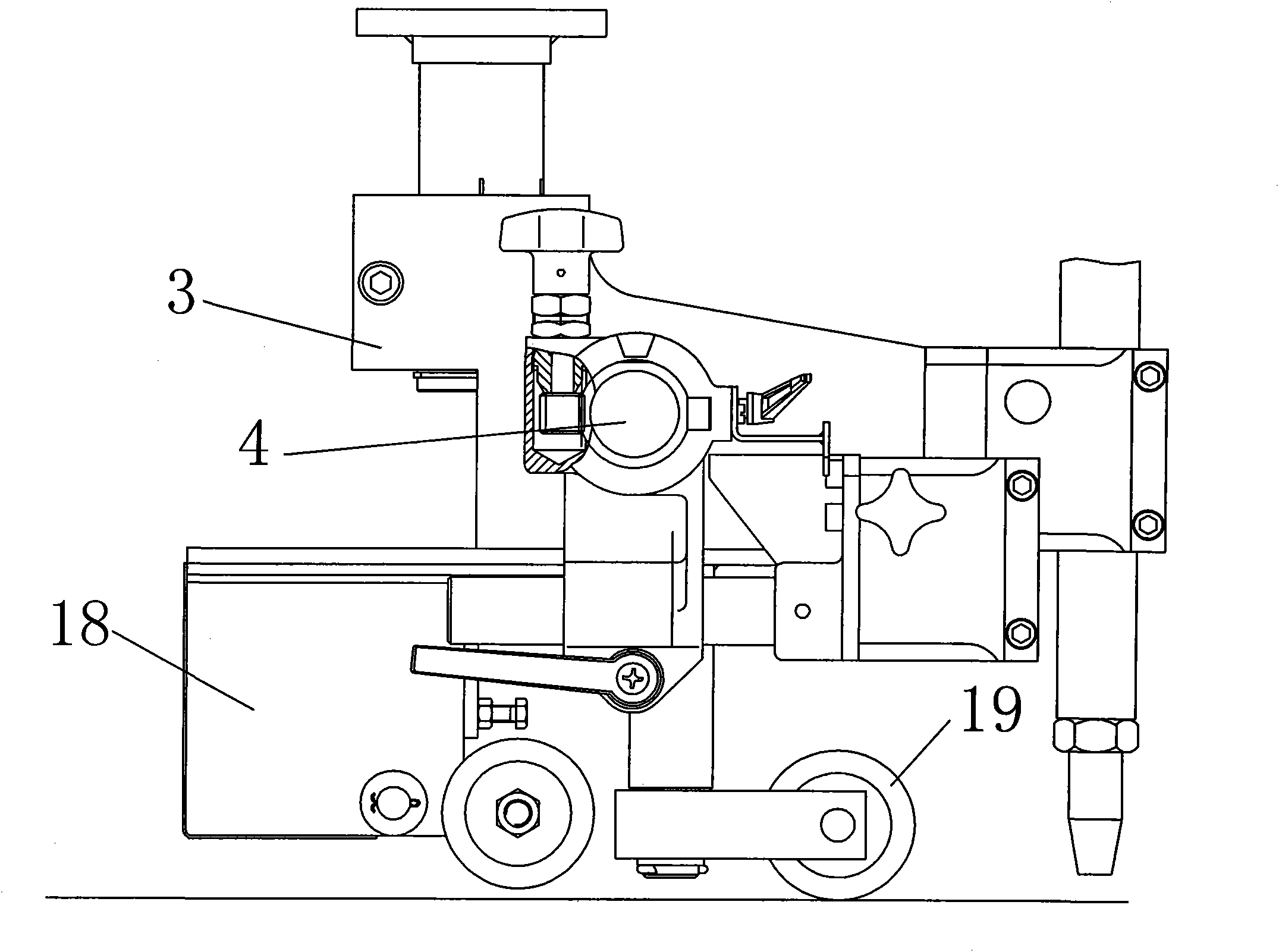

Linear groove and transition groove cutter device

InactiveCN102029493BCompact structureSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesTorchUltimate tensile strength

The invention discloses a linear groove and transition groove cutter device comprising a stand, wherein the stand is provided with a rack rod fixedly provided with a center cutting torch link span; two sides of the center cutting torch link span are respectively provided with a left moving body and a right moving body, wherein the left moving body is connected with a left handwheel meshed with the rack rod; the right moving body is connected with the right handwheel meshed with the rack rod; and the left moving body is provided with a left cutting torch clamp holder, and the right moving body is provided with a right cutting torch clamp holder. The linear groove and transition groove cutter device also comprises a transition moving body connected with a transition handwheel meshed with the rack rod; and the transition moving body is provided with a transition cutting torch clamp holder provided with a transition cutting torch. The whole cutter device has the advantages of compact structure and convenience for operation. The device can simultaneously cut a linear groove and a transition groove, thereby greatly improving cutting production efficiency, and lowering labor intensity. In addition, the cutting precision and the surface quality of workpieces are high, which can satisfy the process requirements of automatic welding, without subsequent processing.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

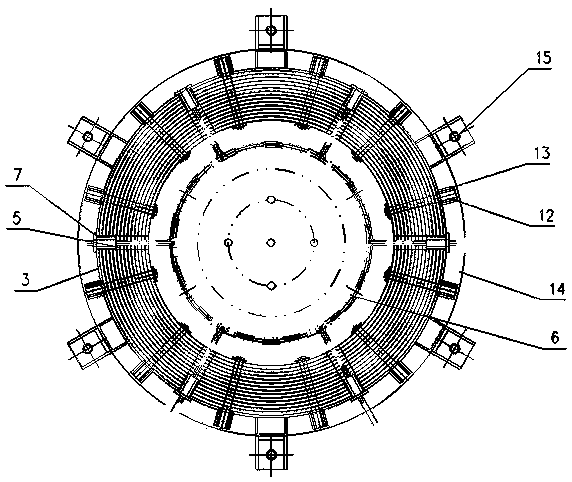

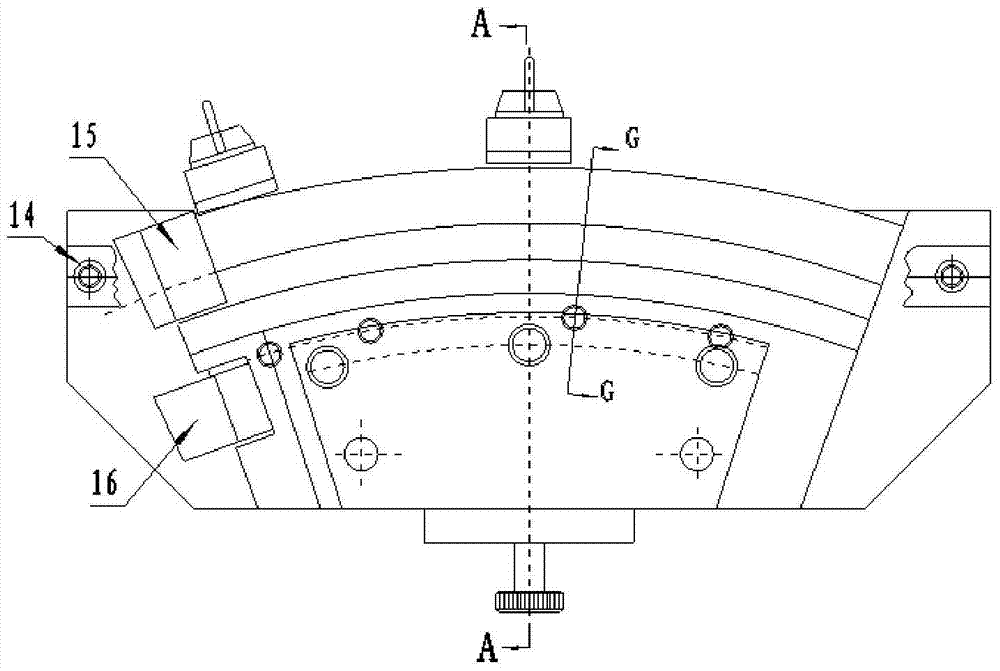

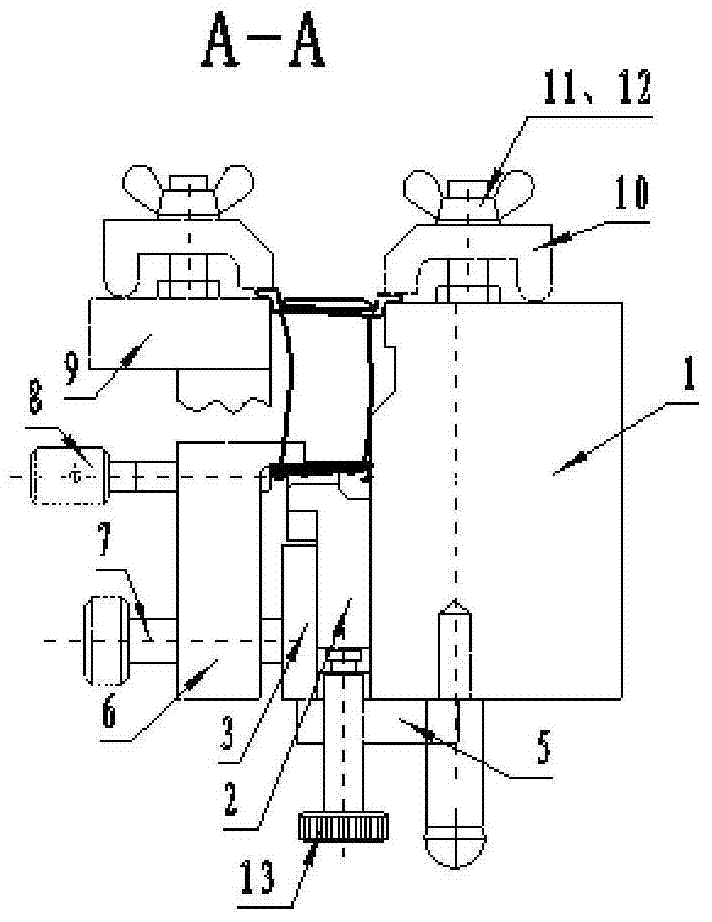

A positioning and clamping device for energy storage spot welding of stator blade sector block welding assembly

ActiveCN105290559BControl thermal deformationImprove welding qualitySoldering auxillary devicesThermal deformationEngineering

The invention provides an energy storage spot-welding locating and clamping device of a stationary blade fan-shaped block welding assembly. The device comprises a base, a press block, a stop pin, a locating block and press plates. The base serves as a main component, is an arc locating surface manufactured according to the structure of the air inlet side of the welding assembly and is used for fixing a supporting piece located on the exhaust side of the welding assembly to the base through cylindrical pins. The press block, the stop pin, the locating block or the press plates are adopted on the inner arc face and the outer arc face of the welding assembly for dual inner arc locating. The clamp structure is compact; all compressing components of the clamping device are connected through screws or pin nuts; the press block and pins can be flexibly adjusted; locating is safe and reliable, and precision is high; operation is convenient and quick; repeated precision is high; the service cycle is long; maintenance is easy; the time for energy storage spot-welding clamping, spot welding and correction is greatly saved; and the production period is shortened. Thermal deformation in the assembly welding process is effectively controlled, and by means of a clamp, the assembly welding quality can be improved, and the reject ratio can be lowered.

Owner:AECC AVIATION POWER CO LTD

Protective case for tablet electronics

InactiveCN103653651BControl thermal deformationMeet the needs of shippingDigital data processing detailsOther accessoriesXylylenePolyethylene terephthalate glycol

A protective case for a flat-panel electronic product, the protective case includes a bottom plate and a card position protruding on the surface of the bottom plate, the bottom plate is a modified ABS material, which includes 10-90% ABS and 90-10% Polyethylene terephthalate, or the bottom plate is polychlorinated xylene modified material, including 45-60% polychlorinated xylene material and 40-55% high-impact polystyrene material. The present invention adopts the above schemes, which can effectively control the thermal deformation of the product, so that the product can fully meet the needs of shipping, reduce the scrap rate, improve the reputation of the product and reduce the transportation cost of the product.

Owner:东莞市泓瀚塑胶制品有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com